The foundation is the main structural element of any building. A brick house is no exception. Without a reliable load-bearing foundation, it is impossible to build a durable and comfortable home. An incorrectly laid foundation of a building can cause many troubles, including the destruction of the entire structure. Therefore, it is so important to choose the right and high-quality foundation for a brick house. This article is intended to answer the questions of which foundation is better and how it is poured.

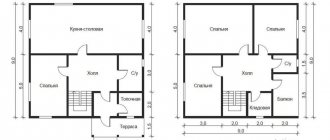

Foundation for a two-story brick house.

With the growing level of social well-being and the simultaneous increase in air pollution, many city residents have a need to move outside the city and build their own home there. The most correct choice is a one-story or two-story brick house. This type of house has many advantages.

Foundation depth for a two-story brick house.

In order for a brick house to be of high quality and durable, you need to pay due attention to the foundation.

The service life of brick houses is on average about 100 years; in addition, they are environmentally friendly, resistant to moisture or fire, and resistant to impacts.

But houses don't just sit on bare ground. A house needs a reliable foundation - a foundation. It is, without exaggeration, the most important part of the house and should be even stronger and more durable than the structure itself. With an improperly executed foundation. which may be caused by errors in calculations or savings on building materials, negative consequences for the house will not take long to appear. To complete the foundation, you can contact a construction organization, leave an order and not worry about anything else. But if the budget is limited and you have free time, then you can make the foundation yourself. Next, we will consider the main types of foundations and the procedure for their construction, based on the conditions of the area where construction will take place.

Foundations are divided into 3 types:

Characteristics of building material

Any brick house, even a one-story one, is very susceptible to various types of shrinkage and also has a lot of weight. These are two indicators that clearly characterize this structure.

Brick is resistant to compression, but can collapse when bent and stretched. With uneven shrinkage of the soil, distortions and cracks in the walls are possible, which can significantly reduce the strength of the structure. Distortion occurs due to:

- Shrinkage of some foundation elements. This problem can arise when the foundation construction technology is violated, as well as when the soil type is incorrectly assessed. Subsidence may occur due to the presence of some water-saturated soil, as well as poor soil density at the construction site.

- Bulging of some parts. A separate part of the foundation can be squeezed upward from the soil under the influence of forces. This occurs as a result of insufficient depth of the foundation, as well as when it is close to the surface of groundwater.

Ribbon type of structure.

Strip foundation diagram.

A strip foundation is a wall made of durable material sunk into the ground to transfer the weight of the main building to the ground.

The strip foundation, in accordance with its name, resembles a strip in appearance, is a wall made of durable material sunk into the ground to transfer the weight of the main building to the ground. The shape of the strip foundation must correspond to the design of the house and pass under all its load-bearing walls. It must withstand the wall of a two-story, and even more so a one-story house without deformation.

In turn, the strip foundation according to the method of execution is divided into 2 types:

Technical characteristics of red brick

The key parameters of red brick include strength and frost resistance. Strength shows the maximum load this material can withstand. Thus, brick grade M175 is able to withstand a weight of 175 kg per 1 sq. cm.

Frost resistance shows how many freezing cycles it can withstand.

Monolithic foundation.

Monolithic foundation for a two-story brick house.

A monolithic foundation is erected by filling the pit with the selected building material.

A monolithic foundation is erected directly on the construction site by filling the pit with the building material selected for the given soil. The following types of material are used to fill a monolithic foundation:

- Rubble concrete (pouring using coarse filler - broken brick, concrete, gravel).

- Reinforced concrete (pouring using steel reinforcement and crushed stone).

- Brick (clay brick masonry).

The process of constructing a monolithic strip foundation is quite simple and consists of the following steps:

- Digging a foundation pit according to the house plan.

- Filling and compacting the sand cushion.

- Installation of formwork.

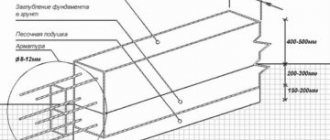

- Installation of reinforcement cage (for reinforced concrete foundation).

- Filling the formwork with the selected concrete.

Formwork for installation.

Foundation formwork for a two-story brick house.

The formwork must be constructed so that it can be installed and removed easily without damaging the foundation.

Some tips for installing formwork, since the quality of the resulting foundation largely depends on its quality. The formwork should be easy to install and just as easy to remove, so as not to damage the finished foundation. Its strength must ensure that it maintains the shape specified by the design. Wooden or steel materials are used to make formwork. For wooden formwork, waterproof plywood, particle board or fiberboard and dry coniferous wood are used, the boards of which must be smoothly planed and have a width of no more than 15 cm. Plywood, fiberboard and chipboard are good to use in the manufacture of curved sections of the foundation. Metal formwork has special fastenings, is easy to assemble, durable and easy to dismantle. You can buy it, or better yet try to rent it.

The reinforcement makes the foundation structure stronger and more flexible, and provides a certain margin of safety in the event of an increase in the weight of the residential part of the house. The reinforcement frame is assembled in parts from ready-made spatial fragments, manufactured in advance according to the foundation design. Each laid fragment should not interfere with the laying of the next one. As they are laid, the fragments are fixed and welded together until a single monolithic structure is obtained. After laying the last section, the readiness of the reinforcement frame with formwork is checked and the pouring of the foundation begins.

Prefabricated option.

Prefabricated foundation for a two-story brick house.

The prefabricated foundation is installed on sand pads made from ready-made factory concrete blocks.

The prefabricated foundation is somewhat reminiscent of a Lego set. All you need to do is dig a hole for the foundation and prepare a sand bed. Such a foundation is assembled from individual reinforced concrete blocks, which are made to order in a factory. Making such a foundation significantly reduces the time and effort that needs to be spent on work. The finished fragments are installed one on top of the other and fastened with cement mortar. At the same time, the manufacture, delivery and installation of prefabricated parts using a truck crane makes the project more expensive and reduces the strength of the foundation, since it cannot be monolithic.

Bored piles.

Pile foundation for a two-story brick house.

A pile foundation is used in unstable soil, as well as in areas prone to flooding. This foundation is considered one of the most economical options.

Pile foundations are used for construction on very unstable soil, in areas subject to flooding, or in order to save construction budget. When building on unstable ground, the job of the piles is to penetrate through it and secure itself to the solid foundation underneath. Today, using this technology, skyscrapers are literally built in swamps. If the site is located next to a river or lake that periodically overflows its banks, the height of the piles above the ground is set based on the known maximum level of water rise. As for efficiency, the benefits are obvious. Piles are installed only under load-bearing walls and columns, if they are provided for in the project. The essence of such a foundation is that piles placed in the ground are connected to each other by horizontal beams - grillages, and the slab of the first floor of a brick house is installed on this structure. Piles can be divided into 5 types, according to which they are installed.

The first 3 types listed require the use of special heavy equipment, but since we are talking about independent work, prefabricated and cast-in-place piles will be considered in more detail.

We build a pile foundation with our own hands. To equip prefabricated piles, square holes are dug at a distance of 1.5-2 m under the load-bearing walls, 30 cm deeper than the foundation will be laid. A mixture of gravel and coarse sand is poured into a thick layer onto the bottom of the pit, insulated with film, it is compacted, and a reinforcement pin or thin steel pipe is driven into the bottom of the pit to give strength to the masonry. Then a pillar of solid brick is laid on cement mortar. After the masonry has hardened, it is waterproofed and covered with soil, which is constantly compacted as it is added.

Strip pile foundation for a two-story brick house.

You can also use a combination of strip and pile foundations. This is very common for the construction of brick houses.

A much less labor-intensive method is to install cast-in-place piles. The technology is as follows: along the perimeter of the building and along the line of load-bearing walls and columns, wells are drilled to the required depth using a manual or motorized drill, the bottom of which is isolated with sand. Next, a pipe made of 1-2 layers of roofing material is inserted into the well, thereby insulating the pile from moisture. After this, a frame of reinforcement 30 cm above the future pile is inserted into the well for attachment to the grillage. During subsequent pouring, every subsequent 40-50 cm of concrete must be exposed to a vibrator to get rid of air bubbles. When the last pile hardens, they are leveled horizontally with cement mortar and a monolithic grillage is installed using the strip foundation construction technology described above. After hardening, the upper surface of the foundation is leveled with cement-sand mortar and insulated with one of the selected materials. The foundation is ready for installation of floor slabs.

Pile type devices.

The use of a pile or pillar structure is most suitable for soil with a fragile or excessively heaving surface.

The columnar foundation design, which includes wide support soles with a drilling device, is very popular.

Such a foundation has one main drawback - its construction requires the use of specialized equipment. The design is well suited for the construction of one-story buildings and all kinds of extensions.

When building a foundation for a brick house with your own hands, which has a pile structure. The following instructions must be followed:

- First, you should clean and mark the area. Check the compliance of the base angles with the specified values;

- Determine the places where the supports will be located;

- Remove soil from the marked areas;

- Drill wells;

- Carry out the manufacture of a frame from reinforcement. Its height should exceed the ground level by 30 cm;

- Pour the sand and gravel mixture into the well recesses;

- Install the frame into the holes for the wells and fill it with concrete mortar.

It will take 4 weeks for the base to harden. When pouring a base of piles, the use of formwork will be required. The material can be simple boards or plywood covering.

Monolithic slab.

Slab foundation for a two-story brick house.

A slab foundation is a monolithic concrete slab measuring 30-50 cm. This type of foundation is considered the most durable.

Slab foundations are used on soft soils. It is a thick monolithic reinforced concrete slab 30-50 cm thick on which the house rests. Its advantages include the reliability of the design. With such a foundation, a brick house has low pressure on the ground and is practically independent of changes in the condition of the soil underneath it. The downside, which does not affect the quality, is the high consumption of material and labor, which in turn increases the cost of the work. This type of foundation, despite the significant amount of work, is made quite simply.

First of all, a pit is torn off, its bottom is leveled, covered with a layer of sand up to 30 cm, which is carefully compacted. If the future brick house is planned to be equipped with bathrooms, pipes for water supply and sewerage are installed. Then a thin, up to 10 cm, screed made of sand-cement mixture is poured. After hardening, a layer of waterproofing and, if desired, thermal insulation is laid on it. Then a metal frame made of reinforcing mesh is mounted on this sandwich. The next step is the installation of very durable and reliable formwork. Finally, concrete is poured into the prepared form, leveled and cured for a month.

Device.

The installation of each foundation for a brick house is carried out in accordance with the requirements of SNiP and the capabilities of the contractor. Let's look at step-by-step instructions for different carrier systems.

Monolithic foundation for a brick house :

- First of all, a project is prepared. The documentation takes into account the terrain features, geodesy requirements and other parameters that affect the durability of the structure. Drawings are being prepared according to which the territory will be marked;

- A trench is dug along the marked lines; it is especially important to ensure that the corners are even. Otherwise, the support will “float” and the building will begin to collapse prematurely - 5–7 years after completion of construction;

- The depth of the pit should be 20 centimeters greater than required, since a sand or crushed stone cushion is taken into account;

- Fine crushed stone or sifted sand is poured onto the leveled surface of the base, and the embankment is compacted. After this, a thin layer of concrete is poured onto the pad. It is recommended to discuss its dimensions with a specialist, since parameters for different objects may vary;

- To build such a structure, it is necessary to additionally insulate and isolate the slab from moisture, so a waterproofing film is laid over the pouring;

- Along the entire perimeter of the future pouring, it is necessary to install formwork that will prevent the solution from spreading;

Reinforcement of a foundation slab for a brick house.

- For the construction of that system, the presence of a reinforcing belt is also very important. To create it, the reinforcement is cut into equal sections and installed over the entire area of the base. It welds together. It is acceptable for the ends of the rods to protrude 5–10 centimeters from the solution;

- All that remains is to fill the support and cover it with film to harden (so that dew and rain do not damage the solution).

In terms of the construction process, a strip foundation for a classic brick house is very similar to a monolithic one, with the exception of pouring the entire area of the building. To create it, it is enough to lay the solution only around the perimeter of the building.

- The area is marked and cleared of various debris, stones and trees;

- Trenches of the required width and depth are dug using an excavator or manually. These parameters must be clarified in advance with surveyors in your region;

Marking a strip foundation for a brick house.

- The thickness of the sand cushion is 20 cm, this parameter is taken into account when preparing the trench. Make sure that only fine crushed stone or sifted river sand is used;

- Similar to a monolith, you will need to equip the foundation with waterproofing. To do this, film, roofing felt or other available materials are laid at the bottom of the trench;

- Next, the base is reinforced. Metal rods are installed in the centers of the corners and welded together. They are connected to each other, forming a metal belt around the perimeter;

What kind of foundation is there for a brick house?

- Depending on the chosen technology, you can fill the entire tape with a clean solution or first lay blocks in it and then treat it with the solution;

Options for installing a strip foundation for a brick house.

- After pouring, you need to wait about a week for complete hardening.

Strip foundation for a one-story brick house.

Bored and pile foundations are used when any other is not suitable. It is universal, quickly installed and can withstand fairly heavy loads. The structure consists of separate supports (piles), which are connected to each other by a grillage (concrete strip). But, despite the fact that the foundation itself is very cheap, to build it requires the use of special drills that will make holes in the ground for the columns. This construction process is carried out only by professionals and accounts for more than half of the estimate for the entire construction.

- The site is prepared and marked. Piles are necessarily placed at every angle and intersection of walls, but they can be installed more often for greater rigidity of the building. For example, at each center of the wall;

Columnar foundation with grillage.

- Next, holes are drilled. An important feature is that the hole in the ground should be smaller in diameter than the pipe. If the width is slightly larger or matches the piles, the base may become loose;

Drawing of a foundation support for a brick house. - The bottom of the holes is compacted with a cushion of crushed stone and sand, the average size is up to 20 cm;

- A metal reinforcing belt is installed in each hole. It is made from reinforcing bars welded together;

Approximate dimensions of the foundation for the house.

- A pipe is installed on top of the resulting mesh. It will be filled with cement regardless of whether a monolithic structure or a bored one is used, therefore, so that it can be raised after completion of the work, it is lubricated inside with oil or other solution;

- A stone, rubble, crushed stone is thrown into the pipe, or a solution is simply poured. Due to its small area, its hardening time is much faster than that of tape or monolith;

- The pipes are removed and formwork is placed on top of the pillars. Filling and reinforcement are carried out in the same way as when installing a strip foundation for a brick house.

Recommendation: A good review article, from it you will learn the general concept of a strip foundation for a brick house. Pay special attention to the soil and weight of the house; if there is an imbalance, the house will shrink and you will lose money. We kindly ask you to be extremely careful.

Features of the bookmark.

When planning the construction of a brick house, it is necessary to study in detail and strictly observe the following rules:

- The soil on which construction is carried out can be very diverse, and each has its own type of foundation.

- The lower edge of the foundation should always be 20-25 cm below the soil freezing level.

- Groundwater has a negative impact on the condition of the foundation, so during construction measures should be planned to combat it.

- During construction, use only high-quality materials.

- Carefully follow all construction technologies and safety measures.

A correctly selected, designed and manufactured foundation will allow a house built on it to stand for decades and serve many generations of its residents.

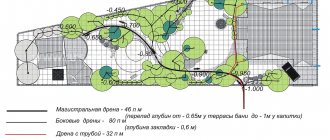

Construction and choice of construction site

In general, you can build anywhere, but not everywhere there is suitable soil.

You can visually determine with a 90% probability only the presence of groundwater by briefly examining the vegetation.

There should be no sow thistle, reeds, or large thickets of bushes.

When choosing a site for building a house, invite a specialist to carry out geodetic surveys, thereby solving more than one issue.

Determine the type of soil, its density, and the presence of groundwater.

Strip foundation for a two-story brick house.

The duration of trouble-free operation of a residential building largely determines the quality of the supporting structure. A two-story brick building has significant weight, so increased demands are placed on its foundation. We will consider in detail what types of foundations are suitable for the construction of private brick houses, the procedure for calculating parameters and the main stages of construction.

Foundation depth for a two-story private brick house.

Types of supporting structures for a private 2-story house.

The massiveness of two-story brick buildings implies the presence of a supporting structure of increased rigidity. These include:

- strip foundation;

- monolithic slab;

- a combined option, when the base of the strip foundation is reinforced with pillars.

It makes no sense to consider a pile foundation as a supporting foundation for a two-story brick house due to its instability. Screw piles will successfully cope with their function under a one-story building or if timber is used for the construction of walls.

Comment! The purpose of the support pillars when arranging a strip foundation for a two-story house is to strengthen the strength of the foundation when it is placed in a swampy area or on moving soils.

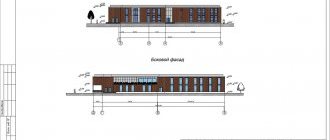

Foundation formwork for a two-story brick cottage.

Due to its capabilities, the best option for placing a two-story building is a strip foundation. It ensures uniform pressure distribution of load-bearing walls and partitions, be it brick or foam concrete, and is cheaper than a monolithic slab. In order for the structure to cope with the task, a competent calculation of loads is required to determine the depth and width of the tape. The complexity of the construction process is mitigated by the ability to complete the work without the involvement of a specialized team.

A monolithic foundation is characterized by increased reliability, which is important when constructing a brick building. But its cost is incomparably higher than the tape type. A significant limitation for wide distribution is the impossibility of arrangement on one’s own.

Strip foundation for the construction of a brick building

The strip type of base is chosen when the structure is going to be erected from components such as stone, brick or concrete.

An example of a strip foundation for building a brick house

The main differences of the strip base are its simplicity and ability to withstand serious loads. It is located not only under the external walls along the border of the house, but also under the interior walls.

It is also worth noting that the use of a strip base makes it possible to organize underground premises, therefore, if there is such a need, it is necessary to replace it with this option.

Factors determining the type and size of the foundation.

The final choice in favor of one type of support structure or another is made after analyzing a combination of factors; the following points deserve attention:

- Information about the geological condition of the site. This includes the soil’s tendency to heave, groundwater level, freezing depth and other characteristics of the site.

- Characteristics of building materials. from which it is planned to build a two-story house. For example, the mass of a two-story house made of foam blocks is incomparably less than a similar building made of brick. The type of floor, roof design, and type of finishing materials matter.

- Presence of additional loads. This takes into account the weight of the planned equipment, furniture, and the mass of snow cover on the roof.

- Financing opportunities.

Foundation depth for a two-story brick house.

In addition to all the listed indicators, the estimated pressure of the foundation that it will exert on the soil is taken into account. The data obtained is compared with standards developed for various types of soil, and a choice is made in favor of the optimal option. As a rule, a strip foundation for a two-story brick house is the most acceptable solution.

To calculate the bearing capacity of the strip base, it is necessary to determine the height and thickness of the structure. With soil freezing rates in different regions ranging from 1.0 to 1.8 m, the average depth is 1.5 m. The information specified in SNiPs and data from the geological bureau of a particular area will help you make calculations.

Important! The calculated indicators indicate the minimum acceptable parameters of the strip foundation. In practice, it is recommended to add at least another 10 cm to the obtained values.

Mistakes and mistakes

The main mistake is neglecting accurate calculations, using average numbers and foundation parameters “like your neighbor’s.”

If you cannot calculate the depth and width of the tape yourself, contact a professional, but you cannot build a building without an accurate calculation.

The second mistake is saving on the quality of materials . It leads to deterioration of the characteristics of the foundation, and this will affect the reliability of the entire house.

Third, neglect of geological research. There is a big difference in bearing capacity between soil types, and the type and parameters of the foundation directly depend on it. There is no room for error here.

The main stages of arranging a strip foundation.

It is better to entrust the design of a strip foundation for a two-story building to a specialized company. After marking the site according to the existing plan, they proceed to earthworks.

Cushion and formwork.

You can dig a trench for the construction of a two-story cottage using an excavator or manually. In the first case, it is difficult to achieve the required indicators for arranging a strip foundation, in the second, the process will take a lot of effort and time. The trench is prepared with a reserve depth for adding crushed stone to the cushion.

The bottom is compacted manually or using vibrating plates. With a mass of 1.2 kg, 10 passes are enough to compact the base and avoid further subsidence of a two-story brick building.

The strip foundation cushion is made from various materials:

- Sand. To ensure high-quality compaction of the sand layer, it is first watered with water. The approximate thickness of the layer is 20 cm.

- Suitable crushed stone fraction is from 20 to 40 mm. It also needs compaction. Sometimes it is mixed with sand for this purpose.

- A concrete base is the most reliable foundation for a two-story brick house. Initially, a 10-centimeter layer of crushed stone is poured under the future strip foundation, then formwork is formed and concrete is poured. The use of reinforcement increases the strength of the concrete pad.

Comment! The size of the pillow exceeds the width of the strip foundation on both sides by 15-20 cm. Its thickness is guided by the groundwater level and ranges from 20 to 80 cm. Waterproofing is designed to protect the lower part of the strip foundation from moisture.

Foundation depth for a two-story brick cottage.

Formwork can be removable or stationary. The removable version is divided into disposable and reusable. The disposable used frame, after the strip foundation has been poured and hardened, is disassembled and spent on other household needs when arranging a two-story brick cottage. It is not profitable to purchase reusable formwork for private use; it is better to rent. Stationary formwork has many advantages - quick assembly, attractive appearance of the strip foundation. But its cost is much higher than the usual plank construction.

Foundation depth for a two-story private brick house.

If the construction of a two-story cottage made of brick is carried out on soil with poor moisture permeability, it is recommended to provide drainage for the strip foundation. This includes:

- drainage pipes;

- inspection wells;

- water intake

The pipes are placed along the outer perimeter of the future two-story building at a distance of 1 m. The laying depth is below the base of the strip support structure. The approximate width of the trench is 30 cm.

Basic steps for arranging drainage:

- The bottom of the trench is covered with geotextile.

- A layer of fine crushed stone (about 10 cm) is poured on top.

- The installation of pipes is carried out with a slope of 5% towards the drainage basin.

- A 10 cm crushed stone layer is also formed on top.

- Everything is covered with geotextile edges.

- Finally, coarse sand or crushed stone is poured in.

Such protective measures help preserve the integrity of the strip foundation for a long time and extend the life of a two-story brick building.

Foundation depth for a two-story private cottage made of brick.

Reinforcement and filling.

The role of reinforcement is to increase the strength of the strip base, because a two-story brick building requires a reinforced foundation. In addition to standard metal rods, it is worth considering an improved version of rods for the frame of a strip support for a two-story building. Manufacturers offer stainless steel reinforcement made from basalt fiber. The set of advantages and disadvantages of composite material makes the issue of its use in the construction of a heavy brick house controversial. Everything is decided on an individual basis. Typically, ribbed metal rods with a diameter of 12 or 14 mm are used to reinforce the strip support structure. Describes in detail the requirements for the arrangement of a strip concrete foundation SNiP 52-01-2003.

Advice! The frame is installed using viscous wire; the use of welding is undesirable due to the risk of damage to the integrity of the structure.

Foundation formwork for a two-story private house made of brick.

Concrete is poured into the formwork to form a strip foundation in one step. Interrupting the process will significantly reduce the strength of the foundation of a two-story brick cottage. Ordering a concrete mixer will significantly facilitate the labor-intensive process, but you must first make an accurate calculation of the need for concrete solution.

Deep vibrators will help eliminate air bubbles and avoid dangerous voids. After pouring, the strip foundation is left to harden. The minimum period is about a month. At high temperatures it is periodically moistened. Covering the strip foundation with polyethylene will help slow down the process of moisture evaporation and ensure uniform drying.

Foundation depth for a two-story brick cottage.

The process of creating a foundation with your own hands

Since the strip type foundation is the most popular for self-production, we will talk about it, although the principles of marking the site, forming the formwork, installing bulk cushions, and concreting too, are the same.

- The decision on what exactly the foundation for a two-story house should be is made based on the results of a soil study. But in any case, the preparatory pie contains a bulk layer of sand, crushed stone or a mixture of them, which depends on the specific construction conditions.

- The minimum thickness of such a cushion is 200 mm, but on highly heaving soils it can reach 60 cm. Although in such a situation it is much more profitable to make the bulk layer thinner - by laying a heat-insulating layer of polystyrene foam under the sole, which will ideally protect the structure from frost heaving.

Option of tape with insulation under the sole, for installation on highly heaving soil - The sand cushion should be three times wider than the base of the foundation. It is very important that it is compacted with a compaction coefficient of 0.95 with an optimal humidity of 8-12%. To prevent the sand from being washed away by water and mixed with the mainland soil when moistened, geotextiles are laid under it, as in the case of a slab.

- When installing gravel pads, additional moisture is not required. They are laid on waterlogged and weakly bearing soils under sand, or in a mixture of crushed stone or gravel with sand in a ratio of 60:40. The sand should be of coarse or medium fraction. Fine-grained and silty sand has a high degree of heaving, so it is not used for foundation embankments.

- On soils with insufficient bearing capacity, the section of the foundation strip is given a T-shaped configuration. It is quite difficult to assemble stepped formwork at once. It’s easier to first make a box for a pillow, say 80 cm wide, install a grid of 4 rows of working reinforcement in it and provide a connection with the tape itself.

- Before installing the reinforcement in the formwork, a PVC membrane is laid in such a way as to cover the ends of the monolith with a reserve. After the vertical part of the tape is poured, overlaps are provided at the joints of the waterproofing. If polystyrene foam is installed under the sole, the membrane may not be used, since EPS itself has good waterproofing properties.

- To reinforce the tape, AIII steel reinforcement with a diameter of at least 12 mm is used (if composite, then 8-10 mm). For pouring, concrete B20 (M250) is used, but B22.5 (M300) is better.

- After the reinforced concrete cushion has gained stripping strength, you can mount panel formwork on it under the tape itself - or simply put on top permanent formwork made of perforated expanded clay concrete blocks or expanded polystyrene. A tape width of 50 cm is enough to build walls 400 mm thick on it, also with insulation.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Alternatively, the vertical part of the tape can be made from FBS blocks. But in this case, a monolithic reinforced belt must be formed on top of them, otherwise the tape will not be rigid, which is very important for walls made of cellular concrete.

After the concrete of the foundation strip reaches 50% of its design strength, the formwork (if it is removable) is removed - and waterproofing work can begin. The easiest way for this purpose is to use the same PVC membrane glued to the base with bitumen-polymer mastic. The canvas should be launched from the vertical surface onto a horizontal plane, on top of which the wall masonry will then be erected.

Is it necessary to use fittings?

The presence of reinforcement is not a prerequisite for a concrete monolith, and proof of this is the FBS foundation blocks, which are made without internal reinforcement. Here the main role is played by the density of concrete, which in this case should be no lower than 1800 kg/m³. It is almost impossible to achieve such a density under construction site conditions, so the lack of strength is compensated for by reinforcement.

Without reinforcement, only rubble concrete foundations can be poured, since the density of rubble stone is the same as that of solid brick - no less than 1600 kg/m³. The density of the finished rubble concrete varies between 1800-2200 kg/m³, which fully ensures the high compressive strength of the monolith.

Mistakes when building foundations

Each type of foundation has its own design features - and, accordingly, individual errors can be made. However, there are certain nuances, non-compliance with which can lead to undesirable consequences in any case.

- When performing excavation work, a pit or trench should always be dug with a gap of 10-20 cm, and then the bottom should be cleaned by hand. Overdoing it violates the natural density of the base and provokes uneven subsidence, since it is equally impossible to compact the topped-up soil. Unless the holes will have to be concreted - and this is an additional expense.

- The sand cushion should be poured and compacted in layers, with moisture content not exceeding 12%. Too wet sand is just as difficult to compact as dry sand, and even spreads in different directions, which is especially fraught with shallow foundations.

- For monolithic foundations, concrete of at least class B20 (M250) must be used - this is a requirement of building codes. The grade may be higher, it all depends on the perceived load. Concrete B22.5 (M300) is most often used in projects, with a water resistance grade of W6 and plasticity grade of P4.

- Laying the foundation must be done immediately after digging a pit or trenches. Open excavations are eroded, washed away by water or frozen out, and the strength of the soil begins to decrease. If this does happen, the pit will have to be drained and the bottom cleaned of the liquefied layer.

- When laying the foundation, it is necessary to immediately provide technological holes for communication inputs - so as not to drill into the monolith later. While drilling holes is still permissible for a strip foundation, it is not for a slab foundation.

- Mistakes can also be made at the stage of formwork formation. If wooden panels are being assembled, it is very important to use a board with a thickness of at least 40 mm. Thin lumber will bend under the pressure of concrete, thereby violating the geometry of the monolith. The boards must be joined without gaps, and the inside must be covered with waste oil or covered with geotextile or roofing felt.

- The bars securing the formwork boards are located on the outside of the panel, and the nail is driven in from the inside. In this case, the length of the nail should be such that it pierces the board and block, and the free end can be bent, which will prevent the possibility of spontaneous pulling out of the fastener. For self-tapping screws, bending is not necessary, since they are held in place by the thread.

- When assembling a reinforcement frame, mistakes are most often made when splicing rods along their length or joining them at the intersections of walls (for strips and grillages). The overlap of the rods must be at least 50 times the diameter of the reinforcement. Between joints in parallel rows of working reinforcement there should be a displacement of 61 cm.

- It is impossible to cut and bend long reinforcement at right angles; special L-shaped elements are used for corner connections.

- The foundation frame must be protected on all sides by a concrete shell. If there is no concrete preparation under the tape or slab, the thickness of the shell should be 70 mm from below (if there is a footing, 50 mm is enough), on the sides and top - 35 mm.

- When pouring concrete, the most important thing is quality compaction. The height of the layer that can be poured and vibrated in one go is 30 cm, so a slab with this or slightly less thickness is poured immediately over its entire height. Strip foundations are poured in horizontal layers, each compacted with a deep vibrator.

Which foundation is better for a two-story brick house?

The foundation is the basis of any capital construction, so before you begin choosing the type of foundation, you should determine several important factors related to both the soil and future loads. If you intend to build a two-story brick house, first of all, you need to do some research.

To ensure that the foundation does not sag, crack, or become distorted over time, it is necessary to order geotechnical studies. At this stage, specialists take soil samples, identify their quality characteristics, and, based on the research conducted, will provide a report and recommendations on which foundation is best for a two-story brick house.

Foundation depth for a two-story brick house.

A mandatory criterion for deciding the type of foundation should be the general load indicator, which carries a large number of indicators related to the weight of all structures and payload. Such values are also very important in order to determine the total area of the foundation. Laying a foundation for a house is a delicate matter. The foundation for a two-story house should not be too large, as this will increase its cost.

What type of foundation is better for a two-story brick house?

For two-story houses, experts recommend choosing a strip foundation. Strip foundations can be shallow or deep.

The choice of foundation type is influenced by the following factors: the weight of the building structures, the type of soil, the groundwater level and the depth of soil freezing. Taking into account all these factors, experts determine the required type of foundation and its dimensions. A visual diagram showing the basic principles of laying a strip foundation for a brick house.

For brick houses it is necessary to install deep strip foundations.

Image of a recessed strip foundation:

Foundation depth for a two-story private cottage made of brick.

A visual diagram of a strip foundation shows what basic components this type of structure consists of.

Foundation depth for a two-story private cottage made of brick.

To build a quality foundation yourself, you will need:

- compact the bottom of the trench well, which is also the foundation of the future foundation;

- make an underlying layer of crushed stone, compact it well into the ground;

- make a sand cushion;

- compact the sand cushion well;

— install formwork corresponding to the dimensions of the future foundation;

— install the reinforcement cage;

We do not recommend choosing slab foundations for two-story houses. Such foundations are not strong and stable. They are designed for small garage-type buildings. Buildings of two or more floors need reliable strengthening from below.

Soil properties

The main problem of all foundations is soil heaving. Often this factor has different indicators within one area.

The degree of soil heaving can only be determined based on soil analysis in laboratory conditions. But geological surveys of a building site are expensive and time-consuming, and therefore developers of small houses often use the advice of colleagues from neighboring sites, or use standard recommendations.

The first rule that should be followed for the optimal choice of foundation: a brick foundation must stand on dry soil. A brick foundation is rigid, its strength level decreases sharply under the influence of moisture. That is why a brick base is optimal for dry soils with low groundwater levels.

Important! If this condition cannot be met, then a set of drainage works should be carried out or another solution for constructing the base of the structure should be used.