Today, cellular concrete is used in various fields; up to 20% of new buildings are built from it. It is a suitable material for residential structures intended for temporary or permanent residence.

Cellular concrete has an affordable price and good performance characteristics.

Foundation for a house made of foam blocks

Foam concrete weighs little, so it is easy to work with. The foundation for the building requires a small load-bearing capacity.

Such a foundation is inexpensive. However, on moving soil, the weight of the base is not enough to suppress heaving processes. High demands are placed on the construction of aerated concrete foundations.

Incorrect calculations will lead to the fact that the foundation will have to be repaired or rebuilt again. Savings on a project usually result in additional expenses.

Advantages and disadvantages

The advantages of volumetric block housing construction were obvious 50 years ago. But only real technologies made it possible to realize them in full force:

- the entire production cycle in the factory reduces to zero the influence of negative external factors of the construction site on quality;

- reducing the volume and complexity of installation work;

- reducing the construction time of the building, and as a result, reducing the cost;

- reducing the level of environmental pollution in the construction area;

- the entire process is standardized and is under the full control of highly specialized specialists.

Disadvantages still prevent the widespread use of WBD in the construction of social housing:

- increasing the carrying capacity of transport and equipment;

- major investments of material resources must be made long before the start of construction;

- certain difficulties with transporting finished blocks, especially in megacities;

- increased requirements for construction sites, in particular access roads, since the weight of one block can reach 45 tons;

- impossibility of redevelopment - all sides are a supporting structure;

- sound insulation leaves much to be desired.

Despite the disadvantages, the construction of block-modular buildings is economically profitable. The modules leave the plant almost completely ready for operation - all utilities, interior decoration, and facade are provided.

Choosing a foundation type

What kind of foundations are built for aerated concrete houses? It is necessary to analyze the condition of the soil; for an area where there is no heaving, a monolithic belt type is built.

It is important that the base goes down to a depth below the freezing mark of the soil. With the help of tape reinforcement, heaving loads are compensated.

In some regions, the soil freezes to a depth of less than 2 m. It is not economically feasible to erect a strip foundation. Instead, a pile-grillage foundation is made. The grillage allows you to compensate for movements - the rise of one pile is higher than the others. If you do not install a grillage, cracks will inevitably appear in the walls.

The most expensive and durable foundation is considered to be a monolithic slab. This is a suitable option for peat bogs and loose sand. The slab is preferred when it is impossible to install piles. Prefabricated foundations are not recommended.

A professional designer can determine exactly what materials are suitable for constructing a foundation for aerated concrete construction on a specific site. To do this, he will need the results of geological research.

The difference between modern technology and the original

Today, the “new” OBD technology is being revived - production facilities are being opened, existing ones are being modernized. And only the basics remain the same: houses are built from volumetric blocks, which are completely manufactured in the factory. The requirements of potential residents for comfort have changed, which are reflected in regulatory documentation. If in the early 70s it was considered happiness to have your own kitchen with an area of 4 m², today the concept of comfortable living space is completely different.

Soviet blocks had no more than 3 standard sizes. These productions provide a wider range, which can be optimized for each large-scale residential complex. Architectural and planning solutions reach 1000 items.

Production has become a conveyor belt - each worker performs his own operation. Due to narrow specialization, labor intensity and volume of work have been reduced.

Is a plinth needed?

The building material is characterized by high hygroscopicity. High humidity negatively affects the heat-insulating properties; when left in water for a long time, the material is destroyed.

An aerated concrete house requires a base and good waterproofing. During construction, the groundwater level and geological research data are taken into account.

Block house: a type of modular construction, tested by the portal’s craftsmen

Modular construction in various variations is becoming increasingly popular, primarily due to the ability to reduce construction time. But if country houses made of metal block containers or wooden modules are already a familiar phenomenon, then block rooms are much less common, despite the fact that in the past in the Land of the Soviets even multi-storey buildings were erected from them. However, the FORUMHOUSE portal has an example of building a modular house from block rooms, which may be of interest to anyone who is at the stage of choosing the type of construction.

Laying aerated concrete material

The preparatory stage is represented by the following steps:

- Checking the horizontalness of the base. Deviations up to 30 mm are allowed.

- Cut-off waterproofing device. A layer of bitumen mastic is applied, and waterproofing is applied on top, using roll material. You should not choose cheap roofing material, which quickly becomes unusable.

- A level base is a prerequisite for simple masonry.

How to lay aerated concrete blocks?

The laying of aerated concrete blocks is carried out in the same way as brick. It is necessary to do horizontal tying of rows. The wall looks more aesthetically pleasing when the vertical seam falls in the middle of the aerated block; it is necessary that the indentation be at least 10 cm.

A special adhesive is applied to the blocks using a carriage equipped with teeth along the edge. To ensure a good fit of individual blocks and minimize heat loss, an adhesive thickness of no more than 1 - 2 mm is needed.

Project overview

The dimensions and weight of block rooms can vary greatly. For example, a product with dimensions of 592x320x270 cm weighs 14,000 kg. For its manufacture, 4.78 cubic meters are used. m of concrete. The size of block rooms can also be:

Accordingly, the weight may vary significantly depending on the width and height of the structure. In typical cases, the weight will be from 5 to 10 tons, when using enlarged structures from 15 to 25 tons.

By individual order it is easy to get a block room of a non-standard size, with a special layout. This allows you to take into account all your needs and nuances, but it will cost significantly more.

There are various options for prefabricated houses. The interior furnishings of the premises themselves are selected at your own discretion.

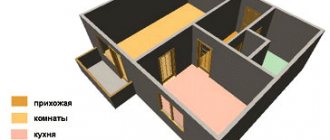

One approach involves using:

- pairs of residential reinforced concrete rooms;

- arrangement of a mixed kitchen and hall;

- preparation of the bathroom.

A house measuring 12.76 x 6.44 m can be built differently. In this option, it is possible to use 4 residential block rooms.

One of these rooms is located separately, across a 2 m wide corridor. The other three are placed in a chain. Additionally, there is a kitchen hall, a bathroom and a wardrobe.

A simple diagram of the block room itself includes:

- floor panel;

- reinforced concrete cap;

- window execution;

- indication of external dimensions.

Why is aerated concrete reinforced?

On heaving soils, reinforcement is required to increase the resistance of the building. The reinforcement is placed in grooves in the middle of the blocks. The overlap of the rods is 10 - 20 cm. The rods are bent in the openings.

Above the window and door assemblies, 4-bar elements are used. They are placed in special U-shaped gas blocks.

The finished elements are filled with M-200 concrete mortar.

Block rooms - reinforced concrete base

Block rooms are a prefabricated reinforced concrete product formed into a room with a ceiling, floor and walls, usually with one window and a doorway, but there may be variations, depending on the application. If we are talking about garage blocks, then they make a characteristic opening for the gate, in the cabins there are smaller windows, and the distribution of the load is different. For garage blocks, the load-bearing parts are the corners, and for indoor blocks, the walls are load-bearing; they come with stiffening ribs. If necessary, when the standard options are not suitable for some reason, the manufacturer can produce a unit to order. They produce both insulated (fully or partially) modules and purely concrete ones, the house of which, after construction, will require insulation according to the region of residence.

A house built from block rooms is comparable in characteristics to a monolithic reinforced concrete house built using removable formwork technology. But the block is filled at one time. Concrete of a grade not lower than M300 is used, and the protective layer, which prevents the negative influence of the external environment on the reinforcement frame, is clearly maintained. With independent layer-by-layer pouring, it is difficult to achieve factory uniformity and clear geometry of walls and ceilings. It is important that building with blocks can be done all year round, the main thing is to have time to prepare the foundation in season, while pouring requires positive temperatures or the use of special additives and heating devices.

The disadvantages of blocks include a lot - all manipulations require the use of special equipment, and problematic delivery. You can count the number of manufacturers in the country on one hand, and bringing blocks, again, on a special tractor to a remote region is an expensive pleasure. However, the cost of the modules, even taking into account delivery, makes this construction method attractive for those who want to get a rough structure as quickly as possible at an affordable cost. For these reasons, a member of our portal vilk1985 (Andrey) from Khabarovsk chose block rooms as the basis of his home.

What to pay attention to when reinforcing window openings?

When the window opening exceeds 1.8 m, the penultimate row of masonry is reinforced. Make 2 grooves 50 cm longer than the openings. Subsequently, the grooves are filled with adhesive or cement mortar.

Is it possible to spend the winter without heating? Sometimes it is not possible to complete construction work completely within a season. The box is left for the winter without connecting the heating system. The following measures will help prevent the appearance of cracks on the walls in the spring:

- If groundwater is close, drainage is needed.

- It is necessary to carry out waterproofing and insulate the foundation and plinth.

- Insulate the blind area around the structure.

- Insulate floors in the basement.

Thanks to the above measures, freezing of the soil under the foundation can be avoided. It is recommended to additionally maintain the temperature in the basement above zero.

Examples of developments in Voronezh

The most famous new buildings built using OBD technology were large residential areas in Voronezh:

- Residential quarter "GREEN PARK" - 9 buildings, 17 floors high. 7 positions have already been put into operation.

- Residential quarter "OZERKI" - 14 houses, 17 floors high. 7 houses have been put into operation and are occupied.

- Residential complex "Tsvetnoy Boulevard" 11 buildings with a height of 17 floors, phases I and II of construction. The first 8 houses are occupied.

All complexes were built by the Vybor insurance company, which actually revived the technology in Voronezh. The company opened its own OBD plant to provide its construction sites with high-quality and inexpensive volumetric blocks. In factory conditions, year-round, up to 80% of all work necessary for the construction of buildings is carried out - the main condition for minimizing construction time is carried out “under one roof”. Every day, 60 block rooms are produced, complete with windows, ventilated facades, balconies and utilities.

Photos of aerated concrete houses

leave a comment

Click to cancel reply.

You must log in to post a comment.