The light weight and compactness of such a neat roof does not overload the load-bearing walls of buildings or put pressure on the foundation.

The cost of wooden materials and installation is several times lower compared to metal structures. Heavy concrete slabs are usually used for the construction of industrial (volumetric) buildings.

Scope of application

Flat roofing made of wood is popular and in demand, primarily in the construction of country houses or cottages, as well as all kinds of terraces, balconies and gazebos, garages and various extensions to buildings. This design is easy to maintain and quick to install.

This option is also in demand when building other houses - from brick, concrete, blocks. In this situation, wooden beams are cut into the mauerlat. But the most preferable is a flat roof in the design of frame buildings made of wood.

Such a roof is often chosen to obtain additional usable space (even with wooden beams at the base). On the roof it is fashionable to create comfortable terraces, places for a summer solarium, relaxation with tea (under a tent), and “break out” spectacular flower beds.

Important! A flat roof on beams (made of wood) is similar in design to interfloor ceilings, but at the same time has excellent protective properties from the effects of natural climatic phenomena (wind, precipitation, temperature changes).

DIY flat roof: reinforced concrete roofing

An alternative is reinforced concrete. With such a roof, the main burden falls on the load-bearing steel I-beams.

These roofs do not have a frame. A reinforced concrete slab must be reinforced longitudinally and transversely, thus increasing the concrete's resistance to bending and damage. If the roof span is less than 5 m, then beams with a height of no more than 15 cm are used to arrange the roof.

When a flat roof is built with your own hands from a cement-concrete mixture, you need to purchase sand, crushed stone and cement, and you will also need water. You can prepare the mixture by hand, but it is better to use a concrete mixer. The ratio of ingredients in the mixture varies and depends on the brand of cement. So for PC-400 grade cement the ratio of parts crushed stone-sand-cement will be 8:4:3 and 2 parts water.

Reinforced concrete roof of a house

Formwork is made from unedged boards. They are laid end to end along the lower edges of the I-beams, then roofing felt is laid. The next stage of work is the laying of a reinforcing structure consisting of reinforcement, which is placed both along and across the beams. For these purposes, steel rods with a diameter of at least 1 cm are used. The pitch for mesh elements made of reinforcement should be 20 cm. The reinforcement is carefully fixed with steel wire or welding to prevent displacement of the elements during the process of pouring the structure.

Pouring concrete is carried out in different ways, but always until the entire surface of the roof under construction is covered with concrete. The laid mixture is carefully compacted (so as not to damage the structure) with a vibrator. The resulting structure is dried naturally.

During the construction of the roof of a modern house, thermal insulation is required, which reduces the overall heat loss of the house through the roof. Flat roofs can be insulated, unlike other types of roofs, both from the inside and outside. Initially, during construction, insulation is done on the outside, and the interior can be done later, when the structure is in use. Mineral construction wool is used as insulation. Also, another insulation material—expanded polystyrene—is becoming increasingly popular among builders. It is mounted on wooden blocks, which are placed in increments of 30-40 cm. And the slabs are glued to the wood with mastic or special glue.

The construction of a flat roof is completed by laying waterproofing. Usually they use special material sold in rolls.

The flexible roof covering itself is laid with an overlap of 7-10 cm.

Important: each layer of flexible roofing building material is laid in such a way that the bottom seams of the elements of the rolled flexible building material are placed closer to the middle. All coating strips are laid in the same direction.

Device and types

There are several options for arranging the roof. Among them:

- Non-operational type - ends with laying a waterproofing coating (which is not resistant to mechanical damage) and does not imply any further operational functions.

These are usually rolled, soft materials. The structure is designed to accommodate several people for the necessary seasonal inspection or repair work and nothing more. - Useable view - in addition to protection from natural influences, this design can turn into additional usable space. The finishing coating in this case is used in the form of wooden flooring or paving stones, decking or tiles. Crushed stone, pebbles or gravel are also popular.

- Inversion view - can be exploited or not. Its design is completely different from the first two in that the order of the “pie” is completely opposite. Fertile soil with various plants is often placed on the roof as the last top layer. The result is a spectacular landscape design, which has been very popular in recent years.

The structures are easy to assemble and are durable and wear-resistant.

Video for DIYers

A video collection will help you consolidate information about the difficult task of constructing flat roofs:

We hope that the information we presented will help future roofers who decide to practice with their own hands in constructing a not-so-simple design.

There are many conditions for the proper construction of a flat roof, but they must be observed for ideal operation and long service. Information about the intricacies and specifics of constructing a flat roof will help not only determined craftsmen, but also owners of country estates who resort to the services of third-party construction organizations.

Frame

To create a flat roof frame, choose beams with a cross section of 100-160 mm. They are laid according to the standard for interfloor slabs. Suitable for work are elements made from several composite (glued) parts, as well as lumber of the required (fixed) size and length.

Installation of a flat roof necessarily (by default) implies a slight slope of the future roof by 1-6 degrees. This is necessary so that the collected water from precipitation and melting snow flows freely towards the drain and does not stagnate. Professionals recommend installing the slope in several ways:

- the beams are laid horizontally, and the angle of inclination is created by laying out thermal insulation material of different thicknesses (on top of the frame);

- beams with different allowances (height) are specially taken into work;

- the beams are laid immediately with the required slope - in this case, it is recommended to create a suspended ceiling inside the room or install lathing, then a flat, horizontal ceiling;

- The beams are laid horizontally, then to create the desired slope, wooden overlays of the required sizes are nailed to them.

The most common option is to use beams with an already prepared slope. A reliable method of installation is to secure a reliable timber purlin along the top of the load-bearing wall (can be replaced with durable boards). It will carefully lift the entire frame of beams on one side and provide the required roof slope.

There is another way, when they create short radial beams. They are pulled from the double central one (diagonally).

Beam calculations

The number of beams to create a flat roof is calculated according to the expected load. SNiPs do not have clear instructions on choosing the section of boards; the main thing is not to skimp on the thickness of the lumber.

The specific pitch between the beams also depends on the further load on the structure and can range from 50 mm to 120-125 mm.

The nuances of leaning on walls

The frame of beams is mounted with obligatory emphasis on the walls, as in the assembly of interfloor ceilings. In a frame or wooden structure, the beams are laid with support on a crown (on top) of logs or frame.

When designing a building from brick or blocks, first create a mauerlat (from timber measuring 150 mm by 100 mm-150 mm), fix it on studs or anchors. Next, a frame of beams is attached to it, in which undercuts are made in advance for a tight connection with the Mauerlat. Fixation is carried out using reliable metal corners and nails.

Important! It is necessary to reliably protect the Mauerlat - builders lay out a layer of waterproofing between it and the walls. For example, roofing felt, this guarantees wear resistance and strength.

Flat roof design.

Design is one of the main characteristics of a building that determines operating conditions, service life and maintenance and current costs.

The choice of one design or another largely determines the possibility of using the attic as an additional living space, resolves the issue of the need for insulation and determines the type of roofing.

A flat roof is a specific option that does not allow the attic to be equipped as a living space (due to its absence).

But it offers a lot of opportunities for using the territory as an auxiliary site, a place for placing equipment, or as a private recreation area, separate from the external space.

A flat roof can provide many interesting possibilities in this regard, but there are limitations to its use.

The main feature of a flat roof is its almost horizontal surface. of such surfaces is low - up to 8 degrees, it is needed only for drainage of rain or melt water.

According to the conditions of the plane's location, there is practically zero wind load (if properly constructed without overhanging edges) with a maximum snow load.

At the same time, the roof structure has a complex multi-layer structure, ensuring the tightness of the coating and the working condition of the insulation.

The most favorable operating conditions for flat roofs:

- Small amount of snow in winter. The most successful use is in regions with warm or little snowy winters, when removing snow from the roof does not cause difficulties.

- The force of the wind does not have a significant effect on the roof, so the construction of such roofs in areas with strong or gusty winds is permissible.

IMPORTANT!

For areas with cold and snowy winters, the use of flat roofs is recommended only for small utility buildings with a relatively small area.

The use of flat roofs on residential buildings is more common in southern regions, where there is no problem with high snow pressure in winter.

Flat roof

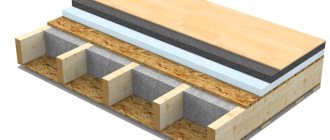

The structure of the roofing pie

There is no specific, classic composition of the roofing pie of a flat roof. The structure of layers is most often based on the following factors:

- Roof purpose;

- Floor type;

- Roofing material.

The decisive factor that determines the composition of the roof from the very beginning of construction is the purpose of the roof. It depends on what material is needed for the construction of the floor, how exactly it will be insulated, and what is the optimal coating material in this case.

Insulation of a flat roof made of soft roofing is done from the outside, since this method is much more convenient and reliable in terms of the tightness of the pie.

The general insulation technology looks like this:

- Base (concrete, wooden floor);

- Vapor barrier film;

- A layer of insulation;

- Top layer of waterproofing;

- Roofing.

This is a general plan; in practice, it is often supplemented or complicated in order to provide more reliable protection against water penetration or the formation of cold bridges.

Roofing pie

One of the options for installing a flat roof is inversion roofing. This is a relatively new type of pie design that takes into account the disadvantages of conventional options.

The fact is that a common problem with flat roofs is water seeping through the insulation into the ceiling and the appearance of stains and stains.

To eliminate this phenomenon, inversion roofing is used, when a reliable waterproofing carpet (often multi-layered) is installed between the ceiling and the insulation.

The composition of the pie is constructed as follows:

- Overlap;

- The waterproofing preparation layer is usually a construction primer;

- Waterproofing carpet;

- Geotextile layer;

- Insulation (optimally extruded polystyrene foam);

- Top layer of geotextile;

- Ballast fill layer of gravel.

If necessary, a rigid covering can be laid on top of the ballast layer to maintain uniform ballast thickness and ease of movement.

Inversion roofing cake

Is the roof based on wood or concrete?

Wood or concrete can be used as a base for a flat roof.

Both options are acceptable, but not interchangeable. Thus, a wooden base is used for small buildings, most often for economic purposes.

If there is no heating, then such a roof is not insulated; a simple rafter system is made and a roofing covering is laid on top. However, wooden floors are also used for residential buildings.

This is due to the desire to lighten the roof and remove excess load from the walls (for example, with the frame construction method).

CAREFULLY!

This option imposes certain restrictions on the functionality of the roof, excluding the presence of heavy equipment, a large number of people, etc. on it.

Most often, for used roofs of residential buildings, a concrete slab is used as a base. This overlap has a number of significant advantages:

- Reliability;

- No noticeable deformation from loads;

Since it is done outside, it ranges from simple painting to installation of a stretch ceiling.

Roofing pie - installation and insulation characteristics

A flat roof is also popular because it can have a different composition of the roofing pie. Depending on the type of device, installation and insulation characteristics may differ.

On top of the timber

The simplest option for arranging a roof is the classic one:

- assemble floor beams;

- lay the sheathing, taking into account the required step;

- attach continuous sheathing made of plywood, OSB or DSP;

- then a layer of vapor barrier is laid, the joints are connected with construction tape or a stapler;

- Next comes an insulating layer of mineral wool or modernized polystyrene foam.

The last layer is waterproofing, for example, from a polymer membrane. It is a single-layer roofing covering that guarantees durability and resistance to weather, climatic conditions and UV radiation. The large width of the roll allows you to minimize the number of seams at the joints.

The membrane is fixed to the roof using fasteners or ballast is used:

- gravel or pebbles - for any type of roof;

- durable paving stones - for exploited options;

- soil - for landscaping.

Do not forget about the maximum load of the finished roof.

Important! The use of PVC membrane and EPS insulation simultaneously leads to the destruction of the former; a layer should be laid between them that isolates them from each other - glass or geomaterials.

Changes can be made to the classic version if the top layer of the roof is made of EPDM membrane or fused waterproofing. In this case, plywood sheets, either DSP or OSB are placed between the finishing layer and the insulation. It is advisable to use adhesive-based roofing felt when assembling Euro - it is suitable for cold installation.

Installation of a built-up roof requires the use of a burner (gas), but according to fire regulations, it is prohibited when working on objects made of wooden materials.

Interbeam

The second option for assembling the roof differs in that it involves laying insulation in the voids between the beams. This is especially convenient if an EPDM membrane with adhesive-based fasteners is chosen as waterproofing. The cross-section of the roof pie will look different:

- installation of floor beams;

- a vapor barrier is laid between the beams;

- then comes a dense layer of insulation;

- installation of sheathing (according to situation and desire);

- sheathing (solid) with plywood sheets, DSP or OSB.

The last layer is waterproofing. The design guarantees durability and weather resistance.

Internal

The next option has its own peculiarity - the supporting structure of beams is sheathed with DSP, OSB or plywood, then waterproofing is applied. The remaining layers of the roofing pie are applied from the inside - from the side of the house. Installation in stages:

- final top layer – waterproofing;

- lathing (solid);

- beam structure;

- installation of a rough ceiling;

- laying and fixing insulation;

- vapor barrier filing;

- ceiling is clean.

A nuance - for internal insulation, for additional sheathing, choose wooden slats, which are attached to the ceiling in increments of up to 40 cm.

Inversion roof

An original and non-standard solution is a durable inversion roof. It has an increased service life due to the fact that the waterproofing layer is covered with insulation. The destructive effects of bad weather, oxygen and UV rays are completely eliminated. The installation diagram for a flat inversion roof pie is as follows:

- beam assembly;

- installation of continuous sheathing;

- laying a waterproofing layer;

- separating layer in the case of using a PVC membrane;

- installation of insulation (EPS);

- geomaterial - for separation;

- finishing coating in the form of ballast, decking, tiles.

This option is indispensable for arranging a spectacular landscape design on the roof.

From the video you will learn what an inversion flat roof is and how good it is:

Flat roof in a private house. How difficult is it to maintain a flat roof?

The great French architect Le Corbusier derived a formula from the “five starting points of modern architecture”, and here is one of them: “the house must have a flat roof in order to equip it with a solarium, sports ground, swimming pool, terrace or garden.” Theoretically, many of us are not averse to following this rule, especially the owners of small plots, viewed from all sides by curious neighbors' eyes. However, we understand that we live in a harsh climate: will a flat roof withstand it? And how difficult is it to care for her?

This green roof of a FORUMHOUSE member with the nickname victorborisov in the photo is five years old, “flying great.” When asked how much time he spends on care, a forum member is surprised:

Victorborisov

I don’t spend any money, but do I need it? No, well, you need to mow the lawn on the ground, so it makes no difference if it’s on the roof or on the ground.

As for roofing, flat roofing is inexpensive and reliable. Snow will never fall on your head and it is easier to drain rainwater from it (less drainpipes). It is completely sealed and will never leak. Snow in winter is free thermal insulation, lies on the roof until spring, then melts on its own.

Vladimir Shalimov, Ph.D., leading technical specialist at TECHNONICOL, also claims that caring for a green roof is no more difficult than caring for a lawn (plus maintenance of possible engineering equipment and checking water intake funnels).

Vladimir Shalimov

Look at the roofs of apartment buildings in modern urban areas. Exactly flat.

To avoid problems with leaks, which all individual developers are afraid of, it is enough to first calculate the snow load, do not forget about the drainage system and drains, and choose the right materials for installing a flat roof.

Our expert claims that in 95% of cases, problems with flat roofs in multi-story buildings are caused by illiterate actions of hired workers who break through the waterproofing with shovels when removing snow. In a private home this is almost impossible. By the way, it is better not to remove snow from a flat roof at all - for a properly designed roofing, this is a big bonus in terms of saving energy resources and heating the house.

Vladimir Shalimov

From the point of view of thermal insulation design standards, snow cover is not involved in the thermal engineering calculations of house roofs. However, snow has long been effectively used on various structural elements of domestic buildings: roofs, rubble, etc. From a technical point of view, this is due to the fact that the thermal conductivity coefficient of snow in favorable conditions approaches the thermal conductivity of roofing mineral wool insulation, amounting to λ = 0.046 W/mK.

Data received from the owners of individual residential buildings showed that in snowy winters, in the presence of stable snow cover, coolant consumption is reduced by 20-25%. At the same time, the safety of the roof is completely preserved, because an avalanche of snow is fundamentally impossible.

Vladimir Shalimov

Practice shows that in central Russia, snow on the roof can lie all winter and melts in the spring on its own. It does not require any special care. Of course, many of my customers try to clean their roofs in winter, but when cleaning there is a risk of accidentally damaging the roofing.

Finish coating

When arranging a flat roof on wooden beams, one should not forget that this option is a fire hazard and has limited load-bearing capacity in comparison with metal and brick structures. The best waterproofing agent in this option is a polymer membrane, and hot installation is not for timber.

As a rule, the flooring on a roof in use is laid on a ready-made waterproofing layer. When choosing a material you should consider:

- lightness of finishing materials;

- the weight of the flooring must be uniform to avoid damage to the waterproofing;

- the coating must be ventilated to avoid the “steam room” effect;

- the possibility of disassembly if there is a need for access to the waterproofing layer;

- the characteristics of the material must be suitable for “street” use - withstand weather conditions, precipitation, etc.

For the finishing coating of a flat roof, it is advisable to choose the lightest materials with high qualities of strength and durability.

Most suitable:

- soft polymer membrane – service life up to 50 years;

- decking – lightweight tile modules with a wooden top layer, non-slip, safe, this is an excellent option for a used flat roof;

- terrace boards, WPC profiles – improves the appearance, it is pleasant to walk on barefoot, wear-resistant;

- paving slabs made of rubber and polymer materials are lightweight, durable with an impressive appearance.

Innovative developments are constantly expanding the list of materials for improving roofing, including flat ones.

Flat built-up roof. Fused roofing: installation technology, choice of material

One of the most common options for covering flat roofs is the installation of a built-up roof. The use of roll materials allows you to create a roof covering with your own hands quite simply and quickly.

The roof of any building, regardless of its purpose, is created to perform certain protective functions, including:

- protecting the building from precipitation;

- preservation of heat during the cold season;

- protection against overheating in summer.

Thus, any roof must meet very serious requirements for strength, tightness and thermal insulation. All of them are specified in the relevant standards and regulations relating to roofing structures. Today there is a huge selection available on the building materials market. Each material has its own strengths and weaknesses, service life and cost. Therefore, it is very important to familiarize yourself with all the characteristics of the roofing material you are purchasing before purchasing.

Roof selection

If we talk about the materials that are used to create soft roofs, they can be classified according to several indicators.

For example, such roofs differ according to the type of base:

By type of binder:

The previously very popular first generation rolled materials (roofing felt) are today used only as a lining and waterproofing layer. The undoubted advantages of roofing felt include its cost, but, unfortunately, in all other indicators it has unsatisfactory results, which has led to a decrease in its popularity among developers.

Today, to create a truly high-quality roofing covering, materials based on polyester or fiberglass are selected, and bitumen-polymer compositions are used as impregnation. There is no generally accepted GOST for such materials, so each manufacturer has its own specifications.

The largest manufacturers mark their products according to a three-letter designation.

The first letter in the marking indicates the type of base:

The second is the type of external coating:

The third letter describes the bottom covering:

Fused roofing technology

Before installing the built-up roof, the foundation should be prepared. The first layer of the roofing pie is a vapor barrier, which is laid directly on the floor slabs. For these purposes, welded or film materials are used. Attention! It is important to know which side to lay the vapor barrier on. In places where the vapor barrier adjoins the vertical elements, the film is applied to the walls, raising it above the level of the future thermal insulation layer. On horizontal surfaces, the vapor barrier film is laid overlapping, and all seams are sealed.

Before you begin laying waterproofing, you must check the moisture level of the screed. Work cannot continue if the cement is not dry enough. Shrinkage seams must be additionally covered with strips of waterproofing 15 cm wide. In this case, it is better to use rolled material with coarse-grained topping, the side of which is placed down.

At the location of the water intake funnels, additional “patches” are laid with square pieces of insulation with a side of 70 cm.

If a roof made of fused materials is being repaired, the base preparation should be carried out according to the following scheme:

- remove debris from the surface;

- remove dust from the surface of the old coating as much as possible;

- carefully inspect the coating to identify bubbles and swellings;

- discovered bubbles must be opened, and then the area must be heated to fuse it.

Necessary materials

To carry out the work you will need the following tools:

- gas burner for roofing work;

- roofing knife;

- brushes for cleaning the base and applying primer;

- putty knife;

- stitching roller;

- overalls - overalls, protective gloves, boots with thick soles.

Setting up a drain

- The reliability of the roof is also related to its slope. You will not find completely flat roofs anywhere, because there is a certain slope for water drainage. Flat roofs have their own percentage for this slope.

Thus, it is not recommended to install a roof that has less than a 2% slope. The best option is a flat roof slope of 2.5%. In this case, the design removes water in a short time. At the same time, roofing materials for flat roofs are in more comfortable operating conditions. It should also be noted that even if there is a small defect, this will not harm the slope.

- The next important roofing element is the drain. It has its own so-called route and eliminates moisture and snow. Flat roofs are most often equipped with an internal drainage system. The roof surface contains special drainage funnels (fittings) that effectively handle water even in heavy rain. This prevents flooding of the roof.

How to raise rafters up

The comments suggested a great way:

Pulley hoist. Cheaper and faster. We install a 100*100mm stand. 6M vertically. We temporarily attach it to the outer wall. We stack the trusses under this wall from the outside.

We lift them one by one with a pulley hoist. Then we wrap it around this crane stand and release the pulley and lower it onto the walls. And so are all farms. Then we simply take them apart and move them along the walls throughout the house.

The main thing is to cling the rafters to the desired side (mirror image).

A pulley block is also called a double block roller. Sold in climbing equipment stores. You need two of these. And three carbines. Ropes 30 meters. The whole set costs about 3,000 rubles. We use it all the time to lift walls, trusses and beams. Up to 400 kg can be lifted.

average cost

The cost of constructing a flat roof is determined by a combination of many factors (read more about pricing for flat roofs here).

The structure in use requires a strong and durable foundation.- If you plan to develop a lawn, you need to take care of anti-corrosion protection and sufficient waterproofing.

- An unused roof does not need a base for the upper platform; the main expenses will go to installing a high-quality roofing pie.

In addition to the cost of building materials, the price of the craftsmen’s work is taken into account (highly dependent on the region). A square meter of operated turnkey roofing costs 3.5-5 thousand rubles. An unused option will cost less: 2-2.5 thousand per sq.m.