Despite the variety of designs, in private construction they prefer to install buildings on strip foundations. The popularity is explained by the combination of simple installation with reliability and durability. Laying does not require the use of special equipment and complex equipment, so even beginners in the construction business can make a strip foundation with their own hands.

Strip foundation for a house

What is a strip foundation

Strip foundations are erected for the construction of buildings.

A strip base means a reinforced concrete closed contour of building elements that are erected under the load-bearing walls of a building.

It transfers the load from the building to the nearby soil. The structure is considered a reliable foundation, because Suitable for most types of soil.

Among its features are the following:

- The foundation resists swelling processes, which reduces the likelihood of subsidence or distortions.

- It is used in the construction of buildings with basement floors or extensive basements.

- It promotes uniform distribution of the mass of the building.

- The stone strip or strip, which represents the foundation, is made not only from reinforced concrete, but also from rubble stone, as well as brick.

- The structure is not used for construction on swampy soil.

Waterproofing

Waterproofing is an important and responsible procedure, which has two types:

- Horizontal. Installing an insulator under the tape and on its upper surface to eliminate the possibility of capillary absorption of moisture from the lower layers of the soil and from above, from moisture flowing from the walls or rain.

- Vertical. It is applied to the side walls of the tape from the outside and inside.

There are several types of vertical waterproofing:

- Impregnation.

- Roll insulation.

- Liquid formulations.

Traditionally, hot bitumen was used, but today it is important to use ready-made mastic. Impregnations stop concrete from absorbing moisture, but they have been used relatively recently and have not yet gained popularity.

NOTE!

The waterproofing tape is completely covered with a layer of insulator, which cuts off the possibility of contact with moisture at any point on the surface.

Pros and cons of strip foundations

The main advantage of this base is its long service life. Such a foundation can last up to 150 years; brick strips – 30–50 years, concrete – 50–70 years (with good insulation and waterproofing).

Long service life is an advantage of strip foundations.

Other advantages:

- Low cost (compared to a monolithic base).

- Availability of materials.

- The presence of several types of structures that allow laying a foundation in different conditions (the width of the tape, the diameter of the reinforcement, the cross-section, and the depth of the foundation change).

- Simplicity of preparatory measures, which makes the construction technology accessible for self-construction.

In addition, thanks to the design features, it is easier to provide high-quality thermal insulation of floors in the house.

Disadvantages of the foundation:

- not suitable for fences and light buildings (barn, bathhouse, gazebo) due to high cost (the best foundation for a fence is a columnar one);

- requires a large amount of excavation work;

- undesirable for structures on waterlogged or weak-bearing soils;

- When erected independently, it does not allow you to correctly perform the concrete pouring technology.

A strip foundation requires a large amount of excavation work.

Types of strip foundation

The main criterion by which foundations differ is their depth. It depends on the massiveness of the building and the type of soil. The design features of the tape are also important.

Solid cast

Another name is a poured, or monolithic, foundation. It is installed at the construction site. The concrete strip itself must be reinforced, and before its construction, wooden formwork is erected to prevent the solution from spreading.

The characteristics of a solid foundation are:

- Ease of construction.

- Reliability of the design.

- High resistance to bending loads.

The solid cast foundation has a reliable design.

Concrete pouring should be done in 1 step, because... It is important that the entire structure hardens evenly. Its disadvantage is the large mass of such a base.

Made

The foundation is constructed using ready-made reinforced concrete blocks. They are laid out on the site, fastened together with cement mortar. Reinforcement of structures is used, but this is not necessary. Prefabricated foundations are used mainly in the construction of small houses (up to 5 floors). In terms of its load-bearing qualities, it is in no way inferior to a solid cast base.

Its features:

- Simple preparatory work.

- High resistance of structures to cold, which makes it possible to construct the foundation in winter.

- The speed of its installation.

However, the foundation is not suitable for soils with organic impurities (peat, silt).

The prefabricated foundation is made of reinforced concrete blocks.

This type also includes a pile-strip foundation. To deliver blocks to the construction site, it is necessary to use lifting and loading equipment, which increases the cost of the foundation. At the same time, the materials themselves are cheap.

In addition, when connecting structures to each other, the problem of adjusting the size of different elements often arises, which slows down the process of laying the foundation.

Shallow

It is used in the construction of frame houses made of timber or logs and other light buildings. The construction of the foundation takes place at minimal depths, so the foundation is suitable only for stable soils (rock, gravelly sand, coarse foundations).

During the construction process, attention is paid to:

- support factor (within 500 mm from the surface);

- arrangement of waterproofing;

- reinforcement;

- laying insulation.

Shallow foundations are used in the construction of frame houses.

High-quality installation of protective layers of the base can reduce the impact of soil heaving. A non-buried structure requires good drainage to remove water that accumulates in the sand.

A significant advantage of a shallow foundation is that it does not require heavy excavation work. However, with such a foundation there are no basements (as compensation, auxiliary buildings, extensions, etc. are often erected on the site).

Deep

It is one of the most reliable grounds, because... has the best load-bearing capacity. A monolithic concrete block is reinforced with composite or steel reinforcement and then immersed in the ground.

The depth of the foundation is determined depending on:

- groundwater level;

- bearing capacity of the soil and alternation of its layers;

- surface freezing level;

- planned height of basements.

A deep foundation is a reliable foundation.

Recessed foundations are used in the construction of multi-story buildings or for the construction of buildings made of heavy materials. Carrying out the work requires considerable material and physical costs, but it can be used on loose and other difficult soils. This type of foundation is practically not used for private construction.

Parameter dependency

When drawing up a project, not only the type of soil composition and territorial location are indicated, but also the area of the future facility. The load effects on the ground will depend on the size.

As follows from the general rules for drawing up a foundation plan, all preparatory work should be indicated. For this purpose, the structure is marked, which shows the boundaries of the foundation ditch and the depth of the places where the columns are planned to be placed.

When planning a residential building, the formation of the formwork structure is taken into account. It is recommended to use edged boards, with the help of which the foundation will be level and will not require additional costs.

The formwork structure is placed about forty centimeters above the trench level, the gaps at the boards do not exceed 3 mm. Having installed the shields, a waterproofing layer is laid, which protects against premature evaporation of water and improves the strength of the supporting elements.

The foundation support frame is an integral part of a solid foundation. For this reason, it is recommended to use steel reinforcing bars with a diameter of 1 – 1.2 cm.

The design of the facility must include calculations of the need for concrete mortar that will be required to fill the base. Errors can cause a lack of mixture, which affects the strength and reliability of the base.

To prepare the solution, use cement material M250 and higher, coarse or medium sand, crushed stone and water.

Features for different buildings

The arrangement of the foundation for the house and its structure depends on the type of soil and the load of the building. When constructing small-sized buildings, a shallow foundation is used (depth - 70 cm). If they are made of stone or brick, then a deep foundation is recommended.

There are other features you need to be aware of:

- In the northern regions, where winter temperatures drop below -20...-30 °C, the main attention is paid to the thermal insulation of blocks (especially if the soil is slightly heaving).

- The preferred form of foundation laying for small buildings is a trapezoid or rectangle with a labyrinth inside. In the latter case, the masonry expands downward.

- The heavier the building, the more extensive the preparatory work on the site should be.

- If they are building a country house with a basement, then they use fundamental reinforced concrete blocks. An important task is to ensure waterproofing, insulation and ventilation. Even in an area with dry soil and low rainfall, it is necessary to protect the foundation from groundwater.

- For buildings that are subject to movement (garages, gates, swings, slides, attractions), a strip base is well suited.

The arrangement of the foundation depends on the type of soil.

At the end

Many ordinary people, planning to build a house, are afraid to take on the pouring themselves, since they do not know the technology.

Deep foundation design option

But if you strictly follow these instructions described above, you can build the foundation for your building with your own hands. In this case, you can save on calling professional construction workers, whose services are not cheap. Arrangement of the foundation for a house is the most important stage in construction, so if you have doubts that you can do it efficiently, it is better to call professionals.

How to Determine Depth

Depth refers to the distance from the soil surface to the base of the foundation (at least 0.5 m).

The density of the soil matters:

- On homogeneous soils (sand with crushed stone and clay), the recommended foundation depth is 0.5 m.

- The laying level in heaving soils (loam, sandy loam, clay) is 0.7 m.

- Weak and mobile soils (quicksands, pseudoquicksands) force the construction of a foundation at a depth of up to 2.5 m.

At the same time, its level can be slightly increased when there are nearby trees growing nearby. The concrete strip is laid at a level of half the soil freezing depth (GPG, determined according to tables depending on the region).

If groundwater is located below the freezing mark, then the concrete strip can be installed at any level. In the case where the groundwater channel passes above the freezing point, the foundation is laid at the level of the GPG.

Foundation depth is the distance from the soil surface to the foundation.

Additional documents

In addition to the design documentation, which is attached to the foundation plan of the structure, a set of the following documents is attached:

- a summary specification indicating the requirements for each element located below the “zero” level;

- development and planning for the installation of prefabricated support elements;

- a diagram showing the reinforcement of the site, taking into account the load effects of the object on the foundation;

- tables indicating the performance indicators of the foundation support pillars;

- information about the placement of slopes.

To ensure a reliable and durable foundation, accurate calculations and qualified specialists are used. Attempts to save money on drawing up a project will definitely lead to the appearance of defects that will entail financial expenses.

Foundation calculation

Excavation and construction are preceded by the calculation of the foundation width, depth and total area of the base.

It is defined as follows: S>k(n)*F/k(c)*R.

In this formula:

- k(n) – reliability coefficient.

- F – load from the building and everything that increases the pressure on the strip base.

- k(c) – coefficient, the value of which is taken depending on the type of soil (from 1 for wet soils to 1.4 for dry soils).

- R – soil resistance.

It is important to take other loads into account.

These include:

- snow cover;

- ceiling and ceiling area;

- the area of the internal elements of the building (stairs, railings, etc.);

- rafter system, weight of the roof and materials from which the roof is made;

- weight of material for cladding and home improvement, plinth, air and thermal insulation.

The calculation of the foundation is determined by formulas.

Approximate initial data for calculation:

- Place of construction (city, region).

- Type of area (village, urban-type settlement).

- Size of the building (in meters, along the outer edges of the foundation).

- Roof angle.

- Estimated height.

- The presence or absence of a base, materials for its construction.

- Internal and external load-bearing walls, their thickness and height.

- Type of roof.

Installation of formwork

Formwork is a form for pouring concrete that determines the width and height of the tape. It is built from edged boards; in some cases, reusable special shields are used.

The formwork panels are assembled next to the trench. They should be tight, without cracks or gaps. The finished panels are lowered into the trench, installed in the desired position, aligned along the axes and horizontally and fixed from the inside with crossbars, and from the outside by vertical support bars, reinforced with inclined struts.

The formwork must be strong, capable of reliably withstanding the load from concrete during pouring and hardening.

Online strip foundation calculator

It is possible to calculate the base using an online calculator and similar programs. It is so easy to calculate the approximate cost of work, determine the volume of supplies, the amount of required materials and purchases.

An online calculator helps you make the calculation.

Step-by-step instructions for a typical construction calculator:

- Select the desired tape type.

- Specify the brand of concrete.

- Enter the values of the ribbon parameters (width, length, height, thickness).

- Specify the length of the reinforcement bar.

- Calculate metal structures (is there concrete preparation on the site, what is the cross-sectional area of the rods and their length).

- Enter the characteristics of the formwork (thickness, width and length of the board).

Based on this data, the program produces a printable drawing and detailed information regarding:

- weight and volume of concrete;

- loads on the soil from the base;

- areas of the outer lateral surface and sole;

- total weight and length of metal structures;

- pitch of transverse bars.

Based on the data, a drawing of the strip foundation is obtained.

Reinforcement

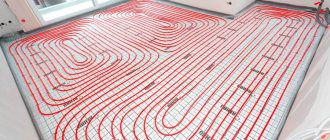

As is known, reinforcing a buried strip foundation with welded frames can improve the elasticity and strength of the structure. On stable soils, you can do without a frame, but it is better to lay reinforcement, which will increase the durability of the building.

For this purpose, metal rods with a diameter of 10-14 millimeters are used. The shape of the frame depends on the loads on the buildings. In a standard situation, it is recommended to use two horizontal and two vertical frames. The rods are connected into a single structure by welding. The frame can be made with your own hands without additional equipment. In this case, the reinforcement is fastened together using binding wire.

To prevent the reinforcement from coming into contact with the ground, the lower part of the frame is laid on bricks, so that there is a gap of 5 centimeters between the metal and the ground. If this condition is met, corrosion of the reinforcement can be prevented.

Required materials and tools

To independently build a foundation from materials you will need:

- For formwork - wood panels, bars, planed boards.

- For the frame - reinforcement and wire for tying rods.

- For the foundation cushion - sand and crushed stone.

- Foamed polystyrene (to ensure waterproofing of wooden structures).

- Materials for protecting the base are cement-polymer, bitumen or roll mixtures.

- Concrete (for mixing - crushed stone, cement and sand).

The list of tools includes a grinder for cutting reinforcement.

The list of tools includes:

- Roulette.

- Grinder (for cutting reinforcement), chainsaw or hand saw.

- Sledgehammer.

- Concrete mixer.

- Bayonet and shovel shovels.

- Axe.

- Vibrating plate.

- Hammer.

- Master OK.

- Tamper.

- Screwdriver, screws, nails.

- Metal containers for preparing concrete mixture.

How to make a strip foundation correctly: step-by-step instructions

When all the calculations have been made and the desired type of foundation has been selected, it is important to pay attention to the expected costs. In private construction, a situation often arises when a well-designed drawing has one drawback - the lack of money for its implementation.

After making the calculations, it is important to pay attention to the costs.

If work on the construction of the foundation has begun, it must be completed as soon as possible.

It is important to take into account that it will not be possible to postpone the process of pouring concrete due to a lack of material or breakdown of the necessary tool.

Preparatory work

Foundation preparation activities take up almost a third of the entire construction budget.

Before building the foundation you need:

- Clear the area of debris, branches, bushes, and trees.

- Artificially reduce or dry groundwater.

- Mark the area using rope and wedges. Draw the outer and inner boundaries of the foundation on the ground.

- Determine the unevenness on the surface, find the lowest point. The bottom of the trench must have the same depth everywhere (evenness is determined using a level).

Marking the area: how to make it level

Correctly carried out markings simplify the work of constructing the foundation for the house and guarantee its reliability.

Good site marking guarantees the reliability of the foundation.

Among the tools for marking the foundation are used:

- Metal tape measure (at least 10 m long).

- Twine, cord, fishing line.

- Wooden stakes, bars, U-shaped fittings.

- Hydraulic level.

To mark the foundation as evenly as possible, it is better to use a laser level.

This device has high accuracy (error 3–7 mm) and ease of use.

When marking, you must comply with the following requirements:

- Frequently check the lengths of the sides of the foundation.

- Establish the axis of the future building.

- Correctly set the corners of the future foundation.

- Maintain the geometry of the foundation, which is specified in the drawing.

- Determine the first angle with a plumb line. Pull a rope from it to 2 other corners located perpendicular to it.

- Stretch a rope between the corners.

It is important to maintain the geometry of the foundation according to the drawing.

Internal markings are done in the same way as external ones (the size of the indentation is from 40 to 90 cm).

Soil development

Activities include excavation work - leveling the site manually or using machinery, digging ditches and trenches, developing a pit for the foundation. By this time, all materials should have been delivered to the site, all formwork panels and reinforcement sections must have been assembled.

For shallow foundations, the trench can be dug by hand. If the construction requires the presence of a basement or basement, you cannot do without special equipment.

Experienced builders advise:

- Develop the soil for the foundation in the summer and in the first autumn months.

- Start digging from the highest angle. In this case, deepening should be done gradually, over the entire area of the trench.

- As the depth increases, strengthen the walls with side shields.

- After excavating the earth from the trench, find in advance a place where to put it.

Soil development involves digging ditches and trenches.

The bottom of the pit should only be horizontal.

Creating a sand cushion

The purpose of the pad is to replace loose soil with a strong foundation that can support the load of the building. The composition of the layer may include gravelly soil, sand-crushed stone mixture, medium or coarse sand. Its thickness depends on the weight of the building and ranges from 10 to 25 cm.

The main requirement when creating a pillow is to compact its surface tightly.

Installation process:

- Level the bottom of the pit.

- Arrange drainage from crushed stone or gravel (if groundwater is located nearby).

- Place an even layer of cushion material on top of the bottom of the pit.

- Compact the layer of sand with a vibrating plate. For efficiency, pour several layers of sand, each of which is compacted separately.

- Check the quality of the tamper. There should be no footprints left on the sand from the shoes of a person standing on it.

Creating a sand cushion is necessary to withstand the load.

Drainage system

High-quality drainage of groundwater prevents flooding of the foundation and increases its service life. In some cases, a storm drain near the foundation is sufficient, but most often it requires the installation of a full-fledged drainage network.

Step-by-step drainage installation technology:

- Strengthening the walls of the foundation and house using construction mesh.

- Treating the base walls with bitumen-based mastic or any other waterproofing substance.

- Digging a trench at least 0.5 m deep below the foundation.

- Creating a slope and cushion. Filling and compacting sand at the bottom of the trench.

- Lining its bottom and walls with technical fabric (geotextile filter).

- Laying crushed stone (1 layer – 10 cm).

- Laying out drainage pipes.

- Backfilling the trench with a 10 cm layer of crushed stone.

- Wrapping her up with geo-fabric.

- Insertion and installation of the system.

- Backfilling, compacting it with earth.

The drainage system prevents flooding of the base.

Installation of formwork

The design determines the shape of the foundation. In private housing construction, wooden structures are most often used.

To install it you need:

- Make boards from wooden blocks 25 mm thick (width equal to the sum of the base and the depth of the trench).

- Drive vertical wedges throughout the site. The step is 1 m.

- Attach the shields to the wedges (use self-tapping screws or nails).

- Strengthen the shields with crossbars and spacers.

- Make sure that the entire structure is level.

Installation of fittings

The main material is steel rods with protruding longitudinal and oblique ribs (diameter from 12 to 20 mm).

Steel rods are used to install reinforcement.

The bottom of the trench is lined with bricks. The bottom row of rods (2–3 rods) are placed at a height of 5–10 cm from the bottom of the trench. The pitch of transverse reinforcement is 0.5 m.

To make a metal mesh, you need to tie the rods together with special wire to make a square with a side of 40–50 cm. It is not recommended to weld the joints of the rods, because they are vulnerable to corrosion.

To reinforce the corners of the foundation, it is most convenient to use L-shaped rods.

Useful tips

Recommendations from experienced builders will help you avoid mistakes when laying a strip foundation:

- concrete will set faster in cold weather if the solution is mixed with warm water;

- the strength of concrete decreases when using sand and gravel mixed with earth or clay;

- when using wet sand, the amount of water must be reduced, otherwise the solution will turn out liquid;

- there should be no shoe marks on a well-compacted cushion, otherwise the building will sag due to poor-quality compaction;

- You should not neglect insulation, since thermal insulation of a strip foundation, even for a light frame house only from the outside, reduces heating costs by 15 - 20%.

To drain rain and melt water from the strip foundation and reduce the amount of heaving, it is recommended to install a blind area. To enhance protection and give a presentable appearance, the base part of the tape is trimmed with stone, clinker tiles, and siding.

Concrete pouring stage

Concreting is carried out in one go to prevent the formation of cold seams, air cavities and delamination in the concrete mass. In addition, the cause of these negative factors may be incorrect concrete formulation, prolonged or intensive compaction of the mixture.

Which to choose

For pouring into formwork, it is advisable to choose heavy grades of concrete, the filler of which is fractions of rocks. Granule size – from 6 mm.

You should focus on one of these brands:

- M100. Suitable for 1-story houses made of aerated concrete or wood. You need to make a pillow with a layer of 100 mm, consisting of the same mixture.

- M150. Designed for light buildings made of cinder blocks, aerated concrete and similar materials.

- M200. Refers to universal brands used in the construction of 2-story houses.

- M250. It has increased frost resistance and density.

- M300. Used for pouring foundations for heavy buildings.

- M350. Characterized by a high cement content. Wear-resistant, waterproof and durable compound.

- M400, M450. Designed for watery soils. The mixture is strong, but expensive. Rarely used in private construction.

To pour the foundation, use heavy grades of concrete.

Most often, the choice of developers falls on the concrete grades M250 and M300.

How to make the mixture yourself

To prepare a concrete mixture, you need to choose the right components. Among them are cement (grades M300, M400), sand without clay, granite crushed stone (fractions of 5–40 mm) and water. Various plasticizing additives and reinforcing fibers (fiber) can be included in the solution.

To prepare concrete without a concrete mixer, you need:

- Pour all components into a large container in the required proportions. Standard - 1–4–2–0.5, where 1 is cement, 4 is granite crushed stone, 2 is sand, 0.5 is water.

- Pour in water (leaving 1/3 of it).

- Stir and check consistency. If the concrete density is too high, add the remaining water.

Algorithm of actions with a concrete mixer:

- Turn on the device.

- Fill in all the components - first water, then cement, then sand and crushed stone.

- If the concrete is very thick, add water.

You can prepare the mixture yourself without a concrete mixer.

The total mixing time is no more than 10 minutes.

Correct filling

Concrete is poured in layers 20 cm thick each. Moreover, they should be laid along the entire length of the formwork, and not in parts.

After pouring, the concrete must be leveled with a flat board or trowel. Then compact the layer manually (with a crowbar, shovel, mechanical tamper) or using a deep vibrator. Each subsequent layer of concrete is poured no earlier than the previous one is compacted.

It is important that the concrete cures in a damp environment. 1.5–2 hours after pouring, it is important to cover it with covering material or sawdust.

Concreting

After installing the formwork and metal frames, they begin concreting the buried foundation with a plinth. The required amount of concrete mixture can be ordered from a specialized organization. The solution can be prepared independently from sand, cement and crushed stone. The proportions of raw materials are 3:1:5. These substances are thoroughly mixed in a mixer, and water is added to the dry bulk materials to create the required consistency of concrete.

The foundation concreting process consists of several simple operations:

- Prepare the solution in a concrete mixer.

- Pour the mixture into the formwork in layers of 15-20 centimeters;

- Each layer must be compacted using a vibrating rammer. During this process, it is necessary to ensure that all air bubbles are released from the concrete.

- The solution must be fed into the trench from a small height; falling the mixture from a distance of 1.5 meters leads to its delamination.

- After pouring, cover the layer with plastic film and wait until it dries completely.

If there is persistent hot weather, the newly constructed foundation must be periodically wetted to prevent cracks in the concrete. When the strength of the concrete mixture exceeds 70%, you can begin to dismantle the formwork.

When pouring formwork through a special pump, the user receives a number of advantages. This means dense and even laying of the tape, high speed of work performed and the ability to pour the foundation in one go. Concreting a buried foundation must be approached with all responsibility. Such operations should be carried out by experienced builders who know their business. The safety and reliability, as well as the strength characteristics of the building, will depend on compliance with the work technology.

What to do next

After concreting the foundation, you need to dry it by covering it with insulating material. The strip base gains strength in 26–28 days (at low temperatures, the period can increase to 4 weeks).

Removing formwork

It is recommended to dismantle the structure after the concrete has reached grade strength. Dismantling the formwork should begin from top to bottom, from the protruding parts of the foundation and corners.

Removal of formwork is done from protruding parts of the foundation.

The process goes like this:

- First, unscrew the bolts and remove the top ties.

- The lower ones are released.

- Separate the shields from the racks.

- The supports are removed.

- Remove the formwork boards.

It is undesirable to abruptly tear off all structural elements, because in this case, chips and cracks may appear in the concrete.

Insulation and waterproofing

Protection of the foundation from the effects of groundwater is carried out before pouring concrete or simultaneously with it.

For waterproofing the base, the following materials are used:

- Bitumen-polymer emulsion.

- Liquid rubber.

- Rolled pasting materials – fiberglass, fiberglass, polyester.

Roll materials are used for waterproofing.

Experienced builders do not recommend using parchment, roofing felt, roofing felt, etc. for waterproofing the base.

It is best to insulate the foundation at the stage of its construction.

The work can be divided into 4 stages:

- Preparation and cleaning of the base.

- Laying waterproofing materials.

- Insulation with polyurethane foam, foam boards or backfill method.

- Finishing.

Other popular insulation materials include expanded clay, mineral wool, penoplex and slag.

To insulate the base with bulk materials, it is necessary to dry the soil and remove dirt and sand from the surface. Slag, gravel or sand are used as backfill.