For people living in an apartment (as opposed to owners of a private house), drilling brick and concrete is a frequent procedure, but not everyone knows and understands how drilling concrete differs from drilling brick. So we’ll try to figure out what can be used to drill into brick and what can be used into concrete; after all, there are differences and they are decent.

So, very often inexperienced craftsmen (and most often single women) confuse an impact drill and a hammer drill. For them, these 2 instruments are one and the same. So they try to drill through the concrete floor with a conventional 500-watt drill, although this operation is obviously doomed to failure. Concrete is very dense, brick is much softer than concrete. A lot can be said about the difference between a hammer drill and an impact drill, so it’s better to read my articles: How to choose a hammer drill for your home. Choosing a drill for the home.

After reading them, you will immediately understand the difference between a drill and a hammer drill; moreover, there are useful buying tips and what to look for. Definitely useful articles for beginners.

In this article, we'll take a quick look at the difference. The whole difference between an impact drill and a hammer drill is that the impact force of a hammer drill is tens of times greater and does not depend on the force of pressing the tool during drilling. The impact of a perfach is electric, while that of an impact drill is mechanical and depends on how hard you press the drill. However, even if you press with all your might, the impact force will still be low. Based on this, it turns out that brick can be drilled with an impact drill, but concrete is better with a hammer drill.

Tools for working with brickwork

Both options are suitable, and a hammer drill and impact drill will do the job. For a hammer drill you will need to buy a drill, for a drill - a pobedit drill bit. I also note that brick can be easily drilled without impact with an ordinary drill. Although most drills now come with impact. Many people do not know which drills are suitable for which dowel diameters. I’ll tell you what dowel, what kind of drill. That is, if the dowel is 6 mm, then take a drill with a diameter of 6 mm. The exception is when the wall is made of “shingles” - wooden planks criss-crossed; such walls are still found in old communal apartments. For such walls, you need to take a drill slightly smaller than a dowel.

Equipment for working on concrete

Of course, if you need to drill just a couple of holes in concrete (for dowels to hang a curtain in a room), then an impact drill can help, but you should immediately warn that you will be drilling for a long time and will spend more than one drill bit)) And of course your own You will also spend a lot of energy. To do this, you will need a regular Victory drill, the cost is low, from 15 to 40 rubles, depending on the diameter and length. When drilling with an impact drill, do not press too hard, but do not hold the drill in the hole for too long, let it cool, otherwise it may even melt (there was one such case). The temperature when drilling concrete is very high.

A hammer drill is the best tool for drilling concrete; you insert the drill and drill without experiencing any problems. One not very expensive drill (diameter 6 mm, price 40 rubles) is enough for about 40-50 holes. Take, for example, inexpensive and quite good drills from the Enkor company.

Drilling large diameter holes.

Sometimes you need to drill large holes in the wall. How to do this? For a hammer drill, you can buy a concrete bit, which can be used to drill without impact. The size range is wide, crowns come in different sizes, ranging from 30 mm to very large 120 mm. The most common size is 68 mm, for drilling holes for a socket. Don’t forget to switch the hammer drill to drilling mode without impact, otherwise your bit will squeak very quickly.

For drills, you can find special tungsten carbide bits on sale. I will only note that such drills can be used to drill not only brick and concrete, but also tiles, paving stones, and porcelain tiles. This is such a universal thing and the most important thing is that the holes made with such a crown turn out very neat and even.

In the video below, they are working with a “practice” crown on a brick. You can also work on concrete.

That's probably all, good luck with your drilling and repairs in general.

Drilling a brick wall

To drill through a brick wall. You need to have certain skills and the right tools. However, there is nothing complicated about it, and you can drill a brick wall yourself, without the help of craftsmen. A brick wall can be drilled in different ways, but when working, you should always keep in mind that brick is a very durable material, and in order for its drilling to be successful, it is necessary to use a cutting drill bit stronger than the brick itself.

Brick wall arrangement diagram/

There are many tricks in drilling holes in a brick wall; knowing them will help you do all the work in the shortest possible time.

In order to drill a brick wall, you will need:

- drill (powerful, impact action), you can use a hammer drill;

- dowel;

- pobedit glass;

- screwdriver;

- metal detector;

- a container filled with cold water;

- mark;

- face shield or safety glasses.

Useful advice from professionals

If you have a solid wall, it is better to choose a pobedit drill. Only it can cope with particularly durable material and not wear off completely. Such equipment lasts longer, and can be used even after that.

In everyday life, 15-centimeter drills are usually used, but on sale you can also find auger drills, which have impressive dimensions and are suitable for hammer drills.

How to make a hole without defects

In order to avoid unpleasant consequences, you need to make sure that there is not only electrical wiring in the wall, but also water and sewer pipes, which are often hidden in the masonry. The presence of electrical wiring can be indicated by a socket on the wall; wires from it run to the switch.

How to drill without dust

If the room is already finished, such a need may arise. If the electric tool you are using does not have a connection pipe for connecting a vacuum cleaner, you can use the help of a second person who will remove dust as soon as it begins to spill out of the new hole, leaning the suction tube against the recess. If you work independently, you can place something like a shelf at the point of impact on the wall, where all the dust will fall.

Creating a Niche

If you plan to drill a recess larger than 20 mm or need to create a niche for a socket, you should purchase a Pobedit drill bit. Multiple holes are made along the intended line, the jumpers between which are then removed using a chisel and hammer. An alternative and more technologically advanced solution would be to use a hammer drill and a crown together with it.

How to drill through thick glass

To do this, you can use a traditional metal or ceramic drill. It is important to position the glass surface so that it rests completely on the base. A drill or screwdriver is used together with the drill. The surface is degreased, and the drilling site is marked with plasticine.

Source

Preparing tools

Drill device diagram.

Before you begin, you should make sure that all the necessary tools are in working order. The drill must have a power of at least 600 W and an impact function. Revolutions up to 2500 beats per minute, so that there is the possibility of smooth adjustment from zero to maximum. You should give preference to a drill with reverse rotation, with a self-clamping chuck (then you won’t have to waste time clamping drills and looking for a constantly lost key).

It should be taken into account that a material such as brick can withstand statistical loads very well, but sudden impacts will only interfere with the process. If you use a drill without a hammer function, the drill simply presses, it is not easy for the cutting edge to catch on to the material, and therefore the drilling progresses slowly, while the drill quickly heats up.

You can drill the wall with a professional hammer drill. If you can’t buy it, you can rent it; drilling holes with such a tool is not difficult. However, when working with a rotary hammer, you should carefully study all the manufacturer’s recommendations.

It is necessary to purchase several drills, the diameter of which should be 6 and 8 mm. Drilling holes in a brick wall can be effectively carried out only with drills that have Pobedite surfacing (it is an alloy of tungsten and cobalt). The advantage of such a cutting tool is that it does not need to be pre-sharpened; it was specially designed for drilling dense surfaces. It will be easy to drill a brick wall with such a tool. If we are talking about drilling a wall made of dense brick, then you should purchase a dowel at a hardware store according to the size of the drill used. If you need to drill a wall to a greater depth or through it, you should use a drill; its cutting edges are not sharp, but rounded, to increase wear resistance.

Video description

A hole in the wall without a hammer drill in 3 minutes.

For holes for ventilation, large-diameter sewer pipes, for installation of openings of complex shapes, etc. Diamond drilling is used in horizontal, vertical and inclined planes. In one pass, a diamond-coated hole saw can make a hole with a diameter of 400 mm and at the same time the edges of the circle will remain clear and neat. Such work is carried out by special drilling machines, which consist of a motor mounted on a special frame and a diamond bit.

During the drilling process, water is supplied to the place where the cutter comes into contact with the object, which cools the bit segments and washes away the waste from pieces of mineral (brick, stone, concrete). For such units, you can additionally use a water vacuum cleaner, which sucks out water from the dump. If it is not possible to supply water (the approaches do not allow it), then drilling is carried out using the dry method, with breaks to cool the cutter.

Preparatory work

Drilling diagram for a brick wall.

Before you begin, you should carefully consider the location of the holes in the wall. The surface where holes are supposed to be drilled must be carefully examined to ensure that there is no possibility of damage to internal electrical wiring, water pipes, etc. To avoid bumping into an obstacle when drilling, you should use a metal detector. After this, we drill the holes safely, nothing will interfere. However, you should remember that even after checking the wall with a metal detector, you need to drill into the wall carefully.

Before you start drilling holes, you need to mark all sockets, switches and lamps. As a rule, electrical wires run from these devices along a vertical line to the distribution box (it must be borne in mind that sometimes they can be run diagonally). For safety reasons, in order to find communications recessed in the plaster in time, we drill the first 10-20 mm by hand (a screwdriver is perfect for these purposes). When doing this, drill very carefully, because... Damage to electrical communications can lead to the most negative consequences.

Selecting suitable self-tapping screws for drilling

Self-tapping screws are fasteners in the form of a rod that have a screw thread, a pointed end and a head. The thread holds the screw shaft in the wall, thereby ensuring fixation and immobility. According to the classification, self-tapping screws for drilling are divided into the following types.

- Universal, suitable for any fastenings - the most common.

- Self-tapping screws that strengthen metal sheets without dowels. Before screwing in the self-tapping screw, drilling is mandatory.

- Self-tapping screws without dowels for fastening soft metal and wood, plastic.

- Self-tapping screws in the form of a herringbone, capable of strengthening a concrete or brick wall, going along with dowels, by driving inward.

- Dowels - self-tapping screws without dowels, are needed to strengthen a brick wall or a concrete wall.

Drilling holes in a brick wall

The future hole in the wall is marked with a core (this is a special tool for marking holes for drilling). This is done in order to fix the drill at the initial stage of work. At the same time, do not forget safety glasses (you can use a welding shield), which will protect your eyes from dust and hard brick fragments. Drill into a brick wall in such a way that the working tool is held straight, otherwise the drill may break. When drilling into a wall, apply gentle pressure to the drill to ensure even drilling. Drilling holes involves significant loads (even if the most powerful machine is used), and therefore the drill must be regularly cooled. The drill is lowered into a container of cold water, but care must be taken to ensure that the water does not get directly into the electrical mechanism.

If during the work you come across a burnt brick, then you need to take into account that drilling it is more difficult. It can be easily recognized by the color of the dust, which is usually black. You can drill such areas at low speeds when the impact mode is turned on. In this case, you need to press harder on the drill handle and carefully ensure that the drill does not overheat. When drilling holes in a wall, you should take the necessary precautions. Thus, the drill can become heated to a high temperature, so you should not touch it, as you may get a severe burn. You also need to know that a very hot drill will quickly dull its cutting edges, and without sharpening it will be very difficult to drill holes. Drilling holes can be done with diamond drilling, which allows you to get a quick result, while significantly saving time; drilling holes in this way is quite easy. If you need to drill holes with a diameter greater than 30 mm, it is permissible to use a core drilling machine; you can drill holes with it quickly, but you need to have certain skills.

Large diameter drill bits for wood

Non-separable type drill bits

The most common type of large-diameter wood drill. Feathers are a sharpened blade with a pointed tip, which is designed to center the drill in the hole (i.e., so that the drill does not go to the side). Using them you can drill holes from 10 to 76 mm. The maximum drilling depth for them is about 150 mm, however, there are special drill attachments that can extend the pen drill up to 300 mm.

The main advantage of pen drills is the ability to drill deep through holes for connecting structures with studs and bolted connections. They are also the cheapest of the large size wood cutting attachments. So, a good feather drill can be bought for 100 – 150 rubles, for example, Sibrteh 703097 with a blade width of 50 mm.

Adjustable feather drills

A separate type of large bits for wood are feather drills with adjustable diameter. They allow you to set different nozzle diameters depending on the required hole. Drilling with such feathers is performed at low speeds with high torque, so they will require a powerful drill.

Depending on the manufacturer, the cost of a drill varies from 500 to 2000 rubles. For that kind of money, in principle, you can buy a small set of ordinary feather drills. But considering that here the step can be set within 1 mm (and not all sets have all standard sizes of drills), then sometimes it is advisable to buy an adjustable pen. For example, for 650 rubles you can buy a good hardened steel drill BK8 STAYER 2951 with the ability to change the diameter from 22 to 76 mm.

Crowns

Core bits or core drills are used for drilling large holes with a diameter of 22 to 127 mm. Using them you can easily drill a hole for wiring or any accessories. Wood crowns consist of a drill and, in fact, a hollow crown attachment. To work with attachments of different diameters, one drill holder is enough. Almost all drills have hexagonal (not round) shanks for better grip on the chuck.

Given the nature of the work, hollow crowns must be made of durable material. The highest quality crowns are made bimetallic - from an alloy of steel and cobalt. The larger the diameter of the nozzle, the more cutting teeth there are on the edge. Please note that on some crowns the teeth are shaped like a right triangle and point straight up, while on others they are inclined in the direction of rotation (clockwise) by 30 - 40°.

The most popular diameter is 68 mm, since this type of crown is used to make socket boxes in wooden walls and sandwich panels. On average, the price of a normal crown starts from 500 rubles. In addition to 68 mm, crowns of 20, 25, 35, 40 and 51 mm are considered common - other sizes are used very rarely in everyday life. If you buy for home, we recommend buying it in a set to save money. Bosch 2608580868 running bits , which, in addition to wood, can also drill sheet metal up to 0.8 mm thick.

Source

How to drill a hole in a brick wall?

- strong impact drill or hammer drill;

- Victory drill;

- dowel;

- metal detector;

- screwdriver;

- mark;

- container with cold water;

- safety glasses or face shield.

Prepare the tools needed to drill into a brick wall. You will need an electric drill with a power of at least 600 W, with an impact function. Brick amazingly withstands static loads, but does not like sharp impacts. A highly professional hammer drill would be a cool option if you have the chance to purchase or rent one. When working with the tool, follow the manufacturer's recommendations.

Buy a pair of drills with a diameter of 6 and 8 mm, certainly with surfacing made of Pobedit (an alloy of cobalt and tungsten). Such a cutting tool does not require advance sharpening; it is deliberately designed for very dense surfaces. Finally, if necessary, select a solid brick dowel from a hardware store based on the size of the drill you are using.

Consider the location of the future hole in the brick wall. Thoroughly examine the surface you are going to perforate - it is important to exclude damage to internal electrical wiring, water pipes and other pitfalls. The easiest way to avoid hitting an obstacle while drilling is to check the surface with a metal detector.

If you don't have a special fixture, sweep up all sockets, switches and light fixtures. Usually, wires run from them to the junction box along a vertical line, although some electricians also run them diagonally. In order to protect yourself and timely find communications recessed in the plaster, make the first 10-20 mm of the hole length manually (say, with the help of a screwdriver). Proceed with great caution.

Mark the upcoming hole with a core (a special device for marking holes for drilling) in order to fix the drill in the first stages of work. Don't forget to wear safety glasses or a welding shield to protect your eyes from dust and hard brick fragments.

Drill into a brick wall while holding the working tool straight - otherwise the drill may break. To ensure even drilling of the brick, apply gentle pressure on the drill.

Even the strongest unit will experience heavy loads when working with such a wall, therefore the drill needs to be cooled. To do this, lower it into cold water, but carefully protect the electrical mechanism itself from moisture.

the system chose this answer as the best

To answer your question, it would not hurt to understand:

- hole size - small from 3 mm to 25 mm or more, for example, a hole for a sill box;

- the surface of a brick wall - it can be a facing brick or a brick wall covered with a layer of plaster;

- availability of tools - is there a hammer drill or impact drill, what drills or crowns are available;

- the nature of the work being performed - is it possible to choose a location for the hole or is it needed in a strictly defined place, for example, when installing any structure for fixing to the wall, etc.

Depending on the above conditions, the correct choice will be made for the correct operation of drilling holes in a brick wall.

Let's consider several ways:

- drilling holes in facing bricks. It is better to carry out the work using diamond drills and a drill in the center of the brick - this way you will not chip the edges of the brick.

- drilling holes in a brick wall lined with plaster. The main difficulty in this case is not to get into the seam between the bricks. To do this, you can make a hole with a 1-2 mm drill and determine what is under the plaster. If the drill gets stuck or, worse, breaks, then you can safely drill with a hammer drill and a concrete drill of the required diameter in this place - you will not get into the seam.

- drilling large diameter holes.

To do this, you cannot do without a powerful hammer drill and a bit with pobedite surfacing. Apart from the larger volume of dust and debris, the technology is no different from drilling with a drill. The only difference is that if the brick inside the crown did not crumble during drilling, it will need to be knocked out with a hammer drill in the Chisel mode. - drilling when installing structures, for example, fastening profiles for drywall. In this case, use a hammer drill with a concrete drill with a diameter the size of the dowel-nail used. If you hit a seam, make a new hole with a slight offset (for a strong connection.

- about the project

The diameter of the hole is extremely important; it is possible to use crowns, or perhaps (smaller diameter) to get by only with drills.

If drills are used, it is better with a pobedit tip (solder).

I usually drill with a hammer drill, but only the first hole is hammered.

We drill from a drill of a smaller diameter to the required one.

For example, an 8 mm hole, markings, punched (so that the drill does not glitch) and drill the 6th with a blow.

The speed is average, if the depth of the hole is significant, periodically remove the drill from the brick and cool it.

Now we drill a hole of the required diameter without impact, that is, we work with two drills.

If you drill this way, the hole will be smooth and not “broken” by a hammer drill.

Try to drill into the brick and not into the seams.

Bricks, of course, are different, for example, silicate (white) can and even should be drilled without hitting, but red brick is difficult to drill through without hitting.

If you need to drill many holes of the same depth, then install a depth gauge (drilling depth limiter) on the hammer drill and drill as described above.

For what and what size? Thick hardened nails are simply driven into a brick wall. Especially from a mounting gun. Can be reused. Driving them in with a hammer. The holes are drilled using a winning drill without a hammer. A couple of small holes with a diameter of 6-8 mm can be drilled with a regular metal drill. They just get stupid quickly. Large holes, one and a half to two centimeters in diameter, need to be drilled using a powerful professional drill.

You need a hammer drill or at least a drill with a hammer drill mode, you need a Victory drill of the appropriate diameter and length.

When drilling a hole in a brick wall, you need to take into account where the body of the brick itself is located; if it is clearly visible, just aim at the middle of the brick and drill, do not drill close to the edges - it may break off.

If the masonry is not visible under the plaster, in order to avoid damage to the wall due to not hitting the brick, and this very often happens with inexperienced repairmen (sometimes five holes are drilled to hang a hook), you need to check.

You can do this with an awl or a gypsy needle, just stick it into the plaster, if you get into a seam and a brick, the difference in hardness will be noticeable, it’s still better to have five small holes than five torn holes.

Find out the cost of construction Photos Reviews

- home

- Construction Bath

- Cottage

- Pool

- Veranda

- Foundation

- Fence

- Gates

- Roof

- Roof

- Insulation

- Gazebos

- Priming

- Garage

- Brick construction

- Construction of a frame house

- Construction of a bathhouse

- Wooden houses

- SRO

- Warm floor

- Plasterboard ceilings

Partitions

Forming a hole for a pipe using construction components

In addition to the tool, you need to be able to choose the right nozzle. Usually for one tool there are several sets of drills and attachments for different types of work. Even for one action, manufacturers offer several options for how it can be carried out.

Drill

A drill for a power tool when working with a solid wall should have a Pobedit tip. The material is characterized by high strength and abrasion resistance.

Compared to similar drills made from other raw materials, Pobedit drills last longer. They are used many times.

Brick drills

The standard length of the element is 15 cm, intended purpose is household use. There are larger models for rotary hammers, the largest ones are called auger drills.

It is possible to make the desired hole with such a nozzle if you draw a circle. Then drill holes along the contour in 1 cm increments. The core is removed with a chisel and hammer.

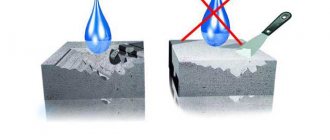

This is the way out, if you don’t have a special drill for a hammer drill, have a spatula - it can be used to easily remove the central part.