A gas water heater or gas heater is a metal body with two pipes attached to it, supplying cold water for heating and gas. A gas water heater has several components:

- Radiator;

- Gas supply pipe;

- Burner;

- Igniter.

Cold water supplied through the pipe puts pressure on the membrane that releases the gas. When it begins to flow into the burner, it is ignited by the igniter, which heats the heat exchanger, through which warm water flows to the tap.

The igniter can be with piezoelectric, manual or electronic ignition. The gas is automatically ignited when the water tap is opened.

Why is the geyser leaking - what to do

If there is no maintenance, after 4-5 years of operation, you may suddenly encounter water starting to drip from your instantaneous gas water heater. Leaks occur for several reasons.

Some problems are easy to fix yourself. Others require skilled maintenance. If the owner is faced with the fact that his gas water heater is leaking, there are several important points to consider:

- Is it possible to use a faulty water heater?

what causes the leak;

- methods for eliminating leaks and increased condensation formation.

Regardless of how intensely water drips from the boiler, it is necessary to determine the cause of the leak and eliminate it immediately.

When and where can I file a complaint?

ABOUT US A úþüÿðýøàøÃÂúûÃÂÃÂà¸ãâââlas ”ã] ã] ãâ² ã¿¿¿ããlaceãââãããâ ]Turey paper ã] ã²ããããulate. ÃÂÃÂõÃÂõý÷øàÿþ ÃÂûðñþüàýðÿþààòþôàò úòðÃÂÃÂøÃÂõ ÃÂûõôÃÂõàÃÂþà VALUE °ÃÂ, þôøý â ÿõÃÂõôðÃÂàò ãÃÂ, ð òÃÂþ ÃÂþù àòÃÂþôÃÂÃÂõù þÃÂüõÃÂúþù â þ ÃÂÃÂðòøÃÂàÃÂõñÃÂ. 59 Chapter 59 ÷ðÃÂòûõýøàóÃÂðöôðý ÃÂðÃÂÃÂüðÃÂÃÂà ¸Ã²Ã°ÃÂÃÂÃÂàôþÔ A A ÿþôðÃÂø ò þÃÂóðýø÷ð ÃÂøÃÂ.

Is it possible to use the column if it leaks?

Only serviceable, operational gas-consuming equipment is allowed for operation. It is prohibited to use a gas water heater if it is dripping. There are several consequences of turning on a faulty water heater:

there is a high probability of the burner flooding with water from the heat exchanger, which leads to an explosion and gas poisoning (if the combustion control function is missing or faulty in the column);

If the leak was caused by a malfunction of the water unit, the automatic gas water heater simply will not start. The block is connected to the ignition system and gas valve. A leak indicates a malfunction of the gearbox and often after a short period of time leads to complete failure of the water heater.

Technical reasons for column leakage

There are two main failures that lead to leaks. The malfunction is determined by the method of exclusion. The breakdown is indicated by the localization of the appearance of liquid. So, if water flows from below, most likely the malfunction is associated with a failure of the gearbox. When condensation appears, the breakdown is associated with the heat exchanger.

Below is a description of common problems:

- The malfunction of the water unit is a gearbox, a simple control device that sends a signal to open the gas valve and to the ignition unit. Inside, the “frog” is a hollow structure divided in half by a membrane. When water is supplied to the reducer, pressure is applied to the diaphragm, which in turn leads to the movement of the rod connected to the gas valve. The membrane fails due to prolonged pressure and mechanical stress. Signs of a breakthrough:

- water drips from the safety valve of the gas water heater - the membrane blocks the access of liquid, but the barrier disappears after damage or wear of the gasket;

- the water unit is leaking - another clear sign of failure of the membrane or rod seal. Initially, only a few drops of water are released during operation. Over time, the flow in the frog becomes more intense.

Corrosion or hole in the heat exchanger (radiator) - the steel or copper tubes of the coil are subject to constant thermal stress. As a result of direct exposure to fire, microcracks form on the metal surface. Burnout of the tubes occurs. The first sign of failure is the accumulation of condensation on the body and internal components of the water heater. In places of leakage, copper changes color to poisonous green.

To eliminate a leak, you must determine its root cause. For this purpose, remove the boiler casing and carry out a visual inspection. Work begins after determining the location and intensity of the leak. Before servicing, turn off the gas and water supplies.

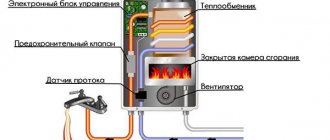

Water heater operating algorithm

If you have little understanding of the structure and operating principle of a modern geyser, we recommend that you familiarize yourself with this section, otherwise you will not be able to repair the device. The design of an atmospheric heater with an open combustion chamber is shown in the diagram below.

Note. The photo shows an old type column with manual ignition of the burner from a piezoelectric element. Updated versions of the devices (including the Russian brand “Neva”) ignite automatically; the power source is batteries or a 220-volt home power supply.

A turbocharged column is designed in a similar way, only the combustion chamber is completely closed, and a fan supplies air to the burner. The algorithm for starting the unit and heating water for DHW needs looks like this:

- After opening the mixer tap, a flow occurs through the water unit and the column heat exchanger.

- A membrane installed inside the frog body pushes the rod forward due to water pressure. The latter compresses the spring of the mechanical valve in the gas block, opening the passage of fuel to the burner.

- At the same time, the rod releases the microswitch button, closing the solenoid valve circuit. It is triggered and releases gas into the supply tube, where there is an already open spring valve.

- At this moment, the pulse device delivers a high-voltage discharge to the electrodes installed near the burner. A spark ignites and the water begins to heat up.

- Three sensors are connected in series to the solenoid valve circuit - thrust, overheating and flame (ionization). When the latter detects the presence of fire, sparking stops.

Reference. In older water heaters, instead of two electrodes igniting the main burner, one contact and a constantly burning pilot light are used. The presence of a flame is monitored by a thermocouple.

Now let's look at the most important point necessary for a successful repair. Under what conditions does the column automatically turn off (the main burner goes out):

- when the flow and pressure of water disappear, the “frog” releases the pusher, the microswitch opens, and the power supply to the solenoid valve is interrupted;

- if the ionization electrode does not “see” the flame and does not give the corresponding signal, the magnetic valve closes the gas;

- the draft in the chimney disappears, the sensor breaks the circuit and the electromagnet turns off, cutting off the fuel supply;

- The overheat sensor installed on the heat exchanger affects the gas block in a similar way.

How to fix a leak in a column

First, identify the source of the leak. This can be done quite simply by visual inspection. The casing is attached with latches or fixed with bolts. If water drips from the geyser only when you turn it on, you will need to start heating the water for a few seconds. After identifying the location of the breakdown, they begin to eliminate the leak:

- Threaded and other connections - leaks are eliminated by changing all the gaskets and re-packing the connection. To improve sealing, special silicone compounds (sealants) are used. If a hose leaks, it must be replaced; it cannot be repaired. The average service life of gaskets is 2-4 years. You can prevent leakage by carrying out regular maintenance of the water heater, with the replacement of all sealing rubber bands.

You can eliminate leaks at threaded connections yourself. Repairing a “frog” requires certain technical skills and a clear understanding of how the water unit works.

Condensate in a gas water heater - what to do

In this case, the problem is more serious. Most likely there is a leak in the heater. Occurs under the influence of small microcracks. Initially, perspiration appears on the body and internal parts of the speaker. Subsequently, condensation begins to drip from the gas water heater.

A heater (radiator, coil or heat exchanger) consists of pipes with fins. When exposed to direct fire, the metal will burn out over time. Thinning pipe walls lead to leaks and condensation. The malfunction must be corrected immediately. Replacing the radiator or soldering the damaged area will help get rid of condensation.

Soldering is performed in the following way:

- the liquid from the heat exchanger is drained;

remove all dirt and scale from the surface;

soldering is performed with a soldering iron heated to 180°C and a power of at least 100 W;

Main types of faults

You can fix a malfunction in a gas water heater by turning to specialists for help or doing it yourself. But still, when working with such equipment, it is necessary to know the safety measures, as well as their strict adherence.

IMPORTANT! Otherwise, independent repair of a gas water heater is fraught with HUMAN SACRIFICES.

List of breakdowns found in geysers:

- The igniter does not light;

- The pilot light goes out;

- There is a pipe leaking in the radiator;

- Water is leaking at the connections.

There are two main reasons why a gas water heater leaks. Failure is determined by elimination. Where exactly the fault is located is indicated by the localization of the liquid. The fact that the gearbox has failed will be indicated by water flowing from below. If condensation appears in the column, the heat exchanger (gas column radiator) is faulty.

The most common breakdowns:

- A reducer or water block is a device that sends a signal to open the gas valve and then to ignite. From the inside, the gearbox looks like a hollow structure, divided in two by a membrane. When water is supplied to the reducer, pressure arises, from which the membrane wears out over time, leading to malfunctions. When liquid drips from the column's safety valve, this means that the membrane is blocking water access, but due to wear, the barrier disappears.

- Another sign of a problem with the membrane is a leaking water unit. Such a breakdown can also be caused by failure of the rod sealing gasket.

At first, during operation, only a few drops of water are released; over time, the flow in the gas water heater becomes more and more intense. Microcracks or corrosion in the radiator appear due to constant exposure to fire. As a result, the copper or steel pipes of the coil burn out. In this case, condensation first accumulates on the internal components and the housing. Leak points are indicated by a change in the color of the copper - it turns green.

First of all, if water is flowing from a gas water heater, you need to check the places to which the pipes are connected. This will prevent leaks due to failure of gaskets and loose threaded connections.

Difficulties with models

In many ways, leaks in geysers are caused by the same reasons. But in devices of different brands, specific breakdowns more often occur, leading to similar problems.

For example, the Neva gas water heater leaks most often for the following reasons:

- Membrane failures.

- Rod seal leaks.

- Violations of the integrity of the rod plate

Automatic budget models of this brand, such as Neva 4510, often leak due to heat exchanger failures. It has an aluminum body and is not very durable.

In such units, gas often leaks due to the thin-walled igniter tube and drying out of the seal.

Solving this problem on your own is dangerous. In many cases, these tubes break when disassembling the column.

It is also extremely difficult to eliminate a leak in the rod seal, since the connecting bolts of the gas and water compartments are very difficult to unscrew, as well as the microswitch. These fasteners often break during disassembly.

Water drips from the Junkers geyser for the following reasons:

- Radiator failures.

- Drying the O-rings (more common in older models).

- Cracks in the place where the frog is attached (flow regulator).

- Membrane wear.

You can solve these difficulties with your own efforts. Point 1 can be corrected by carrying out soldering work. P.2 – replacing these rings. This is also one of the ways to correct step 3.

In general, we need high-quality and timely repair of the water unit of the Junkers geyser.

At home, you will need to disassemble the column and remove this unit. In most cases, the problem lies in a worn membrane and cover. These elements need to be replaced.

Such problems most often occur with models of the Junkers W 275 1 line. And if replacing the problematic parts does not bear fruit, you need to contact the specialists.

Quite often, customers contact the service - owners of Bosch speakers, the membranes of which wear out quite quickly. Experts recommend always having several of these products in stock.

Owners of Ariston speakers often complain about leaks from below. This is due to a worn flange gasket. It has to be replaced. To do this, the device is de-energized and all the water is drained from it. The cover is removed, the flange is taken out, the gasket is changed.

The second common reason for models of this brand is a violation of the sealing of the connecting sections. The solution is to coat these areas with a powerful sealant.

The same problem is relevant for Oasis speakers. They also often leak from under the flange and due to scale accumulation. The owners of this equipment need to change the anode 2-3 times a year. Otherwise, the heating element will leak or completely collapse. Therefore, you should regularly clean the device from dirt and scale.

Owners of Astra gas water heaters often complain about leaks in the connecting areas and wear and tear of the maintenance equipment. A temporary solution to the problem is soldering. Effective - purchasing new maintenance.

In Electrolux speakers, the most common causes of leaks lie in the radiator. The solution is quick and high-quality soldering.

Vaillant models often have problems with gaskets and maintenance. It is logical to replace these elements.

Whatever type of gas water heater you have, regularly remove dirt and scale from it. If problems are discovered, fix them immediately if you have the necessary experience. Most often, the most effective method of solving a problem is to replace a particular part or assembly.

The geyser is leaking: what to do if water drips

The column or flow heater is becoming an increasingly popular product. A small device can fit compactly in the kitchen and provide hot water to several points of intake. In addition, heating with gas is cheaper than heating with electricity. But what to do if the gas water heater is leaking? Should I call a professional or figure out the problem myself? Possible options are indicated in the article.

Where does the water in the column come from?

To understand the causes of the problem, you need to understand the device. The basis of the design is a metal body, to which two pipes are connected. A flow of water passes through one for heating, and gas is supplied through the other.

Water pressure acts on the membrane, the igniter and burner are activated. It heats the heat exchanger through which cold water moves. You open the faucet and get a hot stream.

Most dispensers operate automatically as soon as the tap opens. Manual and piezoelectric ignition is also found.

Why did the column leak?

There can be several reasons for a leak.

- Gaskets between connections are worn out. Rubber gaskets are installed between the pipes and pipes for tightness. Over time, they tear, become deformed, become damaged and require replacement. If a leak is noticed in the area of the connecting elements, you need to remove the old ones and install new gaskets.

- The heat exchanger (radiator) is leaking. Most often, water drips from the connections between the pipes and the radiator. Due to temperature and moisture changes, supply pipes wear out and corrode, so water flows from below. It is necessary to seal or replace faulty parts.

- Prevention has not been carried out for a long time. Gas equipment requires periodic inspection and maintenance to prevent breakdowns.

Methods for eliminating leaks

First of all, inspect the equipment to find the location of the leak. Then proceed with the repair.

Weak traction

If you want to know about which geysers (instantaneous water heaters) you should not choose, about the subtleties and nuances of their installation and connection, as well as hidden information on their proper maintenance for all manufacturers and models, then go here -.

Also, turbocharged dispensers (for example, Termaxi JSG 20R) and dispensers with a hydraulic turbine are distinguished by a more complicated design. It is also advisable to call specialists to repair them.

If you smell gas, you should immediately turn off the heater, close all gas valves, turn off electrical appliances, open the window and call the gas service.

Below watch 3 videos on repairing a Bosch gas water heater.

And now EVERY question from the user and the answer to it, in order to avoid financial costs as a result of improper operation or repair of the flow-through heater. And here it doesn’t matter which manufacturer’s device is involved in the issue. All that matters is the unique situation as a result of which the issue arose, because as one good saying goes: “forewarned is forearmed.”

The gas water heater, or as it is also called, instantaneous water heater, has become a fairly popular household appliance among owners of private houses. A relatively small unit is capable of providing several rooms with hot water. Another advantage of the device is that there is no need for a storage tank, since the system is designed to warm water directly during use. But, like many household devices, the water heater is subject to breakdowns and malfunctions. What to do if, for example, a gas water heater is leaking, and why does this happen?

If even minor deviations occur in the operation of the instantaneous water heater, it is necessary to diagnose the operability of its systems. The cause of the problem may be as follows.

Repairing leaks

A visual inspection allows you to detect leaks. To do this, you need to remove the casing, which is secured with bolts or latches. Before carrying out work, you will need to turn off the water and gas supplies. But if water drips from the gas water heater only during operation, then you need to turn on the water heating for a few seconds.

Once the reason why the column is leaking has been identified, you can begin to fix the problem:

- On average, the membrane lasts from five to eight years. To eliminate the leak, you need to change the gaskets on the rod and replace the worn membrane with a new one (for which you will need to remove the “frog” and disassemble its body).

Gaskets on threaded and other connections last from two to four years. Replacing all gaskets eliminates the leak. A leaking hose cannot be repaired and must be replaced with a new one. The use of sealants or special silicone compounds significantly improves sealing.

Radiator leak

Hot water appears thanks to the existing heat exchanger. The heat exchanger radiator consists of metal pipes and plates located close to each other. The plates come into direct contact with the fire, due to which soot appears on them during operation.

Signs of soot accumulation include:

- The flame is yellow;

- When burning, the fire deviates to the side and heats the body (the flame should tend upward);

- Soot falls off the gas water heater;

- Even when operating at full power, the water heats up weakly.

To remove soot, you will need to remove the casing by unscrewing the bolts (latches) that secure it.

Important! To prevent soot from entering during disassembly of the column, it is necessary to cover the burner with a rag.

After the assembly is removed, it must be washed by placing it in a container with water for several hours to loosen the soot. This will make it easier to clean the space between the heat exchanger plates. For quality cleaning, it is recommended to use running water, a long-bristled brush and detergents. After drying, the radiator is put in place.

Green spots on the heat exchanger indicate existing cracks and holes.

If the geyser is leaking due to a failure of the heat exchanger radiator, then the actions should be as follows:

- The water supply pipes must be shut off to prevent water from entering the gas water heater. After which the hoses are disconnected and the remaining water is drained. The remaining liquid in the coil is removed with a pump or vacuum cleaner; you can try blowing the water out with your mouth using a hose. This must be done, since the remaining moisture absorbs heat during the soldering process, and it will not be possible to heat the metal to the desired temperature.

- Damaged areas (they are green) will need to be cleaned with sandpaper and degreased with a solvent, and then wiped dry.

- Crushed rosin or an aspirin tablet should be sprinkled on the work surface. Rosin and aspirin will serve as solder here.

- Using a soldering iron with a power of at least 100 W (since they will have to work at temperatures above 180 degrees), it is necessary to increase the solder to a height of approximately two millimeters. If the soldering is loose, this means that the working surface is not heated enough. You can additionally heat the soldering area with an iron or another soldering iron.

- Each through-hole fault will need to be soldered in a similar manner.

- After the soldering work is completed, you need to wait until the working surface has completely cooled and assemble the gas water heater.

- Before full operation, the equipment is started in test mode.

Radiator clogged

You can find out complete information on the selection, operation and maintenance of gas water heaters (instantaneous water heaters) from all manufacturers if you go.

In addition to specific information on the site, you can also study specific problems from other people on this topic who have already purchased a gas water heater or instantaneous water heater and thus avoid them. You will find a regularly updated list of such problems and their solutions.

The heat exchanger radiator consists of pipes and metal plates located close to each other. The plates are in direct contact with the flame, so soot accumulates on them over time.

You can determine that this is a problem by the following indicators:

- Yellow color of flame.

- The fire tends not upward, but to the side, heating the body.

- When operating at full power, the water heats up slightly.

- Soot is pouring out from under the column.

In order to clean it, you need to remove the heat exchanger. To do this, remove the casing and unscrew all the elements that hold it. During disassembly, cover the burner with a rag to prevent soot from getting into it.

After removal, the knot is carried to the bathroom and washed there. It is best to leave it in a container with high sides for several hours to allow the soot to soften. Next, the space between the fins of the heat exchanger is cleaned under running water using a long-hair brush and detergents. At the end, drying and installation is carried out in the reverse order.

Scale on heat exchanger pipes

The heat exchanger consists of a casing and pipes into which cold water flows and is heated. In any case, over time, a small layer of scale appears inside. The main reasons for its occurrence are high water hardness and operation of the water heater at temperatures above 80 degrees.

You can determine that the pipes of the dispenser are clogged with scale by the fact that cold water from the tap flows actively, and hot water from the dispenser flows in a thin stream.

You can repair the column without removing the heat exchanger. The gas is turned off and the water valve is closed. You need to remove the casing from the device and drain the water. To do this, unscrew the union nut from the water inlet to the water heater and turn on the tap located lowest in the system, usually a tap in the bathroom. Termaxi geysers have a special tap for draining water from the system. In this case, it is easier to drain the water into a substitute container.

After this, the nuts at the inlet and outlet of the heat exchanger are unscrewed and a special anti-scale liquid, which can be bought at hardware stores, is poured into it through a hose. You can also use a solution with vinegar or citric acid.

The column is left in this form for several hours. Then everything is connected back and the water valve is turned on. You need to slowly turn on the hot water tap. Dirty liquid should flow out. If after this the pressure increases, then the heat exchanger pipes have been cleaned. If necessary, you can repeat the entire cleaning procedure several times.

In order to avoid this breakdown, you need to use the water heater at temperatures of about 40-50 degrees. You can also install a filter at the inlet, which will purify the water from salts, which form scale.

GENERAL PROVISIONS

When operating gas supply systems, the following types of blockages of gas pipelines occur: water, ice, tar or naphthalene and blockages with foreign objects,

1.1. If the gas contains a certain amount of droplet water in the gas supply system at appropriate values of temperature and gas pressure, hydrocarbon hydrates are formed (crystalline hydrates are solid substances that resemble snow or porous ice in their structure). Accumulating in fittings and gas pipelines, crystalline hydrates form plugs that prevent the passage of gas. The presence of water blockages is characterized by pulsation of gas pressure in gas pipelines. This is explained by the fact that due to a decrease in the flow area of the gas pipeline, the amount of passing gas decreases, as a result of which the gas pressure before the blockage occurs increases, and after the blockage it decreases. The gas passes as long as its pressure is sufficient to overcome the resistance created by the water plug.

Hydrate formation occurs as a result of gas cooling during throttling. (When the pressure decreases when throttling the gas to 1.0 MPa, its temperature decreases by approximately 5.5 ° C). Heat losses in the section of gas pipelines from the gas distribution station to the control valves installed at the gas distribution center have a great influence on gas cooling.

The stable existence of natural gas crystalline hydrates is possible at temperatures from minus 5°C to 10°C and at pressures of 0.6-2.0 MPa, respectively. At higher temperatures or at lower gas pressures, crystalline hydrates do not form. At gas pressure (0.6 MPa), the process of hydrate formation occurs when the gas is cooled to a temperature of minus 5-7°C. A further decrease in temperature intensifies the process of formation of crystalline hydrates.

Hydrocarbon crystalline hydrates are stable compounds: when heated, they easily decompose and pass into a gaseous state.

1.2. Ice plugs can form in the area of frozen soil or in cases where a section of a gas pipeline filled with water is open in winter.

Ice jams occur when moist gas is transported through uninsulated areas of gas pipelines (in excavation sites, on external gas pipelines, etc.). In this case, condensing water vapor falls out in the form of frost and gradually reduces the flow area of the gas pipeline.

1.3. Resin or naphthalene plugs are found on gas pipelines transporting various types of artificial gases. Blockages consist of tar and naphthalene, as well as various suspended particles deposited on the walls of the gas pipeline. They form in open sections of gas pipelines when the temperature of the gases decreases.

1.4. Blockage of gas pipelines with foreign objects occurs due to poor quality of cleaning of gas pipelines after completion of installation or repair work on gas pipelines (construction debris, welding beads, tools, etc. remain). During operation, small substances carried by gas (sand, scale, etc.) accumulate around these objects. As these substances accumulate and gas flow increases, blockages form.

1.5. A characteristic sign of the formation of blockages (plugs) in gas pipelines is pulsation of gas pressure in gas pipelines (low-intensity water hammer) with a decrease in gas pressure in the section (along the gas flow) located after the formed plugs. With a further increase in the size of the plugs and, consequently, a decrease in the flow area, a complete cessation of gas flow into the boiler room may occur. Monitoring the pressure in the gas supply system allows you to timely identify and take measures to eliminate system malfunctions.

Leakage of threaded connections

Sometimes water drips from the gas water heater due to leaking threaded connections. In the places where they are located, manufacturers use American nuts (flare nuts).

To seal them, rubber gaskets are used, which, when exposed to high temperatures, lose their elasticity, become hard and allow water to pass through.

To troubleshoot you will need:

- Turn off the water (there is a special tap on the tube through which cold water is supplied to the column);

- Unscrew the threaded connection with an adjustable wrench (it will be easier to unscrew if the connection is slightly heated);

- Take out the old rubber gasket and carefully inspect the threads.

If the thread is not damaged, then you just need to replace the gasket with a new one and tighten the connection with a wrench. If there are defects on the American thread, the union nut will need to be replaced.

Pipeline leak

In some cases, the geyser leaks as a result of the formation of holes in the copper pipes. A thorough inspection of the heat exchanger when the water is turned off will allow you to find the location of the leak. Liquid leaks from large holes, minor damage is detected by rust around it and green spots.

What to do to fix the leak:

- Cold welding. It is important that the welding compound used can withstand high temperatures. Similar information can be found on the packaging of the product. You will need to remove a piece of cold welding from the packaging, knead it with your hands (wearing gloves) until it begins to harden. Then apply the composition to the pipe and smooth it until it hardens completely.

- Soldering holes. You can eliminate the reason why the gas water heater is leaking by soldering the damaged area. It will first need to be cleaned, degreased and coated with flux. Using a powerful soldering iron or torch, it is necessary to cover the damage on the pipe with solder (the solder layer should be approximately 1-2 millimeters thick). It is recommended to solder several holes located close to each other with a piece of copper plate. It is not advisable to solder Chinese inexpensive heat exchangers, since very often they are painted on top. In this case, paint is used by manufacturers to hide the uneven color of low-quality copper (it contains impurities). In this case, the tubes burn out during the soldering process because they are too thin.

- Installing a clamp with a rubber gasket. The simplest way to eliminate a leak without damaging the structure. This measure is especially effective if the tube does not fit tightly to the casing and if there is enough space.

In some cases, it is possible to discover the reason why the column is leaking too late and the pipe manages to rot to such an extent that only its replacement can save the situation. Finding the right part is not easy even in specialized stores. Using a flexible water line or a corrugated stainless steel hose instead of a rotten tube will help solve the problem.

It is easy to replace a worn rod o-ring yourself, as well as rubber gaskets. It is quite possible to fix a leak in a gas water heater yourself; no special skills or knowledge are required. But still, when repairing such equipment, you should not forget about safety. If you do not have confidence in your own abilities, then it is advisable to seek help from specialists.

How to fix a leak?

Having discovered the cause of the leak, you can begin to eliminate it. Our further actions will depend on which part of the gas water column is the source of the leak.

Radiator leak

The fact that there is a crack or hole in the radiator is indicated by the presence of green spots on this part. The procedure for eliminating a leak in the radiator will be as follows:

- We shut off the water pipes to prevent water from entering the column. Disconnect the water supply hoses from the column. Drain the remaining water from the radiator. To remove liquid from the coil, use a vacuum cleaner or pump.

- Armed with sandpaper, we clean the damaged areas. Then we treat these areas with a degreasing solution and wipe them dry.

- We take a soldering iron with solder, which can be used at temperatures above 180 degrees (the power of the soldering iron must be at least 100 W). Grind a piece of rosin or grind an aspirin pill into powder. Sprinkle this mixture onto your work surface.

- Having heated the soldering iron to the desired temperature, we increase the solder to a height of approximately 0.2 cm.

- We repeat this procedure for each through damage.

Alexander Gerasimov in his video will show and tell you how to properly solder a geyser radiator yourself.

Leakage in threaded connections

Quite often you can detect leaks in the threaded connections between parts of the gas water heater. Pay attention to which pipe has a leak: the left pipe usually supplies water for heating, and the right pipe usually supplies gas. As a rule, water begins to leak from the pipe if the sealing gasket is worn out. Changing this part is very easy.

- The first thing to do is block the water supply.

- Then we disassemble the connection in which the problem is detected (we use a regular wrench for this purpose). We remove the worn gasket.

- We clean the connecting elements from dirt and degrease them.

- If the thread on the American nut is damaged, it should be replaced.

- Then we install a new rubber gasket and assemble the connection.

Leaking pipes

Sometimes a leak is found not in the connection of the tubes, but directly in them themselves. Experts advise that if cracks and small holes are detected in the tubes, use the same method as for eliminating a leak in the radiator, that is, soldering. However, in the absence of proper care, it is not always possible to detect damage in time. If you realize it too late, and the tube has already become rotten beyond repair, you will have to replace it.

Those who have encountered a similar problem say that it is very difficult to find a suitable tube, even in stores specializing in the sale of gas equipment. As a replacement for the tube, you can use a corrugated stainless steel hose or flexible water line.

How to properly solder a tube without spoiling it and extending the life of the gas water heater can be seen in the video by Vladimir Pekar, which is presented below.

Source

The essence of the cold welding method

The idea proposed by the inventors of this method of connecting parts is quite simple. The composite material is thoroughly mixed, after which complex chemical reactions are launched, imparting new properties to the mixture. Over time, the soft composition hardens, penetrates the structure of the materials being bonded and becomes comparable in strength to metal surfaces.

Excellent performance characteristics make it possible to use cold welding to solve a wide range of household problems:

- Elimination of leaks in metal and polymer water-pressure structures.

- Sealing cracks in heating radiators.

- Sealing places of damage to metal elements of the car body.

- Strengthening problem areas of pipeline networks.

The material can become indispensable in situations where the problem section of the pipeline is in a hard-to-reach place, where, even if you wanted to, it would not be possible to use a welding machine or other bulky device.