Autonomous sewerage is an excellent alternative to traditional cesspools. Installing a septic tank is the most effective solution in cases where it is not possible to connect to a centralized system. The choice of containers for septic tanks is quite large. Often, owners of country houses, cottages, and summer cottages choose plastic or metal tanks. If you don’t want to spend money on building a sewer system, you can build a system with your own hands from reinforced concrete rings, bricks, or even worn-out car tires.

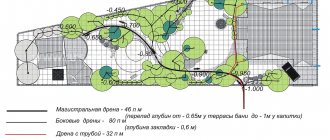

The simplest septic tanks are only suitable for storing wastewater. As soon as the container is full, you need to call a sewage truck and pump out the sewage. More convenient to use are autonomous sewers with soil treatment or deep biological treatment. To set up a full-fledged system, you must first draw up a project, which will include diagrams for the location of wells, connections of pipes and other equipment. Proper implementation of such a project will result in a functional sewer system that will last for many years.

Recommendations for maintenance and operation

For sedimentation tanks with periodic pumping of wastewater, maintenance comes down to monitoring the waste entering the tank and its timely removal so that overflow does not occur.

- It should be surprising that the liquid level in the chamber does not increase when waste is constantly drained in the house. It is possible that the sewer system may depressurize and runoff into the soil, contaminating the aquifer.

- You need to dig a trench above the drain pipe, check its integrity and the tightness of the connection with the container. If a leak is detected, it is necessary to eliminate and continue operation of the structure.

- In chambers without pumping out discharges it is necessary to control:

- the level of sludge sediment in the receiving chamber when it accumulates up to the corner pipe of the water seal;

- operation of the aeration unit to maintain the vital activity of bacteria;

- water level in the 3rd chamber; if it increases, the filtration field may become clogged.

When planning an independent installation of a septic tank in a private house, photo and video materials will help you study wastewater treatment technology, types and designs of treatment facilities, and construction methods.

General information about autonomous sewerage

The direct purpose of a septic tank is to accumulate wastewater. After filling, the contents must be pumped out and removed, then the cycle repeats.

A septic tank, being a storage tank, is part of an autonomous sewer system, which also consists of an internal and external pipeline.

In advanced houses, additional containers, infiltrators and filtration fields are used.

The most productive systems have chambers with bacteria inside, which help process waste into peat and remove harmful substances such as ammonia from waters.

Structure of a biological treatment septic tank

For such systems, a large list of materials is used, the properties of which determine the characteristics of the entire system.

Connecting a septic tank to the sewer system

Even if the septic tank is made from ordinary barrels, this does not mean that access to a sewage truck will not be required.

So it is important to think carefully about the place where the septic tank will be located. It is important to ensure that it is as easy as possible for a fellow assinizer to get to your poop.

After this, you need to start digging a trench, the size of which depends on the size of the barrels, as well as on the climatic conditions inherent in your place of residence

Pay special attention to the fact of freezing of the soil and ground and its permanent frozen state (for the northern regions). If it is located less than 80 centimeters apart, then, in principle, there are no special differences when constructing a septic tank, you will only need to make a special layer called a fur coat

It consists of tar paper, sand, and crushed stone. Thanks to it, freezing of drains will not occur, even when frosts are particularly severe. We should also not forget that it is best to carry out sewerage installations in the winter, when the frozen ground is not yet prone to thawing, which can cause inconvenience. The trench is also covered with sand and small gravel, both from below and from above.

There are other subtleties that need to be taken into account. For example, it is necessary to avoid turning sewer pipes as much as possible, but if they do happen, then no more than ninety degrees, and even then with the possibility of convenient cleaning of corner joints due to the construction of a special rotary well. The slope of the pipe that approaches the barrel should not exceed a couple of centimeters for each meter

It is important to avoid places where damage to the pipe is possible, and you should retreat at least a third of a meter from the surface.

Septic tanks by type of material

All treatment tanks can also be divided into categories and according to the type of material used for their manufacture. Since the use of certain types of containers is relevant for one type of soil and may be completely unsuitable for another. Therefore, it is necessary to analyze all the containers offered by the market.

So, we compare septic tanks by type of material. The reservoirs are as follows:

- Brick treatment systems;

- Concrete tanks;

- Metal tanks;

- Plastic containers.

Brick septic tank

The most standard type of treatment tank in a summer cottage or suburban area. The popularity of such containers is due to the ability to use waste building materials, which allows saving the family budget.

When building a septic tank from brick, it is necessary to ensure the tightness of its walls, since building stone can create cracks and gaps during installation. To avoid this, you can use a sealant or penetrating mastic.

Concrete tanks

This type of treatment plant is more powerful and durable.

A feature of the construction of concrete tanks is the need to dig a pit. If the septic tank is very large, you will have to use complex equipment.

Two types of treatment facilities can be built from concrete:

In the first case, a pit is dug and reinforced concrete is poured into the installed formwork. In the second case, the septic tank is assembled from concrete rings. They are mounted one on one.

Metal septic tanks

The rarest type of wastewater treatment tank. Analysis shows that such containers have more negative features than positive ones. And the most important of them is metal corrosion, which will one day lead to depressurization of the cleaning system.

PVC septic tanks

A comparison of septic tanks made of different materials clearly speaks in favor of plastic. Such containers are made from sand-reinforced polymers using the hot extrusion method (extrusion under high pressure). The result is a strong container that can withstand large mechanical loads of compression and tension. Especially if the tanks have special stiffening ribs.

The features of such tanks are entirely positive:

- Strength and durability;

- Resistance to aggressive environments;

- Environmental friendliness of materials;

- Featuring 100% tightness of the treatment system;

- Light weight.

The last advantage can also play the role of a disadvantage. Thus, plastic containers for a septic tank run the risk of being thrown out of the ground under the influence of temperature changes and groundwater. To prevent this from happening, they (PVC tanks) are installed in special pits, followed by concreting. You can also use a special anchor system to install them.

There are also septic tanks made from any available materials. But this type of equipment is not professional and is used most often in small dachas, where the owners come periodically to harvest crops or prepare for the winter. In this case, simple barrels, car tires, etc. can be used.

Selection and installation diagram

Barrels can be of any size

However, when choosing, it is important to consider the number of family members. A 250 liter capacity is enough for a family of two or three people. The product should not have too thin walls. Installation is carried out in compliance with all sanitary standards (the distance to residential buildings, sources of drinking water, roads is maintained). It is not advisable to use containers with a capacity of less than 200 liters. Installation work includes:

Installation work includes:

- Preliminary preparation of barrels - sawing holes for pipes. A ventilation window is cut into the lid of the first container for a riser through which air will flow.

- Preparation of the pit - backfilling with a sand cushion, pouring a concrete base with metal brackets for fastening containers.

- Installation of barrels and connection of pipes. Silicone cannot be used as a sealant!

- Backfilling of the pit and compaction of the cement-sand mixture.

Problems and consequences of improper installation of a septic tank

Consequences of failure to install a septic tank:

- 1. Rapid equipment failure.

- 2. Waterlogging of the area.

- 3. Pollution of the territory with sewage and harmful microorganisms.

- 4. Financial costs, the level of which will lead to the failure of maintaining a septic tank.

What problems cause the above consequences?

- 1. Floating of the septic tank. The structural elements must be fixed, in particular, the treatment tank is fixed on a concrete pad; additionally, belts, cables, and nylon ropes are used.

- 2. Flooding of the sewer system. The treatment structure must be highly airtight.

- 3. Damage to the septic tank due to fine groundwater solids. The tank, pipes, water supply and discharge pipes must be made of high-strength plastic. Additionally, they create a protective coating for the septic tank or use geotextiles for softening.

- 4. The entry of the contents of the septic tank into groundwater with sewage and harmful microorganisms is the result of the second and/or third point.

How to make and install at the dacha with your own hands

Step-by-step actions for arranging a septic tank from barrels include:

1) Selection of plastic containers in accordance with the prepared project:

- when choosing tanks, the criterion for strength is the thickness of the walls of the product, which is 10-20 mm, depending on the volume of the chamber;

- for the seasonal residence of a family of three, there is enough capacity to receive 4 m3 of wastewater, followed by pumping with a sewer truck after filling;

- It is advisable to make a septic tank from barrels in which liquid materials were previously transported. In addition to the simple option, a single-chamber sump with pumping, you can make a drain for your home from two or three containers without pumping, when the volume of waste exceeds 1 m3/day.

- For complete wastewater treatment, if there is not only a toilet in the house, but also a bath, shower, and a water source in the kitchen, you can use an expensive, ready-made multi-chamber septic tank design.

2) We begin construction work. We dig a pit for a structure made of containers manually or using an excavator.

3) At the bottom of the pit we make a concrete slab on a drainage layer of crushed stone and sand.

4) Place the containers on the slab and secure them with ties and anchor bolts.

5) The flow of wastewater in 2-3-chamber structures is ensured by dispensers, and after purification, the water enters the drainage pipe to the filtration field. 6) Install an aerator in a container with aerobic filtration.

7) For single-chamber wastewater treatment options with pumping, we limit ourselves to connecting water sources in the house to an external sewer pipe:

- We attach the pipe to the container and the home water collection system to the outer pipe using PVC fittings;

- on the tanks, up to the surface of the ground, we install a neck made of a plastic pipe with a diameter of 250 mm for pumping out wastewater and attach it to the chamber with glue and clamps;

- We mount the hatch cover on the neck;

- We install a ventilation pipe on the surface of the container with a rise above ground level of 1.5 meters. First we cut a hole for the pipe, fasten the hood to the chamber with clamps, using plastic glue and sealant.

Existing types and classification

Depending on the volume of wastewater flow, single-chamber septic tanks (up to 1 m³ per day), as well as two-chamber structures (up to 10 m³ per day) and three-chamber devices (more than 10 m³ per day) are distinguished.

Among other things, different types of autonomous sewage systems differ markedly in the method of wastewater processing and the purity of recycled water; they can be energy-dependent and overflow, and are also made of different materials.

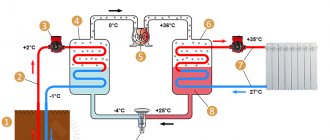

Aerobic and anaerobic are autonomous wastewater treatment systems, which differ from each other only in the bacteria involved in the processing of sewage water.

In the first case, the wastewater is treated in the presence of oxygen, which enters through the vents or is delivered by a compressor and aerators.

All anaerobic septic tanks function due to the microbiological decomposition of the organic component by bacteria in an oxygen-free environment.

Deep treatment facilities are aeration installations for processing wastewater, which can be discharged onto the terrain and, if UV disinfection is available, into water bodies.

In separate chambers of such structures, aeration devices are installed that saturate the wastewater with oxygen using compressors. There is no need to develop a special area for soil post-treatment of discharged water.

The average price is 102 thousand rubles (Eurobion-8 PS model).

Septic tanks with soil post-treatment belong to the category of anaerobic plants. The efficiency indicators of oxygen-free decomposition of wastewater are not high enough, so a two- or three-level treatment option with additional treatment in the soil should be used.

Such post-treatment can only be used on fairly well-filtering sandy loam and sandy soils, characterized by a low level of water passage. The average price is 55 thousand rubles (model ROSTOK Cottage).

Non-volatile septic tanks are characterized by completely autonomous operation, quite affordable cost, ease of installation and maintenance during use, and the absence of complex devices in this design allows the structure to be used for a long time.

Non-volatile models do not need to be preserved for the winter, but soil post-treatment of recycled wastewater is mandatory. The average price is 59 thousand rubles (Kedr septic tank).

Overflow septic tanks are quite simple in design. Such autonomous wastewater treatment systems are represented by several separate containers connected to each other through plastic pipes, which ensure the unity of the design.

High quality sewage treatment in overflow systems is achieved by combining several filtration options. The average price is 32 thousand rubles (Eurolos ECO-3 model).

Septic tanks made of concrete rings are a budget-friendly and quite worthy option for creating an autonomous sewer system with your own hands.

In such facilities, sewage wastewater treatment is carried out by microorganisms. Installation of a pair of cleaning chambers is necessary when serving several users, but the level of wastewater treatment is not high enough. The average price is 45-50 thousand rubles (two tanks with 4 rings each).

Plastic ready-made septic tanks are popular treatment facilities, characterized by their affordable cost, durability, guaranteed tightness, simplicity and ease of maintenance. Such models cost consumers less than concrete septic tanks, but independent installation and subsequent operation require compliance with certain rules and regulations.

Plastic storage tanks are optimally suited for arranging sewage systems for seasonal living in suburban conditions. The average price is 90 thousand rubles (Evo Stok Bio model).

Monolithic concrete septic tanks have guaranteed impermeability and absolute tightness, can be installed in areas with any groundwater level, and also have an increased capacity.

During operation there are no odors or noises, which is due to the complete soundproofness of the housing. The structure does not need to be preserved for the winter and operates autonomously, and standard cleaning of the tank is carried out every one and a half to two years.

The average price is 60 thousand rubles (model “Favorit 2P”).

All single-chamber septic tanks have the simplest possible design and have a volume that is a multiple of the daily discharge. In terms of functionality, such autonomous wastewater treatment facilities are noticeably inferior to multi-chamber septic tanks, and therefore are used most often for the purpose of seasonal operation.

Single-chamber storage tanks can be sealed or drainage type, and the main disadvantage is the need to pump out accumulated sediment quite often. The average price is 65 thousand rubles (Tver model).

Two-chamber septic tanks are represented by a pair of settling tanks, and the bulk of all sediment settles in the first chamber, which helps prevent secondary contamination of clarified waters with decay products. Some models have a filter installed in one of the chambers, which increases the level of wastewater treatment.

Installation and maintenance of metal septic tanks

A metal septic tank, in turn, is distinguished by its weight, so, as a rule, it is impossible to do without special equipment

In any case, it is first important to dig a pit, remembering to step back at least five meters from the house. Then crushed stone is poured onto the bottom, and a concrete foundation is placed on top of it.

Of course, everything depends on the size of the container that needs to be placed in the pit. The tank is firmly attached to the concrete, as a result of which it will not be pushed out by groundwater, and such a danger always exists, even with heavy metal solutions.

To install the container correctly, it must first be filled with water.

By the way, it is important to choose a container of the correct volume. For example, 4 people require 2.5 cubic meters

The volume is calculated as follows: take 250 liters per person and multiply by three.

The fact that a septic tank is installed does not mean that you can forget about it

It is important to clean the containers once or twice a year by calling a sewage disposal truck, but once every seven to ten years it is necessary to completely replace part of the soil

How does a sewerage scheme work?

Regardless of the number of containers, septic tanks work the same. Once in the first chamber, the wastewater is divided into heavy fractions, which settle to the bottom, and light fractions, which remain on top. Mechanical cleaning is complemented by the activity of anaerobes, which convert organic matter into gases. They escape into the atmosphere through the drain pipe of the internal sewage system or the ventilation riser in the septic tank.

A fatty film forms on top. To prevent it from getting into the next chamber, a tee is installed on the overflow, which is lowered into the drains below the film. There may not be a second tank, then the wastewater purified by gravity and anaerobic methods is discharged to filtration facilities, where post-treatment occurs. Such structures are common among summer residents who come only on weekends. But it should be borne in mind that a single-chamber septic tank quickly silts up and needs to be cleaned more often.

The processes in the second chamber do not differ from those that occurred in the storage chamber. Here, the pre-treated wastewater becomes even lighter. Silt falls to the bottom, and the remaining organic matter is processed by anaerobes. Then the water is sent by gravity for additional filtration or goes into an aerobic septic tank. This is where the final cleaning takes place.

Features of installation work

First, using a jigsaw, holes are cut in the barrels for installing overflow pipes and a ventilation riser. The hole intended for connecting the incoming pipe into the chamber is made at a distance of 20 cm from the top edge of the container. The outlet hole is made on the opposite side of the chamber 10 cm lower than the inlet hole, that is, at a distance of 30 cm from the top edge of the barrel.

Installing the overflow pipe into the hole cut in the first plastic settling barrel and filling the gap with two-part epoxy sealant

The ventilation riser for removing gases is installed only in the first settling barrel. It is also advisable to provide this chamber with a removable lid, which allows periodic cleaning of the bottom from settled solid particles. In the second settling barrel, two holes are made at the bottom, located at an angle of 45 degrees relative to each other, to connect drainage pipes laid along the filtration field.

Stage #1 - calculation of dimensions and construction of the pit

When calculating the dimensions of the pit, it is assumed that there should be a gap of 25 cm around the entire perimeter between the barrels and its walls. This gap will subsequently be filled with a dry sand-cement mixture, which will serve to protect the walls of the septic tank from damage during seasonal soil movement.

If you have the funds, the bottom under the settling chambers can be filled with concrete mortar, providing the “cushion” with embedded metal parts with loops that will serve to secure plastic containers. Such fastening will not allow the barrels to “float” through the veins, and thereby disrupt the established autonomous sewage system.

The stepped bottom of the pit must be leveled and covered with a layer of compacted sand, the thickness of which must be at least 10 cm

Stage #2 - installation of plastic containers

Barrels are placed on the prepared bottom of the pit and secured with straps to metal loops embedded in concrete. All pipes are connected and gaps in the holes are sealed. Fill the remaining space between the walls of the pit and the containers with a mixture of cement and sand, not forgetting to compact them layer by layer. As the pit is filled with backfill, water is poured into the containers to prevent deformation of the walls of the barrels under the pressure of the sand-cement mixture.

Preparing the hole in the second settling barrel to connect the overflow pipe. In this version, the flange is connected not from the side, but from the top

Stage #3 - setting up a filtration field

In the immediate vicinity of the septic tank, a trench 60-70 cm deep is dug, the dimensions of which should allow the placement of two perforated pipes. The bottom and walls of the trench are lined with geotextile fabric with a reserve that is necessary to cover pipes covered with crushed stone on top.

A 30-centimeter layer of crushed stone is poured onto the geotextile, the bulk material is leveled and compacted

Drainage pipes are laid with perforations in the walls, which are connected to the second settling barrel. Then another 10 cm of crushed stone is poured on top of the pipes, leveled and the backfill is covered with geotextile fabric so that the edges overlap each other by 15-20 cm. Next, all that remains is to fill the filtration field with soil and decorate this place with lawn grass.

As you can see, any summer resident can make a septic tank from barrels. Just remember that this structure is designed for the collection and disposal of small amounts of liquid household waste.

Operating principle of the treatment plant

Septic tanks are sewer facilities that almost completely recycle wastewater, breaking it down into safe components.

All work on the transformation of human waste is assigned to microorganisms. Aerobic and anaerobic bacteria gradually convert unappetizing sewage masses into water and activated sludge.

Aerobic bacteria can work only in the presence of oxygen, but anaerobic microorganisms successfully perform work in sealed containers.

Such a vessel reliably cuts off unpleasant odors from wastewater, but in order to include aerobic microorganisms in the work, you will need to organize forced air injection into the septic tank.

In practice, such a wastewater treatment system consists of several containers or compartments.

The entire processing process can be divided into several main stages:

- Primary accumulation of wastewater , separation of contaminants that are not biodegradable.

- Processing of remaining wastewater using bacteria , as a result of which the contents of the septic tank decompose into water and neutral sludge.

- Additional treatment and sedimentation of wastewater , during which sludge accumulates at the bottom in the form of sediment.

- Disposal and disposal of treated wastewater.

All this takes time. Wastewater gradually moves from one section of the septic tank to another through overflow holes or special tubes.

Sludge obtained as a result of biological processing of sewage contents is called neutral or active.

Both names can be considered correct. This mass is neutral because it does not pose a danger to the environment.

Settled wastewater processed by bacteria is disposed of in the ground through a post-treatment system. In the diagram this is an absorption well, instead of which there may be an infiltrator or a filtration field

Moreover, sludge can be used on the site as a useful fertilizer for plants. This sludge is called active because some of the bacteria are contained directly in this mass.

Microorganisms that process wastewater reproduce themselves during the purification process. For this reason, there is no need to constantly introduce them into the septic tank.

If such a device is used incorrectly, the number of bacteria inside can decrease catastrophically. This happens if aggressive substances that destroy microorganisms enter the sewer uncontrollably.

This applies, for example, to chlorine-containing preparations, some antibiotics, technical oils, cleaners, etc.

In order to maintain the functionality of expensive equipment and protect the colony of bacteria from death, a septic tank used seasonally must be properly preserved

Another common reason for the death of microorganisms in a septic tank is improper preservation of the device for the winter. Some owners confuse the septic tank with the heating system and completely empty it in the winter.

This is incorrect; the device must remain partially filled even when not in use to maintain an environment suitable for bacteria to live.

More detailed information about the types and principles of operation of aerobic and anaerobic bacteria is available in this article.

If the device is insulated and properly preserved, it is not afraid of either winter frosts or spring floods. It will not float or crack, even if some of its contents freeze.

It is important, of course, to install the device correctly. During wastewater treatment, bacteria effectively eliminate the characteristic sewage odor.

Purified and clarified wastewater that has been processed in a septic tank can be used for watering green spaces and maintaining the area

The resulting water, of course, is not suitable for drinking, cooking, washing or other household needs. With a high degree of purification, it can be used to water plants on the site.

Often water is removed through a filtration well or filtration field. Water gradually enters the soil, passing through a purification system, a layer of sand and crushed stone.

The sludge that settles at the bottom of a sealed container, of course, does not go anywhere. It accumulates, as a result of which the total volume of the septic tank decreases slightly. When the amount of deposits becomes critical, the device should be cleaned using a special pump.

Cleaning a septic tank is performed much less frequently than pumping out a cesspool, and this process is usually not accompanied by a stench, since the sludge has a completely neutral odor.

Construction of a septic tank from a tank or barrel

There are an impressive number of options for septic tanks that can be installed, it’s mind-boggling. An impressive number of companies have also appeared that professionally deal with this installation. However, nothing prevents you from not resorting to their services, but from doing everything yourself, using one of the possible available materials. For example, using brick, concrete or a barrel (tank).

Next, it is important to choose the appropriate volume, which directly depends on how many people will live on the site. And finally, it is important to remember that barrels are only suitable for fecal wastewater

If it is necessary to drain other household waste, it is best to resort to the use of tanks.

Performance

The performance of any treatment facility means its ability to effectively treat a given volume of wastewater generated during the operation of a country house. This indicator determines the number and size of chambers of the purchased structure. With limited volumes of wastewater, it is permissible to use a single-chamber pre-treatment septic tank, which is quite capable of processing a small mass of household waste.

The simplest low-capacity septic tank

To efficiently process large masses of wastewater (with a daily volume of generated waste exceeding 1 m3), you will need a septic tank model with increased productivity.

If your summer cottage is intended for seasonal family vacations, it will be possible to get by with a standard pre-treatment facility with a volume of up to 1 m3.

This simplest version of a cleaning device is usually used as a simple storage tank, periodically emptied by the owner himself, or with the help of special sewage disposal equipment.

Anyone who would like to decide on the choice of a septic tank and plans to live in their country house permanently is not advisable to choose this option. If there is a large amount of waste generated, you will have to use the services of vacuum cleaners too often, which nowadays are not at all cheap.

Description and principle of operation

Unfortunately, not everyone can afford to purchase an expensive treatment facility. And in

On the farm, or at least on the market, there is always a suitable plastic barrel that can be used as a country septic tank. You can dig either one barrel or several into the ground, connecting them to each other according to the principle of communicating vessels. In a design of several barrels, sewage water will be purified more efficiently. And the capacity of the septic tank will increase significantly.

It is useful to know how to make a cesspool with your own hands.

If fecal matter, water from kitchen sinks or dishwashers and washing machines are discharged into the sewer system, it will not be possible to purify the water in a filtering septic tank from several barrels. In these cases, it is advisable to use a large-volume sealed container.

The operating principle of a septic tank made from barrels is quite simple. The containers are dug into the ground below the level of the sewer pipes. Waste enters the septic tank by gravity. Depending on the degree of contamination of wastewater, a sealed barrel or a system of barrels is used, followed by filtration of purified water into the ground.

From polymer to metal

All septic tanks can be made from different materials; many options can be found on the market. In addition to plastic and metal ones offered by manufacturers, there are options for brick septic tanks and even containers made from old tires. They all differ in their characteristics.

Inexpensive but very durable septic tank barrels, which are used in the construction of a sewer system, have become very popular. Such containers are light in weight and very durable. Often fiberglass septic tanks have special stiffening ribs that can withstand even high pressure.

Septic tank operation diagram.

But there are also disadvantages, including such an important factor as light weight. Barrels are easily pushed to the surface, so it is necessary to create a concrete slab in the pit as a base to which the septic tank will be attached with a chain. This will avoid pushing out and ensure strength and reliability. It is recommended to concrete the pit itself so that the soil does not exert excessive pressure; it is recommended to fill the space between the walls with gravel and lay insulation. When choosing plastic barrels, preference should be given to those that have stiffeners.

Efficiency of masonry

For small summer cottages, brick cesspools are popular. How to use them? Such a septic tank is a pit in the ground, which is lined with bricks from the inside. After masonry, the walls are rubbed with cement mortar, a cover is constructed from a wooden panel on the outside, and ventilation is removed.

Septic tank with brick walls.

Among the advantages, it should be noted that the installation of such a septic tank is extremely simple, as is its use. It is only necessary to regularly clean it of the waste that accumulates in it. But there are also disadvantages: the ventilation goes directly outside the ground, that is, a rather unpleasant odor can be observed in the area, which is difficult to get rid of. If the dacha is used only for growing garden crops, then this does not matter much. But if there is a house on the site for year-round use, you need to choose another option.

Reinforced concrete buildings

Reinforced concrete septic tanks can have a variety of interpretations:

- monolithic, for their installation a pit is dug, after which formwork, a reinforced belt are installed, and a concrete mixture is poured;

- prefabricated reinforced concrete for the construction of a sewer well.

Both options are quite durable and reliable, they are easy to use

When building a septic tank from rings, great attention must be paid to sealing the joints using a special sealant and tow. In this case, the wastewater simply will not be able to penetrate the soil and infect it.

Septic tank made of reinforced concrete.

Metal tanks as septic tanks have been used less and less in recent years, as they are highly susceptible to corrosion, the walls can quickly become leaky, which means that untreated wastewater will end up in the ground. Large metal barrels and old tanks are used as containers, in which holes are made for the flow of wastewater. Such barrels can be sunk into the ground or placed in the open air without special supports. Nowadays, experts recommend abandoning them, since their cost is high and their use is not so effective.

Available materials

Quite often, homemade septic tanks are installed in dachas. Experts do not recommend installing them yourself if you do not have the necessary experience, but you can still often see brick containers or septic tanks from an old metal barrel, which are buried in the ground or placed on special supports above ground level.

One of the most unusual homemade septic tanks is a container made from rubber tires. Although it is convenient, there are a number of significant disadvantages. The barrels do not have a bottom, their walls are not airtight, that is, during use, contamination of the soil is possible. Therefore, they should be used carefully, only if the volume of waste is small.

Septic tank maintenance

The procedure involves cleaning the containers. It is impossible to do this yourself; you will need to call a vacuum cleaner. Special biological additives will help increase the period between cleanings. They contribute to the decomposition of solid waste, and accordingly, their quantity decreases.

If a country house is used in the summer, then conservation of the treatment plant is required. There are certain recommendations on this matter:

- You should not remove the liquid from the container completely, so that in the spring the septic tank does not collapse due to soil movements;

- the residual liquid level should be 1/3 or 2/3;

- you need to prepare several bottles of sand, 2 liters each. By immersing it halfway in liquid, it will be possible to avoid icing of the walls;

- the lid must be insulated, but covering it with sand or soil is not recommended.

Septic tank Tver: operating principle and review of popular models

Shambo sewerage: do it yourself

Everything about the Kedr septic tank: characteristics, internal structure, installation

Advantages and disadvantages of storage septic tanks for summer cottages

Storage septic tanks are an excellent option for arranging local sewerage in a country house intended for seasonal recreation. Unlike wastewater treatment plants, they are more affordable and easy to install: they do not require the installation of infiltrates and, therefore, take up less space. This allows you to install storage septic tanks even in small areas, standard 6 drains.

In addition, this type of septic tank is not affected by the groundwater level. The main thing is to securely anchor the container in the soil. Another plus is complete energy independence. The system will work even if there is no power supply.

But such septic tanks also have their drawbacks: they require regular cleaning using a sewage machine or a suction pump. This is a rather expensive service, so installing storage septic tanks in houses equipped with a full set of plumbing equipment and household appliances: a washing machine and dishwasher is undesirable.

Construction of the above-ground part of the street toilet

After constructing the foundation for the outdoor toilet with your own hands and installing the container, you need to start building the booth. This process consists of the following steps:

- You need to lay a piece of roofing felt on the surface of the foundation.

- A wooden beam measuring 100x100 mm should be used for the bottom frame of the base under the floor. Before this, it must be treated with an antiseptic solution.

- To build a reliable foundation, install the bars around the perimeter of the structure and in the middle of the long side of the structure, attach them with nuts, after placing them on metal pins.

- Using 40 mm thick boards, build the floor of the future toilet. In this case, it is necessary to leave a hole under the toilet where the container is located.

- Attach 4 wooden columns to the corners of the base. Two of them should have a height of 2 m, and the other two should have a height of 2.2 m. Choose bars with a cross section of 100x50 mm. They need to be attached using metal corners and wooden spacers. Before final installation of the frame, check the verticality of the posts.

- On the front wall under the doors, install additional columns of the same section. The width of the opening should be 0.7 m and the height 1.97.

- Fasten the racks on the other side with a vertical jumper at a level of 1.77 m, which will also serve as the base for the roof.

- Along the structure, leaning on the installed jumpers, attach two rafter legs.

- As roof sheathing, use 40 mm thick boards, which must be attached to the rafters using regular nails.

- Using screws, install an OSB sheet to the lattice covering, which will act as a base for the roofing material.

- Use soft bitumen shingles or roofing felt as a covering. It is necessary to choose materials that will not create additional load on the structure.

- For wall cladding, use a tongue-and-groove or half-tongue board 2-4 cm thick.

- To prevent the inside of the building from being hot in summer and cold in winter, you need to make thermal insulation with your own hands. To do this, install foam sheets in the inner plane of the frame. After this, you need to additionally sew up the walls with another layer of board.

- Apply a special impregnation to all wooden elements, which will protect their surface from the harmful effects of moisture and other negative environmental factors. You can also additionally use fire retardants.

- Install doors on the curtains. You can equip them with a small window to illuminate the interior space during the daytime.

Types of concrete rings

The rings differ in the type of construction:

The final structural element of a reinforced concrete septic tank

- With a bottom. A monolithic product, which is installed first in the pit, with wall walls on top. Used to create a sealed container, leaks do not occur during the entire period of operation. Standard height is 0.9 m.

- Castle ones. With special recesses in the upper and lower parts. During installation, a reliable connection occurs. Indispensable for the construction of septic tanks on floating soils.

- With lid. There is a hole in the ceiling for a hatch. This is the final element of the well. The monolithic product increases the strength of the entire structure.

How to prepare a pit

The distance from the house to the septic tank should ideally be 7-10 meters, the main outlet pipe should not have any turns, as this will lead to additional costs for installing a manhole and will increase the chances of blockages, and run straight with a slight slope of no more than 20 cm.

At the point where the sewage system exits the house, you need to dig a trench 5-10 meters and 1 meter wide. Where the barrels are placed, a round or rectangular pit with a 10 cm step at the bottom is required so that the chambers can work as communicating vessels. The size of the pit should freely accommodate not only the barrels, but also the insulation for the walls and allow them to be well covered.

To prevent groundwater from squeezing out the barrels, it is necessary to create a concrete cushion at the bottom of the pit. And also attach metal loops to cement for subsequent anchoring.

Metal barrels - temporary wastewater collection system

When arranging a septic tank from iron containers, it is necessary to dig a pit of suitable dimensions and be sure to concrete its bottom. Then prepare two barrels and drill holes on their sides. You will insert the outlet of the drainage pipe and the inlet of the overflow pipe into them. Remember - the pipe product coming from the house is always inserted into the first barrel with a certain slope. Due to this, wastewater will flow by gravity into the septic tank without any problems.

Important pro tips to follow when installing a sewer system made of metal barrels:

- the second metal container should be installed in the pit slightly lower than the first;

- use barrels with a volume of at least 200 liters;

- high-quality insulation of the septic tank on all sides is mandatory (there is no need to lay heat-insulating material only at the bottom of the pit);

- The tanks are backfilled with soil; the top of the septic tank is covered with roofing felt and lids made of wood or iron (do not forget to make a hole in the coating through which wastewater will be periodically pumped out of the tanks).

Construction of a sewer system from metal barrels

If you want to increase the volume of the structure in question, it is possible to install several barrels on top of each other and weld them together. In addition, additional iron jumpers can be mounted. They will provide more reliable fastening of the barrels. All joints between barrels should be thoroughly waterproofed. For this, hot bitumen is most often used.

Let's say it right away. No matter how you set up a system of iron barrels, after 3-4 years the metal tanks will have to be replaced. They will begin to rot and rust under the influence of aggressive wastewater.