An electrode (another name is ion) boiler is one of the variations of electric heating devices. It is used mainly in country houses and differs in that, instead of the usual heating elements, it is equipped with a set of electrodes, which, in fact, heat the working fluid. This innovation made it possible to get rid of the shortcomings characteristic of electrical equipment - low performance and short service life. Due to the simplicity of the design, you can make an electrode boiler with your own hands. But before you start assembling, you should familiarize yourself with the features of its operation.

DIY electrode boiler

What will be needed to assemble the boiler?

Since such a device does not have mechanical components, it is easy to make it yourself. Also thanks to this, it rarely fails and is easy to use.

If you decide to make an electric heating boiler with your own hands, you will need the following parts and tools:

- angle grinder (you can use a grinder instead);

- multimeter;

- to weld pipes you will need a welding machine (the best option is an inverter type unit);

- regular grinder;

- steel sheet with a minimum thickness of 0.2 cm;

- to connect the boiler to the heating system, you will need adapters;

- heating elements – 2 pieces (regular heating elements are needed);

- a piece of steel pipe with a diameter of 159 mm and a length of 60 cm.

It is worth mentioning separately that you can make floor-mounted and wall-mounted heating equipment with your own hands. Such boilers can be single-circuit or double-circuit. According to the principle of operation, they are induction, heating element and electrode.

How to make a heating element boiler

If you are interested in how to make a 220V electric heating boiler with your own hands, then the following assembly instructions will help you figure it out:

- In order to properly connect a homemade device to the heating system of a private home, you need to make special pipes. For this, three steel pipes are prepared. You should end up with two 1.25" pieces and one 3" piece.

- After this, we make a container for the tank. To do this you will need a large diameter pipe. The coolant will be heated in this tank. For this purpose, two holes are cut on the side in a pre-prepared section of pipe. Their edges are well cleaned from burrs and nicks. Two previously prepared pipes are welded to these holes. Then two circles are cut from a piece of sheet steel. Their diameter should be 2-3 mm larger than the diameter of the pipe for the tank. These round blanks are welded to the ends of the heating container. Welding areas are well cleaned and polished.

- A hole with a diameter of 1.25 inches is cut in one of the circles welded to the end. A pipe with the same cross-section is welded to this hole. Two more holes are cut in the bottom of this cylindrical structure. Their edges are also carefully cleaned and polished. The first heating element is inserted into these two holes. An additional heating element will be installed in the previously welded pipe from the other end.

- Then the manufactured boiler must be connected to the heating system of the building. To connect, we use two pipes in the side, which were welded in the first step.

- Now we install the second heating element in the pipe on the top of the tank. Its power should be slightly less than that of the main heating element. However, an additional heating element must have a thermostat to regulate the temperature of the coolant.

- After checking that all parts are connected correctly, the homemade heating element boiler is ready.

Advice! To connect a homemade structure to the power supply, it is better to use the help of a specialist, since without experience it will not be possible to carry out the work correctly and, most importantly, safely.

After connecting the electric boiler to the power supply networks, check its performance and the correct operation of the entire heating system. To estimate the temperature of the coolant, you should use a multimeter. The temperature of the water in the pipes after leaving the boiler should be within 70 degrees.

Assembly and connection of equipment

If you nevertheless decide to independently connect a homemade electric boiler to the power supply, then this should be done in compliance with the following recommendations. Since powerful heaters are installed in the tank, you will need to install a three-phase input.

For this purpose, the following devices are installed in the electrical panel:

- toggle switch;

- machine;

- fuse;

- temperature sensor;

- relay;

- control Panel;

- protective devices;

- magnetic starters.

A grounding circuit must be installed. To make it, you need to weld a bolt to a piece of reinforcing bar. After this, the rod is driven into the ground in the underground of a residential building. A wire coming from the electrical panel is attached to the bolt.

Consumption and circuit of electric heating in a private house

Types and principle of operation

Having decided to make an electric boiler for heating your home with your own hands, you need to understand the types of such devices. It is possible to produce electrode and induction types of boilers. There are other varieties, but they are only modifications of these basic types. The second name for an electrode boiler is an ion unit. It is called that because the device converts electrical energy into thermal energy.

Electrode boiler

A homemade electrode heater has compact dimensions, so it can be easily mounted on a pipe and does not require a separate place for installation on the floor or hanging on the wall. For greater strength and safety, it is secured with two self-tapping screws, but you can omit them if you wish.

Externally, the entire structure looks like a 400 mm long pipe section. On one side the pipe is tightly welded, and on the other there is a steel rod sticking out of it. A pipe is installed on the side or at one of the ends for circulating coolant through the pipes.

A self-made heating element boiler, the manufacturing process of which we described above, must have two pipes on the side for connecting the return and supply pipelines with circulating coolant.

There are several options for the location of these pipes:

- One piece of pipe can be installed at the end of the device, and the other can be welded to the hole in the side. Thus, it is installed perpendicular to the axis of the first pipe.

- The second mounting option involves installing two pipes on the side of the unit. It turns out that both pipe outlets are installed parallel to each other, but perpendicular to the main tank of the heater.

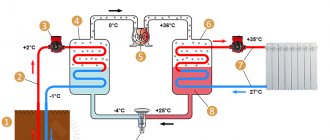

A homemade heater has the following operating principle:

- Positively and negatively charged particles (called anodes and cathodes) constantly circulate within the coolant;

- when voltage is applied, the ions rush to the electrodes with the opposite charge;

- since the polarity of the electrodes constantly changes with a frequency of 50 times per second, the ions move in one direction or the other;

- Such chaotic movement of ions causes friction of the particles and their heating (because of this, the temperature of the coolant increases).

Having made an electric heating boiler with your own hands, you should not forget that it has its drawbacks. The disadvantages are associated with the fact that the coolant is constantly under voltage, so before supplying it to the heating circuit, it is thoroughly cleaned of salts and other impurities that can settle on the walls of the pipelines and the heating element.

Attention! In systems with electric boilers, it is prohibited to use antifreeze as a coolant. For these purposes, purified water is used.

Induction unit

The operating principle of induction-type electrical units is based on heating the coolant through a magnetic field, which is formed by an electric current.

Electric double-circuit boiler for water supply and heating at home

These devices contain the following components:

- coil;

- heater body;

- core (here the coolant is heated);

- insulation.

In induction-type boilers, the coolant is not energized, as in units of the electrode variety. This is ensured by complete isolation of the liquid medium from elements that conduct electricity.

The copper coil winding is connected to the network through an automation system. After this, a magnetic field is formed in the coil, which heats the pipe, which acts as a core. Since the coolant circulates inside it, heat is immediately transferred to the liquid. During operation, the device body does not heat up. For this purpose, a layer of special insulation is provided in the housing design.

The core itself has a curved configuration to ensure longer passage of the coolant through this area in order to heat it sufficiently. The service life of an induction boiler reaches 25 years. There is simply nothing to break in this unit, so it will last until the core pipe is damaged by corrosion.

Heating system in a timber house

Wood has high energy-saving characteristics, but organizing heating for a house made of timber is a responsible matter if you plan to use such housing as a permanent place of residence.

Nowadays, the choice of heating systems is wide, and everyone can choose exactly the one that, in his opinion, will be the most effective for his home.

Where to start choosing

Important!

The heating system in a house made of timber is started only after the wood has completely dried and the house has shrunk. A newly built house cannot be heated, since the difference in temperatures inside the house and outside will lead to cracking of the material.

Choosing a heating system for a house made of timber begins with taking into account the climate, the size of the house, the height of the ceiling and other factors that increase the efficiency of heat retention indoors.

Water heating

For low-rise buildings, water heating is most often chosen. The premises are heated using boiling water moving through radiators. The heating boiler is often placed in the cellar with space allocated for the floor of the boiler.

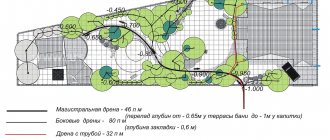

Warm floors can be considered a type of water heating in a wooden house. The pipes are laid in the screed at the stage of arranging the floors in the house. This type of home heating allows you to constantly control the temperature in the room.

Air heating of a house made of timber

Air heating is a good option, but it is difficult to install.

Also, if necessary, the system cannot be dismantled. The rooms are heated by heated air circulating in the heat exchanger.

Electricity

Heating a log house with electricity is not the cheapest option, but it allows you to avoid gas and solid fuel boilers. Also, this system is more secure and reliable.

Infrared heated floor

The infrared floor option for heating a house made of timber is characterized by mobility and efficiency. Films of this kind of flooring are easy to move from place to place; they can be laid on carpeting and any flooring. Such a floor does not heat the air in the room, but objects, which saves energy.

Starting the boiler

Before a test run of the heating unit, check how tight all components and connections are, as well as the correct assembly of the electrical network. After this, coolant is poured into the system. Be sure to make sure that there are no crushed or broken wires in the network, because a three-phase network has a high current strength. All wire connections must be well insulated.

Before starting the unit, it is thoroughly cleaned of contaminants. For proper and uninterrupted operation of such a heater, you need to be protected from power surges. For this purpose, an RCD is installed in the network.

A test run of the boiler is performed in the following sequence:

- Purified coolant is poured into the system.

- It is important that air does not accumulate in the circuit, so it is released using Mayevsky taps. Such fittings should be installed on the upper radiators in the system.

- We turn on the electric boiler and wait for the coolant to heat up.

Direct electric heating

Oil radiators

The housings of these devices consist of several sections with mineral oil as a coolant, which is heated by powerful heating elements up to 200 degrees, maintaining the radiator temperature no higher than 100 degrees.

Oil radiators are capable of heating any living space; they do not “burn” oxygen during operation, but they are used only in extreme cases due to the high consumption of electrical power.

Convectors

In these devices, a heating element heated by electric current directly heats the air without an intermediate coolant. Therefore, they have higher heat transfer and efficiency, but at the same time some of the oxygen is burned out of the air in contact with the hot metal of the heater.

With the radiator and convector method, cold air from below the room, after heating, rushes upward and collects near the ceiling, and from there it is distributed throughout the entire volume of the room.

Therefore, when the temperature at the top of the room reaches +22°C, the air near the floor will warm up to +17°C, which is quite acceptable, but not entirely comfortable.

Convectors use temperature sensors with automatic temperature control systems, which can significantly save energy costs.

Attention! The convector located below the window protects the room from the penetration of cold air through cracks from the street, preventing drafts.

Useful tips

In order for systems with electric boilers to operate efficiently and have high efficiency, pumping equipment is installed in them to circulate the coolant.

Thanks to good circulation, the coolant will warm up evenly. It is recommended to install the circulation pump on the bypass so that you can switch to natural circulation of water in the system. When installing circuits with a gravitational carrier current, the return pipeline is laid with a slope towards the heating boiler. Thanks to this, the cooled liquid will quickly flow into the boiler.

About the advantages

Electrode boiler ROMSTAR 2 smart (set)

- The main advantage of ion boilers is their high efficiency (up to 98%), which is explained by the relative simplicity of the device’s operation.

- Their small size allows them to be used even in small houses.

- Electrode boilers do not have a “dry run”. The liquid is a full-fledged “participant” in the working process, so its absence will not cause overheating of the system - only the circuit will open.

- Voltage drops in this case are not dangerous - if it drops, the device will not turn off, it will simply work with less power.

- Cost-effectiveness is another advantage of electrode boilers.

- Finally, they reach the set temperature quickly and cool down just as quickly, allowing for more efficient use of automatic control. Operating principle

Drawing of an ion electric boiler