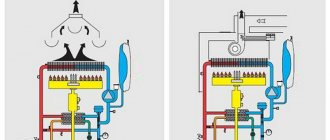

A geyser is a flow-through water heater that runs on natural gas. If you do not have hot water supply, but gas is supplied, this equipment will increase the comfort of your life. You simply open the tap, hot water flows out of it, and its temperature is regulated by you yourself. Even if you have a centralized supply of hot water in your house or apartment, but you are not satisfied with the price you have to pay for heating, or perhaps you are not satisfied with the temperature, installing a gas water heater will also solve these problems. Heating water costs much less than it is provided centrally - this results in significant savings on utility bills. To understand which geyser is better, you will have to study the structure of the equipment and its types. Then the choice for you will be simple and conscious.

Which geyser is better depends on your requirements

Why does the gas water heater not turn on?

Gas instantaneous water heaters have long become an integral part of the comfort of many city apartments and private houses.

This is the simplest and most reliable alternative to both centralized hot water supply and electric boilers. However, despite its simplicity and reliability, the gas water heater often takes a long time to ignite or refuses to work at all. There are many reasons for breakdowns in this case. Therefore, correctly understanding and identifying the main reason why the geyser does not turn on when turned on is the most important task in solving this non-standard situation.

In the general list of situations why a gas water heater does not light up, three main points need to be highlighted:

- A situation where a gas water heater is working properly, but cannot work due to external factors - loss of draft, lack of water pressure or low gas pressure;

- A situation when a gas water heater does not ignite well under normal external factors, that is, problems arise directly with ignition;

- Cases when an automatic geyser does not heat water after normal switching on and the start of hot water supply.

All these cases, although generally similar to each other, indicate that there are completely different reasons why the geyser does not turn on when turned on. At the same time, the reason that the column has stopped igniting or is taking a long time to ignite are quite standard situations typical for most water heaters.

Traction disorder

One of the reasons why the Neva gas water heater does not light up is a violation of the draft in the air duct. Most often, a foreign object entering the air duct causes the automatic protection of dispensers with an open combustion chamber to trigger.

Under normal conditions, when natural air circulation is disrupted, the protective relay reacts to a sharp increase in temperature in the outlet channel and turns off the gas supply. In this case, the device starts to work normally, but does not work for a long time. Devices with a closed combustion chamber work similarly, for example, the vektor lux eco often does not ignite because even one of the channels is blocked - either the air supply to the combustion chamber or the removal of combustion residues.

Solving the problem of why the geyser does not work in this case is quite simple - clean the air duct and ensure normal air circulation in the room. By the way, one of the reasons for the disruption of natural air circulation in the house and draft in the ventilation duct can be metal-plastic windows and tightly closing entrance doors.

No pressure

If the gas water heater does not ignite automatically when you open the water tap, then a possible reason is the lack of pressure in the water supply. In order to make sure that this is the reason, you need to open the cold water tap.

The absence of normal pressure indicates that the water heating column is working properly, and the blocking is triggered because low pressure in the system will lead to overheating of the device and its breakdown. The situation can be corrected by cleaning the general filter for the apartment’s water supply system and the salt filter for water preparation. Usually, clogging of these filters occurs after repair of pipes on the main lines - internal deposits and simply dirt under the pressure of water enter the filter element and settle there.

It’s another matter if the gas water heater does not ignite when the hot water tap is open, while normal pressure comes from the cold water tap. Here you need to clean the mesh filter installed in front of the water block membrane. It turns out that with normal pressure in the system, the filter reduces the pressure in the device itself, preventing the gas valve from opening. The solution is simple - remove the nut and clean the brass mesh.

Gas pressure

If the gas water heater does not light up when you turn on the water, the reason for this situation may be problems with gas pressure or a complete lack of gas in the system.

In this situation, usually the water pressure is normal, and the piezoelectric element gives a spark. The first thing you need to do is check the presence of gas in the gas pipeline; to do this, you need to try turning on the gas stove. If the stove does not turn on either manually or automatically, and the characteristic hiss of flowing gas is inaudible from the burner, then with a high probability it can be said that there is no gas in the gas pipeline.

The option when gas does not flow in the gas column while there is normal gas flow to other devices and when there is a spark on the piezoelectric element indicates a malfunction of the gas equipment or a clogged gas filter. When the gas water heater does not ignite when the water is turned on and the ignition system is activated, it is necessary to check the condition of the gas filter installed in front of the device.

The fact is that the composition of natural gas, the presence of impurities and gas condensate can clog the gas purification filter. Because of this, the gas pressure decreases, the pilot light does not light, or the gas safety valve turns off. One of the symptoms of filter contamination can be cases when the device does not light up immediately, or if it does turn on, it starts working intermittently at first, and then after a few minutes it reaches the desired mode.

What to do if the gas water heater does not light up due to low gas pressure or a clogged filter? First of all, you need to turn off the gas supply valve and open the vents for ventilation. Next, you need to inform the gas service about the problem and if this is not a centralized gas shutdown, then call a gas service technician.

The main thing in this case is not to try to do the repairs yourself and wait for the specialists to arrive.

About air jams

What to do if the gas reducer freezes for this reason?

If this mechanism freezes, it is necessary to carry out special prevention: dry the gas before it penetrates the reducer. Also, oxygen is preheated to 60-70 degrees.

Oxygen is dried this way: it is passed through an element that acts as a moisture absorber, for example, calcined vitriol. This is a drying component. It is placed in a dryer, which runs between the gas tank and the reducer. The ROK-1 apparatus is often used.

After this operation, the reducer hose is removed. The gearbox itself is purged. Moisture is removed from it.

If an air lock still occurs in the gas reducer, it means:

- All connections have weak sealing.

- A powerful funnel appeared when antifreeze was added or replaced. As a result, air does not leave the system. The reason for this is a strong stream of liquid. Because of it, the air does not escape. Therefore, it is better to fill it with a very weak stream.

- The air valve is not working properly. Thermal changes in the engine occur. And the air is concentrated in the cooling system.

- The fiber and seal in the pump do not work well. Because of them, air is pumped up.

- OS leaks in hoses and heating radiators. The volume of liquid decreases, and the air develops. The radiator core becomes clogged and the engine overheats.

- Head gaskets burn out. Antifreeze ends up in the crankcase of the power unit or exhaust mechanism. Its volume is decreasing. It boils due to the huge volume of air. In the first case, the OS level test will determine that it exceeds the maximum value. In the second, white smoke will follow from the chimney.

A logical question arises - how to remove the air lock in the gas reducer?

First you need to determine its cause.

Problems with ignition

One of the most common reasons why a gas water heater does not turn on is problems with ignition.

The most common types of non-standard situations encountered here are:

- For old-style models with an ignition wick, the gas water heater does not ignite when the water is turned on, while there is both draft and normal pressure of water and gas;

- For new models - the piezoelectric element in the gas water heater does not work;

- The spark ignition in the gas water heater occurs frequently, but the burner lights unevenly, and if it does turn on, it operates unstable.

Problems with ignition of the burner of older models arise mainly due to untimely maintenance of the burners. Over time, a layer of soot forms in the holes of the burner nozzles, they become smaller and, accordingly, allow less gas flow.

This affects not only the ignition process, but also the temperature of the heated water - it simply does not heat up normally. Therefore, many people set the regulator to maximum, which makes the coking process even more intense.

What to do if a gas water heater of this design does not light up? You just need to call a technician to service the burner; cleaning it from carbon deposits will ensure normal operation of the device. It is also recommended to install a gas filter; it will ensure gas purification from mechanical impurities and retain gas condensate.

One of the reasons why the Neva gas water heater does not ignite is the lack of a spark on the piezoelectric element. Unlike other models of water heaters, the Neva brand has an autonomous power supply for electronics - from lithium batteries.

During ignition, a weak battery does not provide the necessary charge to trigger the piezoelectric element. Despite the fact that the digital display continues to work and display information about the status of the device, the battery power is no longer sufficient to ignite the burner flame. It is a worn-out battery that is the reason why there is no spark at the Neva gas water heater.

Unstable ignition of the burner on water heaters with a piezo element may be due to incorrect configuration of the device and its connection to the autonomous water supply system of the house. Quite often, the vector geyser does not turn on due to voltage drops in the network and insufficient pressure in the water supply system.

This is due to the fact that when hot water is turned on, the pressure in the accumulator (especially if it is small) drops sharply. The electronics of the water heater diagnoses this moment as an accident due to which the gas supply is blocked. Subsequently, when the water pump is turned on, the pressure increases and when turned on again, the device begins to work safely.

Tip: If the water heater does not start working the first time at normal gas pressure and water pressure, you must turn off the device and set the temperature regulator to the minimum level.

Malfunctions. Repair.

If you decide to carry out repairs or adjustments yourself, make sure you have the necessary qualifications. Poor repair of gas equipment can cause a fire, explosion or poisoning. After completing the work and assembly, make sure that the device is tight and operates correctly. The tightness is checked by applying a soap solution to all joints. No bubbling indicates there is no leak. But you shouldn’t delude yourself. The tightness will need to be checked several more times (after a day, three days, a week of operation), and then checked regularly, since a leak may occur some time after the start of operation.

Main malfunctions: the gas pressure at the outlet does not correspond to the nominal value (reason: the spring is broken or deformed), gas leakage (reasons: the membrane is damaged, the tightness of the connection between the membrane and the housing is broken, the float valve is leaking)

Here is a selection of materials:

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, wood, electricity). Do-it-yourself ovens. Coolant, radiators, pipes, heated floors, circulation pumps. Chimney cleaning. Conditioning

If the float bypass valve leaks, then the leak may not occur in the reducer itself, but somewhere further, for example, in a gas stove, since in this case, in zero consumption mode (when the stove or some other consumer is turned off), at the outlet reducer and gas pipes, the pressure can reach the inlet pressure. Gas gradually leaks through the valve, and there is nowhere for it to go. If there is a gas cylinder at the inlet, the pressure can reach 15 bar, which is 500 times higher than the nominal one. Such pressure will definitely lead to leakage. At the same time, it is difficult to detect this malfunction, since when the stove is turned on, the pressure normalizes. There is no sign of overpressure (flame blowout). The fault can only be identified by measuring the outlet pressure in zero consumption mode. It can be no more than 20% more than nominal.

To repair, the gearbox must be disassembled. Only a dismountable gearbox with a spring can be repaired. Sealed gearboxes are not suitable for repair.

In the picture, the membrane is with the bottom side up.

An inspection will show if there are defects in the membrane or a broken spring. A torn membrane can be replaced. But it’s not worth it, it’s better to buy a new gearbox, since it’s quite difficult to hermetically connect the new membrane with the washers. A broken spring can be replaced. Most often, the spring does not break, but simply compresses a little over time. As a result, the outlet pressure becomes lower than nominal. This malfunction can be easily corrected by placing a gasket between the housing and the spring. Read about this below in the section on transferring to another pressure.

Membrane - top view.

If you have diagnosed problems with the bypass valve, then you need to inspect it. It is a tube with a thin hole. A piece of hard rubber mounted on a rocker arm is pressed against the end of the tube. The valve may not close for the following reasons: Firstly, the mobility of the rocker arm is impaired. Move it with your hands, make sure it moves freely. If there are problems, grind or replace the hinges. Secondly, a piece of rubber was worn out and torn. It can be removed with a sharp knife and replaced by gluing another one of the appropriate size in its place. Thirdly, the end of the inlet tube may not be smooth, with damage and roughness. This prevents a tight seal. The end can be sanded with fine sandpaper.

Very often, a leak occurs due to a leak in the seal between the membrane and the lower part of the housing. Troubleshooting is easy. You need to lubricate the edge of the lower part of the case where the membrane fits with silicone sealant, let it dry a little (10 minutes), install the membrane, assemble the gearbox and let it dry a little more (2 hours).

During disassembly and subsequent reassembly, it is quite easy to break the tightness of the membrane. If you have disassembled the gearbox, then during reassembly in any case, even if there was no leakage, use silicone sealant. This will improve reliability.

Blockages and their removal

If the gas water heater does not light up the first time or after starting, the water pressure is significantly less than usual, and besides, the water flows very hot, this indicates that maintenance is necessary. First of all, pay attention to the condition of the device filters - the gas filter and the mesh filter of the water equipment.

The gas filter is serviced by a gas equipment technician; it is installed in front of the device, so its disassembly and maintenance do not require opening the column. The water filter is a classic mesh sediment filter. To service it, simply remove the casing, unscrew the lid, and remove the mesh element.

If there is little debris and dirt, simply rinse the filter with a stream of water; if the debris cannot be removed, the mesh element simply needs to be replaced with a new one.

If, when you turn on the hot water, the column starts to work, and after a short time it goes out, the reason for this may be contamination of the heat exchanger. During long-term operation, especially from an individual water supply system without sufficient cleaning and preparation of water, scale begins to be deposited inside the heat exchanger.

Narrowing the diameter of the heat exchanger reduces the volume of water passed through, while its temperature increases sharply, which serves as a signal to the device’s safety system about the danger of overheating. Qualified cleaning can solve the problem of heat exchanger contamination. Previously, at home they used acid, pouring it into the heat exchanger tubes; to do this, they literally dismantled the entire device down to the screw. Today the procedure is much simpler - the heat exchanger is connected to the cleaning unit and in an hour or an hour and a half, under the pressure of the device’s pump, all the scale is removed.

Scale formation in the heat exchanger.

This can be determined if the water in the column is not warmed up enough, or if the water pressure at the outlet of the device is low, although the pressure in the water main is quite strong. This breakdown is associated with the low quality of tap water, or more precisely with its hardness.

This problem leads to a significant increase in gas consumption for heating. Deposits can be reduced by lowering the set heating temperature; when heated to more than 70 degrees, it happens much faster. To repair your device, you can resort to store-bought plaque removers, which are expensive; their frequent use is also not recommended, or use a solution with citric acid (100 grams of acid per half liter of water).

Cleaning can be done in two ways:

- Using a special apparatus. This is a reservoir with a pump built into it that drives the cleaning liquid inside the heat exchanger. It is connected to the radiator tubes at the inlet and outlet. Water circulates inside for an hour, dissolving the deposits that have formed. However, not everyone has the opportunity to purchase such a device due to its high cost; there is a cheaper method.

- Drain the water from the system, remove the radiator, and prepare a tank filled one-third with water. Immerse the radiator in it and fill it with a purchased or prepared reagent. Place on the fire and boil for half an hour, then turn off the heat and let stand for an hour. Rinse the radiator; if the pressure has changed, the plaque has gone away; if it remains small, repeat the procedure again.

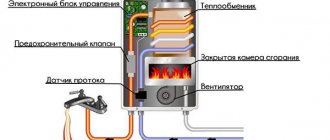

Gas block diaphragm

Another reason why the column does not turn on may be damage to the gas block diaphragm. The gas block diaphragm regulates the gas flow into the burner depending on the water pressure. Entering the housing, water presses on the elastic diaphragm - behind which there is a gas valve rod. The higher the pressure, the more the valve opens and the more gas enters the burner.

If the diaphragm has mechanical through damage and water enters the cavity of the rod, then the pressure on both sides is equalized, and the valve rod remains in place without movement. This is one of the reasons why the gas burner does not light up. You can solve the problem by removing the block and replacing the diaphragm with a new one.

Tip: When choosing a repair kit, it is recommended to pay attention to the silicone diaphragm. Unlike rubber, it is more elastic and has a longer life of “on-off” cycles than rubber.

After replacing the diaphragm, it is recommended to inspect the threaded connections of the column, replacing all gaskets and seals in the valve group.

Dismantling the water unit

To carry out repairs, the unit must be removed from its seat. This is only possible together with the dismantling of the gas unit.

- Turn off the gas supply valve.

- Disconnect the cold water hose.

- Using a wrench, disconnect the assembly from the pipe.

- Disconnect the wiring from the gas valve and microswitch.

- Use a screwdriver to unscrew the flange bolts.

- Remove the water-gas block.

Now you need to disassemble it and replace the broken parts:

- To disconnect the gas part from the water part, unscrew the two screws. One is on top, the other is on bottom. You can not unscrew it completely, but slightly loosen the fastening. It happens that the bolts stick. Spray these areas with WD-40.

- Separate the blocks.

- Now unscrew the frog screws on top.

- The body will split into two parts and the diaphragm will become accessible.

- Remove the rubber part (if it is faulty, prepare a new one).

- Pull out the disc with the stem. Behind them is a spring.

- Remove the spring and check the seal located behind it. It requires periodic cleaning and lubrication.

- Install new parts and reassemble the unit in reverse order. The oil seal can be lubricated before installation.

- When tightening the frog bolts, lubricate them with graphite lubricant.

Electronics failures

The presence in modern models of a large presence of electronic components, on the one hand, ensures high safety of the device and ease of use, on the other hand, it complicates troubleshooting and subsequent repairs.

The causes of electronic malfunctions are mainly related to the influence of external factors - voltage drops in the network, lightning discharges entering the main gas pipes and water entering the circuit boards from leaks inside the device. In addition, failure of individual electronic components due to failures in the electronics itself cannot be ruled out.

The reason that the vector geyser does not light up may be a malfunction of the electronics, and the following situations may arise:

- No spark when igniting;

- Extinguished digital display;

- The device does not start the first time;

- During operation, an alarm signal is constantly displayed;

- Protection systems are constantly triggered;

- The device turns on and then turns off again;

- Diagnosis of a breakdown usually begins with checking the batteries; old or dead batteries need to be replaced with new ones. If there are traces of electrolyte leaking onto the terminals, it must be cleaned.

If this operation does not resolve the device problems, you must call a technician to check the electronic unit. Most often, in such models, the electronics unit cannot be repaired; it is simply replaced with a new one. When replacing a unit, the technician must inspect all components of the device, and when connecting a new unit, in addition, test the system and configure its parameters. Particular attention is paid to the presence of leaks at the junction points and the integrity of the heat exchanger.

Malfunctions. Repair.

If you decide to carry out repairs or adjustments yourself, make sure you have the necessary qualifications. Poor repair of gas equipment can cause a fire, explosion or poisoning. After completing the work and assembly, make sure that the device is tight and operates correctly. The tightness is checked by applying a soap solution to all joints. No bubbling indicates there is no leak. But you shouldn’t delude yourself. The tightness will need to be checked several more times (after a day, three days, a week of operation), and then checked regularly, since a leak may occur some time after the start of operation.

Main malfunctions: the gas pressure at the outlet does not correspond to the nominal value (reason: the spring is broken or deformed), gas leakage (reasons: the membrane is damaged, the tightness of the connection between the membrane and the housing is broken, the float valve is leaking)

Here is a selection of materials:

IN

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, wood, electricity). Do-it-yourself ovens. Coolant, radiators, pipes, heated floors, circulation pumps. Chimney cleaning. Conditioning

If the float bypass valve leaks, then the leak may not occur in the reducer itself, but somewhere further, for example, in a gas stove, since in this case, in zero consumption mode (when the stove or some other consumer is turned off), at the outlet reducer and gas pipes, the pressure can reach the inlet pressure. Gas gradually leaks through the valve, and there is nowhere for it to go. If there is a gas cylinder at the inlet, the pressure can reach 15 bar, which is 500 times higher than the nominal one. Such pressure will definitely lead to leakage. At the same time, it is difficult to detect this malfunction, since when the stove is turned on, the pressure normalizes. There is no sign of overpressure (flame blowout). The fault can only be identified by measuring the outlet pressure in zero consumption mode. It can be no more than 20% more than nominal.

To repair, the gearbox must be disassembled. Only a dismountable gearbox with a spring can be repaired. Sealed gearboxes are not suitable for repair.

In the picture, the membrane is with the bottom side up.

An inspection will show if there are defects in the membrane or a broken spring. A torn membrane can be replaced. But it’s not worth it, it’s better to buy a new gearbox, since it’s quite difficult to hermetically connect the new membrane with the washers. A broken spring can be replaced. Most often, the spring does not break, but simply compresses a little over time. As a result, the outlet pressure becomes lower than nominal. This malfunction can be easily corrected by placing a gasket between the housing and the spring. Read about this below in the section on transferring to another pressure.

Membrane - top view.

If you have diagnosed problems with the bypass valve, then you need to inspect it. It is a tube with a thin hole. A piece of hard rubber mounted on a rocker arm is pressed against the end of the tube. The valve may not close for the following reasons: Firstly

, the mobility of the rocker arm is impaired.

Move it with your hands, make sure it moves freely. If there are problems, grind or replace the hinges. Secondly

, a piece of rubber was worn out and torn.

It can be removed with a sharp knife and replaced by gluing another one of the appropriate size in its place. Thirdly

, the end of the inlet tube may not be smooth, with damage and roughness. This prevents a tight seal. The end can be sanded with fine sandpaper.

Very often, a leak occurs due to a leak in the seal between the membrane and the lower part of the housing. Troubleshooting is easy. You need to lubricate the edge of the lower part of the case where the membrane fits with silicone sealant, let it dry a little (10 minutes), install the membrane, assemble the gearbox and let it dry a little more (2 hours).

During disassembly and subsequent reassembly, it is quite easy to break the tightness of the membrane. If you have disassembled the gearbox, then during reassembly in any case, even if there was no leakage, use silicone sealant. This will improve reliability.

Why does the gas water heater igniter go out:

• The wick of the gas water heater is clogged with dust;

• Air flows from the outside (flame separation); • Lack of draft in the chimney; • Traction control sensors are faulty; • The thermocouple is worn out or burnt out; • Poor contact between the sensor and the control unit; • Ionization sensor outside the flame range. The most common reason why the pilot light goes out is a faulty thermocouple. The thermocouple is an element of a safety device designed to shut off the gas flow in case of unstable operation of the gas column. When the pilot goes out, the thermocouple detects the lack of heat due to the lack of fire and turns off the gas. However, if the thermocouple is burnt and its tip has become loose from prolonged exposure to fire, then it becomes the reason why the igniter goes out.

On this page we have described in detail all the faults, so the cost of this service for you is

We will charge 500 rubles for the call if the repair is refused, but this service costs

The cost of the technical work performed without the cost of the required spare parts in our company varies

Before leaving, our employees will issue a guarantee from our company for the work done for a period of time.

However, if the thermocouple is burnt and its tip has become loose from prolonged exposure to fire, then it becomes the reason why the igniter goes out. Another problem is that the gas injector holes on the igniter are small in diameter and can become clogged with debris and dust, thus preventing the gas at the igniter from burning properly and resulting in insufficient heating of the thermocouple.

Outgoing air currents from outside can blow out the pilot burner. Downdrafts typically occur if the appliance is not properly ventilated. When repairing a gas water heater, be careful not to confuse this phenomenon with a lack of traction.

Geysers have electromagnetic valves that belong to the gas control system. If the ventilation system is faulty and carbon monoxide enters the room, the solenoid valve will shut off the gas supply and the igniter will go out.

Black soot deposited around the igniter area and on the heat exchanger itself is another problem why the igniter goes out. This soot appears from incomplete combustion of gas. The accumulation of soot on the heat exchanger can cause major problems with air ventilation and cause the pilot to go out during operation.

Signs that the igniter is not working properly

Pay attention to the color of the igniter flame. It shows how well and correctly the gas burns. A wick that effectively burns natural gas burns with a blue flame. The blue flame color should be at least 90% with small red flecks and a slightly yellow tip. An orange or predominantly yellow color indicates problems with the pilot burner, which can lead to an emergency stop of the column.

Why does the igniter smoke? If the ratio of air and fuel becomes less than standard values, the color of the flame turns yellow and the igniter begins to smoke and burn sluggishly. This leads to insufficient heating of the thermocouple and the igniter goes out.

Which geyser to choose: Beretta or Mora?

The geyser itself is an alternative when there is no full and regular supply of hot water. You can list all its advantages, but they are probably already known to many.

Still, when buying a gas water heater, it is difficult to give preference to any type or even brand for a person who has never had such a water heating device before.

We will try to talk about different types of automatic gas water heaters, their advantages, weaknesses and operating nuances. Also read about what to do if the device requires repair.

The gas water heater does not ignite: 7 main reasons and instructions for eliminating them

If the column does not light up, then it turns from an important plumbing fixture into a useless piece of furniture.

Does your gas water heater not light at home? Do not rush to call a specialist; the experience I have accumulated allows me to say that owners can cope with most of the causes of such a problem on their own. A detailed analysis of each situation will help me prove this.

Terms of use

If the column is open type, then you should adhere to the following recommendations:

- When installing the speaker, you should take care of ventilation;

- It is strictly forbidden to turn on the device if there is no draft in the chimney;

- There is no need to leave the device on if no one is at home;

- You cannot change the design yourself;

- There is no need to leave the valve open if the burner is not lit.

Important! Only a professional can reinstall a geyser.

Finding and eliminating causes

So, why doesn’t the gas water heater turn on? A number of situations could be to blame:

- Error in connecting pipes;

- Lack of draft in the chimney;

- High sensitivity protective relay;

- Low ignition system batteries;

- Weak water pressure or its complete absence;

- Filter contamination;

- Membrane deformation.

Let's consider all the listed reasons in more detail and look at effective methods for eliminating them:

Reason #1: error in connecting pipes

The water heater protection system itself shuts off the gas supply if errors are made in connecting the pipes. To prevent this from happening, simply stick to a simple and clear scheme:

From left to right, a gas pipe, a pipe for supplying cold water and a pipe for collecting hot water are connected to the water heater

Also, if gas does not flow into the gas water heater, check the position of all shut-off valves that may be installed on the gas pipeline. It is possible that after installing the device you simply did not open one of the taps.

All taps with yellow handles must be open before turning on the gas water heater

Reason No. 2: lack of draft in the chimney

Due to contamination of the chimney as a result of the accumulation of soot or construction debris entering it, the vector of movement of combustion products changes to the opposite direction. This poses two dangers:

- The returning mixture of carbon monoxide and air extinguishes the burner . As a result, the protection system is triggered and the operation of the gas water heater is blocked;

A gas water heater from the famous Bosch brand will not work if the burner is extinguished.

- The returning mixture of carbon monoxide and air penetrates into living spaces . This option is even worse, as it poses a danger to the health and even the life of household members. It is possible in the case when the force of the “overturned” draft is not enough to extinguish the fire.

HBO 3rd generation

The engine does not develop full power

— The gas filter is clogged; — Gas lines are clogged; — The gearbox is faulty; — The stepper gas supply regulator is faulty; — The lambda probe is faulty; — The system adjustment is broken (can be corrected by software).

Failure" when the throttle valve is opened sharply

— The throttle position sensor is faulty; — The system adjustment is broken; — The mixer is not selected correctly.

The engine does not switch to gas power after reaching the “transition” temperature designated by the software.

— The gearbox temperature sensor is faulty; — There is no engine speed signal (tachometer).

Popping sounds in the intake manifold when the throttle valve is opened sharply

— Leaning of the mixture due to incorrect adjustment of the system; — Leaning of the mixture due to incorrect operation of the stepper gas supply regulator; — “Air leakage” into the engine due to a leak in the intake tract; — The ignition system is faulty; — The engine gas distribution mechanism is faulty; — The adjustment of the thermal clearances of the timing valves is disrupted.

Increased gas consumption

— The air filter is clogged; — The ignition system is faulty; — The gearbox adjustment is broken; — Reduced engine compression; — The gearbox is faulty; — Poor heating of the gearbox with coolant; — The stepper gas supply regulator is faulty; — The lambda probe is faulty. — The adjustment of the lambda control system is broken.

Typical breakdowns of geysers of different brands

- The solenoid valve fails;

- Poor ignition as a result of incorrectly adjusted cold water supply.

- Water block fails;

- Membrane deformation.

- Gas burner malfunction , which can be solved by replacing it;

- Membrane deformation.

- Repeating the “on and off” mode until the column heats up;

- Rapid battery failure.

- Valve block failure;

- Clogged filtration system.

- The heat exchanger housing burns out.

Why doesn't the gas water heater work?

There are several common reasons why a gas water heater does not work. You can detect and correct them yourself.

Lack of traction

Any geyser has a function that controls the presence of draft. If there is a shortage of it, the gas is automatically shut off and the ignition on the gas water heater does not work.

It is very easy to check the presence of traction yourself. You need to bring the match to the vent or chimney. If the flame burns evenly, it means there is no draft. If the fire is drawn into the hole, then the chimney is working correctly. It happens that backdraft occurs, and then the air flow blows out the fire in the burner.

If there is no traction, then it is necessary to determine the reason for this. Most likely, there is a blockage in the ventilation or pipe that needs to be removed.

The batteries are low

In an automatic gas water heater, the cause of the problem is often dead batteries. They give a spark when ignited. Basically, the batteries last for 7-15 months of operation.

In this case, the problem can be solved very simply by replacing the old batteries with new ones.

How not to make a mistake about the power of a gas water heater?

Insufficient water pressure

Each geyser operates only at a certain water pressure in the main. There are models that can heat water only at 0.2 or 0.3 bar. If the pressure is lower, the device will not work.

After detecting low pressure in the line, it is necessary to find out the cause and eliminate it:

- If the pressure has decreased throughout the water supply network, then you need to call the utility service and report the problem.

- Sometimes the cause of a drop in pressure is a clogged pipe or filter. It is recommended to check the filter and clean it if necessary.

Note! If a drop in water pressure in your main is not uncommon, then you can improve the situation by installing a pump that will increase the water pressure or replace the device with another one that can operate at 0.1-0.15 bar.

Gas burner clogged

Most often, the piezoelectric element in a gas column does not work due to a clogged burner. If it is clogged with soot and soot, it is necessary to disassemble the structure and thoroughly clean each of its elements. Then you should collect all the parts and try to light the column again.

No gas supply

Usually, when you turn on the column, you can hear the sound of incoming gas and smell it slightly. If there is neither one nor the other, then fuel is not supplied. This is one of the reasons why the ignition of the gas water heater does not work.

If gas does not flow, it is recommended to first check whether the gas filter is clogged. If so, the filter is cleared of blockages. In other cases, you need to call the gas service and find out the reason for the lack of fuel.

Note! If there is a gas leak and you smell it in the room, then you cannot turn on the gas water heater. Call a gas specialist immediately.

Problems in the water unit

After 3-4 years of intensive use, the membrane of the column water unit gradually loses its elasticity and may even break. If this happens, the device will not be able to work.

To check the membrane, you need to remove the device body and unscrew the bolts that hold the assembly. Then remove the cover of the water block and inspect the membrane. If it is damaged, replace it with a new one. It is better to purchase an element made from silicone. This membrane will last longer.

Replacing the elements of the water unit should only be carried out if you are confident in your abilities and have the skills to repair such devices.

If you cannot identify the reason why the geyser does not work when turned on, call a specialist. He will quickly figure out what's wrong and fix the problem.

Malfunctions. Repair.

If you decide to carry out repairs or adjustments yourself, make sure you have the necessary qualifications. Poor repair of gas equipment can cause a fire, explosion or poisoning. After completing the work and assembly, make sure that the device is tight and operates correctly. The tightness is checked by applying a soap solution to all joints. No bubbling indicates there is no leak. But you shouldn’t delude yourself. The tightness will need to be checked several more times (after a day, three days, a week of operation), and then checked regularly, since a leak may occur some time after the start of operation.

Main malfunctions: the gas pressure at the outlet does not correspond to the nominal value (reason: the spring is broken or deformed), gas leakage (reasons: the membrane is damaged, the tightness of the connection between the membrane and the housing is broken, the float valve is leaking)

Here is a selection of materials:

Everything you need to know about heating and climate control Features of the selection and maintenance of boilers and burners. Comparison of fuels (gas, diesel, oil, coal, wood, electricity). Do-it-yourself ovens. Coolant, radiators, pipes, heated floors, circulation pumps. Chimney cleaning. Conditioning

If the float bypass valve leaks, then the leak may not occur in the reducer itself, but somewhere further, for example, in a gas stove, since in this case, in zero consumption mode (when the stove or some other consumer is turned off), at the outlet reducer and gas pipes, the pressure can reach the inlet pressure. Gas gradually leaks through the valve, and there is nowhere for it to go. If there is a gas cylinder at the inlet, the pressure can reach 15 bar, which is 500 times higher than the nominal one. Such pressure will definitely lead to leakage. At the same time, it is difficult to detect this malfunction, since when the stove is turned on, the pressure normalizes. There is no sign of overpressure (flame blowout). The fault can only be identified by measuring the outlet pressure in zero consumption mode. It can be no more than 20% more than nominal.

To repair, the gearbox must be disassembled. Only a dismountable gearbox with a spring can be repaired. Sealed gearboxes are not suitable for repair.

In the picture, the membrane is with the bottom side up.

An inspection will show if there are defects in the membrane or a broken spring. A torn membrane can be replaced. But it’s not worth it, it’s better to buy a new gearbox, since it’s quite difficult to hermetically connect the new membrane with the washers. A broken spring can be replaced. Most often, the spring does not break, but simply compresses a little over time. As a result, the outlet pressure becomes lower than nominal. This malfunction can be easily corrected by placing a gasket between the housing and the spring. Read about this below in the section on transferring to another pressure.

Membrane - top view.

If you have diagnosed problems with the bypass valve, then you need to inspect it. It is a tube with a thin hole. A piece of hard rubber mounted on a rocker arm is pressed against the end of the tube. The valve may not close for the following reasons: Firstly, the mobility of the rocker arm is impaired. Move it with your hands, make sure it moves freely. If there are problems, grind or replace the hinges. Secondly, a piece of rubber was worn out and torn. It can be removed with a sharp knife and replaced by gluing another one of the appropriate size in its place. Thirdly, the end of the inlet tube may not be smooth, with damage and roughness. This prevents a tight seal. The end can be sanded with fine sandpaper.

Very often, a leak occurs due to a leak in the seal between the membrane and the lower part of the housing. Troubleshooting is easy. You need to lubricate the edge of the lower part of the case where the membrane fits with silicone sealant, let it dry a little (10 minutes), install the membrane, assemble the gearbox and let it dry a little more (2 hours).

During disassembly and subsequent reassembly, it is quite easy to break the tightness of the membrane. If you have disassembled the gearbox, then during reassembly in any case, even if there was no leakage, use silicone sealant. This will improve reliability.