What is marmoleum? This is a new material for flooring, the production of which is rapidly developing. In the future, marmoleum will most likely replace all types of floor coverings, except for fine wood parquet, which will remain as a luxury item.

This explosive spread of marmoleum is due to its truly outstanding advantages:

- Marmoleum is absolutely environmentally friendly, it is made only from natural ingredients, and they are so cheap that counterfeiting is not economically justified.

- Marmoleum is non-toxic, does not cause allergies, and in addition also has bactericidal properties.

- Marmoleum is cheap: a marmoleum floor is 15-30% cheaper than the cheapest current material - laminate.

- Marmoleum flooring does not require additional insulation or thermal insulation: the material itself has insulating properties.

- Marmoleum is durable and hygienic: it does not fade, does not swell when wet and does not warp, withstands enormous local loads, and even spilled paint does not stick to it. The guaranteed service life of marmoleum is 20 years, but judging by the structure and manufacturing technology, in the future it will be increased to 100 years.

- Marmoleum does not accumulate static electricity and is not flammable: a cigarette butt thrown on it will smolder without leaving a trace, and it is only possible to burn through marmoleum with an autogenous gun.

- Marmoleum is decorative: it can be painted in a variety of colors, textured to resemble wood, stone, etc. Currently, marmoleum is produced in 100 primary colors and more than 2000 shades.

- And finally, marmoleum is extremely easy to work with: literally a preschooler can do the laying of marmoleum with his own hands.

Video: marmoleum and its safety

How did such a wonderful material come into being? This took several centuries.

Even in ancient times, fabrics were impregnated with oil to increase their durability. By the 17th century In Europe, jute came into use - a very coarse and durable burlap made from fibers of plants of the genus Corchorus

linden family: Indian flax, Calcutta hemp, Tossa jute. At the same time, oiled jute fabric, coated with various hardening compounds, began to be used for flooring. The prehistory of marmoleum ended in 1863 with British Patent No. 209/1860 for linoleum, issued to Frederick Walton. In 1864, mass production of linoleum began.

Walton managed to develop a very cheap and fairly durable topcoat based on linseed oil, pine resin (resin), wood flour, natural dyes and chalk. After World War II, natural linoleum replaced PVC-based linoleum, but the global oil crisis and increased environmental awareness revived the demand for natural linoleum, which contributed to the improvement of its manufacturing technology.

By the beginning of the 90s, even cheaper and higher-quality substitutes for linseed oil and resin, obtained from highly productive tropical crops, were found. At the same time, a third, intermediate layer of pressed cork chips was introduced into the linoleum structure. The finishing touch was the use of hot dry pressing technology, developed for the production of MDF, in the production of linoleum.

The coatings obtained in this way went on sale under the general name marmoleum. In fact, marmoleum is natural linoleum taken to the limit of its perfection.

Marmoleum is especially good for children's rooms.

Pros and cons of linoleum on warm floors

The use of linoleum for decorative covering of heated floors has its positive aspects, which include:

- versatility for different rooms (from living rooms to loggias);

- long service life with preservation of appearance;

- not afraid of moisture;

- cost-effectiveness in terms of the price of material and installation work.

The linoleum coating is easy to maintain and can be easily cleaned even from complex stains using conventional means.

Linoleum care items

The intensity of heat transfer and the overall energy efficiency of the structure depend on the texture characteristics and quality of the finishing material. Linoleum, as a homogeneous, dense and thin material, is quite suitable for this.

But there is a drawback that limits the use of linoleum for finishing under heated floors. This is the presence of an overheating threshold.

How to lay marmoleum on film heating elements?

The technology is practically no different from the one described above. But first, the warm infrared floor under linoleum needs to be prepared, namely, the film needs to be covered with dense material. After the system has been checked, a vapor barrier must be laid on top of the film to prevent condensation. The vapor barrier material (for example, PET film) should overlap the walls by 50 mm.

Next, the system should be covered with fiberboard, plywood or OSB with a thickness of no more than 6-8 mm. The material must be secured to the floor with self-tapping screws, but only along a line where there are no heating elements. Sand the joints of the sheets so that there are no noticeable differences.

Criteria for choosing linoleum for heated floors

For a competent approach to purchasing linoleum, you need to have an idea of its types.

Classification of linoleum

Taking into account the conditions and scope of application, linoleum is classified by type and degree of wear resistance.

Classification by purpose of linoleum

Household - for finishing rooms with light traffic loads.

Semi-commercial - as a rule, used in institutions, offices, hotels with average traffic.

Commercial - can be used in production in areas with increased load on the flooring.

According to the type of base, linoleum is:

- Natural.

- Polyvinyl chloride.

- Nitrocellulose (colloxylin).

- Glypthal (alkyd).

- Rubber (relin).

All these coatings have specific structure and chemical composition.

Chemical composition, structure of linoleum

According to their characteristics, natural (marmoleum) or PVC (vinyl) coatings are better suited for finishing a warm base.

Natural "marmoleum"

Marmoleum contains at least 97% natural ingredients.

Composition of marmoleum

The basis of marmoleum is jute fabric, a type of textile obtained from the plant of the same name. The fibers of the fabric are arranged crosswise, creating an elastic and durable mesh.

The binding components for the base are:

- oil obtained by pressing from flax seeds (at least 30% according to European standards);

- resin - resin from coniferous, mainly pine, trees;

- wood flour from the bark of the cork tree;

- powdered limestone.

Compositions of natural, eco-friendly dyes that do not contain heavy chemical elements are used for coloring. This linoleum corresponds to the premium class.

You can find out more about marmoleum here

Vinyl linoleum (PVC)

The binding material of this type of linoleum is a thermoplastic polymer.

Linoleum on a foamed PVC base

Additional components:

- Plasticizers. They give the material useful flexibility (plasticity). As a rule, these are phthalic acid esters.

- Fillers add the necessary strength and, by reducing PVC consumption, reduce costs. Calcium carbonates (chalk, micromarble) are most widely used as fillers.

- Modifying multifunctional additives that increase the service life of the material.

- Technological additives (antistatic agents, flame retardants, blowing agents).

- Dyes, thinners.

Based on the number of layers, PVC coating is divided into two subtypes:

- Homogeneous - single layer, with a pattern throughout the entire depth of the layer. The thickness of this coating is up to 2 mm.

- Heterogeneous - from 2 to 6 layers, with a total material thickness of up to 0.6 cm.

For “warm systems” a more versatile second type of linoleum is used.

Structure of heterogeneous linoleum

Foamed PVC, jute or felt fabric, or polyester can be used as a base. Some manufacturers use additional protective layers in the heterogeneous coating structure.

Components used in production

Modern material is divided into categories:

- industrial,

- commercial,

- domestic.

The thickness of the canvas ranges from 4 to 9.8 mm, depending on the purpose. The surface of marmoleum is also heterogeneous. The flooring is available with a smooth or textured texture. The color palette is amazing. Connoisseurs of aesthetic styles can buy; red, green, dark, yellow marmoleum.

The floor covering is made without the use of synthetic bases and components hazardous to health. Basic materials used in the production of marmoleum:

- lime;

- jute fiber;

- chalk;

- linseed oil;

- wood, lime flour;

- softwood resins;

- crushed cork;

- natural dyes.

Marmoleum can withstand high operating loads and does not deform over time. The cost of finishing the floor is much higher than traditional linoleum, but the period of use is much longer.

Linoleum marking

Significant help when choosing a linoleum covering can be provided by its marking, which is encrypted with a set of alphanumeric designations or special characters. The main ones are presented in the table.

Marking of linoleum covering

The first digit in the material class indicates the type of room in which it is planned to be used: “2” - in your own houses, apartments; “3” - for premises in which the traffic of personnel and clients is assessed as medium and high; “4” - production and special premises.

The second number characterizes the load the material can withstand and has 4 gradations. The degree of load that corresponds to each stage is presented in column 3 of the table.

You can also find out about the compatibility of the coating with heated floors by looking at the stylized symbols.

Permissive marking

Linoleum from some manufacturers may have extended markings indicating the specific properties of the material:

- antistatic;

- fire retardant qualities;

- increased degree of protection against scratches;

- compliance with the global eco-label GEN “Leaf of Life”.

Domestic PVC linoleums have additional articles indicating the underlying material:

- woven - T;

- non-woven - NT;

- artificial leather - RK.

Single-color and multi-color graphic printing on the coating is marked respectively - OP and MP.

The best manufacturers

Marmoleum Forbo

The Swiss corporation Forbo is rightfully considered the leader in the production and sales of marmoleum. It is she who owns the Marmoleum brand, popular and recognizable among consumers due to its excellent performance characteristics and the highest quality. Marmoleum Forbo is distinguished by a wide variety of colors, produced in a classic format and with special properties (acoustic, current dissipative). All Forbo natural linoleum collections are coated with a patented Topshield2 layer, providing double protection and reliable operation. The entire range of Forbo products is available in tiles, panels and rolls.

Marmoleum Armstrong

Another manufacturer of natural coatings, Armstrong, is no less popular. Marmoleum Armstrong is a product of the highest quality and excellent performance properties. All Armstrong brand collections are distinguished by high reliability, thoughtful design, and environmental friendliness.

When choosing products of appropriate quality, following installation technology and operating rules, it is guaranteed to last at least 20 years while maintaining its performance properties. In terms of functionality, aesthetics and price, linoleum has no analogues. By choosing marmoleum, you get a practical, comfortable floor of unsurpassed quality.

Types of heated floors

Such home comfort technology as heated floors can be implemented in several versions. The implementation of this system in combination with a properly selected coating provides a pleasant tactile sensation.

Warm floors finished with linoleum can also effectively complement the heating system. This is achieved by covering the entire area of the room with heating elements and heating it optimally - with a higher temperature below at the heat source (22 - 24°C) and a little lower, but quite comfortable, under the ceiling (18 - 22°C).

Comparison of heat transfers for different types of heating

According to the technology of thermal energy transfer, heated floor structures can be divided into two main types:

- Water.

- Electric.

Systems with electrical heating and liquid coolant may differ in the way the project is implemented.

Water heated floor

The standard version of warm water flooring is performed according to the following scheme:

- laying hydro- and heat-insulating materials on the base;

- fixing pipelines on a metal mesh;

- pouring pipes with concrete.

The thickness of the screed over pipes with a diameter of 16-18 mm is usually at least 30 mm.

Option for laying pipes with water heating

Due to the need to turn the pipes, the laying step is limited and should be within 22.5 - 35 cm. The hydraulically heated base is compatible with marmoleum and PVC material.

Heating cables

Another solution for warm flooring under linoleum is the use of an electric heating cable.

Heating cable

The electrical cabling system using resistive cables is equipped with a thermostat and a temperature sensor.

Modern self-regulating thermal cables are becoming increasingly popular. The basis of such a heating cable is a heating matrix made of cross-linked polymer with graphite additives. Two copper cores are placed in this matrix.

The heating power of the system is adjusted by changing the resistance of the matrix depending on the temperature of the heating element.

Self-regulating heating cable

The covering with a cable heating system can be universal, including linoleum, compatible with the “warm floor” system.

Infrared floor

Infrared technology is based on the use of a special film.

IR technology with low heat transfer intensity is quite compatible with the option of installing linoleum flooring.

The infrared heated floor system is one of the most energy-saving. Compared to a heating cable, energy consumption is 25% less.

The heating elements are sealed in polypropylene film, supplied in rolls.

Infrared film material

The strips are heated by a source of electricity transmitted through copper-silver busbars located along the edges. Due to the carbon paste applied to the film, thermal energy in the form of infrared radiation heats the surface of the flooring and is transferred to the environment.

Cable thermomats

The operating principle of the thermomat is based on heating resistive cables woven into a dielectric fiberglass mesh. To reduce the level of electromagnetic radiation, the cable cores in mats used for residential premises are double, shielded and protected by an outer sheath.

Thermal mat roll

The design and operation of a heating system using thermomats is simple. Automatic heating temperature control allows you to combine not very heat-sensitive coatings with heating mats.

Reliable, safe flooring

Marmoleum appeared on the markets of construction and finishing materials relatively recently. It differs from traditional linoleum in improved properties: elasticity, wear resistance, and environmental safety. Thanks to improved qualities, flooring has become in steady demand.

The technology for making linoleum flooring was invented by Frederick Watson. In 1863, he tried to invent an artificial substitute for natural rubber. The Scot gave the resulting know-how a name that is generally known in the modern world. With the development of the chemical industry and the expansion of the use of natural materials, it became possible to produce marmoleum.

Compliance with thermal conditions

The use of a specific type of coating with the selected heating system is determined by the thermal conductivity and thermal sensitivity of the material. It is important to take into account the maximum heating temperature specified by the manufacturer.

Optimal values:

- temperature - from 26 to 28°C;

- power 110-130 W/m2.

Overheating of any type of linoleum above 25 - 30°C is unacceptable.

It follows from this that the heating system with linoleum coating does not serve as the main direct heating, but can only be used as additional heating.

The estimated heating power of a linoleum floor is taken taking into account the area of the room.

Power for different premises

An electrical power of 2.5 kW is sufficient for rooms with heated floors.

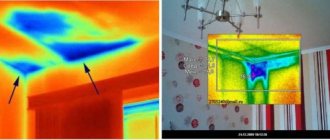

The consequences of overheating of the finishing coating when heating the room due to underfloor heating can be seen in the video at the link

https://www.youtube.com/watch?v=_LVCDJEhEcU.

Due to their thermal characteristics, colloxylin coatings and linoleums based on glyphthalic and rubber are not suitable for finishing heated floors.

↑ A little about Forbo marmoleum

It is impossible not to say about the manufacturers of quality products, or rather about one of the manufacturers whose reputation leaves no doubt. The Forbo brand, specializing in the production of flooring, was founded in 1928. The company's branches are located in 40 countries of the European Union, the brand's products are recognizable and revered due to their high quality, confirmed by numerous certificates.

forbo marmoleum meets all necessary environmental standards, as proven by tests from 7 leading laboratories in the world: Environmental Quality Mark (Netherlands), Ecolabelling Trust (New Zealand), Good Environmental Choice (Australia), SMART (USA), UZ 56 (Austria), Nordic Swan Label (Northern Europe) and Nature Plus (Germany).

Marmoleum forbo is a time-tested brand

Forbo “click” marmoleum is especially popular, equipped with a locking mechanism using Aquaprotect technology. This coating is produced in the form of boards or tiles based on cork and moisture-resistant NDF, which is coated with a special protective layer Topshield.

The quality of forbo marmoleum is confirmed by tests

A variety of color variations and patterns provide the opportunity to lay floors that are artistically unique. Forbo marmoleum is not afraid of the claws of pets, thin women's stiletto heels and heavy shoes. It will not be difficult to wipe off chewing gum or paint stains. It is not for nothing that the coating received the title of “indestructible” - where laminate, parquet, cork board or carpet are hopelessly damaged, marmolu will serve and delight you with its impeccable appearance for quite a long time.

Important points for installing linoleum and “warm floors”

You need to know several important points regarding the installation of linoleum and the installation of a heating base.

Basics when installing the floor

A significant point when installing an electric floor is laying the cable and thermomats.

The heating cable in the additional heating system is mounted directly on the reinforcing mesh or on the guides of the heat insulator, without the first layer of screed.

When installing a cable over an old concrete or tiled base, do not neglect the thermal insulation layer. The deck level will be slightly higher, but the cost of energy loss will be reduced.

Installation procedure for cable heated floors

The base on which the heated floor is laid should not have large differences in height (no more than 2 mm per 2 m of surface).

When laying thermomats, the mesh is cut to rotate the cable. The wire itself cannot be cut, shortened or extended. The “cold” ends of the cable are connected to the mat through special adapter couplings.

Attention! When laying pipes in a screed, you can turn on the heating system only after the concrete has completely hardened.

Advantages

- Natural environmentally friendly material.

- It has bactericidal properties as it contains linseed oil.

- The material is non-toxic and does not cause allergic reactions.

- Resistant to solvents, acids and other chemicals.

- Does not fade when exposed to sunlight.

- It has antistatic and soundproofing properties.

- It is not susceptible to deformation under mechanical stress, can withstand loads of up to 160 kg/cm2, is easy to maintain, and is fire resistant.

- Wide variety of shades, easy to install.

- Service life more than 20 years.

- The material is tough, but brittle at the edges and requires careful handling.

- Over time, it hardens and spreads, so the cracks become smaller.

- New sheets have an unpleasant odor that dissipates over time.

- The heavy coating has residual plasticity along the layers.

- It doesn't cut well with a knife; it's hard to get a straight edge.

- Not suitable for heated floors as it does not transmit heat well.

- Not recommended for use in kitchens and bathrooms (manufacturers' recommendations), as the material may become deformed with high humidity. The optimal temperature is 18°C, humidity no more than 60%.

- It is not recommended to use on unheated balconies and loggias.

- Expensive coating compared to linoleum and laminate.

Important Disadvantages

Flooring, in turn, has certain disadvantages. Reviews indicate the following disadvantages:

- Fragile, high risk of edge damage. When moving, care is required during the transportation process;

- Rigidity, lack of flexibility. This creates certain difficulties during storage and transportation;

- The property of spreading and hardening. When purchasing marmoleum, you need to pay attention to the production date and shelf life;

- Cannot be used for finishing walls or ceilings. The coating retains residual plasticity and is able to “float” under its own weight;

- Difficulties when cutting, problems with creating a straight edge. The material is cut only along the walls, where the edge of the flooring will be covered with a plinth;

- High cost due to the use of high-quality natural raw materials.

Self-installation technology

Laying of roll coverings should be entrusted to professionals. The material is heavy, fragile, and may crumble at the edges.

It is better to install tiles or panels yourself, with or without a base. Laying marmoleum in general is not difficult if the base is level and the installer does not forget about the fragility of the material. Tiles should be handled very carefully.

Laying marmoleum tiles or panels without a base is reminiscent of installing quartz vinyl tiles, PVC or natural cork, and installing boards on an HDF base is similar to working with laminate, with some subtleties.

Let's consider laying marmoleum with and without a base. The stages are as follows:

- Leveling the base. This is the most important and responsible stage, since marmoleum is very sensitive to floor unevenness. A wooden floor is leveled with sheets of plywood or OSB; a concrete floor is better leveled with a self-leveling screed. After this, the floor under the adhesive tiles should be treated with a deep penetration primer.

- Temperature gaps of 1.5–2 cm are made along the perimeter of the room by inserting wooden planks wrapped in plastic film or liners (liners are attached to the material, which are removed after laying the coating).

- Laying of interlocking panels is carried out according to the type of laminate installation, staggered: each subsequent row begins with the remainder of the board of the previous row. If a pattern of tiles of different colors is expected on the floor, it should first be drawn on paper and on the floor, and it is better to start work from the center of the room.

- Due to the flexibility of the top layer, joining the fragments is somewhat difficult. To cope with the problem, bars cut into a wedge with an angle of inclination at which the fragment is inserted into the lock will help. The bars are placed under the marmoleum and inserted into the groove of the previous row. Then the bars are removed, and the coating strip takes its position.

- To cut boards, you should use a jigsaw with a metal file or a hacksaw with fine teeth.

Laminate features

Laminate flooring was developed in the late 70s of the 20th century and was positioned as a budget analogue of parquet. This is a finishing multilayer material consisting of four layers:

- Overlay is a protective high-strength polymer film that is resistant to abrasion, compression, shear and other types of loads. Thanks to its variability, it creates a smooth or textured coating, thereby creating the effect of a natural or brushed board.

- The decorative layer is durable craft paper with images of wood, parquet, ceramics, stone, textiles and even grass or pebbles. Thanks to high-precision laser printing, laminate flooring is produced with a huge number of decors in a wide variety of shades.

- The supporting board is a high-density HDF or PVC base with a thickness of 6-14 mm. It takes on all the loads, and thanks to the lock cut at the ends of the planks, the laminate is easily and quickly assembled into a single, monolithic floor. Some manufacturers treat the grooves and ridges around the perimeter with wax compounds, which provide increased moisture resistance of the finish and joint density.

- Stabilizing paper impregnated with thermosetting resins is the bottom layer, the purpose of which is to protect the floor material from excess moisture in the base and prevent deformation processes of the planks.

Laminate flooring is available in all load classes - from 21 to 43. A properly selected and installed coating will successfully serve for 10-25 years, and is aesthetically pleasing, practical and easy to use.

Due to the widest selection of designs, it is popular among the population. Craftsmen are attracted by the ease of installation, but most of them do not know the basic rules for preparing the base.

Statistics show that 85% of complaints from buyers are not related to the quality of the laminate, but to violations of the installation technology.