When carrying out construction or repair work, it is almost always necessary to fasten together various building materials, panels or structures.

Very often this is done using screws, bolts or bolts. In this case, you cannot do without the appropriate tools - a screwdriver and a screwdriver. How do they differ from each other and what do they have in common?

Both of these tools are designed for screwing (or unscrewing) various fasteners and, in general, the principle of their operation is the same: the electric motor creates a rotational movement, and the planetary gearbox transmits energy from the motor to the spindle, on which the clamping chuck of the screwdriver or screwdriver is fixed. Both of these tools can be powered either by mains or battery.

Main principle: tangential impact

Directed tangentially.

This is a special type of impact, not at all the one used by hammer drills or hammer drills.

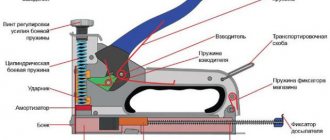

To understand, imagine putting a wrench on a nut and hitting it with a hammer, tightening the fastener more and more. It’s the same in our case: at first the tool quickly rotates the screw or nut, and when more or less noticeable force is needed, it switches to frequent blows. How it works?

The blow is provided by the so-called “hammer”, which moves back and forth under the action of a spring. When moving forward, the “hammer” at some point engages with the “anvil” (it is part of the spindle) and thereby transmits an angular impulse.

How much does a screwdriver cost?

Screwdrivers are a basic tool for any electrician, auto mechanic, seamstress, commissioning operator and countless other professions.

Like any other tools, you will find a screwdriver at a reasonable price, from the cheapest screwdriver to the most expensive electronic screwdriver. The price always depends on the quality of materials and brand.

- If you want a tool that will last a long time, you need to choose a reputable brand.

- The materials from which it is made affect the service life of the tool; a cheap screwdriver may last less time.

- It is advisable to choose a reliable and durable tool; it is worth spending a little more money on it.

This is easier to do if you buy from construction supermarkets that cooperate with famous brands.

What are impact wrenches?

Pictured: Hilti cordless impact wrench SIW 22T-A.

Cordless impact wrench

- this is, by and large, the same screwdriver, only designed to work with nuts and bolts.

It has a slightly higher tightening torque, and instead of a chuck with a ¼" internal hexagon, there is a ½" square for socket heads. It is not surprising that today these two instruments are often supplied to the market as a pair, in the form of two compact models with minimal differences. Corded impact wrenches

are a completely different case.

They are heavy, bulky and do not have a twin screwdriver. A cordless angle wrench

is a machine with a long, narrow body that can tighten nuts in hard-to-reach places.

Rating of the best screwdrivers

| Place | Model | ||

| 1. | BOSCH GSB 120-LI Li-Ion 2.0 Ah 12 V x2 case | Prices | Review |

| 2. | Bort BAB-18IX2LI-FD | Prices | Review |

| 3. | Makita DHP482Z | Prices | Review |

| 4. | STANLEY STDC18LHBK | Prices | Review |

| 5. | DeWALT DCD996P2 | Prices | Review |

| 6. | RESANTA DA-24-2LK-U | Prices | Review |

| 7. | DeWALT DCD716D2 | Prices | Review |

| 8. | VORTEX DA-24L-2KU | Prices | Review |

| 9. | Sturm! CD3220LI | Prices | Review |

| 10. | PIT PID03003-20M2/BL | Prices | Review |

High torque

Pictured: AEG cordless screwdriver BSS 18C LI.

Not to be confused with torque.

In the technical data sheet of a screwdriver or impact wrench you will see incredible numbers: 100, 150, 180 N*m. And if this is a very powerful cordless impact wrench, then we are talking about hundreds of “newtons”. There are no errors here, you just need to know that the tightening torque of the fasteners is given, and not the torque that the gearbox develops. Those “unrealistically” high Newton meters are not the result of a gigantic effort applied, but only a consequence of a series of blows on the edges or slots.

Types of screwdrivers

Currently, there is a large offer of screwdrivers: from cordless electric models to familiar screwdrivers of all types and from any materials.

The ideal option for you would be to look for a product that is made from quality materials, is suitable for the job you want to do, and is also comfortable.

There are several different types of screwdrivers, so you should be familiar with all of their specifications before purchasing.

How much does a screwdriver weigh?

The weight and size of the screwdriver will depend on the model as well as the type. Screwdrivers are usually compact and lightweight. Their length does not exceed twenty centimeters, and their weight is several hundred grams. As always, this will depend on the model you choose. Some models may weigh more, but this is not the practice.

There are unique sets of screwdrivers with a large number of attachments. They usually consist of several pieces (from six to eighteen). The screwdrivers in these sets have different tips and sizes. With these kits you can do all types of work. Some are sold in tool storage cases.

Main differences

A screwdriver is a tool for installing a variety of fasteners. If you equip it with an adapter and a socket head, it can be used as a wrench. A screwdriver can only be used for small jobs. Impact wrenches are professional tools. The devices differ from each other as follows:

- Power. Screwdrivers are less powerful than impact wrenches. There are models of impact wrenches that are equipped with a gasoline engine and are used in the railway industry.

- Mass. Screwdrivers weigh less than screwdrivers. The weight of the “domestic” does not exceed a couple of kilograms. Pneumatic or hydraulic impact wrenches, common in industrial production, weigh many times more.

- Dimensions. Professional impact wrenches are up to 60 cm long, screwdrivers are about 20 cm long.

- Patron. Impact wrenches generally do not have them. The design does not provide for equipping with a cartridge. Instead, the tool is equipped with a rod that has a special mount for socket nut heads;

- Functionality. The screwdriver is designed for installing various types of fasteners: bits with straight and cross slots, disc shears, attachments for restoring chamfers of bolts, polishing, and cutting metal. It is used mainly in construction work - when screwing or drilling low-density materials. With an adapter it can be used for tightening nuts or as a regular drill. The impact wrench does not please with its multifunctionality. It is intended only for unscrewing and tightening nuts with rods of different diameters.

Adapters. The clamp at the top securely holds the heads under the nuts

- Impact mechanism. The impact wrench is not intended for drilling holes; its impact block serves to gradually loosen a stuck bolt and has a different operating principle than a screwdriver. The latter has a direct blow to the bit, while the impact wrench has an angular impulse.

- Resistant to loads. The impact wrench is wear-resistant because equipped with a more powerful motor. The competitor is not designed for heavy work.

- Nozzles A screwdriver works with bits and drills; only heads are suitable for a wrench.

Set of bits for a screwdriver

- Cost. The difference is not in favor of the impact wrenches.

Visually the tools are very similar

How does a screwdriver work?

Screwdrivers are so easy to use that we can find them in some games for children. Simply insert the tip of the screwdriver into the recess of the screw to tighten or unscrew it.

You must make sure that the notches on the screw head and the tip are perfectly aligned, otherwise it may happen that the screw becomes deformed and becomes unusable.

Safety rules must be followed:

- Always keep the instrument clean;

- Do not allow dust and grease to accumulate on the tips of the nozzles;

- Do not use the screwdriver if the tip is damaged. If you notice the tip wobbling or vibrating while screwing, stop using the tool;

- When working with screwdrivers, protect your eyes and hands with safety glasses and gloves;

- Make sure the tip and screw fit together well;

- Do not force the screwdriver. If the tip slips, it can damage the surface you are working on;

- Do not use the screwdriver as a lever;

- Hold the screwdriver with your entire palm. If the tool is uncomfortable for you, you will need to replace it to avoid injury or wrist pain;

- Use a screwdriver with insulating rubber grips, especially if you are an electrician.

Tips for choosing a tool

First of all, pay attention to the purpose of using the device. Impact wrenches are used in construction and vehicle repair; a standard screwdriver is suitable for furniture assembly and home installation.

It is not recommended to use a wrench to tighten screws: due to the tangential impact, there is a high risk of breakage or severe twisting of the screw. Another disadvantage of the impact wrench is the noise level; it is better not to use the tool at night.

What is important to know when choosing a wrench?

Almost all impact wrenches have an impact action that allows you to unscrew even the oldest and rustiest bolts. By fuel type they are divided into:

- gasoline;

- electrical;

- hydraulic;

- pneumatic (powered by compressed air).

The last type is the safest, and therefore the most popular. Pneumatic impact wrenches are powerful, non-flammable and do not require cooling, thereby maintaining their functionality in any weather.

According to the type of action, impact wrenches are divided into torque and impact. The former are used when performing complex tasks. Despite the high torque (up to 12,000 Newton meters!), the rotation speed is only up to 16 revolutions per minute.

Impact wrenches of the second type are cheaper and have increased power (up to 4000 watts!).

How to choose a screwdriver to buy?

Based on the type of power supply, screwdrivers are divided into mains and cordless.

The first type is designed for continuous work at home or in a warehouse if large-scale operations with drills and all kinds of fasteners are planned. As a rule, they are equipped with brush motors.

Tools of the second type are more mobile and have additional functionality and equipment. Most screwdrivers support lithium-ion batteries, characterized by the absence of memory effect and a large number of possible recharges. However, units are produced that run on nickel-cadmium batteries that are resistant to low temperatures.

Based on their mechanism, screwdrivers are classified into impact and non-impact. The advantage of the first type is the ability to screw screws and drill in concrete and masonry. Impact screwdrivers are also used for ice drilling.