Hello everyone, Not long ago I reviewed a very interesting tool: a screwdriver from Worx and used it in the first part of building a “den” for my four-legged friend. This time, an equally (and maybe even more) interesting tool is a pneumatic nailer from Dewalt, model DWFP12231, which also made a big contribution to this project. Please under cat. (great review). A little bit of summer in your timeline

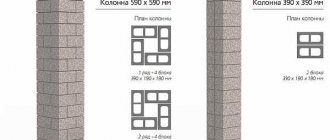

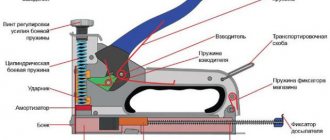

You can read the first part here. A little about pneumatic nailers: A pneumatic nailer is a tool that, using compressed air pumped by a compressor at the input, allows you to almost instantly drive special nails (nails, “needles”) into wood or other not very hard material, thereby fixing the parts to be connected to each other . Nailers come in different types and purposes, and also differ in the nail supply pattern (and, of course, price): straight, angular, frame (drum), etc. The simplest and cheapest is with a direct needle feeder. The consumables are cut steel strips of different widths, which contain about 100 pieces of these nails. They come in different lengths, square cross-section, and a width of about 1 mm. They look like this:

A similar strip is inserted into the nailer, which in turn is connected to the compressor with a flexible hose...

During operation, the needles are fed automatically (the strip at the bottom of the nailer is pressed by a spring), and the user only has to place the nailer against the workpiece and press the trigger, the compressed air pushes with great force a special striker plate, which “tears off” the upper needle from the “clip” and drives her into a tree. After the “shot”, a new needle is supplied, the firing pin automatically returns to its original position and, within a couple of seconds, a new portion of compressed air is injected. Such “nails” are quite enough for the installation of lining, block house and other wooden cladding materials, as well as for fixing frame structures that are not very loaded. More complex and expensive models use more serious consumption:

For household chores, I chose one of the most inexpensive direct feed models from Dewalt. A LITTLE BACKGROUND...

For some reason, there is an opinion that a pneumatic tool in a home craftsman’s workshop is: - expensive, - bulky, - exotic and very complicated. I will try to dispel this myth, because... I myself became its victim at first. It all started with the construction of a dacha, when the need arose to upholster approximately 200 sq.m. with clapboards individually (that is, practically, as one person). ceiling at a height of 3 to 4.5 meters:

Of all the considered options for how this can be done, in a time frame that does not tend to infinity, with the presence of human power alone, it turned out that the only option is the use of such an exotic device as a pneumatic nailer. At that moment, the tool was completely unfamiliar to me (like all pneumatic equipment, my acquaintance with which was limited to observing the work of impact wrenches in a tire shop during seasonal wheel changes). The Internet produced very encouraging price offers for the instrument itself: the Russian-Chinese Matrix cost about 3000 rubles (~$45), however, as you understand, it also required a source of this very “PNEUMO”, i.e. compressed air under pressure, and in fairly large volumes. And while studying the issue with compressors, I fell into some despondency - they are quite expensive, require regular maintenance (oil-based) and, in general, they are heavy. The Internet is full of detailed information about what types of compressors there are. In short: - piston and screw, 1-2-3 cylinder, with direct and belt drive, oil and oil-free, with and without a receiver. I won’t bore you with the theory, after reading a bunch of articles, reluctantly, I bought an oil compressor with a 24-liter receiver, 1500 W power, for something more than 10,000 rubles. (3 years ago). Weighing about 24 kg. Something like this:

And also this nailer:

And all so equipped, with equipment weighing about 30 kg (let me remind you that it was necessary to cover the CEILINGS at height with clapboard), I went to the dacha, where, fortunately for me, I caught my eye, pushed into the far corner and taken out once a year, an old piston compressor , which I used to pump out residual water from pipes before winter. The compressor was the simplest: oil-free, without a receiver, single-cylinder with a piston on the engine shaft, power 1100 W, discharge pressure: up to 8 atm. But it weighs about 8 kg, is very compact, and even made in Italy (I have no idea how it ended up on the market where I bought it for almost nothing):

Unfortunately, I didn’t save any photos of him in his “early childhood”, but now this dinosaur looks like this:

To wrap up with the preamble, I will say that with the help of this compressor, I completed the entire amount of work, although it took quite a lot of time. Result (this is just one part):

Surprisingly, its resource was enough for the entire volume, and for this review I only used it, although it is becoming more and more difficult for the “old man” to pump large atmospheres and the compression periods are becoming longer and longer. And the new one, big, beautiful and heavy, just sits there collecting dust. Yes, and the Chinese-Russian nailer completed the entire volume, although from time to time, especially at the end of the work, it caused trouble with stuck nails and a blocked striker (although I lubricated it):

Accordingly, as often happens, when a large volume has already been completed, you go to buy yourself a good tool. In this case, I could not pass up the Dewalt DWFP12231 premoneyailer. I really love the tools of this company and the price at the time of purchase was very good, $77.25 (and then I came across even lower ones). Now it's over $90, so you need to catch it. There is also a new model DWFP12233.

I ordered a new one, in a plastic case:

Suitcase parameters:

Inside:

Equipment:

The kit includes only the tool itself, a box of nails and instructions. Handsome:

Another argument why

Dewalt

.

This brand is part of the large Stanley Black & Decker concern, which also includes the Bostich

- a world-recognized leader in the production of pneumatic tools (I was still “licking my lips” at them when I was just planning to sheathe the ceiling - but it was very expensive to buy from us ). When I started looking into it, I realized that Dewalt nailers are the same Bostich, just with a different label and part number, but a little cheaper, and many of the models of these brands are the same.

Tool weight:

Size:

In hand:

Compared to the “old man”:

The only ambush that was that the supplied Devolt fitting is not very compatible with the hoses that are sold here, its diameter is 8mm, while in our country they are sold everywhere, mainly under 10mm. However, the mounting hole is the same as ours, and I twisted it from an old nailer without any problems (they are sold separately in any market and are quite inexpensive):

The flexible hose has a connector that snaps onto the fitting, and the other side is inserted into the compressor using the same fitting:

Assembled:

What is the tool

A nailer is a tool for hammering nails that replaces a regular hammer. The device is highly powerful, so it allows fasteners to pierce not only a soft base in the form of wood, but also durable materials, including brick, concrete, etc., without applying almost any effort.

The gun drives nails into the surface with one shot. Thanks to this, construction and installation work can be completed in a short time.

Pneumatic nailers

This is the most popular and diverse subtype of nail guns. Most of them work on wood, but there are guns for concrete and even metal.

Pros: Low price, rate of fire, power, simplicity of design, durability, fire safety, low price for spare parts and consumables.

Cons: Only one – the mandatory presence of a compressor. True, the nailer requires very little air flow.

According to the equipment used, nailers can be divided into pin-driving, pin-driving, finishing (these three types are more often used for finishing work, for example, for cladding) and nailing. Single-shot, most often these are handheld nail guns for some specific work (fastening, insulation), and multi-shot, into which a strip of nails is loaded.

Nailers also differ in the type of fastening of the tape with nails - rack and drum. Drum clips are larger, more powerful and more economical in terms of nail prices. In slatted ones, the nail fastening bar is fixed at an angle, which allows it to be used as a stop for certain work, for example, during frame construction. The angle of inclination of nails in such models is 21, 34 and 28 degrees.

There are other specific types of nailers

- Roofing nailer – designed for roofing work on soft tiles, shoots nails with an enlarged head, nail length up to 45 mm

- Frame nailer is a gun for constructing building frames. Most often, slatted nailers with the ability to drive a nail 90 mm or higher are used for these purposes.

- Parquet nailer – multifunctional devices for laying parquet. Able to work with several types of equipment

- Pallet nailer - this is the name of drum nailers used when assembling pallets, working with nails up to 80-90 mm

- Universal or combo gun - capable of working with staples and one or more types of nails

We offer you a video in which our specialist will show you one of the pneumatic nailer models. You can watch this and other videos on our YouTube channel. We also invite you to enter the catalog, read reviews about nailers and learn in more detail about the models you are interested in and their technical characteristics. Leave your feedback! Your opinion is important to us!

Peculiarities

A nailer is a tool that looks like a gun. For this reason, it is also called a nail gun.

The device consists of the following elements:

- frame;

- lever;

- a magazine in which fasteners are placed;

- trigger;

- piston.

The tool is easy to use. To drive a nail into a surface, simply place the gun against the base and pull the trigger. When performing a manipulation, the drive transfers energy to the piston. The result is a shot. Immediately after this, the piston returns to its original position.

Then the next fastening element from the magazine enters the barrel of the device and immediately after this the procedure can be performed again.

The tool fires an average of 1-3 shots per second. It is thanks to this that the relevant construction and installation work occurs at high speed.

Characteristics

The exact characteristics of the nailer depend on the specific model. However, the general parameters of any device are highlighted:

- case material – plastic or metal;

- magazine material – metal;

- weight – 0.8-7 kg;

- length – 269-538 mm;

- width – 128-153 mm;

- height – 273-568 mm;

- magazine type - rack or drum;

- magazine capacity – 150-200 fasteners;

- impact power – up to 100 J;

- operating mode – sequential mode or single shot;

- shot speed per second – from 1 to 3.

In addition, the tool may have additional options:

- Overheat protection . It deactivates devices in case of prolonged use and strong heating of the case.

- Blank shot protection . Does not allow the device to be activated if there are no fastening elements in the magazine.

- Repeated shot protection . This option is relevant for pistols with automatic operation. It prevents several nails in a row from coming out in the same place.

- Adjusting the shot energy . Allows you to adjust the depth of insertion of the fastener into the base, taking into account the material.

- Backlight . Allows you to use the tool even in poor lighting.

Areas of application

Nailers are used in any area where a procedure such as driving nails is required. It is used in construction, when performing installation work. Using the device, you can straighten a fence in the garden, build a gazebo, etc. The device is used for assembling furniture, repairing facades, etc.

Construction nailers for wood and light steel.

Hammering a couple of dozen nails is not very difficult. But when the task is to create a wooden frame or install a fence, the number of nails is already measured in the hundreds. Routine nailing can take an enormous amount of time.

You can, of course, consider the option of self-tapping screws, but they are more fragile to break, especially at low temperatures, and are not suitable for all types of work. It is worth understanding that by purchasing a nailer, you can use it for a large number of different jobs; you can read more about the use of nail guns in construction in this material.

The nailer is suitable not only for creating a frame, but also for internal and external cladding work. When laying a floor in a house, a nail gun with rough nails will allow you to achieve a perfectly flat surface with minimal time.

Assembly guns will come in handy not only in production or in the equipment of a construction team. But also in the home workshop. There are many different types of nailers that can be used to accomplish many jobs around the house.

Types of tool magazine

As already mentioned, there are two types of pistol magazine:

Rack and pinion

In this case, the fasteners are glued onto a paper or plastic base. The nails here form a straight strip. The main advantage of the store is its light weight.

The only drawback is the small capacity. Up to 100 nails are loaded into the magazine, which is why the clip has to be changed frequently in case of large-scale work.

Drum

Here the nails are connected to each other with wire into a tape. It is wound up and fixed in the drum. This allows you to place up to 200 nails in the magazine, which is especially important when performing installation work, when there is no time to frequently refill the magazine.

The disadvantages include high cost.

Expert opinion

Torsunov Pavel Maksimovich

Rack and pinion magazines reload much faster than drum magazines, so they are in high demand, despite their small capacity.

Varieties

There are several types of pistols, depending on the drive.

Electrical

Such tools help drive nails even into very hard surfaces, including concrete. They are used for types of fastening tools such as staples, pins, and studs.

Electric nailers come in two types:

Network

They work accordingly from the network. Such tools are characterized by high power and light weight. The disadvantage is that it needs to be used near an outlet.

Rechargeable

Powered by its own battery. This indicates their mobility and the ability to use them away from outlets. Disadvantages: low power compared to the previous version, heavy weight.

Pneumatic

These guns are powered by compressed air. For this reason, a compressor is required to use them. They are highly powerful and are capable of driving nails with a diameter of up to 5 mm and a length of up to 22 cm into any surface.

The tools are light in weight, easy to maintain and have an affordable price.

Other advantages of the devices:

- high performance;

- safety of use;

- impressive power;

- low noise level;

- small recoil;

- moisture-resistant housing;

- no special permission required for use.

Flaws:

- requires a compressor and electricity to operate;

- inconvenient high pressure hose connected to the compressor.

Gas

Devices powered by explosion energy that occurs during the reaction of propane-butane and oxygen. Such devices allow you to fix fasteners even in hard-to-reach places.

Advantages:

- ergonomic design;

- convenience and ease of use;

- autonomy;

- suitable for driving nails into any surface, including hard ones;

- relatively light weight;

- no special permission is required for use;

- ease of maintenance;

- You don't need to put much effort into pressing the hook.

Flaws:

- the gases used to operate the device can harm the operator, so tools can only be used in well-ventilated areas or outdoors;

- the need for regular cleaning of the combustion chamber;

- significant sizes.

Powder

To operate, the tools require gunpowder, which is loaded into the combustion chamber. Once it ignites, the gun fires. The device is highly powerful. It allows you to drive a nail into the hardest material, including metal.

Advantages:

- high impact power;

- significant performance;

- mobility;

- autonomy;

- compact dimensions;

- a light weight;

- Possibility of use for different types of nails.

Flaws:

- exhaust during use;

- special permission is required to use the tool;

- high cost of ammunition;

- Regular maintenance is required;

- Difficult to use due to strong recoil.

The sales consultant expressed his opinion on which nailer is best to choose.

Ryzhkov Dmitry, sales consultant, work experience – 7 years

Our store offers a large selection of nailers. The range includes electric, pneumatic and gas models. When advising on the purchase of a pistol, I take into account the purposes for which it will be used.

So, if you need a tool for your home, to hammer nails into walls from time to time, or to straighten fences in the garden, I recommend using electric models. They cope well with their tasks and are easy to use and maintain.

If a gun is needed for work - for builders, furniture assemblers, etc., I recommend choosing pneumatic or gas models. They are characterized by high power, so they allow you to complete even complex work in a short time.

Gas nailers

Most often used for working on concrete, but there are models that are used in woodworking. These guns work on concrete with nails up to 65 mm long, and on wood up to 90 mm.

Pros: Powerful tool. Equipped with a battery and a compressed gas cylinder, which is enough for approximately a thousand shots. Autonomy.

Cons: This tool is quite expensive compared to other nailing tools. It also has a significant weight of equipment compared to the same pneumatic tools. As for the cost of equipment - and here, most often, gas pistols are inferior to pneumatic ones.

Selection rules

When purchasing a nailer, you should consider the following points:

Tool type

In this case, it all depends on what the gun is used for - for work or for use at home. In addition, when choosing, take into account the type of surface into which the nails will be driven and the type of fastening tools.

Fastener type

Some tools only allow you to use branded nails. Because of this, the master has to constantly look for specific fasteners. For this reason, it is best to purchase a gun that works with more than just brand name nails.

Availability of driving depth adjustment function

This option is important if the tool is used for surfaces that do not allow fasteners to be immersed all the way to the head.

Weight

To prevent your hand from getting tired for as long as possible, it is best to choose lightweight models. However, such tools cannot boast of high productivity due to their low power. If the gun is needed for work, then its weight cannot be less than 4 kg.

Magazine capacity

The best option is from 100 units. Magazines with a smaller capacity will have to be reloaded frequently.

Nail thickness and length

Which fasteners are suitable for the tool are indicated in the instructions for the model.

Availability of protection

Options such as protection against overheating, dry firing, etc. not only guarantees the safe operation of the tool, but also increases its service life.

"The Lair of the Wild Beast." The final

For manufacturing, we used to the maximum what was left from the construction site: bars, remnants of lining, etc. I assembled the frame in the first part. The project, as such, was drawn on the knee and was adjusted as the necessary pieces of material were found. The dog’s “residence” is summer, so I didn’t insulate it, I just raised it to the thickness of a block (5 cm) above the ground, and made the floor with plywood. I covered it with clapboard using a nailer:

The rafters, by the way, are also very convenient to connect to the main frame and to each other with 50mm needles, 5 of them side by side, they are held quite firmly, given the small structure of the booth, although in some places, nevertheless, they were reinforced with self-tapping screws:

It turned out like this:

Painted:

And he finished the cut edges with a layout, securing it also with nailer:

The roof was covered with the remnants of corrugated sheeting. Opens:

Result:

The owner looked closely at the dwelling for a long time, but never decided to replace it with a large house in which people live and feed him deliciously:

It comes in periodically, but doesn’t use it all the time. A little later I made a sign in the shape of a bone:

A little later I made a sign in the shape of a bone:

In principle, I am satisfied, because... the booth was no longer conceived as a home for a dog, but rather as an element of country pastoral and design. It turned out, IMHO, not so bad

As for the nailer, I continue to use it quite often (only now I need to change the compressor). I made canvas frames for my child to paint with oil paints. Enough 4 needles in each corner, hold tightly:

I finished all the doors with homemade wooden frames. IMHO, a nailer is generally the only tool for quickly and accurately installing them yourself. I know that they also take thin finishing nails, insert them into a screwdriver and “twist” them, it turns out the same way, but much longer and more tedious:

TOP best models

The TOP included only models with optimal characteristics that received a large number of user reviews.

RYOBI R18N18G-0

High performance cordless tool. Recommended for use at home. It is light in weight, so the master’s hand does not get tired even when using the model for a long time. Allows you to drive nails even into hard surfaces.

Characteristics:

- power supply – own battery;

- productivity – 60 beats per minute;

- store type - rack and pinion;

- magazine capacity – 105 nails;

- impact force adjustment – yes;

- backlight - yes;

- nail length – from 15 to 50 mm;

- the minimum diameter of the fastening element is 1.2 mm;

- weight – 2.93 kg.

Pros:

- ease of use;

- a light weight;

- high-quality assembly without backlash;

- ergonomic handle;

- long operational period;

- high performance.

Minuses:

- small magazine capacity;

- not suitable for nails with a diameter of less than 1.2 mm.

Makita DPT353Z

High quality tool with high performance. It has a spacious magazine that can hold up to 130 fasteners. The model can be used regardless of the location of the outlet.

Characteristics:

- power supply – own battery;

- store type - rack and pinion;

- magazine capacity – 130 nails;

- nail length – from 15 to 35 mm;

- the minimum diameter of the fastening element is 10.6 mm;

- weight – 2.1 kg.

Pros:

- ease of use;

- battery operation;

- good balancing;

- ergonomic handle;

- a light weight;

- high quality assembly;

- low return.

Minuses:

- none.

AEG B18N18-0

A high-quality tool that is easy to use and high-speed. Capable of firing 2 shots per second. Equipped with an ergonomic handle and lightweight. Serves for a long time without malfunctions.

Characteristics:

- power supply – own battery;

- performance – 120 beats per minute;

- store type - rack and pinion;

- magazine capacity – 105 nails;

- impact force adjustment – yes;

- backlight - yes;

- nail length – from 15.9 to 55 mm;

- the minimum diameter of the fastening element is 1.2 mm;

- weight – 2.7 kg.

Pros:

- high performance;

- autonomous work;

- ergonomic handle;

- long service life;

- ease of use;

- assembly without backlash.

Minuses:

- small magazine capacity;

- not suitable for nails with a diameter of less than 1.2 mm.

Questions and answers

What is the best nailer to buy for working at home?

For personal use, it is recommended to purchase an electric tool. If the device will be used near an outlet, it is best to use a corded nailer; if there is no outlet nearby, you should use a battery-powered device.

How to use nailer?

To use the tool, you need to fill the magazine, press the nose to the surface and pull the trigger. Next, the instrument is transferred to another area and the procedure is repeated.

Is it necessary to buy a nailer with overheat protection?

No, but they take into account that this option increases the period of maintenance-free operation of the tool. If the gun is rarely used and is not used for a long period, then you can buy a device without overheating protection.

Can nailer be used on soft roofs?

It all depends on the type of specific model. In the instructions for the tool, manufacturers indicate what type of material the gun can be used for.

Which magazine is better - rack or drum?

Each type has its own advantages and disadvantages. Thus, a rack and pinion magazine is light in weight and has an acceptable cost, but has a small capacity, while a drum magazine, on the contrary, is more expensive, but can accommodate up to 200 fasteners.

A nailer is a nailing tool that is indispensable for some gardening work, repairs, etc. It helps to fix the fastener in the base without applying much effort.

Bottom line

The nailer is an excellent tool for use in finishing work in the country or at home.

It saves an order of magnitude in effort and time on a large amount of work, allows you to achieve an accurate result, and the pneumatic attachment allows you to buy it for reasonable money (since battery-powered ones are completely inadequate). The pneumatic tool itself is not such a complicated thing; for most jobs, the simplest compressor is enough (which can also be used for, for example, paint and paint work). Naturally, a nailer will not replace a screwdriver and a hammer where load-bearing structures need to be made, but in finishing it is just the thing. Video of work.

Part 1: Part 2: That's all.