Modern water heaters can be used as a reliable source of heating for small individually located residential buildings. A boiler with a high thermal power in the range of 7-12 kW will be quite capable of heating private housing construction up to 100 m2 or a cottage. This heat supply option has its advantages and disadvantages, however, it completely copes with this option.

The positive aspect of a heating boiler is that it can be installed by a home craftsman with his own hands, provided that all individual conditions for such a connection are met. An equally significant argument in favor of such a scheme is the availability of this type of heating at a price and a simple wiring diagram.

Possibility of heating using a boiler

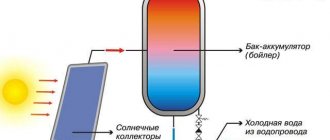

A boiler is an electric heating device for hot water supply. At its core, it is a container inside which a thermal electric heater (TEH) is located. To understand whether it is possible to heat a house using a boiler, you need to understand the fundamental differences between a heating boiler and a heating apparatus. In the first case, when the coolant (water) is heated, it naturally circulates inside the tank (boiler). Cold water enters from above and exits from below.

Boiler market overview

Today, there are many Russian and foreign manufacturers on the domestic water heater market, although the latter are predominantly dominant: MTS, Lorenzi Vasco and others.

Many manufacturers are opening full-cycle production in Russia, producing basic components. This allows us to reduce the price on the domestic market and increase the availability of products for a wide range of consumers. One of these developers is considered to be the Italian corporation Ariston, whose heaters have actually already become a domestic brand.

It has been successfully operating in the Russian market for a long period of time, opening its factories and providing Russians with high-quality heaters. The range of models includes various types of water heating equipment.

Ariston is one of the most recognizable brands of water heatersSource goods.ru

The prevalence of Ariston boilers among buyers is quite high due to the quality of the products and the regular introduction of innovative technologies.

Before using the Ariston water heater, let’s consider its technological and design features:

- the model range includes round and flat heaters of various sizes with a bright design;

- high-quality thermal insulation of boilers and automatic control of operating modes make it possible to save on electricity;

- heater tanks are made of special stainless steel with increased anti-corrosion resistance;

- different models use electronic and mechanical control, which makes it possible to control the water heating process;

- in instantaneous boilers, the heating module is made of copper, which increases its service life;

- In a number of boiler models, the internal coating of the tanks is covered with bioglass porcelain, which completely eliminates the occurrence of corrosion.

In addition, the product range includes electric heaters with a mixed water heating system.

Ariston water heater with touch controlSource santeh.ks.ua

Distinctive features of the boiler for the heating system

As you know, a boiler is a closed vessel that has two holes. The first hole serves as an inlet for cold water, the second as an outlet for hot water. The boiler is powered from the electrical network. All boilers are divided into two groups - flow-through and storage. In a storage boiler, a certain amount of water is heated (the amount of water depends on the displacement of the boiler); in a flow-through boiler, any amount of water can be heated, but this requires more electricity.

Read also: When did the last mammoths become extinct? —

It must be said that using a boiler for heating is quite possible; moreover, today manufacturers produce boilers specifically designed for heating water in the system. These boilers have two significant differences from those intended exclusively for heating water for domestic purposes - for example, for bathing or washing dishes.

- Firstly, in such boilers the inlet for cold water is located at the bottom, and the outlet for hot water is at the top. This arrangement of the holes is explained by the fact that when the water heats up, it rises, and therefore the hottest water is located at the top of the boiler, and it is the use of such water that will make the heating system as efficient as possible.

- Secondly, the boiler, designed for heating water in the heating system, has a large hole diameter. If you look at factory-made boilers, you will see that both the cold water inlet and the hot water outlet are never smaller than 2 inches in diameter (about 4.8 cm).

If the boiler has both of these distinctive features, then it can safely be used as the basis for a heating system - that is exactly what it is intended for. And the movement of water through the heating system itself is carried out due to the fact that cold and hot water have different densities, and cold water, entering the boiler, displaces the hot water first to the top, and then through the hole into the pipes of the system.

Types of double-circuit boilers

There are a considerable number of options for boilers with two circuits. We have divided them into segments and will describe each in detail.

By heating method

- Flow-through. Such models are very popular. They are very powerful and allow hot water to flow into the faucet quickly. In such boilers, either two separate heat exchangers are used (one is used to heat the coolant, and the other is used to transfer heat from the heated coolant of the heating system to the hot water supply circuit), or one bithermic (one heat exchanger heats the coolant of the heating system and hot water).

- With built-in tank. Less common. With this design, the water is first heated in a separate tank and only then enters the mixer. Often, such boiler models are purchased quite rarely. Many people prefer to install a separate boiler and indirect heating tank. But such boiler options are quite possible. As an example, you can look at the Baxi Luna 3 Combi boiler.

By installation method

- Wall-mounted. They are extremely convenient, as they can be installed in any room, be it a corridor or a kitchen. At a fairly low price, these models have good performance. On average, they can provide heat to rooms up to 350 square meters in size. Such models are readily installed both in private houses and in apartments.

- Floor-standing. These boilers are more expensive, but they have high power and are capable of heating a huge cottage with several floors. They take up a lot of space, require a separate room and special care. Often, high-power boilers are all single-circuit, which initially means using a separate tank that will be heated by the boiler.

By method of removing liquid

- With open camera. The chamber receives oxygen from the living space. This is not always possible. The disadvantage of this solution is often the lower efficiency of the boiler. Especially if the chimney is mounted “from the bulldozer”.

- With a closed camera. Air from outside is used. They have high power and excellent tightness. They do not require a full chimney. They are usually equipped with a meter-long coaxial pipe, which is sufficient for normal operation of the boiler.

How to use the boiler?

Turn on the unit and set the desired hot water temperature. On most heaters, manufacturers provide 3 positions: 35, 55-57 and 75 ºС. Some models also have a fourth position – “anti-freeze”, then the temperature in the tank is maintained at 10 ºС. The actual operation is to set the temperature regulator to the desired position and use water. In this case, it is worth following these recommendations:

- never turn on the boiler if for some reason the unit’s tank is empty, this can lead to failure of the heating element. The inlet safety valve has a built-in check valve; its performance must be checked at least once a year;

- Although the boiler temperature is adjusted according to your wishes, you need to turn it on to maximum once every 2 weeks and maintain this mode for 2 hours. This is necessary so that harmful bacteria living in warm water do not multiply in the tank;

- There should be a strainer at the cold water inlet into the house. If the water is hard, then it is necessary to organize additional cleaning and desalting, otherwise all heating equipment, including the boiler, will not last long;

- Once every 2 years, clean the tank from scale, and also check the condition of the protective magnesium anode and, if necessary, change it.

Using an electric instantaneous water heater is also quite simple. The device turns on immediately after opening the tap, the water temperature is regulated by decreasing and increasing the pressure. When the water runs too hot, the pressure must be increased; if it is cold, then decrease. For these devices, water hardness is also important; the presence of a large amount of salts will cause scale inside the heating element. First, the heating intensity will drop, and then the element will fail.

Furnishing a country house with hot water

If the house has just been built and is not yet equipped with a heating system, purchasing a separate water heater is not necessary. You can purchase a double-circuit boiler that connects to both the heating system and the water supply. It works according to the following scheme: when there is no hot water flow, the coolant circulates along the usual route:

- through the main heat exchanger of the heater and the heating system;

- when the user opens the tap, the valves in the boiler switch, so that the coolant is directed to an additional hot water heat exchanger (this is the second circuit).

In summer, a 2-circuit boiler provides hot water flawlessly, but in winter an important drawback appears: while the hot water tap is open, no heat enters the heating system. There are models that periodically add heat to the heating circuit, but then the water from the tap flows either a little hotter or cooler, which is very inconvenient.

Connecting an electric water heater

However, 2-circuit heaters are quite in demand today due to two important advantages:

- one combined device costs less than two separate ones;

- and at the same time takes up a minimum of space.

A double-circuit boiler heats water in flow mode, and if it has low power, the performance will probably seem insufficient. For example, in winter, in order to heat water to a temperature of +40 C in the amount of 5 - 6 l/min (about 0.1 l/sec), and this is exactly the flow rate and temperature needed for taking a shower, you will need power

Q = 4200 * 0.1 *(40 – 7) = 13860 W = 13.86 kW,

Where 4200 J/kg* C is the heat capacity of water, (40 – 7) is the temperature difference. In order to be able to use hot water in at least one more place, you will need a boiler 1.5 times more powerful. It is not practical to buy one for a small house, so instead of a 2-circuit unit it is better to purchase a heater with the ability to connect an indirect heating boiler.

Electric flower

The boiler has a decent volume and, accordingly, takes up a lot of space, but it can fully supply several consumers with hot water, albeit for a limited time (depending on its volume). After the supply of heated water is used up, you will have to wait some time until a new portion warms up.

Indirect heating boilers in winter have the same disadvantages as 2-circuit boilers. Those who are not ready to put up with them buy separate water heaters.

Advantages and disadvantages of heating using a water heater

Like any system, this one has its pros and cons. Let's consider the benefits

- reduction of cash costs for the purchase of equipment. Boilers are an order of magnitude more expensive than heaters, and using an old tank will generally reduce costs to a minimum

- ease of installation. Installing heating from a water boiler only with your own hands without involving third-party specialists is a completely solvable task

- minimal energy loss. Any heater model includes a thermal insulation layer, which is almost always absent from the boiler.

The disadvantages of such a complex include the low power level. It will not be possible to achieve high performance, even if you use a device with a high-performance heating element and a significant tank capacity. The maximum that the design is capable of is the preparation of coolant for hot water supply and heating of a small private house, cottage, or apartment. In addition, the life of the boiler is not designed for uninterrupted operation, which is necessary to maintain a comfortable temperature in the premises. Operating at maximum capacity can lead to a significant reduction in its service life.

How to ensure water supply through pipes - connection diagram

First, let's look at the internal components of the boiler itself. It includes the following parts:

- coil: located inside the water heater and is required to heat the liquid using circulating coolant;

- thermostat: designed to control the temperature of the water inside the boiler itself; when the control temperature is reached, the device turns off automatically and starts working again when the water cools down;

- insulation: ensures long-term heat retention inside the water heater and does not allow the water to cool quickly;

- water supply pipes: they connect the device and the heating system, connecting to the coolant source.

When the boiler itself is already installed in its place, you can begin to connect it to the heating network. It is necessary to remember that the water heater has 4 pipes through which cold and hot water supply passes. They need to be connected according to this diagram.

During one circle with water, the following happens:

- cold water enters the device through 1 pipe;

- using a coil it heats up and remains in the boiler until the thermostat stops heating;

- Water flows through the pipes into the batteries and heat supply occurs.

So you can see that installation does not require much effort. You just need to understand the structure of the device itself. Connecting a storage water heater with your own hands.

Advantages

Such a system has its undeniable advantages. After all, the boiler in this case performs two functions at once, which makes it the most indispensable device in a house or apartment. The device has the following advantages:

- wastes significantly less heat than conventional heaters, this is due to a special layer of thermal insulation;

- simple and convenient installation that does not require much energy;

- saves a lot of money and does not require large installation and maintenance costs; heating boilers are much more expensive than average boilers. Old water heaters are the most economical to use;

- you can independently adjust the required temperature level or stop the heat supply altogether;

- easy to assemble yourself at home, no special tools or plumbing equipment, skills and knowledge in this area are required, just strictly follow the instructions;

- the heating itself comes from the coolant, which reduces the risks of breakthroughs and improper functioning of the system;

- You can use hot water and heating at any time, even if an accident occurs at the station; this is especially common among pipe breaks at thermal power plants in winter - the house will always be warm.

Installation of equipment

Arrangement of your own heating system using a boiler is carried out as follows:

- Selecting a location and preparing it for installing a storage tank. For this purpose, a flat area of at least 1×1 m in size is prepared with the possibility of unhindered approach and maintenance. The degree of reinforcement depends on the volume and mass of the tank. For tanks larger than 200 liters, it is necessary to build a separate concrete foundation, reinforced with reinforcement. The best option is to form an individual platform with thermal insulation. This condition is not significant if there are mounting feet in the design.

- Tank installation. Installation is carried out in strict accordance with the instructions. It is necessary to ensure rigid, stable and reliable fastening in a vertical position. Tilting the tank in any direction is not allowed.

- Installation of a circulation pump. It is installed when used for heating water boilers. In specialized heating devices, the pump is installed only when the pipes in the heating system are long.

- Connecting the heating system. The outlet pipe of the storage tank is connected to the inlet to the system or pump (if available), and the inlet pipe is connected to the heating outlet. To avoid the appearance of excessive hydrostatic resistance, it is necessary to fully match the dimensions of the tank outlet pipe and the system inlet pipe.

- Connection to the water supply is provided through the inlet pipe of the storage tank. Shut-off equipment must be installed to shut off the water as the tank fills.

- Power supply. The boiler must be powered through an individual panel, in which a circuit breaker and an RCD are installed.

- Checking the tightness of connections. It is produced without heating the water.

When installing a heating boiler, the following recommendations should be taken into account:

- If the storage tank is installed in a special compartment outside a heated room, then its body should be additionally insulated. To do this, it is better to use rolled thermal insulation or polystyrene foam.

- After putting the system into operation, it is necessary to constantly monitor the heating temperature and the operation of the automatic control for days. This is necessary to clarify the correct installation and quality of the equipment.

- To simultaneously provide hot water supply, it is recommended to provide an additional outlet for hot water at the outlet of the storage tank.

- Heating using a boiler has a reduced pressure in the network, so the number of turns and branches in the system should be minimized.

- To increase the durability and performance of the system, constant maintenance is required - cleaning the tank from settled impurities and heating elements from scale.

Recommendations for use

Ensuring long-term and uninterrupted operation of the heater is possible with systematic maintenance, which includes

- Cleaning the storage tank. If this is an electrical device, then so is the heating element. It is necessary to remove scale, which quickly corrodes metal walls.

- Timely replacement of the magnesium anode. This point also applies to electric boilers.

- Check the integrity of the thermal insulation layer, as damage to it will cause serious heat loss.

- Checking pipe connections and fittings for leaks. A leak that is not detected in time can cause a decrease in the efficiency of the entire system.

Design of an indirect heating unit

The indirect heating boiler shown in the photo consists of a number of elements, including:

- thermostat with external control unit and control indicator;

- enameled stainless steel tank;

- thermostat sleeves;

- polyurethane insulation without freon, having a thickness of 42 millimeters;

- casing for water heater;

- tubular heat exchanger;

- drain hole;

- inlet for cold coolant;

- outlet for heated water;

- circulation;

- magnesium anode;

- covers for electrical connection.

Method of heating water with a water heater

Modern electric water heaters for heating operate on the same principle as boilers. A large sealed container is filled with water, which is heated using electric heating elements. In this case, heat loss occurs through the housing.

In boilers, the coolant increases the temperature when passing through a heat exchanger with a built-in heating element. Since the volume of this chamber is relatively small, heating occurs quickly. At the same time, heat losses are minimal. It should also be noted that in most cases the design already includes a circulation pump, an expansion tank and a convenient control system. Apart from the latter, electric water heaters for heating of the VEO type do not have these elements.

Criterias of choice

How to choose a boiler for heating your home? To do this, you need to consider the following factors:

- Design features. The best option for a heating boiler is to place the inlet on top of the tank, and the outlet on the bottom, and their diameter should be more than 2 inches. When the inlet and outlet are located on one side, a pump is installed.

- Device power. When using a boiler to heat water, it is necessary to select a device with maximum power - which will make it possible to heat a room of up to 50 m². A specialized heating boiler must have a power of at least

- Volume of the tank. For heating, only a device with a large tank is suitable, which will make it possible to operate the heating element in a gentle mode - the maximum power is set during initial heating to form a reserve of coolant, and then decreases. In domestic boilers, the tank volume should be about 200 liters in specialized ones.

- Materials used. During operation, the tank material is subject to significant corrosion.

When choosing a boiler, you should pay attention to the presence of a protective coating and the material used:

- Porcelain glass or enamel coating provides good protection against corrosion only if it is intact. Mechanical stress and sudden temperature changes cause cracks and other damage, which creates an active corrosion zone.

- The tank body made of stainless steel or titanium is strong and durable, not subject to corrosion. The main disadvantage is that such boilers have a higher cost.

Instructions for starting a Thermex boiler

If installation of equipment is usually carried out by specialists, then the owners themselves have to deal with its startup at least once a year. Let's take a closer look at how to turn on a Termex water heater so as not to negatively affect its performance properties. After all, the duration of operation and frequency of maintenance largely depend on the correct execution of the process.

Work order

Turning on the boiler: The steps for starting the water heater and the settings may vary slightly. It all depends on whether a flow or storage device is used. However, despite the design differences, the order of their inclusion has the same principle. The universal instructions for starting a Termex boiler are as follows:

- Before turning on the water heater, the shut-off valve for supplying hot liquid from the common riser is closed.

This occurs even if a check valve is installed on the pipe. After all, if there is a slight malfunction, the device will heat the central water supply without blocking the channel. - Before connecting the Termex storage water heater to the network, it is filled with water. The outlet of the hot liquid device and the mixer open in turn, and after them the inlet of the cold flow. These manipulations are necessary to displace air from the system.

- After the water has flowed in an even stream, you can turn it off, turn on the unit to the power grid and, after setting the settings and waiting an hour or two, start using it.

The connection diagram for a Thermex water heater when using flow-type devices will be similar, except that the result will be felt immediately.

The next stage after switching on is checking the functionality. Before using the Thermex water heater you need to:

- Make sure that the power indicators light up when plugged in.

- Measure the temperature of the liquid supplied to the mixer.

- After 20 minutes, look at the equipment sensors; if the connection of the boiler with the touch panel is done correctly, the temperature indicator on the device should already increase. If there is no electronic panel, you must once again measure the degree of heating of the water at the outlet of the mixer.

What to do if Thermex does not turn on

The installation process of a Thermex instantaneous water heater or any other model requires the presence of serviceable network elements: sockets, circuit breakers, cables of sufficient thickness. The devices have very high power, so if they do not work, first of all, armed with a tester, you need to check the presence of electricity in the outlet, then the power terminals. Video instructions for installing a Termex water heater will help you find their location, and the tester will help you take readings. If the voltage is zero, then the cable of the electrical appliance is broken.

What to do if the Thermex water heater does not turn on, or rather, power is supplied, but it gives an error - the most popular question. In this case, you need to open the device instructions and look at the explanation corresponding to the code indicated on the display. If this option is not available, the causes of the problem may be the following:

The heating element has a damaged or burnt-out coil. A sign is often a breakdown of electricity on the housing, then the RCD automatically trips and cuts off the power supply. The only way to combat this is by replacing the heating element. The protection is triggered if the heating of the coolant rises above the set limit (usually more than 90 degrees), which occurs both when the control thermostat breaks down and when scale accumulates on the heating element, after which it overheats. The tank is not filled with water. How to turn on a Thermex ID 50V boiler or another model for the first time was discussed above, and if the requirements for removing air from the pipes are not met, a protective mechanism is triggered

Please note that this must be done even if the system is full but has not been used for a long time.

How to use a water heater in a heating system

Power calculation basis : for every 10 m² at least 1 kW is required, otherwise there is no point in installing, the result will be zero.

The boiler can

be connected to heating systems of all possible options.

But it is advisable to do this only for circuits with closed (ring) circulation. Installation - according to standard rules. Types of systems:

- closed

- with pressure, there is no contact of the coolant with air; - open

(fill) – the tank and elements can be opened to add/drain liquid. Less common; - with forced and natural circulation

(gravity, gravity, for which it is necessary to observe the angles of inclination of the pipe distribution); - two- and one-pipe.

A single-pipe scheme is organized when there are few radiators (for a room, a cottage), it is simpler, but there is a minus: the coolant moves through the batteries sequentially, accordingly, becoming colder from section to section. In a two-pipe distribution, all devices have almost the same temperature of the heat-carrying fluid.

The composition of a closed heating system through a storage electric water heater, in brief: boiler, pump, safety group (expansion tank, safety valve) and radiators.

Detailed composition and characteristics of a closed circuit with forced circulation:

| Parameter | Description |

| Type | · closed, circular; · closed, with the ability to add water from the water supply or through a valve. |

| Pump | 35, 60, 100 W. |

| Shut-off valves | Not necessarily, but in front of the radiators, you can install bypasses for cutoff, the pump should also have this capability. |

| Safety | · expansion tank (volume 5% of the total liquid) in front of the pump on the return line paired with a safety valve. Sometimes they put one thing if the expansion is weak; · air vents (Mayevsky valves) are recommended on each battery; at least there should be one on the wiring. In the water heater itself, the issue of air bleeding must be resolved; · a check valve is not necessary if there is no risk of backflow. In open systems, you don't have to set a security group. |

| Filtration | An optional, but recommended pre-filter. |

| Temperature sensor with shutdown relay | They are placed in a heated room so that the boiler and pump work to maintain the temperature. |

| Batteries and pipes | A less labor-intensive option is metal-plastic pipes, which are easily cut and connected with fittings. |

| Coolant | • water – technical, drinking; • antifreeze (anti-freeze) – no need to drain at sub-zero temperatures. |

The schemes are usual, as in equipment with boilers, several options:

Open heating system with pump

Open heating system without pump

Closed two-pipe heating system with safety group

Open single-pipe system (Leningradka) with pump without safety group

Examples of existing schemes for connecting a storage electric boiler to heating

Examples of successfully implemented schemes for using storage water heaters for heating:

- area 10 m², 10 liter boiler with top connection for sink (the issue of air bleed has been resolved). Composition: 5 l hydraulic tank, pressure gauge, thermometer, tee for filling, air vent, 60 W pump. Antifreeze is used. Equipped with 2 atm. The main thing is tightness - the antifreeze has high fluidity;

- boiler 15 l, 2 kW, pump, pipes (plastic) 20 mm, aluminum batteries 2 pcs. There is no longer enough power for 3 radiators. Warms a well-insulated space of 30 m²;

- storage boiler 80 l, pump, expansion tank, 3 batteries in three rooms, hydraulic arrow;

- capacity 50 l, area 32 m², two ten-section aluminum batteries. The pump and expansion tank are placed on the return line. Antifreeze acts as a coolant.

How a heating system with a boiler works: limitations, warnings

Cautions for storage water heaters:

- EWHs with lower fittings, and these are the majority, are not suitable for gravity-flow options;

- the inlet and outlet are small in diameter in household appliances, 1/2″, 3/4″, but to connect to pipes you need 2″. Adapters will be required, and if the area is large, for example, 150 m², then it is advisable to increase the fittings themselves.

The main obstacle is bleeding air: if it becomes airy, the pump will simply stop pumping.

Storage electric water heaters have an entrance at the bottom and an exit at the top. The water heats up and rises, which allows them to be used in gravity flow systems, and there is also a natural removal of air, which is then released by diverters on the pipes.

In most household EWHs for domestic hot water, the fittings are at the bottom, air accumulates at the top and is difficult to bleed off.

In hot water supply with a domestic boiler, the air comes out naturally through the mixer - no airing occurs, but in heating this is impossible. It is necessary to organize an outlet or intake at the top so that the air goes into the main line, where it is released by a valve.

Solving the problems of air traffic jams (we will also consider controversial methods):

- the best way is to embed a safety group with a vent at the top of the tank (Mayevsky tap, automatic air vent);

- some EWHs have a magnesium anode screwed into the top, which is unscrewed, transferred to a flange with heating elements, the hot pipe is turned off at the bottom, and the pipe is brought out from above;

- find models with an air vent or a hot outlet at the top. Such solutions are available for floor-mounted water heaters, small tanks for washing, with side connections;

- place the circulation pump at the entrance to the tank at a large distance (1 - 2 m), and after the pump - an expansion tank and a safety valve;

- It would seem that the simplest solution - turning the boiler over - will not work. The heating elements are at the top, the water below will not warm up, but will boil near the heater.

Installation and use for heating

After all the calculations and measurements are completed, you can safely begin installing the boiler and introducing it into the heating system of the house. Before this, one question needs to be resolved - what place the device will take. This is an extremely important point in modernizing the system. Professionals advise installing the boiler in close proximity to the boiler, then the temperature indicators will be quite optimal for heating the premises. And after that, you should study the instructions for the device, because everything is indicated there - from technical characteristics to recommendations from manufacturers.

Even with strict adherence to all the advice, owners often encounter difficulties in introducing a water heater into the heating system. The situations are:

- Hot water supply. The ideal location for a solid fuel boiler is a boiler room or a room where the main communication mechanisms in the house are concentrated. The problem is that hot water requires the installation of an additional pump and all its accessories.

- A large volume of water heater in the case when the purchase of a boiler is needed for heating rooms with a large cubic capacity. And placing a large device even in large rooms is another concern.

- Connecting the electrical network of the heating element. In order for the water heater to operate without interruption, it must be provided with a separate autonomous source of energy.

If the problems are resolved or they did not arise at all before, then you can proceed to installation and commissioning.

The temperature of the water inside the device is controlled and viewed through a mounted thermometer. It is usually not included as a component in the kit, but it can be purchased at any hardware store.

Heating storage tank equipment

To place the heat accumulator in its rightful place, you must first prepare the site. Since the unit weighs a lot, the flooring must be strong and perfectly level to support the weight. In this case, it is equipped with an additional foundation or a new concrete screed.

The ideal option would be to equip a separate area for a weighty device. Thus, the housing does not touch the concrete and does not create pressure on it. In addition, it significantly reduces the number of heat losses.

You can buy a model equipped with special legs. Then, instead of a platform, a layer of heat-insulating material should be laid on that area under the floor.

Installation and implementation follow step-by-step instructions:

- First, you should check how level the boiler is in its place. It must be either strictly horizontal or vertical. Under no circumstances are even the slightest tilts allowed.

- Then comes the most crucial moment - connection. For high-quality operation, the pipes of the system and the boiler itself must have an equal diameter in order to avoid excessive hydraulic resistance during testing and subsequent operation.

- Provided that the room is not equipped with radiators and other heating elements, the body of the water heater should be wrapped with a layer of thermal insulation.

- Now the boiler can be connected to the hot water pipes. Then it will not only heat the room, but also provide water for household and household needs.

The final stage is always checking the nodes and connections. The owner should run the entire system. For half a month, you will have to note the temperature regime maintained in the pipes and the boiler itself by disconnecting the boiler from the network.

Professionals do not recommend pouring antifreeze liquid inside to increase efficiency. It does not have the necessary characteristics for full heating of water. Then the quality and temperature will be low.

Recommendations for use

Any electrical equipment requires additional care. With proper operation and inspection, the device will serve reliably for many years. To do this, it is enough to follow all the recommendations given by the manufacturers in the instructions.

The procedures begin immediately from the moment of purchase. And the very first thing is to purchase a model with dry heating elements. Their advantages are that scale settles inside the elements much more slowly (and there are much more impurities and salts in hot water). An additional measure is to fill the unit with pre-filtered water into a storage tank.

There are a number of other measures to protect the heater:

- Inspect the structure for integrity once every 30 days.

- Monitor temperature conditions during working hours. This applies to both the boiler and the boiler, especially in late autumn and winter. Under ideal conditions, the difference between them is no more than 15%.

- Replace gaskets in a timely manner. Then the heating system will work well and heat the house efficiently.

- Particular attention should be paid to the control unit. His life and work depend on fluctuations in the electrical network, which is why he often breaks down. To avoid this, you need to additionally connect a stabilizer.

To clean the heating elements of the boiler, you should open it and pull it out. But before that, think about whether you have enough strength and experience to put everything back together, and whether the manufacturer’s warranty will remain valid.

Installation of a heating water heater

The body of the unit is placed on the floor, as it has significant weight. The equipment may include height-adjustable legs. If they are not available, to install it, it is recommended to pour a separate concrete platform and put a layer of thermal insulation on it. It is important that the tank is positioned strictly vertically, which must be checked for level.

Do-it-yourself heating from a water heater is installed in a standard manner, for which the diagram is shown in Figure 1. A safety valve is installed at the inlet to regulate the pressure, and at the point of supply from the cold water complex, a shut-off valve is connected to prevent the reverse movement of the coolant.

A circulation pump is installed on the supply line after the hot water supply comb, ensuring forced movement of the working medium through the heating system. If DHW is not provided for in the engineering complex plan, the boiler is connected directly to the heating distribution.

Selection of design and materials for installation

First of all, you need to decide on the type of water heater that will act as a boiler. This characteristic will largely affect the installation and connection algorithm. Here you can use one of three types of equipment

- Gas. In order for heating from a water heater equipped with your own hands to be energy efficient, it is recommended to use flow-through devices that operate online. They usually have sufficient power and performance, in addition, gas as a fuel is economical. When organizing such a system, it is important to pay special attention to safety issues, since overheating, burner extinguishing or lack of draft in the chimney can lead to emergency situations.

- Electric. In this case, the heat generator is created on the basis of a storage tank with a heating element. It is better to choose models with a “dry” heating element, as they are less susceptible to corrosion. It is also necessary to take into account its power, which should be from 8 kW. It makes no sense to install devices with smaller parameters in the heating system. It is also important to pay attention to the condition of the wiring, which must be able to withstand peak loads. It would be a good idea to calculate the operating costs of the complex, since electrical equipment is more expensive than fuel-powered units.

- Indirect heating. Such equipment is a storage tank equipped with a coil that is connected to the boiler. The heated working medium circulates inside this tube. In this scheme, the boiler acts as an energy accumulator, which, after turning off the main unit, heats the coolant in the coil. Here, heating from a water heater is created with your own hands to increase the power of an existing complex. At the same time, it is possible to provide hot water supply in full. The main thing is to correctly calculate the tank capacity.

Electric boiler for heating: is there an alternative to the boiler?

When designing a heating system, many of us try to simplify its design as much as possible, thereby reducing the costs of purchasing components, connecting and operating. It is these considerations that most often underlie the idea of using an electric boiler for heating an apartment or private house.

Despite the fact that the inappropriate use of electrical appliances in itself is not the best idea, we will still try to figure it out - is it possible, in principle, to assemble a room heating system based on a household electric boiler?

Electric water heater as a heating device

Check valve for pump

When you open a water tap while the pump is not working, parasitic circulation of water may appear along the circuit: from the water supply through the pump - the boiler and the boiler. A check valve installed after the pump prevents this. The opening pressure of the check valve (the minimum differential pressure of the valve opening) must be such that the parasitic circulation of water in the circuit does not start the boiler into operation. As a rule, installing a conventional spring check valve for heating is sufficient for this.

There are commercially available check valves with different spring forces (minimum opening pressure) or even with adjustable “opening pressure”. For example, a Genebre valve has an opening pressure of 0.04 Bar, almost 2 times more than Valtec (0.025 Bar) or Barberi (0.02 Bar). See valve data sheet.

Be sure to choose a check valve whose body and spool plate are made of brass. The valve must be designed for an operating temperature of at least 95 °C and a pressure of at least 10 bar.

In addition, I recommend connecting the pipe from the water supply to the system as close as possible to the boiler pipe.

How to make a water heater with your own hands: ov

Before you begin the process of installing a water heater, you need to stock up on the required parts and tools. Today, many are forced to use water heaters due to the lack of mechanized water supply. A water heater allows you to use hot water at any convenient time, which significantly saves time and effort on heating water on the stove. Equipment of this kind is very expensive, but when used correctly it lasts a long time. Those who want to save money or do not have the opportunity to purchase a new electric storage water heater can make a water heater with their own hands

.

Peculiarities

There is no need for very complex calculations or the use of precise instruments and measurements. Every self-respecting paint manufacturer, for example, Dulux, presents on its website a special calculator that allows you to calculate the actual consumption of paint and varnish material almost accurately. In addition, the consumption rate of paint and varnish material must be written on cans and other containers (how much surface can be painted with 1 kg or 1 liter of paint)

It is important to note that the marking shows the consumption of dye applied to a hard and perfectly smooth surface, which was treated with two layers of paint after thorough priming

Types of devices

All boilers are divided into 2 main types:

- Flow type. In such a device there is only a small container, and the water is heated “on pass”. This is ensured by equipping boilers with high-power heaters. This type can be used to heat small rooms, but it will require high power consumption and continuous operation of the heater.

- Cumulative type. It is most suitable for heating systems, because... contains a tank in which water is heated. This boiler has a certain inertia, i.e. Heating of the room will begin only when the entire volume of the tank is heated, which will take a certain time. Subsequently, by creating a coolant reserve, you can periodically turn off the electricity supply, which reduces its consumption.

When we talk about boilers, we usually mean electrical devices containing heating elements. However, there is another option when water heating is provided by gas - gas boilers. They are used less frequently, but are quite suitable if there is a centralized gas supply. In this case, you can use the flow-through design of the device.

Keep in mind that the use of gas boilers for home heating requires obtaining special permission from the relevant services and installing a gas flow meter. No permit is required when using electrical household appliances.

Advantages and disadvantages

The main advantage of boilers for heating a home is the simplicity of the system and low cost. To install boiler heating, no special equipment is required, and installation can be done independently.

The main disadvantage of boilers is their low power. Conventional household appliances are capable of heating only small houses and cottages, and even in moderate frost outside. In addition, heating elements must operate continuously in the cold season, which leads to their frequent failure. The heaters themselves have a low price, but repairs are quite labor-intensive, which stops the heating system for a long time.

Main technical characteristics

- Power. Its choice depends on the heated area. On average, the calculation is taken from the ratio of 1 kW boiler – 1 m2 of room area.

- Storage tank volume. The amount of coolant in the system directly depends on this indicator, so the larger it is, the more productive it will be. The best option is to choose a container of 300 liters or more.

- Location of pipes. It is advisable that the cold water inlet be at the bottom and the hot water outlet at the top of the housing. In this case, heating from the boiler will be effective since the scheme with opposite placement of connections implies the impossibility of mixing flows with different temperatures. As a result, the maximum heated coolant will flow from the device into the system.

- Diameter of connections. Most often, ¾-inch pipes or flexible connections are used to install a water heater. To install a heating complex, it is recommended to use wiring with a diameter of 2 inches.

- The degree of branching of the complex. The fewer circuits and consumers, the easier it will be to maintain a comfortable temperature.

- Circulation pump flow. Determines the ability to pass a certain volume of working medium per unit of time. The larger it is, the faster the coolant will move through the pipeline.

Instructions for starting the boiler for the first time

Boiler installed

Whether the installation work was carried out by specialists or the owner does not matter. In any case, you need to check the operation of the system

To do this, following the given tips, you need to start the heater for the first time.

We start by checking the correct connection of the systems that are responsible for heating the water. Fidelity, reliability of connection of phase and neutral wires, presence of grounding. The functionality of the circuit breaker should also be checked. To do this, use a device - a tester or a special electrician's screwdriver.

Next comes the search for leaks in the system. It would be useful to control the connection of underwater pipes. Presence and diagnostics of check valve operation.

Running water into the boiler

Attention, the correct sequence of actions for the first and subsequent starts of the system will be described in the next section. Repeated search for water leaks in pipe installation areas.

Diagnostics of heater operation. Turn on the device by pressing the power button.

Fixing the initial temperature sensor readings.

Recheck after 15 minutes

An increase in indicators indicates the correct connection of the heating elements.

Review of water heaters for electric heating

Manufacturers of heating devices already produce conventional boilers, adapted for installation in heat supply networks. Their thermal power has been increased to 12 kW, in addition, they have increased input diameters for connection to the in-house heating system.

Heating from a boiler is not difficult to implement. Since such equipment is widely represented on the market, both domestic and foreign manufacturers. Their choice will depend on the required type of energy carrier and the type of heating: capacitive or indirect heating. The latter are more used in autonomous heat supply schemes, so the principle applies here - the more, the better. They are well used during the heating season, and

In summer, for hot water supply, it is wiser to use combined water heaters.

The most popular models of water heaters that are used in heating systems:

- Heating boiler Thermex Champion Titaniumheat 150 V, made in Russia, heating element, volume 150 l, price - 12,190 rubles.

- Water heater for heating Gorenje TGU150NGB6, made in Serbia, heating element, volume 150 l, price - 14,320 rubles.

- Ariston ABS PRO R 150 V, made in Russia, heating element, volume 150 l, price – 14970 rub.

- Bosch WSTB 200, made in Germany, indirect heating, volume 197 l, price - 40,833 rubles.

- Baxi Premier plus 150 (30 kW), made in Italy, indirect heating, volume 150 l, stainless steel tank price - 68,600 rubles.

- Buderus Logalux SU160/5 made in Germany, indirect heating “coil in coil”, stainless steel DUPLEX, volume 160 l, price - 68869 rub.

The principle of operation of a boiler with two circuits

From the name it is clear that such a device has all two circuits. The first circuit is intended for heating. The second is to provide hot water. The operating principle of a double-circuit boiler is simple. The default is to use the first circuit. No heat enters the second circuit. A special valve is used for this. When the hot water turns on, the valve prevents heat from entering the heating system. Instead, it enters the second circuit and heats the water. When the water turns off, only the heating works again. That is, hot water is used on demand and the rest of the time there is no excess gas consumption

Storage tank as an alternative to a traditional boiler

Indirect heating tank design

The storage tank is structurally almost completely similar to a classic boiler. The difference lies in the internal piping that connects to the heating system. In this case, it is necessary to resolve the question - why is a boiler needed in the heating system?

Properly organized heating through a boiler assumes that this element will act as a heat accumulator. The water in the container receives thermal energy through an internal coil connected to the heating system. After the boiler is turned off, the reverse process will occur - the temperature of the coolant from the water in the boiler will increase.

Connection diagram of the boiler to heating

In addition, after the boiler has been correctly connected to the heating system, it will be able to perform the following functions:

- Organization of hot water supply . Since the liquid from the container does not come into contact with the coolant, it can be used on the farm. But to do this, it is necessary to correctly calculate the power of the boiler for heating the house so that this does not affect the heat supply parameters;

- Heating of water using a built-in heating element . In this way, it is possible to maintain the heating level of the coolant even when the boiler is inactive. This can only be done by purchasing an electric heating boiler.

It is important to initially decide on the purpose of the storage tank - will it be intended for hot water supply, work as a heat accumulator, or combine these functions. Based on the decision made, the optimal volume is calculated and a heating scheme from the boiler is selected.

You can make a storage container yourself. To reduce heat losses, it is necessary to insulate the housing.

How to choose the best appliance for your home?

The answer to the question of why a boiler is needed in a heating system has already been found. The next point for owners who have decided that this device is necessary will be to become familiar with the criteria for its selection.

What do they pay attention to?

Before purchasing, you need to check the power of the heating system. An incorrectly selected device will definitely cause problems. If the unit is too large, the coolant in the heating circuit will not be able to cope with heating the water. There are two options: either very slow heating of the liquid, or an inevitable and noticeable drop in temperature in the premises of the house.

The type of boiler also matters, so future owners will have to choose between a wall-mounted and a floor-standing unit. In this case, they act in a logical way - choose a device similar to a heating boiler. If it is wall-mounted, then it is better to buy the same model of water heater, or vice versa, for a floor-standing device - the same equipment. There is one more point: experts recommend purchasing a tandem made by one manufacturer. In this case, there will be no problems with the installation or operation of the units.

If the house has a gas supply system, then it is logical to purchase a gas unit: these models are economical, so costs will be minimal. It often happens that there is no way to connect to the gas main, and the owners do not consider the use of gas tanks or cylinders an attractive option. In this case, the only solution is to purchase an electric boiler: up to 8 kW from a 220 V network and up to 30 kW for 380 V.

Capacity is the main criterion

To find the optimal volume, you can use one simple method. You need to find out the average statistical indicators of water consumption, select the closest options (or maximum), sum them up, and then multiply them by the number of people permanently living in the house. It is recommended to round up the result obtained.

Now we need to give these “very average” fluid consumption figures:

- taking a bath - from 160 to 180 l;

- taking a shower - from 60 to 85 l;

- washing dishes - from 20 to 25 l;

- washing - from 6 to 16 liters.

As already noted, the time required for high-quality heating of water depends on the volume of the boiler tank. Therefore, we need to give two examples: the liquid in a 200-liter water heater will heat up for 6 hours. It will take approximately 40 minutes for the coolant to prepare water in a tank with a capacity of 20 liters.

There are several other points on which the service life and ease of operation and maintenance of devices depend.

Coil material

It's better to find out in advance. As a rule, inexpensive water heaters are equipped with steel elements that are welded to the tank. Models in a higher price category use heat exchangers made of brass. They are made removable, which allows you to periodically disassemble the device and clean the coil, removing scale.

Tank material

The inner surface of the tank of budget models is protected by coatings - layers of enamel or glass ceramics. This is not to say that this option is reliable. Frequent temperature changes will have a detrimental effect on both types of materials. Cracks will inevitably appear on the surface, which means that sooner or later the owners will be faced with metal corrosion. A stainless steel tank, on the contrary, is an option without any disadvantages, so its higher price is fully justified.

Insulation quality

The type of thermal insulation material is the last point on which you need to dwell when getting acquainted with the model of water heater you like. Some boilers use the simplest option - foam rubber. This heat insulator is impractical and short-lived, so it is better not to consider such models at all. The ideal choice for a water heater would be polyurethane. This insulation is a guarantee that there will be virtually no heat loss, which means that spending on “extra” electricity is eliminated.

Manufacturers

It will not be a revelation to anyone that it is always better to purchase equipment from well-known manufacturers. If we consider only water heating equipment, then it is better to give preference to companies that have long earned a reputation. These include Ariston, Bosch, Electrolux, Gorenje, Thermona, Viessmann, Zanussi, etc.

The following video will tell and show why a boiler is needed in a heating system:

Calculation of the volume of the storage tank and the power of the heating element

Areas of application of the heat accumulator

At the first stage, it is necessary to calculate the power of the boiler for heating the house. There are several ways to solve this problem. The best way is to read the recommendations from the manufacturer of a specific tank model.

It must be taken into account that the heating scheme from the boiler directly depends on the power of the entire system. Therefore, this value is taken as the initial parameter. Let's assume it is 1 kW/h. After installing a boiler in the heating system of a private home, it must maintain the optimal level of water heating for another 5 hours. In this case, the thermal mode of the system is 75/50 (low temperature). In this case, the optimal volume of the boiler for heating and hot water supply is calculated using the following formula:

V=5/(75-50)=0.5 m³ or 500 l

The resulting volume can be reduced if you purchase a boiler model for heating a summer house with a heating element. Then, when calculating, you need to take into account the specific power of this device. On average, to ensure full heating operation when the boiler is turned off and the average DHW consumption rate (10 l/hour), you need to purchase a model with a volume of about 400-450 liters.

To fully calculate the power of a boiler for heating a house, it is necessary to take into account all factors - heat losses in the building, location of the tank in the system, etc.

Do-it-yourself electric boiler for the heating system

The price of industrial modifications of heating water heaters is very high - from 12,000 to 70,000 rubles. and higher. Therefore, their alternative can be a heater made in-house. For this case, it is allowed to use an arbitrary steel tank of increased strength, with parameters corresponding to the design ones.

To wire the heating circuits of a homemade water heater, you will need the following parts:

- Tank. It would be preferable to place an order from a specialized organization for a device made of non-corrosive steel or assemble it yourself. It is necessary to place holes on the body in order to solder the inlet/outlet pipes.

- Coil heating element, the best choice is copper. This metal has the best heat transfer coefficient and temperature elasticity.

- Fastening elements for piping heating and hot water systems.

- Automatic safety with primary sensors and protective devices in the form of an air vent and an expansion tank. The kit is purchased in a retail chain according to the parameters of the working tank.

- Thermal protection of the boiler from loss of thermal energy. To do this, a glass wool/basalt heat insulator of at least 5 cm is placed in the layer between the tank and the protective casing.

Solenoid valve for DHW system with water recirculation

Solenoid valve UNIPUMP BCX-20 3/4″ (normally closed)

Operating medium temperature range – 0…+120 ºС Operating pressure – 0.5…16 bar Power supply parameters – ~220 ±10% V, 50 Hz Protection degree – IP65 Normal closed 20 – DN (nominal diameter) in mm

A normally closed valve opens the way for liquid flow when voltage of ~220 V enters the valve coil (solenoid).