| Place | Name | Characteristics in the rating |

| The best electric jackhammers |

| 1 | Makita HM1812 | The most powerful. Small vibration |

| 2 | Bosch GSH 5 CE Professional | Compact. Better comfort at work |

| 3 | Makita HM1203C | Powerful. Comfortable |

| 4 | CALIBER Master OM-1700M | The best ratio of price and quality |

| 5 | SOYUZ PES-2520RB | Affordable price |

| The best pneumatic jackhammers |

| 1 | Bison “Concrete Breaker” (1600 W) | The best choice |

| 2 | ARCHIMEDES MW510 | The most powerful bumper |

| 3 | Wester MH-10 | Compact hammer for small jobs |

| 4 | SUMAKE ST-2200A/H | Best ergonomics |

| 5 | Concorde (CD-MO-3) | Powerful standard hammer |

The best electric jackhammers

The electric jackhammer operates on a standard 220 volt network. Its main advantage is the absence of additional elements in the system. You simply plug the tool into a power outlet and you can use it. True, there are also disadvantages regarding power limitations. Pneumatic hammers are more powerful and more economical, but due to a certain complexity in their work, they are more often used in production or large construction sites. At home, an electric hammer is the best option.

The path from pickaxe to chipper

When stone caves were the predominant habitation of man, then the first signs in history of the use of devices to facilitate the processing of hard rocks appeared. Most likely, these were stone chisels and axes.

For tens of thousands of years, nothing fundamentally changed in this area of human activity. Just as blocks were cut by hand for the construction of pyramids in ancient times, until the end of the 19th century, technologies for breaking stone, mining coal and salt remained at the level of a hand pick.

The invention of electric motors and internal combustion engines revolutionized this business. The simplicity of converting rotational motion into translational motion with periodic action on the pickaxe led to the emergence of mechanical jackhammers, without which it is impossible to imagine either road construction, mining, or rescue operations after an earthquake.

The best pneumatic jackhammers

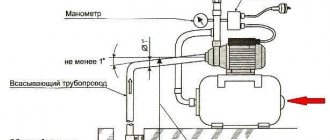

A pneumatic jackhammer is powered by compressed air, which pushes the tip of the tool under very high pressure. To provide this pressure, a compressor is needed, and its size directly depends on the power of the tool. Simply put, you will not be able to connect a powerful hammer to a small compressor with a low-capacity receiver and work. You will need an industrial device. All this makes it almost impossible to use pneumatic tools at home, and there is no need for them if you do not plan to break concrete piles or FSK.

Which company should you choose?

When choosing a jackhammer, you should focus not only on its technical characteristics, but also on the manufacturer of the device.

Since this tool is a professional one, you should give preference to products from reliable and proven brands.

In 2021, professional builders highly appreciated the jackhammers of the brands STAVR, Bosch, TZK, Makita, PATRIOT, Metabo, Fubag, STANLEY, CALIBR and ONNESWAY.

The most successful models from these manufacturers are included in the rating.

Criterias of choice

The principle of operation of a jackhammer is very similar to that of a hammer drill. The only difference is that the latter can also drill, but the chipper does not have such a function. it is aimed solely at striking. The process is carried out by a built-in electric motor, with the help of which the rotor is started. Next, a special firing pin, which is built inside the body, begins to move. Rapid reciprocating actions transfer force to the material, causing it to break.

As you can see, there is nothing complicated in the principle of operation of this equipment. Its operation also usually does not raise questions among both professionals and home craftsmen. The main thing is to initially choose the right tool, since there are several varieties, each of which has a specific purpose. The main differences between the models are the weight and power of the tool, impact force, as well as additional functionality that makes work more comfortable and safe.

Weight

Let's start with the first criterion. All jackhammers are divided into three categories:

- lungs,

- average,

- heavy.

Representatives of the first category weigh up to 5 kg. They are designed for relatively simple work. The main advantage is the ability to carry out the necessary operations in a horizontal plane. Moreover, the range of these operations is quite wide - representatives of the light category can well be called universal equipment. In addition, the low weight allows the craftsman to save physical strength, especially when it is necessary to carry out long-term work.

The medium category includes equipment weighing from 5 to 10 kg. Tools weighing from 10 to 30 kg are considered heavy. Both categories are more powerful than the first, so they are suitable for tasks of increased complexity. For example, it’s not for nothing that heavy breakers are called concrete breakers.

You can’t work with such a tool in a horizontal position, primarily because of the mass. As a rule, it is used to perform operations with soil or foundation. That is, the scope of his activity is related to vertical chiselling. This equipment is also used for road work and breaking through frozen soil.

Despite the fact that representatives of the medium and heavy categories have approximately the same scope of application, they still differ from each other in power, and therefore in capabilities. The more serious work you have to do, the heavier the tool you need for it.

Power

First of all, the force of the impact, as well as the frequency of reciprocating movements, depends on the power. In addition, this indicator affects both the possible duration of continuous operation of the equipment and the size of the equipment that can be installed on it.

In other words, the higher the power, the more impressive the tool's performance. Therefore, when choosing, you need to pay attention to this indicator and correlate it with what kind of work you are going to do using this tool. The power range of all options presented on the modern market is from 500 to 2000 W.

Let’s say right away - you shouldn’t grab the most productive tool, overpaying and complicating your work with the heavy weight of the equipment. First, objectively decide whether you really need this kind of power. For example, for household needs (although, in theory, chippers do not have a “household” category at all), a lightweight tool is usually quite sufficient.

Impact force

Maximum impact force is the same indicator that has no less impact on equipment performance than power. It is measured in joules. Naturally, the greater the force, the stronger the material can succumb to it. As mentioned above, the most impressive indicator is typical for models from the heavy tool category. Such equipment can have an impact force of 60 J or more. For light models, this level is, of course, unattainable. Their single impact force varies from 3 to 8 J.

However, it is not only strength that matters in this case. You should also pay attention to the frequency of reciprocating movements. The higher it is, the more complex work can be performed with the tool. If, for example, we take two models from different weight categories (and, accordingly, with different strength indicators), but the weaker one has a higher strike frequency than the second, then the question is which of them will cope with the task best.

Additional functionality

From the main indicators, let's move on to those elements that significantly facilitate the work and increase the safety of the operator during their production:

- beat frequency regulator. Allows you to switch equipment to different modes, depending on current needs. To make adjustments, the tool is equipped with either a special button or a regulator,

- start button lock. It is necessary so that there is no need to constantly hold it while working. However, many models are launched not by a button, but by a slider - in this case, the problem with the need to hold does not arise at all,

- Standby mode. A mechanism that can be used to disable the shock function at idle,

- limitation of starting currents. Relevant for models with high power. The presence of this system allows you to avoid power surges when starting equipment,

- control panel. This is a specific set of sensors that monitor the condition of the jackhammer. If there is a need for any repairs or maintenance - for example, it's time to replace the brushes - then this is signaled using indicators. Thus, the condition of the equipment is monitored, defects are corrected in a timely manner, which leads to a much longer service life of the tool and to high reliability of its operation,

- anti-vibration elements. A jackhammer produces a lot of noise and vibration. To make working with it more comfortable, a dynamic counterweight system is built into the tool. With this approach, vibration becomes at least half as much. Additionally, the equipment is equipped with special handles, inserts and overlays. As a result, its operation becomes much easier.

In addition to the presence of all these elements, attention should be paid to the material from which the case is made. It can be metal or plastic. As a rule, masters trust the latter less. But in vain, since the production of jackhammers uses high-strength plastic with increased wear resistance. In addition, it has another significant advantage - it is lighter than metal. This means that it will be easier to work with the equipment, especially if we are talking about a horizontal tool.

Overall, the ergonomics of the device are of great importance. It should be comfortable to work, otherwise you simply won’t be able to do it for a long time. To do this, the hammer is equipped with an additional handle, which can be installed in various positions - the more, the better. When choosing a bumper in a store, be sure to hold it, check how comfortable it is for you to do this, especially considering that in fact the work will be accompanied by strong vibration.

Fenders with a gasoline engine

Gasoline jackhammer

This type of fenders differs from previous ones in its mobility. The fact is that such models have a gasoline engine, which means that neither the lack of electricity nor the absence of a compressor can in any way affect the operation of the equipment. In most cases, the manufacturer tries to equip the device with a tank of such a volume that the device can be used for a long time without stopping. Gasoline models have the same design (except for the presence of a tank) and operational parameters as the devices described above.

Return to content

Types of nozzles

For each type of work with a jackhammer there is its own equipment. To ensure that the attachments match the parameters of your tool, it is better to buy a set directly from the manufacturer.

Set of attachments for jackhammers

The most common items that may come in handy are:

- chisel for creating openings and holes in walls with reinforcement, dismantling metal structures;

- crowbar for removing a layer of asphalt, loosening frozen soil, working with rocks, concrete, bricks;

- tamping plate for compacting various building materials and soils;

- spatula for removing old tiles, plaster layers, concrete screeds. The width of the spade chisel is most often from 40 to 80 mm, but can be 100 mm wide for excavating hard soil or asphalt.

When choosing a jackhammer in our online store of building materials "Kuzmich24" - section "Tools and Equipment" - you should look not only at the catalog page "Jackhammers", but also immediately select the equipment in the subsection "Consumables", where bits are presented for jackhammers and adapters for them.

Good luck with your choice and long operation without repairs!

Your Kuzmich.

2 Bosch GSH 5 CE Professional

Despite the dimensions being comparable to a conventional hammer drill, the Bosch electric hammer can perform a huge range of jobs. With an impact energy of only 8.3 J, this breaker easily crushes reinforced concrete castings. Its compactness makes it convenient to use for interior repair work. Low noise level (86 dB), vibration damping system using a spring-loaded handle, adjustable number of impacts, allow us to consider the bump stop the best in its class.

Reviews from builders who use the Bosch GSH 5 CE hammer in their work are generally positive. The convenience of chiselling walls and removing plaster is noted - the power is quite enough for such work. Craftsmen talk about the successful use of a professional hammer to remove old screed in an apartment. The ergonomic handle makes it easy to use - the weight of the tool is felt significantly lower than the nominal weight (6.2 kg).