When buying a vacuum cleaner for your home, carefully study the technical characteristics and design features, which determine the quality of cleaning and operating conditions. More and more manufacturers are abandoning the dust bag and using a cyclone filter for a vacuum cleaner - a large plastic container in which waste is separated.

What is the operating principle of such a unit, what are its advantages over traditional devices? Let's look at these questions in order, and also give a brief overview of cyclonic vacuum cleaners.

What does a cyclone filter mean in a vacuum cleaner?

To understand what it is - a cyclone filter as a type of dust collector, you do not need to have any special knowledge. Most models on the market are equipped with transparent tanks or containers for collecting debris and dust, which allows you to see how the entire cleaning process occurs.

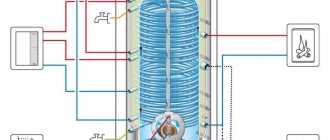

When air is sucked in with a certain force, an air flow is formed inside the cyclone, flowing with turbulence.

FOR YOUR INFORMATION!

The principle of operation of a cyclone type filter is reminiscent of a tornado, only in a reduced size.

Inside the cyclone vacuum cleaner there is a special filter that has the shape of a cone.

The centrifugal force generated by the suction of the air flow causes all collected debris, dust and dirt to be “pressed” into the walls of the container and deposited on the filter pad.

Step by step, the work of a cyclone-type industrial vacuum cleaner or home models can be divided into a number of sequential operations:

- The user turns on the device, which results in a powerful air flow that sucks debris and dust into the vacuum cleaner.

- Before entering the cyclone filter tank, all dirt passes through the primary filter, which is a fine-mesh plastic mesh.

- Next, a second barrier stands in the way of dust, which is represented by a HEPA filter, which is a plate made of a material similar in structure to ordinary cotton wool.

- The next step is to get 90% of the garbage into the cyclone itself.

- This form is not chosen by chance, but is the result of engineering calculations. It is the truncated cone that ensures the creation of a vortex effect, leading to the fact that the remaining particles of debris settle on the bottom and walls of the container.

- As a result of work, the vacuum cleaner comes out of air purified of unnecessary impurities by 97%, which is a very good indicator of operating efficiency.

The most important thing in the operation of a cyclone is the creation of centrifugal force of the air flow, which ensures that particles settle on the walls of the tank

FOR YOUR INFORMATION!

To obtain a more powerful centrifugal force, the container is shaped like a cut cone.

The invention of the cyclone dates back to the 80s of the 19th century. During the existence of the technology, various designs of cyclone filters have been developed, but the essence of the work of all remains the same.

Before entering the cyclone, dust passes through two filters: mechanical, in the form of a mesh, and HEPA, which has a porous structure

FOR YOUR INFORMATION!

There is a rule that follows from the physical meaning of the cyclone: the degree of cleaning depends on the height and diameter of the device to create centrifugal force. At the same time, the greatest efficiency is demonstrated in the retention of particles of a large fraction.

Working version of a construction vacuum cleaner from a household one

The main additional element here is a filter bag made of non-woven material. Instances from Karcher are very suitable - article number 2.863-006.0

Actually, this filter is disposable. Your task is to make a reusable element out of it.

To do this, cut its lower part and fold it a little, slightly reducing the width (up to 22cm).

Next, this lower part needs to be closed with a special lid. You make it from two elements of a plastic cable channel and a piece of polypropylene pipe.

Saw the tube lengthwise, with a slot width of approximately 5mm.

Everything else is simple. Apply glue to the lids.

Apply them with the back side to the fabric at the bottom.

Then insert the prepared tube through the slot.

As a result, from a disposable one you have a reusable filter bag. Moreover, it is much larger than the one installed inside the household model.

Next, you go through the previously discussed steps to modernize the bucket. Drill holes in the lid and insert rubber corrugated adapters into them.

One will be for connecting the filter bag, the other will be for the hose. Select the sizes according to the diameters of your devices.

Here you can do without fan pipes and corners. Next, place the plastic insert from the reusable filter onto the adapter.

All that remains is to tightly close the lid on the bucket. The structure is ready for use.

Although it is similar, it differs from the first option above. After you turn on the unit and begin to suck in debris, it is the homemade reusable dust collector that will collect all the muck and dirt.

Dust will not fly around as in the previous case. On the contrary, this bag will swell inside the bucket due to the air flow.

Gradually it will be filled with both heavy and small fractions that could have been missed by the cyclone.

However, do not forget about clogging the walls of the reusable filter and reducing the draft of the cooling air flow. In order not to burn out the motor of a household vacuum cleaner, it is necessary to carry out one more action.

Cyclone filters in a vacuum cleaner: pros and cons of technology

Any technology, even the most advanced, has its positive and negative sides, which are not always a defect of engineers and creators, but can arise from the physical meaning of the invention. Cyclone-type vacuum cleaners are not without their pros and cons.

The advantages of the technology can be considered the following parameters:

- the absence of a dust collector bag, which ensures ease of use, since when emptying, high hygiene is achieved due to the absence of direct contact with the contents of the tank;

- strength of the plastic filter. When vacuuming regular dust that does not contain objects with sharp edges, the likelihood of damage to the dust collector is minimal, unlike a paper bag that wears out over time.

- maintaining constant suction power. Devices equipped with dust collection bags tend to significantly lose air intake when the latter becomes clogged. Since in Samsung cyclonic vacuum cleaners with a filter on the handle or other other models there are no obstacles in the path of the air flow, the power remains unchanged;

- cost-effectiveness resulting from the absence of the need to change dust bags;

- durability;

- sizes. Compared to vacuum cleaners equipped with water filters or with a wet cleaning function, cyclone models have significantly smaller dimensions and even a child can handle them;

- visual control. Since the garbage collection tank is made of transparent plastic, if a small but necessary item gets sucked in, it is easy to find.

One of the advantages of a cyclone vacuum cleaner is the ease of cleaning the container.

FOR YOUR INFORMATION!

Despite the strength of the plastic used to make the container, scratches may appear on it over time as dust and debris move inside at considerable speed.

Cyclones are often used in production when large quantities of industrial waste are required to be collected

But despite the advantages, such devices have a number of disadvantages, in particular:

- problem with collecting fine and light waste. The design of the cyclone does not allow for high-quality collection of feathers, down, pet hair, hair and threads. If it is assumed that this type of garbage will be prevalent during cleaning, then other types of devices should be chosen;

- accumulation of static electricity. The centrifugal force, leading to constant friction of air with dust against the walls of the tank, contributes to the fact that over time there is an accumulation of static, which is transmitted to parts of the device. When touched, there is a risk of receiving a slight but unpleasant discharge;

- dependence of suction on the stability of air flow. If the suction tube is blocked during the cleaning process (for example, when cleaning furniture or curtains), there will be a sharp reduction in air flow, which will lead to dust settling on the filter and clogging it;

- creating noise from large particles. If there are large particles in the garbage, they can cause an unpleasant noise when they appear in the tank. Also, large debris can cause scratches on the walls;

- increased noise level. Since the cyclone operates by creating a centrifugal force of the air flow, with constant suction an increased sound level is observed;

- price. Cyclone models are somewhat more expensive than their traditional counterparts, and if you choose vacuum cleaners equipped with additional functions, you will have to be prepared to pay extra for comfort and convenience.

Constant circulation of air with dust leads to the gradual appearance of scratches on the body of the garbage disposal tank

When deciding to buy a vacuum cleaner with a cyclone filter, ratings and reviews will not be the only determining factor. Advantages and disadvantages should also be taken into account when determining whether this type will be optimal for the end user's purposes.

In dusty industries, similar household cyclones are used, only of greater power and size.

Advantages and disadvantages

Understanding the principle of operation of a hydrocyclone makes the advantages of such water treatment obvious. In addition to obvious advantages, for example, simplicity of design, hydrocyclones are distinguished by the properties associated with them:

No moving mechanical parts;- Lack of need for consumables (colloids, filter media, etc.).

- Low cost of the device and ease of repair due to the low manufacturability of the product.

- Ease of arrangement in a sequential system of batteries that perform step-by-step cleaning.

- Possibility of work automation.

- Safe use of devices of any kind.

However, the scope of application of hydrocyclones is still limited mainly to industrial use. This fact is associated with few but significant disadvantages of the products:

- The need to maintain stable pressure and the resulting energy consumption, as well as depreciation of the pump;

- Mechanical wear of parts of the main body due to the abrasive effect of sludge;

- A decrease in pressure in the system, causing the use of a second pump.

In addition, it is extremely difficult to correctly calculate the parameters and select the elements of a hydrocyclone for a precise separation of fractions. There is no talk of automatic or simplified reconfiguration of the unit. For example, to catch coarse sand, install one sand attachment, for fine sand, another.

To remove sludge, in general, a GC of a different shape and size is required, operating at a different pressure. In any case, the separation will be only approximate, which is not particularly welcome in private water treatment. A primitive settling tank may work slower, but it has no other serious drawbacks.

Dust collectors with cyclone filter: areas of application

The use of cyclones initially became in demand not in the process of cleaning an apartment, but in industry, where devices like vacuum cleaners, which operated on the principle of creating vortex air flows, began to be actively used for various purposes.

The main areas of application of dust collectors with a cyclone filter, in addition to a regular household vacuum cleaner, are:

- various workshops, both private and industrial;

- wood processing shops;

- powder or sandblasting chambers;

- construction sites, when it is necessary to remove dust and small debris in a timely manner;

- metal machining;

- refilling cartridges for printers and copying equipment;

- production where separation of fine and light fractions is required.

The presence of a filter in the handle allows you to get rid of hoses and reduce the size of the device itself

Hydrocyclones PVO-GTsTO-P

Hydrocyclones made of high-strength plastic of our own production.

| Model | Productivity, m3/hour | Input/output, inch | Weight, kg | Dimensions (H/L/B) | Download passport (PDF) | Download (DWG) | Price |

| PVO-GTSTO-25-P | 0,9-1,3 | 1/2 | 0,2 | 342x70x44 | DWG | from 18,000 ք | |

| PVO-GTSTO-40-P | 2,4-3,3 | 1 | 0,47 | 552x98x67 | DWG | from 24,000 ք |

Buy a cyclone vacuum cleaner with a filter on the handle: what is the convenience?

Americans have always been distinguished by their desire to do something different from others, to stand out. This also affected cyclone vacuum cleaners. It was in the USA that models first appeared in which the waste collection tank was located on the handle. This was done for the sake of mobility and ease of operation, since such a device lacks a hose and a massive body.

Due to their compactness and mobility, units with a dust collector in the handle are suitable for cleaning in hard-to-reach places, for example, inside a car. But you have to pay extra for high mobility and ease of storage, since manual models are more expensive than their full-fledged counterparts.

All models of vacuum cleaners are equipped with HEPA filters, which ensures that some of the sucked dust and debris are retained before entering the container.

Another innovation from Samsung can be considered the invention of the newest Twister filter, which is placed not in the body of the vacuum cleaner, but directly on the handle. Its task is to retain large debris, and its use also helps to increase suction power.

FOR YOUR INFORMATION!

The Soviet Union also had cyclone models, or rather one. This is a Cyclone M vacuum cleaner, which had a power of 210 W, had a flexible hose, a telescopic tube and was very noisy during operation.

Industrial bagless models can be quite large depending on the application

Advantages:

- Own production in the Russian Federation

- Ease of use and compactness combined with high specific productivity.

- Increased separation efficiency due to optimized shape, dimensions and high quality flow path.

- Possibility of assembly into battery devices for any given performance.

The choice of a hydrocyclone as a basic device for a water treatment system is determined, first of all, by the high efficiency of filtration of aqueous media from large inclusions and productivity at a relatively small size and cost. In addition, as practice shows, the operation of hydrocyclones does not require large costs and additional personnel for maintenance. Hydrocyclones can be successfully used as clarifiers for water circulation equipment in the residential sector. In industrial production, single hydrocyclones are combined into complexes (batteries) to provide the necessary throughput for power supplied for finer filtration in many technological cycles of industrial production.

Industrial vacuum cleaner with cyclone filter

As the name suggests, models that are classified as industrial designs are intended for use in production workshops or construction sites. They are capable of handling debris such as metal shavings, ceramic or glass shards, concrete dust, sawdust and other types of waste.

The main difference between industrial vacuum cleaners is their increased power, longer service life, and the presence of rubberized wheels for ease of movement.

Professional cyclones can be equipped with additional add-ons that increase their functionality

All industrial devices for collecting garbage and dust are classified according to their class based on the characteristics of the dirt they collect:

- L – low degree of danger (for cleaning simple dust);

- M – average degree, where concrete and wood dust falls;

- H – high hazard, which includes asbestos or carcinogenic dust;

- ATEX – explosive mixtures, such as flour dust.

Additionally, construction vacuum cleaners with a cyclone can be equipped with cooling systems, which allows you to increase their service life, a manual or vibration cleaning function, and sockets for connecting tools that create dust and debris.

Dyson Cinetic Big Ball Animal Pro 2 is one of the best cyclonic vacuum cleaners from a famous brand

Hydrocyclones PVO-GC

Hydrocyclones made of carbon and stainless steel of our own production.

| Model | Productivity, m3/hour | Input/output, mm | Weight, kg | Dimensions (H/L/B) | Download passport (PDF) | Download (DWG) | Price |

| PVO-GC-1025 | 3,5-7,5 | 25 | 8 | 527/312/150 | DWG | from 36,960 ք | |

| PV0-GC-1040 | 9.5-12 | 40 | 16 | 640/457/178 | DWG | from 51,920 ք | |

| PVO-GC-1050 | 14-18 | 50 | 40 | 964/505/245 | DWG | from 61,600 ք | |

| PVO-GC-1080 | 35-45 | 80 | 50 | 990/505/245 | DWG | from 73,040 ք | |

| PVO-GC-1090 | 50-62 | 100/80 | 80 | 1550/790/362 | DWG | from 177 540 ք | |

| PVO-GC-1100 | 86-120 | 100 | 100 | 1950/820/432 | DWG | from 193 160 ք | |

| PVO-GC-1150 | 150-190 | 150 | 175 | 1911/1085/700 | DWG | on request | |

| PVO-GC-1200 | 230-370 | 200 | 328 | 2897/1363/809 | DWG | on request |

The best cyclone vacuum cleaners according to consumer reviews

When choosing models equipped with a cyclone, you should pay attention not only to the technical characteristics, but also read reviews from real customers, which will help identify the strengths or weaknesses of a particular model. The ranking of the best samples includes household and industrial devices.

Household vacuum cleaners with cyclone dust collector

The best models for home use, which do not have a dust collection bag and are equipped with a cyclone, are considered to be products from Dyson, which is the founder of this type of device. One of the best models can be considered the new Dyson Cinetic Big Ball Animal Pro 2. This is a vacuum cleaner that has a number of unique features:

- Dyson Cinetic technology, which captures the smallest particles, which is important for people suffering from allergies. At the same time, after cleaning, no additional washing or replacement of filter elements is required;

- Ball system, which ensures the stability of the vacuum cleaner and increases its maneuverability. Even if accidentally tipped over, the device returns to its correct position;

- Musclehead brush, which is a turbo head with carbon fiber bristles.

Cinetic technology allows you to achieve constant stability of the vacuum cleaner during operation

The only drawback of the model can be considered its high cost, which is 39,000 rubles. But such a pricing policy is normal for a company that positions its products as products of the highest quality.

Review of Dyson Cinetic Big Ball Animal Pro 2

More details on Otzovik: https://otzovik.com/review_6463819.html

Dyson Cinetic Big Ball Animal Pro 2

Construction vacuum cleaners with cyclone filter

One of the best industrial-type models, according to professionals, is the Ghibli Power WD 80.2 I model. This is a device that is designed for cleaning class M dust over large areas. Its features include the presence of a larger tank (80 l). There are also two turbines inside the device, which together create a power of 22.5 kPa.

Ghibli Power WD 80.2 I – device with 80 liter stainless steel tank

Among the advantages, it should be noted the presence of a reliable stainless steel case, a drainage hole for draining dirt, a long power cord (10 m), three replaceable nozzles, and not the highest noise level for similar models. Among the disadvantages, users highlight the limited actual volume of liquid garbage (56 l) and the optional ability to collect dry garbage. The cost of the device is 34,000 rubles.

Cyclone filters are sold separately, making them easy to replace if necessary.

Criteria and characteristics that are important when selecting and ordering devices

The most important source of data when designing any water treatment plant is source water analysis . Its quality, quantity, as well as dimensions, hydraulic size and origin of particles affect all parameters of the hydrocyclone.

Including the following parameters:

- Diameter,

- Height,

- Diameters and number of pipes,

- Rotation speed (feed or suction pressure),

- Type of hydraulic mechanism (open or closed).

However, “approximate” use of hydrocyclones is also possible. An example of this is homemade devices. They are assembled practically without calculations, selecting the diameters of the inlet and outlet pipes experimentally.

A popular blank is a fire nozzle of the RS-70 type. However, when choosing a supplier, it is advisable to pay attention to the equipment of the structure. As standard, it may include:

- Water-filled pressure gauges;

- Cranes,

- Diaphragm valve for automatic flushing of the sludge collector;

- Electrically operated valves;

- Control system for gate valves and self-powered valves;

- Anti-corrosion protection;

- Lining and antistatic coating.

Of course, this list is not complete, because patents for inventions of various hydrocyclones are still being received. For example, the installation can optionally be supplemented with an expanded control system with operator display or an enlarged “sand collector”.

Also - for an additional fee - backup control mechanisms and bypass paths for water supply can be provided.

Service Features

Maintenance of hydrocyclone units consists of monitoring and cleaning. As a rule, the tightness of all components of the unit, as well as the fullness of the sludge collector, is subject to control. Cleaning and rinsing from time to time is generally necessary. However, sediment may also remain on the walls of pipes or taps.

If the design involves electromagnetic, electromechanical or electronic components, their elements require special care. As a rule, these responsibilities fall on the shoulders of the service organization servicing this treatment complex.

Is it possible to buy a cyclone filter for a vacuum cleaner separately?

On the Internet or in retail sales in specialized stores you can find cyclones for almost all models of household or industrial vacuum cleaners. If desired, purchase an analogue, which will cost several times less than the original product, but will not be worse in quality.

Cyclones for household vacuum cleaners are most often made universal and are suitable for a number of manufacturers. Industrial designs are more individual. Therefore, when purchasing, you should check the specifications. Also, professional filters are divided according to the material for which a vacuum cleaner will be used, which should be taken into account when choosing.

Replacement filters for vacuum cleaners are most often universal, and for industrial models you will need a clear knowledge of the characteristics when choosing

Process of creation

Making homemade products depends on the available materials and tasks. In this case, different schemes can be used.

From improvised means

First of all, you need to make holes in the central part of the bucket lid and near the edge. Then you need to insert a tube into the center. However, first its edges must be processed with a file or sandpaper. This will help strengthen the adhesion of the surfaces. You should also prepare the lid. Then you need to lay the tube and apply glue.

When using a powerful vacuum cleaner, you should not use a plastic bucket, but a steel tank of a similar shape. Thanks to this, you don’t have to worry about the product being crushed.

From a household vacuum cleaner

Many craftsmen are interested in how to turn a regular vacuum cleaner into a construction one. To improve the properties of the device, you need to unscrew the wheels from it. Similar actions must be performed with the nameplate.

After removing all rivets and latches, you need to install the plug. To increase its reliability, it is necessary to wrap electrical tape and make a hole in the bottom. Its internal cross-section should be 3-4 cm. To seal the structure, you can use gaskets. You need to install a lid and a pipe in the waste container.

The cover must be secured with self-tapping screws. Then you can move on to working with the suction pipe. The hole into which it will be attached must be cut with metal scissors. Self-tapping screws can be used for fixation. To increase the tightness of the connection, gauze or a pharmaceutical bandage is suitable. Before winding, they should be soaked in glue.

An effective device can be made from a household vacuum cleaner

How to make a cyclone filter for a vacuum cleaner with your own hands

Often, when carrying out construction or repair work in a garage or on your own site, a cyclone may be required. It is not advisable to buy a whole vacuum cleaner equipped with such a filtration system for one-time work.

Most often, homemade cyclone filters for vacuum cleaners are made from plastic buckets or small metal barrels

It is possible to make your own cyclone without special knowledge of physics. Craftsmen offer tips on how to make a cyclone filter from a traffic cone, a plastic bucket with a lid, or a car filter.

FOR YOUR INFORMATION!

If you plan to use a vacuum cleaner with high power, then it is better to use metal buckets to make a homemade cyclone, since plastic can simply “collapse.”

Using a bucket to make a homemade cyclone filter is the easiest way to obtain a finished product. You can see how to make a cyclone yourself from the video presented.

Aytok hydrocyclones

Plastic hydrocyclones Aytok made in Türkiye.

| Model | Productivity, m3/h | Inlet/outlet diameter, inch | Net weight, kg | Price |

| P2020 | 20-30 | 2 | 9,5 | from 391$ |

| P2025 | 30-40 | 2½ | 9,5 | from 391$ |

| P203006 (tank 8 liters) | 40-60 | 3 | 19 | from 566$ |

| P203010 (tank 25 liters) | 40-60 | 3 | 19 | from 771$ |

Hydrocyclone made of Aytok steel made in Türkiye.

| Model | Productivity, m3/h | Inlet/outlet diameter, inch | Net weight, kg | Price |

| 2020 | 20 | 2 | 27 | from $656 |

| 2025 | 30 | 2½ | 33 | from 770$ |

| 2030 | 40 | 3 | 35 | from $798 |

| 2040 | 60 | 4 | 38 | from $1,017 |

| 2050 | 120-140 | 5 | 65 | from $1,895 |

| 2060 | 140-160 | 6 | 92 | from $2,486 |

Preparatory actions

When you have stored all the materials to make a cyclone vacuum cleaner with your own hands, you can begin preparing the individual parts. First, in the upper part of the barrel, you need to cut an ellipsoidal hole for the inlet pipe, which will be attached to the wall of the barrel at a tangential angle, going inside by 10-15 cm. A hole of round diameter must be made in the lid of the barrel according to the size of the inlet coupling of the adapter from a sewer pipe 40X50 mm .

As an option, you can make a removable cyclone with your own hands with a home vacuum cleaner, if you use a piece of plastic pipe 40X100 mm, and insert the pipe into the lid, which will tightly close the larger diameter.