Metal beds combine unmatched durability and sophisticated beauty to create a unique style that matches your bedroom decor. Of course, do DIY metal bed a little more complicated than wood. But the strength of the metal is undeniable.

A metal bed will not crack or bend. You'll never have to worry about the frame warping or weakening, plus it makes it easier to move the bed if necessary. And in order to do without a welding machine and other expensive equipment, you can make a bed from metal pipes using fittings and adapters. In this article you will find 20 examples with step-by-step photos on how to make a metal bed with your own hands in various ways.

Final processing

The fully finished prefabricated iron bed, welded and sanded, is treated with a rust-resistant primer. You cannot paint the metal immediately after welding, since rust may appear in the joints, especially thin ones after grinding. After the primer has dried, which it is advisable to apply in 2 layers, you can begin painting the bed.

The most beautiful way to paint metal is to spray it with gold varnish using a spray bottle. However, this is long and expensive. If it is not possible to do this, you can paint the bed with metal paint using ordinary brushes. It turns out beautiful in beds decorated with metal roses, paintings or engravings. Homemade decorations are usually more beautiful and creative than store-bought ones. Decorating metal products with your own hands is painstaking and hard work, but it allows you to approach the design of the bed with a creative approach and originality.

As can be seen from the information described in this article, making a metal bed yourself is a completely doable job if you prepare for it and have the necessary materials and tools.

Prime the surface

Installing the bed on posts

It is best to use a spray can. Apply the first layer.

After it dries, apply a second layer

We coat the metal with varnish

Step-by-step technology for creating a metal bed

Making a metal bed at home is not easy, but if you follow the rules and technologies, it is doable. The whole process is divided into preparatory work, assembly of components together and finishing of the finished product.

When making metal beds with your own hands, at each stage it is necessary to sand the sharp edges of the cuts and level the seams with a grinder.

Tools and materials for work

To make a welded bed from a profile pipe, you will first need a welding machine. In addition, the following must be available:

- electric angle grinder;

- powerful drill with metal drills of various diameters;

- tape measure and square;

- file and sandpaper, brush with metal bristles;

- primer, paint and varnish intended for coating metal products;

- brushes

If you plan to independently create a bed from corrugated pipes using the forging method, you need to acquire forging equipment equipped with different forms for bending metal, these are:

- cochlea (spiral elements);

- flexion (bending at an angle);

- flashlight (parts in the form of flashlights);

- twister (twisting along the longitudinal axis);

- volumetric;

- wave (to create wave patterns).

The use of hot forging requires the presence of a forge, anvil, sledgehammer, hammer, tongs, handbrake and slaps.

Depending on the final result, the manufacturing process may involve the use of all metal processing methods.

Blueprints

Drawing a drawing involves creating a schematic drawing of the finished product indicating the dimensions of each part, attachment points, and location of functional elements.

The accuracy of the drawing is important when components are ordered from specialists.

Making a metal frame

At the first stage you need to make two headboards. Based on the table of blanks, the pipes are cut into the required quantity and laid on a flat surface in the required order. If possible, they are firmly fixed. All elements are welded, carefully controlling the right angles and parallels of the opposite posts.

Then the backrests need to be equipped with hook-shaped brackets for installing the frame. The brackets are welded to the backs with a slight slope from the vertical 35 cm above the floor. Since the entire weight of the product will be placed on them, the seam must be made continuous and of high quality.

To make the frame, a metal corner and a channel are used, which are connected to each other by welding, having previously cut off a small section from the horizontal side of the corner.

To make high-quality drilling of the counter hole for the bracket, the backs and frame need to be placed next to each other and the exact location of their location must be marked. First, a round hole is made using a drill and a drill bit, then it is given the desired shape using a square file.

If all three components are assembled and the strength of the structure is observed, you can begin to weld 2 longitudinal and 6 transverse slats onto the frame, which will serve as the base for the mattress.

Features of the material

The peculiarity of the metal is its:

- durability;

- resistance to mechanical damage;

- resistance to negative factors;

- aesthetic appearance;

- the ability to give metal any shape and design.

To make a metal bed with your own hands, you need to be able to work with the material , know the intricacies of making furniture items, have patience and have some free time.

Metal furniture pleases users with nobility, luxury and elegance. In addition, these products differ:

- environmental friendliness;

- hygiene;

- light weight;

- fire safety.

Types of structures

Iron beds were widespread during the Soviet era, when quality and durability were always in the foreground, and the appearance did not always satisfy consumers. Therefore, many users still have a stereotype about unsightly headboards and creaky springs.

Today, metal beds have become works of art. Some models have superior aesthetic characteristics to luxurious wooden beds.

According to the method of creation, metal structures are:

- Forged, for the manufacture of which pipes with sections of various diameters are used. Forging can be cold (all processes of changing the shape of workpieces are carried out using a special stamping-type apparatus) and hot (before forming, the metal is heated to 600°C and the work is done manually using a hammer).

- Welded - involves joining parts by welding, but the workpieces are produced by forging.

Regardless of the method of creation, the main elements of the bed are: the frame (the support of the entire product) and the frame (the base on which the mattress is located), the legs and the back (headboard). The last component has an aesthetic function, and its creation is given the most attention and time. In addition, the headboard can be purchased in a retail chain separately from the bed itself.

Areas of use and benefits

Beds with iron mesh of different sizes are used in the following places:

- military barracks;

- children's camps;

- medical institutions;

- boarding schools;

- sanatoriums;

- student dormitories.

Modern version

Where does this popularity come from? It turns out that these designs are reliable and durable. In addition, neither adults nor children will experience discomfort during sleep.

You will probably be interested to know what types of Russian bed manufacturers there are.

An armored bed has many advantages:

- High strength. The design can withstand heavy weight and loads. This feature is useful where the bed is used continuously, for example, in a hospital.

- Saving. A bed or cot with a metal mesh is much cheaper than other models.

- Long service life. This piece of furniture will last at least 15 years, which is convenient for medical institutions that do not have the opportunity to frequently update furniture.

- Hygiene. Metal structures do not harbor insects. In addition, they are easy to care for. There is no need to buy any special detergents - just wipe all parts with a damp cloth.

- Reliability. The use of metal almost completely eliminates the risk of breakage.

Rules for constructing a drawing

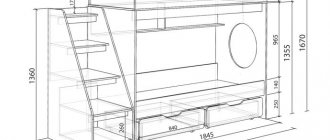

The drawings contain specific parameters and dimensions, the number of parts, and the order of their assembly

A schematic representation of the planned structure is the basis for successful completion of the assembly job. A drawing is considered to be of high quality if it contains:

- dimensions of the structure in centimeters with a margin

- dimensions of individual elements

- order of assembly of parts (frame, back, handles, stairs, headboard, footboard, side panels)

- method and order of connecting node elements

Drawings can be flat or three-dimensional, made manually on paper or in special computer design programs.

When calculating design parameters, take into account:

- Length and width. Measurements are made according to the size of the mattress or the height of children with a margin

- Location of the staircase (right, left, end) and its dimensions

- The height of the tiers and the distance between them. Most often, the height from the lower sleeping tier to the floor is such that it is comfortable for an adult to sit

- Distance from the floor to the sleeping area below (for placing drawers for things or linen, toys)

- Width of supporting beams

- Pull-out dimensions

Design drawing with a sleeping area at the top and a work area in the lower tier

The following sizes are considered optimal for school-age children (from 7 to 14 years old):

- Length of the lower berth – 180 cm, upper – 160 cm

- The width of the lower berth is 80 cm, the upper one is 70 cm

- The height of the entire structure is 170-185 cm

- Height of sides – 35-40 cm

- Staircase height – 150 cm, width – 40 cm

- The distance between the steps of the stairs is 20-25 cm

Characteristics of a reliable sleeping place

A bed with 2 tiers saves space and is suitable for a children's room

A bunk bed consists of 2 sleeping places, located one above the other and connected by a ladder.

High-quality furniture for children's sleep should be:

- safe (eliminate the risk of injury, fire, breakage)

- sustainable

- durable

- comfortable

- beautiful

- functional

- durable

Self-assembly of furniture for a non-professional is a responsible and time-consuming process, which, however, also has a number of positive aspects:

- exact measurements for a specific child

- unique author's design

- low price compared to finished products

- high quality

- maximum safety

- assembly reliability

How to design a table from a profile pipe

For finishing work on homemade furniture made from steel profiles and wood, the same set of materials is almost always used.

Metal parts are painted with a dark varnish that imitates powder paint or blued coating. This recognized style and technique allows not only to decorate the metal, but also to effectively protect black steel from corrosion.

For wood, furniture polishes, varnishes, and toners are used. Almost always they strive to preserve the pattern of wood fibers, to make it more expressive and rich.

Paints and plastics for wood in combination with a profile pipe are practically not used. Even if the countertop is lined with plastic, the surface is sealed with a film with a pattern that imitates valuable wood species.

Construction of pipe trusses

The unit of a metal rafter system is a truss - a flat structure assembled from several straight rods. The outline of the truss is formed by the upper and lower chords. Between them there is a lattice consisting of braces and racks.

The truss elements - straight profile pipes - are connected either directly to each other or through knotted gussets. For fastening, welding, bolts, and rivets are used.

Metal trusses of standard sizes and designs can be purchased ready-made or assembled from pipes yourself. However, independent production requires high professionalism, the ability to work with metal structures and correctly make calculations. Therefore, for a private developer, it is much more convenient to purchase ready-made trusses, which only need to be installed correctly.

Sizing

The dimensions of a bed are influenced by 2 factors: the number of people who will use it and the available space for installation.

The bed model depends on the size of the bedroom. A luxurious backrest will look awkward in a small area, and in large apartments it is inappropriate to install a narrow bed with a low headboard.

Depending on the size of the bed, the bed can be:

- single, intended for use by a child;

- one and a half, on which a teenager can sleep comfortably;

- double – intended for use by two people.

The larger the bed, the more space it will take up in the room. Given the need to install other pieces of furniture, there may not be any room left to move freely. Therefore, sometimes you should refuse to purchase or make a metal bed.

If all the requirements for comfortable accommodation are met, you can begin to create a drawing and make a bed with your own hands.

Decorating the product

A bunk children's bed should not only be absolutely safe for small users, but also beautiful, because the aesthetic aspect is one of the important criteria for children. The color is selected to match the shade of the walls and the tone of the furniture, taking into account the overall style of the interior.

For girls, a children's corner is made in light brown, pink, and white colors. The walls and backs are painted with patterns or ornaments are cut out on them. On the bottom floor of the bed you can make a real house, for example, by hanging curtains and making a window in the side backrest.

The structure is decorated with forged parts, mosaics, or ornaments are applied to the surface using the decoupage technique. For girls, bunk bed models with drawers are suitable: they are convenient for storing clothes, linen, toys or books, while at the same time they act as a laconic, stylish decoration of the structure.

For boys, beds are made in the shape of a ship or car. All shades of blue, green, brown, gray are suitable. Yellow, orange, neon elements would be appropriate. From the second tier you can go down not only the stairs, but also the rope or the slide.

Teenagers are often keen on sports, so designs with a sports wall are suitable for high school students. Often vertical surfaces are decorated with posters and placards - this is the most practical and cheapest option, allowing you to change the decor every day without damaging the furniture.

The model for adults has a more strict design, and a crib for babies can be made in the spirit of your favorite animated film, painting the surface with images of fairy-tale characters.

Instructions on how to build a barn with your own hands

Work begins with marking the site. You need to drive pegs in the corners, and then check the diagonal. The twine can then be pulled only if everything turns out smooth.

This detail is important for marking the places where the racks will be installed. Mines up to 60 centimeters deep are made in places marked with a drill.

Metal pipes are placed in them. We take a concrete solution of at least M200 grade and fill it all in.

Video

The racks are poured in the corners immediately after installation. Fishing lines are tied to them when the concrete hardens a little. They should be both below and above. The rest are aligned according to the first parts fixed in place.

Next, the metal frame is welded. A 60 by 40 mm pipe is welded at the top of the structure. Its wall thickness is 2 millimeters. On the corner pipes it is necessary to mark the level where the floor will be located.

A 40 by 20 millimeter pipe is tied around the perimeter, the main thing is to comply with the markings. The cross members are welded in the middle following the same principle. You will definitely need two pipes. At this stage, the metal frame for the shed can already be considered assembled.

Economical option

The use of MDF, furniture panels, chipboards for furniture assembly simplifies the work and makes it more cost-effective. It is enough to cut out the necessary parts from the sheet and connect them together. Cutting into parts can be ordered in construction stores and construction markets.

Multi-storey structures involve the use of additional materials, metal, wood to impart stability, ensure reliability and strength.

Furniture panels are mainly intended for covering the finished frame. What is the advantage of mastering such material, its ready-made appearance, wide range of “wood-like” colors. It is already covered with a smooth, laminated sheet with a water-repellent surface and does not require additional impregnation.

The disadvantages of operation include the release of the adhesive composition used in the production of shields. To reduce the effect, all edges are securely insulated.