Articles

All photos from the article

Vibration of a washing machine on a wooden floor can not only lead to destruction of the base, but also cause damage to the device itself. This is why experts recommend approaching this task very responsibly: even seemingly durable boards may not withstand the impact of a loaded drum rotating at high speed.

However, even if you need to mark the device specifically on a wooden floor, this can be done with relatively little labor.

The structure must be level and solid

Installation features and location selection

The most suitable place to install a washing machine in the house is a separate room (laundry room). Not only the washing machine itself is placed here, but also a dryer, baskets for dirty and clean laundry, an ironing board, an iron and household chemicals.

However, for most Russians, a separate laundry room in an apartment is a luxury, and the unit is placed where there is space. Where to place the washing machine so that it is convenient to use and has a long service life?

The kitchen is the next best place. Why? The answer is simple. Installing the unit in the bathroom condemns it to work in conditions of high humidity, which leads to breakdowns and failure of the machine’s electronics.

Attention. Excessive humidity reduces the service life of the device by an average of 1.5 times.

The steam generated in the bathroom when washing with hot water is especially harmful to the car. It condenses on electronic components, causing short circuits.

If your device is installed in a bathroom, do not turn it on in high humidity. First, let any condensation that has formed dry. It is also necessary to protect the device from direct moisture, for example, with a cover.

When installing the machine in the kitchen, give preference to a place in close proximity to the kitchen sink. This will simplify the connection to communications for draining and collecting water and reduce the likelihood of leaks.

If it is not possible to place it next to the sink, you will have to additionally purchase connecting hoses for extension and decide how to hide them so that they do not spoil the look of the kitchen.

Preparation

The first thing to do before transportation is to secure the drum. Any basic configuration of the unit includes special bolts that secure the drum. After transporting the cars from the salon to the apartment, it is better not to throw them away, but to leave them in case they are moved again.

Transporting a washing machine

Afterwards, it is important not to forget to wrap the outside of the equipment with cardboard or soft film, which will help prevent damage to the outer covering. You can secure the drain hose of the washing machine using wire, soft cord, or tape. The interior of the drum can be filled with soft cloth or foam rubber.

Preparatory stage

This stage is divided into preparing the machine itself for installation and preparing the selected location.

Preparing the device

If the car is new and just brought from the store, then first of all you need to unpack it. If the packaging is damaged, this may indicate damage to the machine itself.

Advice. When unpacking, try to remove the box undamaged. Subsequently, if a return is required, damage to the packaging may be grounds for refusal of a replacement. The packaging is stored during the entire warranty period.

After removing the packaging, the equipment is inspected for defects. Carefully check the completeness, checking the list in the passport.

After this, remove the bolts and fasteners installed for safe transportation. These parts are needed to secure the drum during transportation.

Important. Be sure to remove shipping fasteners before installation. If this is not done, the device will quickly fail. Moreover, the manufacturer's warranty will not apply in this case.

The location of the fasteners is indicated in the instructions. The holes for the transport bolts are usually closed with special plugs. Bolts are stored for the life of the equipment. They are reinstalled if the device needs to be transported.

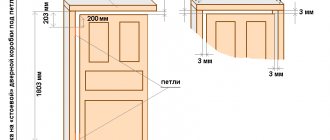

Preparing the site

The main requirements for the surface at the location are strength and strictly horizontal location of the machine.

During operation, the device is constantly exposed to vibration from the centrifuge. Therefore, a surface that is not sufficiently rigid and strong will quickly wear out, creating a misalignment.

Preparation of engineering systems

To connect the washing machine you need the following communications:

- Water pipes . In order to save money, it is better to provide a supply of both cold and hot water to the machine. If this is not possible, then only cold water is connected. At the same time, the amount of electricity consumed to heat the water in the device increases. The most convenient place to connect to the water supply is under the sink in the kitchen or under the sink in the bathroom. If you organize the water supply through a filter, this will increase the life of the machine.

- Drain . During washing, the unit changes the water several times. Dirty water is drained into the sewer. The drain hose is connected to the sewer system using special connectors. Any washing machine is also equipped with a special hose, the end of which can simply be placed in the bathtub.

- Electricity supply. When placed in a bathroom, it is necessary to make special wiring to install an outlet for the machine. It is placed above the device to prevent water from entering. Using an extension cord in the bathroom is prohibited as it creates dangerous operating conditions. The outlet installed in the bathroom must be grounded.

Is it possible to fix the washing machine to the floor?

During the spin cycle, the Samsung SM moves quite a lot.

Has anyone attached the SM to the floor? What was the result? What's the best way to do this? You can make four holes on the tile for the legs, if it’s in the bathroom. Maybe there’s just an imbalance in the linen?

Is the machine level?

2ndreika I am interested in principle: will the SM break if it is rigidly attached to the floor?

2Alex_Kov You wrote a very valuable comment

2mixator No. Just standing on the floor.

coyot78 wrote: won't the SM break if it is rigidly attached to the floor?

It seems to me that with a policy of complete trust in the existing modern drum balancing system (with its clearly observable efficiency) and rigid fastening of the SM body to the floor, its innards will be smashed into rubbish in less than a year.

Samsung doesn't mind. You can thread the legs through a link in a piece of chain and screw them in. And the second ends of the chain - with dowels to the floor. So that she doesn't run away. The chains will shake.

Shikhael Muma wrote: it seems to me that with a policy of complete trust in the existing modern drum balancing system (with its clearly observable efficiency) and rigid fastening of the SM body to the floor, its innards will be smashed into rubbish in less than a year.

and if she jumps with all her guts, then there is a chance of breaking them in the same period of time.

coyot78 wrote: During the spin cycle, the Samsung SM moves quite a lot. Has anyone attached the SM to the floor? What was the result? What's the best way to do this?

did you remove the shipping bolts? I found some information here,” > “In general, rigid fastening of the machine’s legs to the floor is not provided. But in a number of cases (for example, when installed on a plinth, on an inclined slippery floor, on an unstable wooden floor, etc.), such fastening can be done. For this purpose, some models have special brackets for attaching the front legs.”

A short digression about what will happen if the transport bolts are not removed. We once received an application for warranty repair of an ARDO A-600X washing machine located in a rural area. When asked what was wrong with the machine, the owner answered briefly: it doesn’t work.

When the master arrived at the place, the following picture appeared before his eyes. The machine worked for 8 (.) months with the transport fastenings not removed. To prevent the machine from jumping around the room, the owner replaced the front rubber support legs with a stationary mount made of a metal corner, fixed with dowels to the floor.

In addition, the machine is almost completely covered with brickwork on both sides. After the owner dismantled his structures and removed the machine and opened it, the following was discovered:

Complete absence of bearings - the shaft “rotated?” in the landing bushings of the cross. Due to the beating under the weight of the drum, the edge of the pulley facing the tank was completely worn out, simultaneously cutting through the crosspiece, causing the drive belt to jump off and break. Further disassembly revealed even more terrible consequences of the owner’s lack of intelligence - drum

I cut off the heating element and the front part of the tank, which simply fell off under the weight of the front counterweight. The belt apparently broke after that. When water poured out of the cut tank onto the floor and the machine stopped completely, the owner decided to call a technician to carry out warranty repairs! According to the master, he had to explain to the client for quite a long time about his violation of the terms of the warranty and the inappropriateness of restoring this machine.

Important external factors

When installing and connecting the device yourself, external factors such as the floor covering at the installation site and air temperature are taken into account.

Flooring

As mentioned above, the surface where the machine is placed must be durable.

We list the main types of floor coverings and their advantages and disadvantages from the point of view of installing a washing machine.

Tree

Not the best basis for installing the device. Firstly, wooden flooring is rarely perfectly level, secondly, it “plays” under load and, thirdly, it deteriorates when exposed to moisture.

If you still have to install the machine on a wooden floor, then it must first be strengthened to reduce vibration. A washing device with a depth of at least 45 cm is installed on the tree.

Laminate

Laminate flooring, like parquet boards, is laid on a waterproofing or soundproofing base. Such a substrate is elastic and will cause vibration of the floor covering during operation of the unit. In addition, parquet and laminate deteriorate when exposed to water.

Linoleum

Installing a washing machine on a wooden floor covered with linoleum is the least preferable option. It contains all the disadvantages: softness, slippery surface, hidden floor irregularities. When installing the device on such a surface, choose only a full-sized unit with a depth of 60 cm.

Ceramic tile

A ceramic tile floor is a good base for a washing machine. It is smooth, durable and well dampens vibration from a running drum.

The only drawback of this coating is its smoothness. During operation, the machine may slide on such a floor and shift. A special rubber mat or pads under the machine’s feet will help solve this problem. You can purchase such accessories at a hardware store.

Concrete

Concrete is perhaps the best option for installing a washing machine. It is hard, smooth and not at all slippery. A device of any depth is installed on such a coating.

Ambient temperature

Another important external factor is the air temperature where the machine is installed. It should not be below +10°C. You should not choose a place such as an unheated garage, loggia or veranda for the device. The problem is the lack of ventilation in such rooms and low temperatures in winter.

During operation, the washing machine generates heat. If the room is cold, moisture condenses on the inside of the machine, damaging the electronic components. Condensation also causes the appearance of black fungus and rust.

Rules for transportation by car

It is important to remember that such fragile large equipment as automatic washing machines are transported in an upright position. To do this you will have to call a cargo taxi. If transportation is carried out in a passenger car, it is unlikely that it will be possible to place the machine vertically.

Transporting the washing machine

In such cases, carefully lay it on its side, not forgetting to secure the washing machine motor. Owners of Zanussi cars should be aware that due to the peculiarities of the internal structure, this method of transportation is absolutely not suitable for them.

When choosing a truck, you need to make sure that the vehicle will not bounce on bumps and will not ride on the wooden floor of the body when entering sharp turns. This can be avoided by placing the unit in a corner of the body and crowding it with large objects (relevant when moving).

Level adjustment of legs

The drum of the machine, rotating even at low speed, creates vibration. If the laundry is unevenly distributed, it becomes stronger. Vibration is dangerous because it wears out machine parts faster. How to install a washing machine so it doesn't jump? The answer is simple - align the legs.

Attention. Adjusting the legs in height will reduce vibration and give the device stability.

To begin with, by adjusting the height of the legs, the machine is brought into a stable state (so that it does not swing) . After this, take a building level and install it parallel to the front wall. The front legs are adjusted so that the air bubble is exactly in the middle.

Then the level is alternately moved to the side walls of the machine and the rear legs are adjusted. The end result of the work should be a position where the body of the machine is stable, and the level shows a strictly horizontal position both in front and on the sides.

Installation without level

If you don’t have a building level, you can use a glass or saucer of water instead. Place the dishes with water on the top lid of the washing machine and adjust the legs so that the water in the glass or saucer is at the same distance from the edge of the dish.

Washing machine in the kitchen with different layouts

Here are some interesting ideas on how to beautifully arrange a stationary or built-in washing machine.

- Corner kitchens with washing machine.

- Linear (straight) layout.

- U-shaped kitchen with SM.

- Double row.

Another reason for strong vibration

It happens that strong vibration is caused by unevenness of the supporting surface, which cannot be corrected. Or, after operating the machine for a long time, local wear has occurred on the supporting surface under the legs. As a result, the device becomes unbalanced during operation and the machine begins to jump and shake.

If adjusting the feet does not solve the problem, you can use an anti-vibration stand. It will reduce vibration and noise levels, and also prevent further damage to the flooring. This stand is made of polymer material and comes in different shapes and sizes. You can buy it at hardware stores.

Correct installation of the washing machine, anti-jump protection

No matter what anyone says, purchasing an automatic washing machine is still a definite event. If it hasn’t happened before, this event is quite serious and expectations are very high.

If there was already a washing machine, something more is expected than it was before. Absolutely normal and justified desires. And now, after a careful selection of various “candidates”, the choice is finally made, the washing machine is paid for in the store and delivered.

In the end, it’s already even connected. Everything seems to be fine. The car starts. Washes and rinses. Everything seems to be fine. The process comes to spinning the laundry. And then an unexpected problem: the car begins to vibrate strongly. It doesn’t just vibrate – it just jumps.

We have to hold her so that she doesn’t “go away.” And then joy turns into disappointment. My first thoughts are that I was sold a defective product. Just don’t rush to call a store or service center. Do you think it's the washing machine? Let's try to figure it out.

Common errors during connection and operation

We list the common mistakes made during installation and subsequent operation of a washing machine.

Incorrect installation of the drain hose

The end of the drain hose is installed at a certain height. The recommended height for each model is indicated in the instructions for the device. The general principle is that the highest point of installation of the hose should be slightly higher than the maximum water level in the machine tank.

Incorrect installation results in water leakage from the tank, a reverse siphon effect, and an unpleasant odor in the machine.

Network connection errors

A typical mistake is the use of non-standard electrical wiring (insufficient wire cross-section, single-layer insulation). This leads to overheating of electrical wiring, melting of insulation, short circuits, and electric shock.

Important. Improper connection of the device to the electrical network is not only dangerous to life and health, but can also cause malfunctions in the machine.

If the room was not originally designed for the installation of a washing machine, then the power supply is carried out using an individual (three-core) cable of the appropriate cross-section. The cable leads from the distribution panel with the installation of automatic switches rated for a current of at least 16 A.

Attention. The use of faulty or low-quality two-wire sockets and extension cords is unacceptable.

Incorrect water connection

The machine is connected to the water supply through autonomous taps located in an accessible place for operation. This makes it possible to quickly turn off the water if necessary.

Use of highly foaming powders

Excess foam fills the internal cavities of the machine, leading to malfunctions and breakdowns in the operation of electronic components.

Entry of foreign objects

Foreign objects falling into the machine along with laundry cause serious damage to internal parts, including engine failure. Therefore, before loading the laundry, carefully check it and remove all foreign objects from the pockets, as well as loose buttons and fasteners.

Incorrect switching of operating modes

The mode change is set after turning off the power and in a clockwise direction. Failure to comply with this requirement leads to damage to the control apparatus of the washing machine.

Failure to comply with loading standards

Overloading the machine and rolling the laundry into a lump causes increased vibration and rapid wear of the equipment. If a problem occurs, the machine is turned off, the laundry is redistributed and started again.

In addition, it is not recommended to leave machines that are more than 4-5 years old unattended and turned on. The likelihood of breakdowns and leaks at this “age” is very high.

This is interesting:

Small corner kitchen with washing machine: how to fit everything in.

How to wash kitchen towels with vegetable oil.

How to wash kitchen towels without boiling at home.

Installing the machine into the wall

This option is non-standard, but very effective. This is because in this way, you don’t have to take up space on the floor with the washing machine. Thus, you will make the room more free.

If your house is full of holes in the walls for various wiring, or has a closet, then transform it all into a place where you can put a washing machine. You may need to drill out and widen the hole in the wall a little. But there will be a washing machine installed there, which will not interfere and take up space on the floor.

For reliable operation of the machine, it is important to secure the product well. To do this, you first need to drill holes in the wall for the bolts on which the straps installed at the back of the machine will be attached. It is also important to check the stability of the bottom of the wall closet. If there is a risk that the washing machine will fail, then you should crush and concrete the entire lower opening.

Location of counterweights

Finding counterweights in an automatic machine is very easy. The easiest place to get to is the top weight. However, there are always more problems with dismantling this block. To “climb” to it, you need to:

The upper counterweight will be immediately in front of your eyes. The unit must be inspected for defects. Next, you need to evaluate the condition of the front weights; to do this, you will have to remove the front wall of the case. The further algorithm of actions will be as follows:

Now you can inspect the front counterweights. If there are many cracks on them, the elements will have to be replaced. We'll show you how to remove damaged concrete weights to make room for new blocks.

Concrete pad

The best way to upgrade the coating for a washing machine is to prepare a concrete base. It has sufficient strength and good rigidity, which allow you to confidently hold the machine loaded for washing in all operating modes. The disadvantage of this option is that it is time consuming. In addition, it will require more tools and materials.

Tools and materials

To complete this work you will need to purchase:

It is necessary to select a set of the following tools for the material:

Pouring the base

Before starting work, you need to dismantle the laminate or other wooden floor. Next, you should mark the perimeter of the future base according to the dimensions of the machine and begin its manufacture:

You will need to wait about two weeks for the solution to harden sufficiently before installing the machine.

Anti-vibration mats

Another product that is designed to prevent the washing machine from spontaneously moving on the tiles is anti-vibration mats. A thin and aesthetically pleasing product will make the body stand in place, significantly reduce vibration during spinning, and therefore help reduce the level of noise produced.

Externally, the product looks like an ordinary rubber mat, but structurally it consists of two layers with different characteristics. The top layer provides anti-slip action, the bottom has anti-vibration properties. The product has a porous structure. The materials used in its manufacture ensure resistance to deformation under load. The mat is resistant to moisture and household chemicals and can be used in a wide temperature range.

All that needs to be done to prevent the car from jumping on the tile is to lay this product on the floor so that each of the legs stands on it.

Proflex products are distinguished by their high quality and environmental safety. Anti-vibration mats are two-layer, odorless, and in addition to reducing noise levels, they act as an antistatic agent, preventing charge from accumulating on the body.

Mattix-Vibromats sheets and stands are characterized by high wear resistance. Can be used even at extremely low temperatures. This is a good choice for a warm apartment and cottage that does not have heating.

Anti-vibration stands

Since this problem is not new, there has long been a simple and inexpensive solution to it - anti-vibration stands. For the most part, these products are small circles made of durable polymer that absorbs vibration, thereby ensuring stability and reliable fixation of the case on a smooth surface.

These stands have an attractive appearance and will definitely not spoil the impression of good repairs and high-quality household appliances. There are different models of stands available for sale; they differ in shape and color, so it’s easy to choose the ideal solution for any interior.

The process of installing anti-vibration products is not particularly difficult; moreover, you don’t even have to turn off the device. To prevent the machine from wobbling, simply tilt its body to one side and place a stand under each of the legs. Then the same actions are performed for the other side. There is no need to re-align the case; the material of the stands itself will ensure its horizontal position.