In the home workshop, every DIY enthusiast always has an angle grinder (angle grinder) in their arsenal. This tool is almost indispensable as it can perform many functions. Moreover, if the owner has additional accessories, his capabilities expand significantly. Homemade machines for grinders are very popular, as they are easy to manufacture and do not have a bulky design.

Homemade cutting machine

Scope of application of cutting machines

The use of additional accessories for angle grinders provides a very wide range of their use, but the main task remains cutting materials such as metals, wood, and stone.

A do-it-yourself cutting machine from an angle grinder is made for the following purposes:

- Control of cutting thickness.

- Evenness of the cut.

- Possibility of setting different cutting angles.

All these criteria give the homemaker the opportunity to use a cutting machine to produce parts of a more complex design, as the quality of workmanship improves.

Attention! Without a machine, you can perform these tasks at home, but it will take more time, since you will have to ensure the evenness of the cuts. At the same time, it will be important to double-check the correctness of the angles for identical workpieces several times.

Should I buy or not?

Finding a ready-made machine on store shelves that at first glance satisfies your needs is a fairly simple task. But it is unlikely that there will be a design made entirely in accordance with your requirements, and they are different for everyone. In such cases, owners of machine tools try to improve or remodel them, but are faced with very serious obstacles - either the manufacturers made the machine from alloys that are very difficult to work with by welding, or they did not take into account the little things that you need specifically - for example, an accurate ruler or a more elastic spring. Remaking someone else's is much more difficult than making your own.

The device of a pendulum saw from a grinder

In most cases, a cutting machine from an angle grinder is performed using a pendulum system. Such a tool is popularly called a pendulum saw.

The operating principle of such a device is based on outweighing. Two metal corners are installed on the edge of the vertical support. They must be attached to the hinges strictly in the middle. An assembled device of this type resembles a children's swing. In the place where the parts will be cut, the grinder is attached. At the other edge of the pendulum, a load is installed that will lift the grinder when the cut is completed.

Instead of a load, you can also install a spring that works for compression. The spring stiffness is selected in practice.

How to secure an angle grinder for precise cutting? You need to unscrew the handle on the tool. And using the existing holes in the angle grinder, drill the same ones in the corner. To fasten it you need to screw it with two bolts.

Next, it is recommended to install the angle grinder handle in its place for ease of cutting.

The device of a homemade pendulum machine

Industrial bed designs

A stand for an angle grinder will be required in the following cases:

- A structure made of difficult-to-cut material or with a large surface area is being cut/grinded.

- Increased cutting accuracy is required.

- It is necessary to process several products with the same parameters.

- The workpiece material is not continuous in cross-section, and the presence of voids and cavities can provoke vibration, shock and, consequently, sudden movement of the machine body.

The frame for the grinder is produced by almost the same companies that produce the tool itself. The price for the simplest design, depending on its manufacturer, does not exceed 2500...3000 rubles, but with increasing functionality, the price of the frame increases to 20,000...25,000 rubles, and not every home craftsman can afford such costs. In addition, such racks are not particularly versatile, and, of course, do not take into account the individual needs of the user.

Such beds consist of the following elements:

- A base plate, which is made of thick sheet steel and is equipped with T-shaped slots for fastening the workpiece. It may also be a cast iron stove;

- The actual rack, on which a mounting device is provided for an angle grinder of a specific model;

- Adjustment devices that allow you to rotate the stand itself, as well as change the vertical position of the angle grinder;

- Optional: clamps or clamps for workpieces, the dimensions of which are unified with T-slots. Sometimes the kit also includes a bench vice with a set of profiled stands;

- A rotary handle, with the help of which the working movement of the grinder itself is performed;

- Measuring devices, usually an angular or regular ruler;

- Particularly advanced models also have a return mechanism with a spring.

Positive features include the ability to cleanly cut pipes from round profiles, which is problematic and even dangerous without stable clamping of the workpiece. The grinder bed is also necessary for corner cuts of any profile.

The technical capabilities of these devices depend on the area of the supporting surface of the plate and the lifting height of the angle grinder in the frame. Typically, the parameters are calculated for a grinder disc with a diameter of up to 250 mm, and for the size of the fixed part of the workpiece no more than 100...150 mm.

Required tools and materials

To make a cutting stand you will need power tools:

- Grinder for cutting metal blanks.

- Drill, used for drilling holes.

- Jigsaw. It is used to cut plywood for the base. You can also use sheet metal for this part.

Hand tools are also used, without which it is impossible to carry out work:

- Roulette.

- Pencil or marker.

- Corner.

- Set of drills.

- A set of spanners or wrenches.

- Pliers.

Advantages of homemade equipment

Homemade accessories for hand tools are very popular. The demand is explained by the fact that they do not take up much space in the workshop, which is very convenient in small spaces such as a garage or basement, which is what do-it-yourselfers mainly use.

For reference! The small dimensions of the equipment mean that it is quite easy to hide and take out at the right time.

Another advantage of homemade equipment is that the owner will make it well, although such homemade equipment will add weight, but it will have a margin of safety.

Drawings of such equipment are available for general use, but many craftsmen modify them independently, based on their own needs.

Design Features

Having prepared all the necessary tools and materials, you can safely begin modifying your grinder. The huge advantage lies in the fact that you can equip the bed with all the devices from available mechanisms. For example: as a support niche you can use the base of a table-top drilling unit or the base plate from a compact universal prefabricated device (USP). The advantage of such blanks is that they already have all the necessary T-shaped cutouts.

Making a cutting machine with your own hands

To understand how easy it is to make a cutting machine out of an angle grinder, you need to have at least initial experience working with an angle grinder. It is quite easy to make such equipment yourself if you know exactly all the components of the future desktop equipment.

Preparatory stage

At the beginning of all work, you should find an exact sketch of the machine, in which, in a step-by-step version, the entire assembly will be outlined. Such forethought will allow you to collect in advance all the necessary material for manufacturing.

The drawing option is chosen arbitrarily, regardless of the power of the grinder. Free sizes can be easily found on the Internet.

You also need to prepare all the tools that will be needed during the entire work.

Drawings for making a homemade cutting machine

Finding ready ones won't be difficult. Below is one of the simplest options.

Drawing of homemade equipment

Step-by-step instruction

At the initial stage, a base should be made. You need to cut the corner into four parts at an angle of 45° on each side. The dimensions of the parts can be chosen arbitrarily since there are different dimensions of grinders. They are welded together to form a rectangle. Tires are welded in the middle of the base, which are additionally reinforced from below with a corner. This way you should get a platform of the correct size.

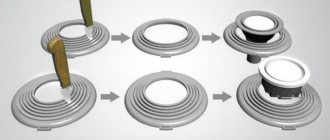

The next step is to perform a pendulum. The first step is to make its base. It is necessary to weld two parts from a professional pipe at an angle of 90°. They are installed on the base, with a distance from each other of 40 mm. The edges of the parts should be filed at 45°. This is necessary so that the parts have a complete fit to the base.

Next, you need to prepare the mechanism for swinging. It is made of a pin and a tube. Instead of a metal pipe, you can use nuts with internal threads like a stud.

Two parts of the tubes are welded to the tops of the corners, which will serve as a pumping unit.

For the pendulum, a profile pipe with a cross section of 40×40 mm is taken. The wall thickness must be at least 3 mm. A hole is drilled in the middle of the pipe, the diameter of which must strictly correspond to the diameter of the stud.

Important! When making this unit, you should be sure to ensure that there is no backlash, because it affects the evenness of the cut.

One or more springs are installed on one edge of the pendulum: holes for the hook are drilled on the edge.

To attach the angle grinder to the pendulum boom, you need to drill holes in its base. It is necessary to attach a grinder and mark the location for the hole in the boom. Since fastening to one bolt is not reliable, it is necessary to fasten the cutting tool itself to two additional bolts. To do this, using welding, special fasteners are made, which are installed on the edge of the pendulum boom.

Before testing the machine, it is necessary to fine-tune it. Install the cutting element and make the first broach along the frame. In this place you need to install a stop or a special vice for the drilling machine. The initial cut will be the zero reference point.

Important! When cutting any part, it must be firmly clamped. This will prevent the cutting disc from getting knocked or bent.

When the disk is installed on the angle grinder, it is applied to the bed and using an angle, check the evenness of the cutting angle. If the angle is not adjusted, then this must be done.

Why make a machine from an angle grinder

There are several reasons to make such an attachment for an angle grinder yourself.

- Making it yourself will save you money on purchases. Such a device is not complicated, so its production will not require much expense.

- The machine, made by hand, is adjusted individually for each condition. This allows you to make original fastenings to the table. As well as individual installation of the cutting part, which will allow you to mount angle grinders of different sizes.

- It is also possible to make separate attachments for such equipment, which will allow you to sharpen saws or use wood blades.

- It is possible to install a speed controller, which will help facilitate many jobs in the future.

Direction of sparks when cutting metal

Electrical part

Since the grinder will be fixed from below, we will no longer be able to turn it on in the usual way. It is necessary to provide for the installation of the following elements:

- a clamp that will constantly hold the control key in the “on” position;

- socket for connecting an angle grinder;

- control station that turns the electricity on and off at that outlet.

It is very good to use an industrial control station in such a design. This unit has two keys. The “Start” button is quite tight, which prevents accidental activation. The large and soft “Stop” key allows you, if necessary, to quickly turn off the device by reaching it with any part of the body.

Safety rules when working with a homemade machine

Since an angle grinder generates a lot of noise when cutting metal, it is necessary to ensure that there are no flammable materials nearby. The side where the spark will be directed must be protected with resistant sheet metal.

When working on a homemade machine, it is mandatory to install protection, since parts of the disk can fly off in any direction. This protective part also stops circular sparks from the disc.

When making a machine, it is necessary to take into account that sparks should fly from a person, and not towards him, that is, it is necessary to secure the angle grinder with the correct side. But even in this case, it is important to wear protective clothing, glasses, and gloves.