Gas heating equipment is the most profitable in terms of operating investments. Natural fuel is an order of magnitude cheaper than electricity and is easier to accumulate compared to solid combustible materials. Small heating boilers can be used in an apartment or in a private house. They are distinguished by their modest size, convenient operation and quiet operation. In the wide range of this segment, Daewoo gas boilers occupy far from the first positions. These products are more likely to belong to the middle class, which means a relatively affordable price, acceptable quality and certain technological innovations.

Device and technical characteristics

The Korean company is ready to offer the buyer two main models of gas equipment: atmospheric and turbocharged.

Regardless of the internal solution, there are still general technical parameters that characterize all equipment of the Daewoo brand:

- Burner ignition control. The mode is selected depending on the gas pressure in the line, the condition of the smoke removal system, as well as the presence of draft and mains voltage. The flame is regulated by a control panel or using a mechanical regulator.

- Remote control. The operation of boiler equipment can be controlled from any room using the following methods: a remote panel or a remote control.

- Circulation pump device. The boiler's technical characteristics, simplicity and high efficiency contributed to the replacement of the traditional three-way valve. The developers of the Daewoo have introduced a two-way pump with a “ball-switch” system. Large capacity of the hot water supply circuit - warm water warms up evenly. The simultaneous number of users, as well as the pressure in the water supply system, does not affect the heating degree.

- Automatic boiler diagnostics. Test data is displayed on the remote control unit of the unit, which has a digital display.

Basic error codes

e1

Error e1 indicates that there is insufficient coolant in the heating system. To resolve this, first check to see if the water supply is blocked. Next, we look at the serviceability of the main board, cold water pipes and pressure switch. It is also possible that the cause of the device malfunction is the failure of the manual water fill valve.

e2

Error e2 means incomplete combustion of gas in the heating boiler. The reason is poor draft due to clogged chimney or air duct pipes. They should be inspected and cleaned.

e3

Error e3 shows the "Boiling" signal. The device generates an error if the water supplied for heating has a temperature above 98 degrees for five seconds or more.

Circulation pump for Daewoo boilers

The problem may be in the pump, the main electronic circuit board, or the temperature sensor. If necessary, the sensor is replaced with a new copy. Dirt filters are inspected and cleaned.

e4

Error e4 means that the exhaust gas output control sensor has tripped. The draft force is measured and the chimney is inspected for blockages.

e5

Error e5 is displayed when the ignition voltage is excessively high. It is necessary to check the functionality of the printed circuit board. Using a voltmeter, you need to measure the voltage between the contacts of the infrared sensor CN05, it should be equal to 5 volts. If necessary, the sensor is replaced.

e7

Error e7 appears when there is a communication error if contact between the boiler and the control panel is interrupted for more than 1 minute. The communication connections in the room console are checked, if they are working, they look for a breakdown in the control board and determine what to do next.

EU

The ec error indicates that the power of the DIP switches is set incorrectly. Set the correct combination by checking it with the table located next to them. Also, the cause may be unstable voltage in the electrical network. In this case, it is recommended to install an additional stabilizer.

Stabilizer for gas boilers

u0

Error u0 (uo) means that the flame control sensor does not see it. It is necessary to increase the flame level in the burner or replace the control sensor with a working one.

Operation and setup

Boilers are adjusted during manufacturing, in the factory. Additional setup is a small adjustment made during installation and first run.

The operating limits of temperature and pressure of gas and working fluids are determined. These actions must be performed by specialists from the warranty workshop, otherwise the warranty agreement will be void.

After the first launch, no special actions are required from the owner. Adjusting the temperature to your liking is done as a matter of routine.

It is necessary to invite a specialist once a year to carry out maintenance.

If problems occur, you should immediately invite a technician from the service center.

Kinds

The Daewoo company produces the most popular and convenient wall-mounted gas boilers for use in a private home.

There are no floor-standing models in the company’s arsenal, which is not a drawback, but demonstrates the approach of the company’s engineers to creating the most compact and multifunctional models.

According to the type of combustion chamber, two options are available:

- Atmospheric boilers. The combustion chamber is open type, and the air required for combustion and smoke removal is taken directly from the room in which the boiler is installed. They are connected to a common house chimney and require the creation of certain conditions for operation. DO NOT tolerate drafts or sharp gusts of wind outside - the flame may go out.

- Turbocharged boilers. The air supply occurs under the action of a turbocharging fan. This design makes the boiler completely independent of external factors, and the operating mode is stable and sustainable. Connecting the boiler to a common chimney is not required; special chimneys of the coaxial type (“pipe in pipe”) of the horizontal type are used, which can be led directly out of the room through the wall. Forced air units are stable and in higher demand.

By type of heat transfer there are:

- Convection boilers. They work on the usual principle - heating the coolant in a burner flame.

- Condensation models. A new type of design that uses two-stage heating of the coolant. First, the thermal energy obtained by condensing water vapor from the exhaust smoke is used. Then the coolant, which has received some heating, is sent to the primary heat exchanger, where it is finally heated to a given temperature.

The use of condensing boilers began recently, but statistics have already been collected. They provide significant fuel savings due to the recycling of thermal energy.

It becomes possible to reduce the heating intensity of the heat exchanger, which saves gas and increases the service life of boiler components that are not subject to too much load.

NOTE! Condensing boilers require specific operating conditions. The temperature difference between the outside and inside the building should not exceed 20°, otherwise the condensation process will become impossible

Because of this feature, the use of condensing boilers in Russia does not make sense. When purchasing such installations, you should know in advance about the existing restrictions so as not to pay extra money.

Popular models

DGB 160 MSC

Double-circuit model – gas/boiler, designed for heating a room up to 180 sq. m.

The device is wall-mounted and is suitable for heating an area of up to 186 m2. In order for the unit to operate without interruption, stably and economically, it must be connected correctly. Features an improved security system. Several modifications of this model have been developed.

Main characteristics:

- double-circuit;

- energy dependent;

- wall installation;

- Efficiency – 91%;

- runs on natural gas;

- maximum hot water temperature – 85;

- minimum temperature – 40;

- voltage – single-phase;

- closed combustion chamber;

- auto diagnostics;

- electronic control;

- There is a thermometer and pressure gauge.

Altoen Daewoo 110 MCF

A model with an open burner and the need to install a chimney is intended for a private home

Atmospheric type apparatus, mounted. Constant temperature conditions are maintained using electronic control. Designed for heating private country houses. Since the firebox is open, a separate room is required to install the boiler. Works quietly.

Specifications:

- heated area – 128 m2;

- open combustion chamber;

- two independent circuits;

- Efficiency – 91%;

- depends on the presence of electric current;

- there is a circulation pump;

- nominal gas pressure – 4 mbar;

- maximum hot water temperature – 85;

- minimum temperature – 40;

- room thermostat and remote control available;

- autodiagnostics of equipment.

DWB-201 GOM (Turbo)

Turbocharged boiler for apartments up to 250 sq. m.

A turbocharged boiler is designed for heating a large area of a residential private house. The turbine has a lower location, unlike conventional versions of such equipment, which increases functionality. Powerful device with a large expansion tank, without a chimney. Electronic ignition is another advantage of the model. The assembly is of the same quality as other units in the series. Used for heating and hot water supply.

Specifications:

- double-circuit;

- heated area – 250 m2;

- maximum power – 23.3 kW;

- Efficiency - 89-92%;

- remote control with thermostat;

- lower location of the turbine;

- self-diagnosis system;

- protection against overheating and boiling water;

- expansion tank – 8 l;

- chimneyless;

- mounted;

- weight – 28 kg.

Feedback about DWB-201 GOM

If previous models are focused on the common requirements of the average owner of a small house or apartment, then this option is usually used by private owners who require more powerful equipment. According to the manufacturer’s calculations, the Daewoo gas boiler version 201 GOM is capable of serving an area of up to 250 m2. And the opinions of the majority of cottage users confirm this. At the same time, high-quality assembly based on modern element base is noted.

Compared to traditional boilers equipped with a combustion chamber, this option is also advantageous due to the lower placement of the turbine. The fact is that Daewoo gas boilers in the latest versions create adjustable air pressure, which increases operating efficiency. To this, users add the advantages of electronic ignition, which eliminates routine operator actions.

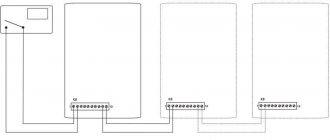

Installation of gas boilers

The manufacturer produces gas boilers in the format of so-called boilers. These are units whose function is performed in the process of heating water circulating through the circuits. Mainly on the market are Daewoo wall-mounted gas boilers, which take up little space and at the same time do not limit the owner’s options for laying circuit heating networks for the room.

The structure is formed by several component groups. The basics are the burner, which serves the gas and then transfers the energy to the heat exchanger. The latter is interfaced with circulation pumps - two or one. The workflow is carried out over this infrastructure. However, for monitoring and control, measuring instruments are also provided in the form of a thermostat, pressure gauge and thermometer. These devices allow you to use a gas boiler with optimal heat transfer. The price of equipment varies on average from 15 to 25 thousand rubles. Again, these are average price standards that determine the appropriate quality of the units.

Reviews of the DGB-160 MSC model

Models of the DGB line are suitable for use in the engineering structure of private houses and apartments. According to users, the 160 MSC option, the power potential of which reaches 18.6 kW, may be optimal for the needs of the average family. Practice shows that this power is sufficient for hot water supply and heating functions. Another thing is that achieving high operating efficiency in different modes is only possible with high-quality installation and proper use of the control system. Those who use a Daewoo gas boiler in this modification also point to an improved security system. For example, the developers have optimized the stabilization system when supplying gas. At the same time, ergonomics could not be improved. The heating process is carried out in an accelerated mode, which saves time both on cooking food and on bringing the air to the required temperature.

Series and models

Daewoo produces the following series of gas boilers:

- Daewoo Gasboiler DGB. Consists of models DGB-100, 130, 160, 200, 250, 300 and 350. Their power is 10, 13, 16, 20, 25, 30 and 35 kW. Double-circuit atmospheric boilers capable of heating rooms from 100 to 350 m2. Equipped with a copper primary heat exchanger with high efficiency and long service life. The secondary heat exchanger is plate type, made of stainless steel.

- Daewoo MCF. Wall-mounted boilers with an open combustion chamber. Equipped with a separate heat exchanger, they have the ability to operate for up to 3 days in emergency mode. The boiler power is in the range of 10.5-29 kW.

- Daewoo MSC. Double-circuit units with a closed burner. The expanded model line consists of boilers with a capacity of 7-45 kW. Equipped with a separate heat exchanger. They can be controlled from a remote control, which has a range of up to 50 m. There is a weekly programmer, which makes it possible to plan the operation of the boiler with high accuracy.

- Daewoo MES. Series of condensing boilers. The power of the models ranges from 19.8 to 40.6 kW. For normal operation, it is necessary to provide the units with appropriate conditions, which is only possible in certain climatic conditions.

All boilers are made in accordance with the most efficient and advanced production methods and have a balanced configuration.

The Daewoo company consistently embodies the principle of simplicity, low cost and high quality products.

Device and technical characteristics

The Korean company is ready to offer the buyer two main models of gas equipment: atmospheric and turbocharged.

Regardless of the internal solution, there are still general technical parameters that characterize all equipment of the Daewoo brand:

- Burner ignition control. The mode is selected depending on the gas pressure in the line, the condition of the smoke removal system, as well as the presence of draft and mains voltage. The flame is regulated by a control panel or using a mechanical regulator.

- Remote control. The operation of boiler equipment can be controlled from any room using the following methods: a remote panel or a remote control.

- Circulation pump device. The boiler's technical characteristics, simplicity and high efficiency contributed to the replacement of the traditional three-way valve. The developers of the Daewoo have introduced a two-way pump with a “ball-switch” system. Large capacity of the hot water supply circuit - warm water warms up evenly. The simultaneous number of users, as well as the pressure in the water supply system, does not affect the heating degree.

- Automatic boiler diagnostics. Test data is displayed on the remote control unit of the unit, which has a digital display.

Other faults

During operation of a Daewoo boiler, error codes cannot always help with malfunctions.

The following problems may occur:

- The room remote control power buttons do not work when the power cord is connected. You should measure the voltage at the signal end of the remote control and at the blue CN terminals. It should be equal to 12 volts. The solution is to replace the defective controls and configure the terminal unit.

- If overheating is detected, check whether the circulation pump is working correctly, check the pressure in the heating pipe and the cleanliness of the distribution pipe.

- If a pump failure occurs during testing, the mains voltage is measured between the two black-and-white and white-black terminals on the CN pump

- When ignition does not occur, the locking condition and operation of the control panel are inspected. The operation of the main board is also checked. Diagnostic points for this are indicated in a special table in the operating instructions.

Price range

The cost of Daewoo gas boilers is in the conventional range of 34-59 thousand rubles. The price difference depends on the model, power and other factors.

If the region is located far from large populated areas, the price of the boiler will increase due to logistics costs. Before purchasing, you should find out in what configuration the equipment is supplied and what needs to be purchased in addition for optimal and safe operation of the boiler.

In addition, you need to take care of concluding a warranty agreement, which will also cost a certain amount.

IMPORTANT!

Some users do without warranty service, but this approach is only possible for specialists who can independently repair and configure the boiler. For mass users, it is strongly recommended to use the services of warranty workshops.

Maintenance instructions

Once again, the user will be required to carefully configure automatic functions. For example, most Korean gas boilers support options for air removal, tank disinfection, fault detection, etc. As for physical maintenance, it is important to prepare for some repair operations, which a Daewoo gas boiler can undergo at home. Spare parts are supplied separately - a typical list of main components includes heat exchangers, expansion tanks, fans, pipes, pipes and accessories for the loop infrastructure.

It is important to note that regular maintenance can significantly increase the cost of maintaining equipment. This depends on the gas consumed and on the use of new consumables and components. For example, a gas boiler, the price of which is no more than 20 thousand, on average every six months requires an investment of up to 2-3 thousand to update pipes and fittings.

Popular models

Many boiler models presented in the brand’s assortment are fully adapted to the needs of modern people. Almost all boilers are equipped with convenient control panels that can be used to easily control them.

Today, the assortment includes the following types of gas boiler series:

- MCF (options with an open combustion chamber);

- MSC (models with a closed combustion chamber with a modern automatic control system);

- MES (condensing gas models. Boilers from this series are considered energy saving).

Each of the listed series includes several types of boilers, which differ in their technical characteristics (size, power, etc.).

Next, we will consider some of the most current boiler models for purchase:

Of course, these are not all the models that are presented in the brand’s assortment.

There are many worthy options, but you should select the right boiler not only taking into account all the technical characteristics and capabilities of this type of technical product, but also taking into account the area of the room that will need to be heated. If you are not sure that you can choose the right model yourself, it is best to use the services of specialists

Reviews about the boiler DGB-160 MES

The version of the gas boiler is similar in general characteristics, but the MES series has its own features that are highlighted by users. This modification has a significantly improved control system. For example, we can note the presence of a weekly programmer of operating modes, autonomy of the control panel, as well as simplified connection of the chimney. In other words, the model design saves space for loop integration and maintains high control reliability. In addition, the Daewoo gas boilers in this series, according to the owners, are distinguished by the presence of a built-in pulse stabilization module for energy supply SMPS. Together with the durable materials of the technical components of this version, the latest control systems make it almost ideal for private needs. True, you still have to forget about high power. This option is good primarily for its environmental friendliness, safety and ergonomics.

Wall-mounted gas boilers Daewoo Gasboiler (Daewoo Gasboiler)

Most homeowners prefer to create an autonomous heating system.

Sometimes such a decision is made even if it is possible to connect to a centralized network.

The reasons for this choice are the desire to independently regulate the heating mode and too high housing and communal services tariffs.

There are a lot of gas heating boilers on sale, which are recognized as the most efficient and economical of all alternative options.

Let's consider gas boilers from Daewoo, which represent one of the most advanced groups of heating equipment.

Types of Daewoo gas boilers

Turbocharged boilers

The Daewoo boiler is small in size, can be mounted in a kitchen cabinet, and requires an electrical connection

The device can be located in any room. The device is quite light, about 26 kg, so it does not create excessive load on the wall. It is often placed in a suspended state in the kitchen. Since the boiler is small in size, a separate room is not required for it; even a kitchen cabinet is quite suitable for placement.

Advantages of a turbocharged boiler:

- compactness;

- light weight;

- the necessary fastenings are included in the kit;

- remote control available;

- Efficiency – 91%;

- economical fuel consumption.

Coaxial chimney in turbocharged boilers

Technical features:

- pressure – 3 atmospheres for heating, 7 – for hot water supply;

- electricity consumption – 0.1 kW per hour;

- power – 11.6 or 15.1 kW;

- the highest water temperature for heating is 85, for hot water supply – 60.

The specifics of devices may differ depending on a particular model.

Atmospheric boilers

The atmospheric type Deo boiler has an open burner type

When installing it, it is important to comply with gas equipment safety regulations. The mounted unit is installed in a separate boiler room; the room must be appropriately equipped

Basic requirements: forced ventilation, sufficient room size, ceiling height.

Open burner in an atmospheric boiler

Advantages of atmospheric units:

- safety;

- long service life;

- simple device;

- silent operation;

- breakdowns are observed less frequently than with turbocharged engines;

- independent of electricity;

- heating a large area - up to 200 m2.

The disadvantages of a Daewoo atmospheric gas boiler include the mandatory presence of a chimney and a constant flow of fresh air.

Dual-circuit

Boiler with heating circuit and DHW

Models with two circuits are produced. They heat water evenly, have heat exchangers independent from each other, and are easy to install and maintain. The design of these devices has the following features:

- the first circuit is made of copper;

- the second is lamellar;

- heat exchangers have an independent device;

- heating of water does not depend on the number of water intake points and pressure;

- convenient control.

The process of creating boilers is controlled at every stage. The products comply with international quality standards.

Errors and methods for eliminating them

The number of automatically detected faults in Daewoo boilers is grouped into 19 events, each of which has its own code. Seeing the display, you can try to solve the problem yourself or give called technicians a first idea of the problem that has arisen.

Some malfunctions of gas boilers do not depend on the type of combustion chamber or other features of the equipment. And there are problems that are typical only for a certain line. Daewoo Altoen (Gasboiler) boilers have continuous numbering of errors, and the methods for eliminating them are almost the same for all models.

Error type “E0”

This code indicates an error in the room temperature sensor, which is built into the control panel. The example of this malfunction shows that it is not every time that you need to call a repair team.

It is necessary to disassemble the device, clean the contacts and check the sensor using a tester. If necessary, it must be replaced. If you do not have the skills to disassemble and repair such products, then you can take the remote control to any workshop specializing in electronics.

Error type “E1”

A decrease in pressure in the heating system was recorded. The simplest case that leads to this problem is a breakdown of the minimum pressure switch or a lack of signal between the sensor and the control board. However, first of all, you need to immediately check the heating circuit for leaks.

Coolant leakage can occur not only in the circuit, but also in heating equipment components, such as:

- heat exchangers;

- hydraulic pump;

- relief valve;

- make-up tap, etc.

In this case, the hydraulic unit will have to be changed, although sometimes replacing the gaskets may be sufficient.

The supply may also be cut off for some reason. Although in this case the issue of leakage also arises, which is gradual.

A decrease in pressure in the circuit without leakage of coolant can occur in the event of a drop in pressure in the closed expansion tank, which is installed in the boiler. In this case, it will have to be repaired.

After eliminating the cause of the leak, it is necessary to fill the circuit and restore the operating pressure.

Error type “E2”

Triggering of a gas analyzer, signaling incomplete combustion of the supplied mixture or smoke entering the chimney.

The problem lies in insufficient traction, which can be caused by:

- Change in the open cross-section of the smoke exhaust duct as a result of its contamination. It happens rarely, mainly due to a foreign object or small animal getting into it. Icing is also possible in the area where the pipe exits. The chimney of a gas boiler needs to be cleaned.

- Strong wind pressure. A difficult case, since it is necessary to recalculate the geometry of the pipe or install a windproof structure.

There may also be a problem with the fan. Most often, this is contamination of the blades, which can be seen, or a rotation disorder, which is easy to hear.

You can identify the problems described above yourself. If the chimney and fan are functioning normally, there is still a possibility of sensor failure. It will have to be replaced.

Error type “E3”

An error occurs when the fact of overheating of the coolant is detected. There are two main reasons:

- malfunction of the emergency thermostat;

- slowing down or stopping coolant circulation.

If such an error occurs, you need to wait until the device has cooled down, reset it (turn it off and on) and start it again. If the error repeats, this means that the trigger was not false (this happens) and will have to be sorted out.

First of all, it is necessary to determine whether the coolant circulation rate is sufficient. To do this, you need to start the boiler without heating and listen to the operation of the pump. Its hum should be normal.

Problems with this node can be caused by several reasons:

- No power supply. You'll have to call the wiring and find a break.

- There is power, but the pump does not work. You need to show it to an electrician. If there is a break in the winding, it is cheaper to replace the entire assembly. If other wires break down, the problem can be eliminated and the pump will work again.

- Rotor shaft jamming. This event rarely occurs without damage, so it is best to replace the pump.

- Impeller wear. The pump needs to be replaced.

It is also possible that the contacts of the signal wire from the pump to the board are disconnected or the central board itself is damaged.

If the pump is running at full power, then the cause of poor circulation is in the circuit. She may be:

- Reduced pressure in the system and failure of the pressure sensor. Rare case.

- Air lock formation. It is necessary to check the entire circuit by bleeding air through Mayevsky taps and similar fittings.

- Accidental closure of one of the shut-off valve elements. All taps and plugs must be checked.

- Formation of blockage. Rare case. A difficult problem primarily due to the difficulties associated with finding the location of the mud plug.

If the pump operates normally and the circuit normally passes coolant, then the temperature sensors need to be replaced. Most likely they are out of order.

Error type “E4”

This code signals the activation of a pressure switch - a draft sensor in the chimney. The main reasons are the same as for error code “E2”.

If the gas boiler chimney and fan are working normally, then the problem may lie in the signal from the sensor. First of all, you need to check the tightness of the connection of the contacts to the sensor and to the central board, and also check the wiring.

It is also possible that condensation may form in the tubes or that they are poorly connected to the sensor. Failure of the pressure switch itself is unlikely.

Error type “E5”

Receipt of an alarm signal from the flame sensor. If visually, when turning the boiler on and off, ignition occurs normally, then you need to check the flame sensor.

First of all, you need to make sure that it is in good contact with the main board (check the wire connection and test it). You also need to make sure that there is a voltage of 5 Volts between the terminals of the CN05 sensor.

If the sensor works normally and ignition does not cause problems, then the error is in the central board. It will have to be replaced.

If you can visually detect a problem with ignition, you must perform the following steps:

- Reset the unit and try to ignite again. Perhaps the reason is one of the capacitors or a residual charge on the ignition transformer.

- Make sure that the maximum and minimum gas pressure is properly adjusted for the injectors installed in the device. Standard indicators can be found in the instruction manual.

- Inspect the ionization electrode for contamination. Make sure that there is an acceptable gap between it and the burner device. Make sure there is a spark (by first shutting off the gas).

- Adjust the ignition power in the service menu. You need to use the parameters that are specified in the user manual.

- Make sure that there is no breakdown on the body (that is, the user does not receive an electric shock when touching the boiler elements).

- Make sure that the grounding is present and not broken.

- Check that the gas valve is not stuck. Simply insert the silicone tube into the fitting and press firmly.

- Check for a broken valve coil.

If the problem is in the gas valve, it will have to be replaced.

Using this error as an example, it can be seen that sometimes to repair a Daewoo gas boiler, knowledge in several areas is needed: electrical, electronics, and mechanics. Therefore, in case of complex errors, it is still better to call experienced gas service technicians, with whom an agreement has been concluded for the supply of blue fuel and maintenance of units.

Error type “E6”

Gas leak sensor triggered. If you smell gas in the boiler room, you must first turn off the shut-off valve at the entrance to the house. Then you need to check the gas pipeline (up to the boiler valve) and fittings for damage. If you find them, you should contact your gas service.

If the smell of gas is not felt, then after a while you can start the boiler again. It is advisable to be nearby at this time and have a gas analyzer with you. If the sensor triggers falsely, it needs to be replaced.

Error type “E7”

This code is displayed if the board has “lost” the remote control. The problem may be a breakdown of the control panel or the board unit responsible for communication.

Control devices from other Korean manufacturers (Navien, Hydrosta, etc.) are suitable for Daewoo boilers, so there is no particular problem in replacing this part.

Error type “E8”

Lost connection between the heating circuit temperature sensor and the central board. Typically, the problem occurs when the thermistor breaks. First, of course, you need to see if the contacts have come loose, then call the wiring. If it is working properly, then the sensor should be replaced.

Theoretically, a breakdown of the central board unit is possible, although usually in this case it fails completely, rather than partially.

Error type “E9”

Leak in the boiler. The water presence sensor has tripped. You need to open the boiler and look where the fistula has formed. There may also be a problem with the gaskets of the sockets where the heating and hot water temperature sensors are installed.

Error type "EA"

The circuit is refilled with water more often than once every 5 minutes. This indicates the presence of a leak. Its volume is not so significant as to stop the boiler as a result of boiling water or releasing pressure.

This situation cannot be ignored, since a small leak at any moment can turn into a full-fledged leak with an emergency stop of the boiler and serious consequences for objects in the house.

Error type "EC"

Central control boards are universal for all models within the same line. The error code “EC” indicates an incorrect choice of boiler model. This usually occurs when the central board is replaced or when parameters are reset due to a sudden power outage.

To solve this problem, just configure the settings using the service menu.

Error type “Ed”

The second letter of this code is lowercase “d”. Manufacturers moved away from the template so that users do not confuse the capital “D” and the number “0”, which have similar outlines. The error means that the built-in stabilizer has detected a deviation in the current frequency.

If power parameters often deviate from standard values, the boiler electronics may fail.

Error type “EE”

This code indicates a problem with the smoke exhaust fan. The speed sensor shows a low value.

The malfunction may be caused by:

- clogged impeller;

- violation of shaft lubrication;

- inaccurate sensor readings.

Also, a board error cannot be ruled out, although this option is unlikely.

Error type "EF"

A signal that the three-way valve responsible for switching the water flow has been open for more than 90 minutes. This indicates that it is jammed. To prevent this damage, it is necessary to install a filter that will prevent clogging.

The most serious failure is a burnt out valve servomotor. In this case, it is better to replace the entire distribution assembly.

Error type “U0”

The flame sensor does not “see” the fire. Ignition problem. If the flame lights up and goes out, the reason may be the quality of the supplied mixture, gas pressure or lack of exhaust hood.

If the flame lights up, the auto-ignition electrode continues to click, but the error still remains, then the reason may be a defective sensor or a poor connection to the board.

One of the defects of the sensor is simply its contamination. If you wipe this part, the problem is often solved.

Error type “U1”

The buttons on the control panel are stuck. Such repairs do not relate directly to the gas boiler, but can be carried out by any electronics specialist. To do this, you need to disconnect the panel from the boiler body and take it for repair.

Error type “U8”

Hot water temperature sensor error. The reasons for the breakdown and the necessary actions in this case are similar to the situation with error “E8”. The boiler does not stop its operation, but operates only in heating support mode.

While replacing the sensor, the boiler will need to be stopped and disconnected from the power supply.

Error type “U9”

Signal from a temperature sensor located in the chimney. The most likely situation is clogged pipes. They need to be cleaned. If no contamination is detected, then the problem may be with an uncorrected sensor.

Almost half of the stoppages of the Daewoo gas boiler are associated with problems that arose in other components of the heating circuit.

In addition, many boiler malfunctions can be eliminated independently if you have at least minimal skills in repairing any equipment. Therefore, it is necessary to analyze the type of error and only after that make a decision either to repair it yourself or to call specialists.

Installation

Installation of Daewoo equipment does not cause any difficulties for experts in their field, while an inexperienced user may have questions and problems during operation. Dealers who sell Korean equipment may well refuse repairs under warranty if the buyer did the installation himself. It is worth remembering that when tying, you need to connect to electrical networks and connect thermostats. To carry out similar work, you need special permission and knowledge of the rules of electrical installations.

During installation work, it is important to strictly follow the manufacturer's recommendations. Look at the instructions and read about the wiring diagram

Operation and setup

Boilers are adjusted during manufacturing, in the factory. Additional setup is a small adjustment made during installation and first run.

The operating limits of temperature and pressure of gas and working fluids are determined. These actions must be performed by specialists from the warranty workshop, otherwise the warranty agreement will be void.

After the first launch, no special actions are required from the owner. Adjusting the temperature to your liking is done as a matter of routine.

It is necessary to invite a specialist once a year to carry out maintenance.

If problems occur, you should immediately invite a technician from the service center.

Device and technical characteristics

Daewoo offers consumers two main modifications of gas boilers: atmospheric and turbocharged. Each device has its own distinctive features, advantages and disadvantages.

Regardless of the internal structure, there are general technical characteristics characteristic of all South Korean heating equipment of the Daewoo brand:

- The burner is ignited in a controlled manner. The choice of operating mode is determined by the gas pressure in the main, the state of the smoke removal system, the presence of draft and voltage in the network. Flame adjustment is carried out from the control panel or using a mechanical regulator.

Equipment with remote control. The operation of the boiler can be controlled from any room in the room in two ways: with a remote panel or with a remote control.

Circulation pump device. The technical characteristics of the device, the simplicity and efficiency of the design made it possible to replace the traditional three-way valve. Daewoo has developed and implemented a two-way pump with a “ball-switch” system. Large DHW throughput - hot water is heated evenly. The temperature does not depend on the simultaneous number of consumers and pressure in the water supply system.

Boiler diagnostics are carried out automatically. The test results are displayed on a remote boiler control unit with a digital display.

One of the advantages of Daewoo heating boilers is their simplicity of design. According to reviews from craftsmen, equipment can be disassembled, repaired and adjusted practically with “one screwdriver.”

Advantages and disadvantages

The advantages of boilers include:

- High efficiency of units.

- Reliability, durability of boilers.

- Resistance to external influences.

- The ability to independently identify problems and notify the owner about them.

- Together with space heating, hot water is supplied.

- Low fuel consumption, which does not affect the performance of the units.

The disadvantages of Daewoo boilers are considered to be:

- Energy dependence. If there is a power failure, the system will stop operating.

- Sensitivity to water quality, stable supply voltage, requiring the use of additional equipment.

- Some users report increased noise levels when heating water.

Most of the disadvantages can be attributed to the general features of gas boilers.

Daewoo MSC series

Daewoo MSC boilers are double-circuit devices with a closed chamber, the rated power of which, depending on the modification, can range from 7 to 46.5 kW. This line of units is represented by 8 different models.

This technique has some peculiarities. In particular, its main heat exchanger is made of copper, which provides the equipment with a long service life. In turn, the hot water heat exchanger has a plate shape, which ensures rapid heating of the coolant. The burner installed in Daewoo MSC boilers is made of stainless steel. In this case, the unit is equipped with all the necessary automation and security systems. You can control the operation of the boiler using a remote control with an LCD display.

The device has several modes that make it easier to control its operation. Among them:

- "Heating";

- "DHW";

- “Heating + DHW”;

- "Minimum heating";

- "Accelerated DHW"

- And so on.

The coaxial chimney provided by the design of the MSC unit prevents the burner flame from blowing out in the event of sudden gusts of wind outside the window. It is possible to install separate chimneys, which is important when heating several apartments. The factory design of the MSC boiler is designed to operate on natural gas, but the nozzles can be changed at any time, and the unit will be able to operate on liquefied fuel.

conclusions

Daewoo boilers today are represented by a large selection of heating systems offered on the domestic market for relatively little money. If you are looking for reliable and at the same time innovative equipment, but are not ready to overpay for European units, then the equipment of the South Korean brand is ideal for you.

User manual

While using the equipment, the user will have to deal with several groups of parameters. In the future, you can completely rely on automation, but at first the boiler needs to be tested according to operating modes to ensure it meets specific needs. So, you should initially determine the heating modes by indicating the temperature limits through the control display. The same applies to the water supply regime, but in this part the volumes of coolant along the circuits that serve Daewoo gas boilers are also determined. The instructions note that protecting equipment from freezing in automatic mode will only work when switching to the appropriate mode. This nuance is taken into account when operating indicators are switched from winter to summer use and vice versa.