We are already accustomed to frequent breakdowns of washing machines, microwaves, dishwashers, air conditioners, vacuum cleaners, and refrigerators. But relatively simple and well-designed technical products rarely fail. Therefore, the situation when a gas water heater lights up and goes out will be unexpected for many users, isn’t it? This type of equipment falls into the category of reliable and durable devices.

But should you worry and call a specialist? In this article we will talk about the reasons for such a breakdown, look at common and rare situations. We will figure out how to independently adjust the operation of the heater and when it is better not to do this, but to immediately contact specialists. We will also provide recommendations on how to prevent malfunctions from occurring.

Typical problems

Let's look at why the gas water heater goes out.

Attenuation can be caused by a number of reasons. A sensor may turn on and detect a gas leak. There may be problems with the operation of the chimney. A clogged igniter will also often cause damping problems. Sometimes the automation fails. Often the problem of attenuation is also related to the quality of the fuel. Some gas facilities do not supply pure gas, but diluted gas. Such low-quality fuel is easily identified by the orange color of the flame. If serious automatic protection systems are installed in the column, they will turn off the system

It is also worth paying attention to gas leaks. Even minor leaks are the reason why these units fail

Repairing geysers at home can help. But you should only turn to professionals - gas is not something to joke about.

Does water pressure affect the performance of the column?

The reason why the equipment does not ignite may be low water pressure in the supply water supply. This is easy to check; you just need to open the cold water tap at the sink. If you see that the pressure is weak, then this is the reason. But if the pressure is excellent, then the problem of the malfunction lies in the water unit of the gas device itself. Most likely, the filters are clogged or the special membrane is deformed. In some cases, the hot water supply tap becomes clogged and becomes covered with scale from the inside.

In very rare cases, the cause of low pressure is a deep cleaning filter, which is installed additionally. How to fix the problem? If the cold water supply pressure is very weak in the general water supply system, you need to call the utility services to find out why this is happening. If the column does not light up due to the fact that the filters are clogged, then they should be removed and washed using special means.

If the filters are heavily soiled, they need to be replaced, as cleaning them is no longer useful. If the hot water pipes are clogged, you need to call a technician who can clean them; you do not need to do this work yourself. If the membrane is deformed, there is no need to try to straighten it; you need to purchase a new one and install it. If the column becomes clogged with combustion products and soot, turn it off, then remove the casing and clean its components from traces of soot.

The column refuses to light up when turned on or goes out immediately, due to the fact that the supply of cold or hot water is not adjusted. In this case, there is no need to try to dilute the hot water by increasing the flow of cold water, as this will lead to a gradual attenuation of the flame and the column turning off. Such incorrect actions lead to a reduction in the service life of the device. It is also necessary to correctly adjust all the taps during installation; if you cannot do this yourself, then it is better to call a specialist.

Pollution prevention

If the water heater produces weak water pressure, it is worth not only removing the blockage, but also taking care of prevention.

What to do for normal operation of the gas water heater:

- Prevent the appearance of scale and salts. Clean parts of the device periodically. But the number of procedures can be reduced by choosing the optimal temperature regime.

- The heating temperature should not exceed 50 degrees. Therefore, it is worth choosing one indicator and making sure that there are no sharp jumps.

- Install a water filter that will retain salts and prevent them from damaging the surface of the pipes. Replace it with a new one in a timely manner.

- Install an electric softener to reduce the risk of scale formation.

- Clean the column correctly. Contact a specialist to check the quality of work. He will appreciate how hot water is supplied.

Problems and their solutions will not disturb speaker users if they prevent contamination and properly care for the device

It is important that the water is soft and clean. If the pressure decreases, you should immediately check for contamination and clean it with gentle means.

The geyser goes out when switching to shower

Does the heater keep turning off when switching to shower? What's happened:

clean the chimney; replace ignition batteries; remove scale and soot from instantaneous water heater components; Ensuring good air ventilation in the room is important not only for the normal functioning of the device, but also for the safety of people.

These are the most common problems that cause the gas water heater to turn off and go out. As you can see, in most cases the owner of the device can eliminate them on his own. If repairs are unsuccessful, or maintenance requires special equipment or knowledge, you should call a qualified specialist.

Gas pressure

If the gas water heater does not light up when you turn on the water, the reason for this situation may be problems with gas pressure or a complete lack of gas in the system.

In this situation, usually the water pressure is normal, and the piezoelectric element gives a spark. The first thing you need to do is check the presence of gas in the gas pipeline; to do this, you need to try turning on the gas stove. If the stove does not turn on either manually or automatically, and the characteristic hiss of flowing gas is inaudible from the burner, then with a high probability it can be said that there is no gas in the gas pipeline.

The option when gas does not flow in the gas column while there is normal gas flow to other devices and when there is a spark on the piezoelectric element indicates a malfunction of the gas equipment or a clogged gas filter. When the gas water heater does not ignite when the water is turned on and the ignition system is activated, it is necessary to check the condition of the gas filter installed in front of the device.

The fact is that the composition of natural gas, the presence of impurities and gas condensate can clog the gas purification filter. Because of this, the gas pressure decreases, the pilot light does not light, or the gas safety valve turns off. One of the symptoms of filter contamination can be cases when the device does not light up immediately, or if it does turn on, it starts working intermittently at first, and then after a few minutes it reaches the desired mode.

What to do if the gas water heater does not light up due to low gas pressure or a clogged filter? First of all, you need to turn off the gas supply valve and open the vents for ventilation. Next, you need to inform the gas service about the problem and if this is not a centralized gas shutdown, then call a gas service technician.

The main thing in this case is not to try to do the repairs yourself and wait for the specialists to arrive.

Clogged chimney

If too many combustion products have accumulated in the chimney or there are foreign objects inside, the heater system will trigger a protection system that will shut off the gas. You can check for what reasons the gas water heater lights up and goes out in this case as follows. You need to open a window or window, light a match, and then apply it to the hole in the chimney. If there is no draft, then the flame will not deviate. Insufficient draft or its absence can be eliminated by cleaning the chimney and ventilation duct. In this matter, it is best to contact specialists who will qualitatively clean the chimney for a small amount.

Design features of gas devices

Some gas stoves of certain European brands are noisy by definition. This is due to their design features and the introduction of technologies aimed at saving resources. These technologies allow you to save gas.

To maximize gas consumption, this stove uses the turbo effect. Some modern burners have two or three rows of perforations (unlike older devices), which results in faster heating. But this can also cause additional background noise.

Those. The combustion intensity increases, but due to all the innovations, the burners begin to make a lot of noise. In addition, on new stoves, the burners suck in air directly under the flame, which is why characteristic sounds are heard (whistles, hissing, tapping, etc.).

On old tiles, this process took place inside the burners, so it was barely audible. If the noise is too loud, you can try to reduce it by increasing or decreasing the gas.

When purchasing modern gas stoves, you need to be prepared for the fact that it will not be possible to completely get rid of the noise of the burners.

Also, the appearance of background noise when a gas stove is operating may be associated with the installation of inappropriate parts. A set of new plates often contains additional elements that can be mistaken for spare parts, but they are not.

In most cases, such parts are designed for different gas pressures. But only an employee of the GorGaz department, with whom the owner of the residential property has entered into an agreement for the maintenance of gas units and the supply of blue fuel, should replace parts of the gas stove with new suitable elements.

If an ordinary gas stove was moved from an apartment with main gas and installed in a country house, connected to a cylinder, and it began to make noise during operation, then in most cases this is due to unsuitable jets.

The jets are responsible for supplying gas in the required volume at a certain pressure. The fact is that the gas in the main pipes and cylinders has a different composition, therefore the nozzles differ in structure and size.

What if the equipment is still noisy?

If, after these manipulations, the gas water heater still ignites with a bang when you turn on the water, then it is better to stop further independent research. In such situations, you will have to seek help from qualified specialists.

They will carry out competent diagnostics of the equipment, will be able to clearly determine what is causing the cotton and, based on the data obtained, will be able to provide you with options for solving the problem.

In certain cases, independent repair is impossible, then cooperation with qualified specialists will be a rational solution.

Principle of operation

This wall-mounted water heater does not have a storage tank for storing and heating water. The device is compact in size. The water temperature rises instantly as it passes through the heat exchanger. The main advantage is the provision of warm water to several water intake points simultaneously. The energy source of such water heating systems is natural or bottled gas. This is precisely what explains their popularity of installation in those houses where installation of gas equipment is possible.

Gas is cheaper than electricity, and although the cost of such units is several times more expensive, they pay for themselves during operation. In turn, the quality of these raw materials must be at the proper level, otherwise the service life of the equipment will not be long. In addition, constant clogging of the filtration system due to the poor quality of the gas mixture will lead to the device constantly turning off.

Read more about the design and operating principle of a gas water heater.

What other reasons are there for extinction?

Failure of the gas water heater can also be caused by these elements.

Outdated membrane

The polymer material from which the membranes are made has sufficient elasticity, but after many years of use it disappears and the element becomes rigid, and it is possible that cracks or lime deposits may appear in it. Such defects will not allow the gas water heater to work regardless of how the tap is opened. Therefore, it is worth removing and inspecting the membrane: if its condition causes concern, a replacement for this element should be found as soon as possible.

Ignition system and piezo element

In devices that do not have an igniter, its functions are performed by electronic ignition, where the spark is generated by batteries. Perhaps the fault lies with them, since they are not always able to work for a whole year. In other geysers, a piezoelectric element driven by a water turbine is responsible for producing a spark. Such an ignition system will not help if the water pressure is low.

A regular igniter is also at risk of clogging; this can be easily determined by the yellow color of the flame. If the burner ignites with a loud bang, this is your case. After cleaning the element, everything returns to normal.

The shower turns on - the speaker goes off

If the water heater only turns off when the shower is turned on, then it is entirely its fault. The reasons may be:

- The mesh filter installed in the shower head is clogged.

- When the watering can becomes clogged, the water pressure decreases. You can try to unscrew it. If the column starts working, the reason has been found.

- The inner rubber pipe of the hose has become twisted, blocking the flow of water.

Protection systems

Most geysers, which are found in many apartments and houses, have a mechanical safety system installed. Even the most modern unit, which contains many electronic sensors and devices, has a mechanical connection between the membrane in the water supply system and the valve installed in the gas pipe.

Gas will be supplied only when the water pressure is sufficient to put pressure on the membrane. The principle here is very simple. If there is no water, then gas will not be supplied to the column burner. If you turn off the tap and water flows, the column will light up.

Not enough charge

When you open the water, you observe a normal flow, when you turn it on, there is a characteristic click, a spark is formed and everything is generally visually good. But there is one noticeable point: the burner itself in the gas water heater does not ignite. If you look through the window, there is no flame. This is the reason why there is no hot water. The owner does not have hot water, which causes a lot of inconvenience. This reason must be eliminated as soon as possible.

The reason for the malfunction and lack of hot water lies in a completely simple phenomenon. When the batteries stop working, the speaker stops functioning. It does not heat up and therefore the hot water supply stops.

The battery charge in the final stages is only enough to produce a spark. Therefore, visually you observe a spark, and there is also a noticeable click. But the battery energy is not enough to ignite the burner itself.

Replacing the batteries yourself is not difficult. To do this, you need to open the box with the batteries and take them out. Next, you should replace it with new, high-quality, powerful batteries.

More about batteries

Polarity in batteries matters. If you insert batteries without taking into account their polarity, the column will not light up. Batteries can sometimes get stuck in the pack, so keep an eye on them.

Replacement with new functioning batteries is carried out if two main criteria are met:

- The polarity of the batteries must be taken into account;

- The box intended for batteries must be closed until it clicks.

The batteries used in geysers must be standard D (in other words, barrel batteries). Salt options are not suitable because they have the ability to quickly fail. In most cases, alkaline batteries are used for geysers. They are otherwise called alkaline batteries.

There are often cases when a person purchases batteries, but they do not light the column. Here, too, several questions arise as to why even new batteries cannot cope with their functions. At this stage, the owner may also become confused and look for a completely different reason. In order not to find yourself in such an unpleasant situation, you need to wisely choose batteries for the operation of the gas water heater. There are a few tips to keep in mind...

Tips for choosing batteries

It is not advisable to choose too cheap ones. In this case, it is recommended to choose more expensive batteries (normal ones cost about 200 rubles). If you buy cheap ones, they most likely will not work properly, which means that in the future you will need to overpay

Therefore, initially purchase good quality expensive batteries; Pay attention to the expiration date of the batteries; As for brands, Duracell and Energizer brands are preferred. The battery must be alkaline or lithium

It will be more informative to use a specific multimeter tester that accurately determines the charge. Anyone can use such a tester; it won’t be difficult. This method is convenient and practical to use, and you can purchase a battery tester at any store.

Troubleshooting new equipment

New equipment may also experience various problems. Most often they manifest themselves in the operation of the flow sensor, in the operation of the candle, or in the power system. Let's take a closer look at these problems.

Column microswitch failure

Often the problem with a loud bang during ignition is the insufficient discharge of batteries, which provokes the inability to instantly ignite the gas-air mixture.

The power supply is connected to the control unit via special microswitches, which are responsible for generating a signal to activate the ignition when the DHW tap is opened. If the signal arrives at the wrong time, this causes the problem. This malfunction occurs most often due to oxidized contacts. The microswitch cannot be repaired; it will need to be replaced.

If the microswitch breaks down, repairs cannot be carried out, since this system will have to be completely replaced

Flow sensor malfunction

Often the problem with popping is the flow sensor. It is located in the input circuit. A signal is sent to the control unit controller indicating the presence of liquid in the pipe. The data instantly activates the ignition system. Intensive use of this element creates an increased risk of breakdowns. For example, contact groups can be oxidized.

Such sensors are most often manufactured in a non-separable design, therefore, if a problem occurs, they cannot be repaired and must be replaced.

Working candle offset

The problem may be with the spark plug. After applying voltage, it provokes the formation of an electric spark. Modern candles are made in such a way that they can last for a long time. Element failures are rare, but they do happen.

The most common occurrence is that the ignition device is displaced relative to its nominal position. It can occur as a result of repeated heating and cooling. Such processes are associated with changes in the dimensions of individual structural elements. As a result of adjusting the position of the spark plug, the spark parameters become normal, and extraneous noise completely disappears.

Incorrect operation of the ignition retarder

A rare breakdown is considered to be incorrect operation of the ignition retarder. When disassembling the column, you need to remove the water regulator. On its cover there is a hole in the bypass channel, in this hole the ball is located. The adjusting screw determines the position of the ball.

If, when shaking the lid, you hear the sound of a moving ball, then you should not manipulate this part further. If there is no knocking, then you can move the ball using a thin copper or aluminum wire through the passage channel hole, which is located in the regulator cover.

Most often, the retarder is a ball of metal or plastic that blocks part of the bypass channel in the water regulator. In most column designs, this moderator is located in the boss of the water regulator cover.

As a last resort, you will have to resort to the procedure of parsing the element. It must be said right away that the external screw does not affect the position of the ball in any way.

The inner screw must be removed very carefully. You should first remember its initial position, and also clearly determine the number of revolutions by which this screw is screwed in

This will allow you to maintain the required location of the element (ball) during subsequent assembly.

After repair work, be sure to check all connections to completely eliminate leaks of both water and gas. All connections must be treated with a sealant to ensure tightness. After which you can put the casing in place and use the column as usual.

Why does the washing machine hum when washing?

There are many reasons. Extraneous sounds appear from mechanical wear and breakdown of mechanisms, malfunctions of the control module, etc.

Due to improper use

- Constant overload of laundry leads to wear and destruction of bearings. It manifests itself as a loud hum and grinding noise.

- The drain filter is clogged. The pump makes a loud noise.

- No water softener is used. Lime deposits form inside hoses and pipes. It manifests itself as a loud hissing sound when filling and draining water.

Foreign objects

Keys, cufflinks, coins, etc., caught between the drum and the tub during washing, can jam the rotation of the shaft. This will destroy the bearing assembly, motor and electronic module. The sound is characteristic: a loud knock and grinding against the walls of the drum.

If the laundry is improperly distributed in the machine or it is overloaded

Loading laundry in a lump or exceeding the permissible weight leads to additional load on the axle with bearings and shock absorbers. During washing and especially spinning, vibration increases significantly, a dull knock of the drum on the cuff appears, the machine can bounce and hit the walls.

Due to incorrect installation

- The transport bolts have not been removed. When washing, threatening vibrating and knocking sounds are heard, the device bounces and moves on its own.

- Tilt installation. The hum and squeaks heard in the washing machine during washing indicate a misalignment of the tank. When rotating, it touches the rubber cuff.

- A kinked drain hose causes a loud noise from the pump.

The hatch seal does not fit

An incorrectly installed rubber cuff of the hatch causes extraneous sounds caused by friction against the edge of the rotating drum. The washing machine whistles, creaks, whistles with a characteristic “rubber” timbre.

Broken springs

The springs on which the tank is suspended from the body fly off their mounting points or burst (rarely). This is manifested by sudden strong vibration and loud impacts of the tank on the back wall of the machine.

Drain pump faulty

- A loud hum that may gradually become louder. In this case, there are no characteristic “pumping” noises, and no drainage occurs.

- The usual pump sound, but louder. The drainage is slow.

- A rattling noise appears due to a broken pump impeller.

Wear of bearings and seals

Characteristic noises:

- Increased vibration caused by misalignment of the bearing assembly.

- Metallic grinding, crunching, indicating the beginning of bearing destruction.

- Sounds of friction against the hatch cuff that occur when the drum moves. Damper is broken.

When shock absorbers break down, vibration increases sharply, causing the tank to beat with a loud “thumping” sound. Often accompanied by the tank knocking on the back and front walls of the device. The car sways and hits the walls.

Worn drum pulley or drive belt

- When the fastening nut wears out, the pulley begins to dangle and rhythmically hits the rear panel of the unit.

- After several years of operation, the drive belt loses its elasticity. This manifests itself as a squeaking sound at the beginning of the program at slow speeds.

- If the belt breaks, there is no noise from the rotating drum, but the program continues.

The counterweight mounts are loose

When the mounting bolts are loosened, the counterweights shift, the drum loses alignment and begins to oscillate. The more the fasteners are loosened, the stronger the vibrations and louder the impacts.

The engine mount is loose

Due to prolonged operation or poor quality repairs, the engine mount may become loose. A whistling sound of high-frequency vibration appears, which intensifies during the spin cycle. If the fastening nuts are loosened too much, rattling noise is added.

Engine failure

- Worn commutator brushes. During operation, a crackling sound from spark discharges is heard at the engine mounting location.

- Strong engine noise, increased vibration. Causes: bearing failure, capacitor failure.

- There is no sound, the engine does not work.

Electronic module malfunction

The electronic unit operates silently, so its breakdown can be indirectly judged by the sounds the machine makes when washing.

- Chaotic changes in the volume of the engine, the rotation speed of the drum randomly changes.

- The sound of water heating (hissing) in the cold water or rinse modes.

- The relay in the control unit clicks, but the wash does not start.

Rotation shaft failure

Sound features:

- Increased vibration, the frequency of which can vary arbitrarily.

- Beating of the drum against the door seal in a certain place.

- At low speeds there is a metallic “dangling” sound in the absence of pulley play.

Internal breakdowns

Now let's see what undesirable phenomena can occur inside the column itself:

Water circuit

Most often you encounter the following problems:

- The “original” filters included in some speakers are clogged.

- The flow area has decreased due to scale deposits.

Solid deposits, commonly referred to as scale, are formed by magnesium and calcium salts dissolved in water. The higher the water temperature, the higher the rate of scale formation, so the heat exchanger is the first to suffer from this problem. Its thin tubes clog very easily, resulting in a drop in pressure with all the consequences described above.

Today, a number of effective products are produced to clean the pipeline from scale. If a special composition for geysers is used, the heat exchanger does not need to be dismantled. It is enough to disconnect the supply pipe from it and drain the water by opening the hot water tap on the mixer.

Gas water heater water circuits

Then a rubber hose is secured to the inlet pipe of the heat exchanger using a clamp, into which the reagent is poured through a watering can. You need to pour it slowly, otherwise the product will splash out due to a violent reaction.

Descaling products contain very aggressive components, for example, hydrochloric acid. When working with them, you must carefully follow safety rules and use protective equipment - gloves and goggles.

After a 2-hour soak, the supply pipe is again connected to the heat exchanger, the root valve is opened and a certain amount of water is driven through the column.

If you couldn’t get a special product for speakers, you can use any, but then the heat exchanger will need to be removed and washed separately. Otherwise, an important element of the column - the aluminum gearbox - may be damaged.

If for some reason you cannot purchase a factory-made reagent, use a folk remedy - a solution of 100 g of citric acid per 0.5 liter of water.

Ignition system

In some columns, the spark to ignite the burner is generated by batteries - this is the so-called. electronic ignition.

The reason for the “strike” declared by the water heater can be very simple - the batteries are dead and need to be replaced.

The igniter may go out due to the fact that the ignition button was not held down long enough (less than 20 seconds) - the bimetallic plate did not have time to heat up.

Smoke removal system

Soot build-ups can form not only in the chimney, but also inside the column - on the heat exchanger. It needs to be cleaned periodically.

In turbocharged engines, the cause of poor draft may be a malfunctioning fan.

Modern instantaneous water heaters are very different from outdated models, so before purchasing you need to study the main characteristics of the equipment. : recommendations from experts and review of models.

We will consider the technology for pumping a well after drilling in the article. And also read useful tips on choosing equipment.

Automation

The most common type of automatic equipment that fails is the rubber membrane in contact with water. It may become deformed or crack. This element needs to be replaced.

When choosing a new membrane, give preference to silicone-based products - they are the most reliable and durable.

The traction sensor also fails relatively often. To check its functionality, you need to measure its resistance by connecting a tester to the terminals. The device should show “infinity”.

Cleaning the heat exchanger without dismantling

There is also a way to clean the heat exchanger without completely dismantling it. To do this, you must first remove the casing from the device and disconnect the water supply pipe from the heat exchanger. The inlet copper tube of the coil should be slightly shifted to make it easier to work with.

“Antinscale” is considered a very effective and safe means for removing scale from the heat exchanger of a gas water heater, although other household products can also be used

A hose is put on the outlet pipe. Then you need to open the tap and drain a little water, about a liter, to free the coil from liquid. If it is possible to clarify the capacity of the heat exchanger in the technical passport of the geyser, then it is recommended to drain exactly the same amount of water or a little more from the system.

To clean the column using this method, it is better to take Antiscale powder, which is diluted with hot water before use. It doesn’t hurt to take care to protect your skin and eyes from accidental exposure to the composition, since it contains hydrochloric acid.

Now you need to insert a funnel into the inlet pipe and pour Antiscale into the heat exchanger. It should be remembered that when pouring quickly, a reaction may begin inside, which will lead to the ejection of the dangerous solution in the opposite direction. Therefore, you need to pour the composition in small portions and in a thin stream.

If a gas leak is discovered during the cleaning of the column, you need to immediately shut off the pipe and call the experts from the gas industry

The heat exchanger filled with solution should be left for about two hours. To speed up the cleaning process, you can turn on the igniter (it is not necessary to turn off the gas for this cleaning method). When the process is over, you should open the tap and drain the water with the sludge dissolved in it from the column.

If a lot of contaminants come out and the jet shows good pressure, cleaning can be considered satisfactory. If not, you need to carry out the procedure again, but when using Antiscale, such a need usually does not arise.

This cleaning method is recommended to be carried out using just such a cleaner. The use of vinegar or citric acid in this case can have a bad effect on the condition of the aluminum gearbox.

Boiler problems

All systems have been checked, but there is still no heat? So, the problem is still in the boiler itself. Let's figure out why it doesn't work. Malfunctions may appear as follows:

- The burner does not turn on or burns weakly

. The injectors may be clogged. They can be cleaned with a soft brush or thin wire. In addition, air could get into the gas line (especially if the connection unit was disassembled). Usually in such cases the gas boiler is blocked and an error code lights up on the display. It is necessary to restart by resetting the lock (how to do this is written in the instructions); - The burner does not turn on when trying to manually or automatically ignite.

Perhaps the gap in the ignition electrode is broken, contact with the current-carrying wire is lost, or the air supply filter to the burner is clogged. It is quite difficult to adjust the gap yourself, but cleaning the filter and checking the wire connection is quite possible; - The burner goes out after burning for some time.

It is possible that the ionization electrode is dirty, the gap in it is broken, or the connecting wire is unsoldered. You need to do the same as in the previous case; - Flame separation

. With such a malfunction, the injector makes a lot of noise (or a characteristic whistle is heard from it). It is necessary to adjust the gas pressure at the igniter. Separation is also possible with excessively high draft and increased supply ventilation (air blows out the flame in the burner). This situation can arise, for example, if the chimney pipe is too high; - The boiler makes noise and switches off spontaneously

. The cause may be a breakdown in the pump or built-in fan (for turbocharged models), failure of the thermostat (water boils), flame separation or breakthrough.

Hot water supply, without a doubt, can be considered a prerequisite for a comfortable life, therefore the occurrence of interruptions in the operation of the gas water heater requires the most urgent measures to be taken.

But you shouldn’t immediately rush to the phone and call a repairman, because the cause of the breakdown may well be trivial and easily fixable even by the user.

Let's try to figure out why the geyser goes out and in what cases the owner himself can restore its functionality.

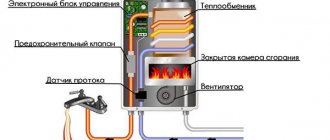

The main working elements of the gas water heater are:

- gas-burner;

- the heat exchanger located above it is a long coiled tube in which the water flowing through it is heated.

Auxiliary components of the gas water heater include:

- Ignition device:

can be electronic (generates a spark in one way or another) or have the form of a pilot burner (pilot or wick) that burns constantly. In old speakers, the igniter had to be lit with a match. In modern ones, a piezoelectric element is installed for this purpose, which the user activates by pressing a special button. - Water-gas unit:

consists of an interconnected membrane (installed in the water supply) and a gas valve (installed in the gas path). As soon as the user opens the tap and water flows through the column, the membrane bends and opens the gas valve, thus supplying gas to the burner. - Safety automation:

consists of several sensors and a special solenoid valve in the gas path, to which these sensors are connected mechanically or. If deviations occur in the operation of the column, the corresponding sensor will close the valve, thereby turning off the device. In columns with an igniter, a thermocouple is also connected to this valve, heated by the igniter flame. It is triggered when the pilot burner goes out.

External fault factors

What to do if the gas water heater does not light? Malfunctions of the gas water heater can be caused by circumstances beyond its control. Let's look at them in order:

Gas supply

There is nothing special to talk about here, and everything is clear: if the gas is turned off, the water heater will not work.

Just don’t rush to blame the gas workers for everything.

If the system has a filter, first make sure it is not clogged.

Water pipes

Here are the surprises the water supply system can present:

Pipe connections were made incorrectly

This is quite a likely reason, especially if an amateur undertakes the installation of the column. If a newly installed water heater refuses to work, check the connection diagram again.

Insufficient pressure

Some of the geysers are equipped with an ignition system, which is driven by a flow of water - it rotates a turbine connected to a piezoelectric element.

With low pressure, naturally, such a system will be inoperative.

The opening of the gas valve is also carried out by water pressure - through the membrane mentioned above. If the water flows barely, the valve will remain tightly closed.

Most often, pressure problems occur in rural areas.

When purchasing a water pump, their residents should definitely check at what minimum pressure it can operate.

However, even in urban conditions, the pressure in the pipe can be negligible. The reason is a clogged mesh filter installed in front of the column. To test this hypothesis, open the cold water tap on your faucet. If the pressure here is normal, then the problem is really local in nature - you need to check the mesh filter or heat exchanger (more on this below).

The inlet water temperature has risen

Due to inexperience, some users forget to take into account the fact that the water in the water supply becomes warmer with the beginning of the spring-summer season. If the speaker remains set to winter mode, it will constantly turn off due to overheating.

Smoke removal system

If there is no draft in the chimney, the automatic protective equipment, despite all your admonitions, will not allow you to use the column.

For example, if the chimney is clogged, the gas water heater will not light.

External reasons due to which the outflow of combustion products may deteriorate include the following:

- Chimney blockage:

debris or birds may get into the chimney. In addition, over time it becomes overgrown with soot, so it needs periodic cleaning. - Installation of large objects above the chimney head:

in most cases, such an object becomes a television satellite dish. It prevents the free flow of gases, to which the traction sensor immediately responds. - Lack of outside air flow:

the user must not forget that for normal draft it is necessary to provide air supply to the room from the outside. When the speaker is operating, at least the window must be open. This is especially true for sealed double-glazed windows in metal-plastic frames. - Unfavorable weather conditions:

the column can go out due to the fact that a strong wind or whirlwind worsens the draft or, conversely, sharply increases it, causing the flame to break off.

The presence of traction is checked by holding a column of paper sheet or a lit match to the “viewing window”. If the smoke exhaust system is in proper condition, the flame will be drawn into the “window” and the paper will be pressed against it.

Overheat

Most often, overheating occurs for the following reasons:

- The user dilutes hot water with cold. Due to the addition of cold water, the consumption of hot water is reduced, therefore, the heat extraction is reduced and the water in the heat exchanger overheats. Remember: you can regulate the temperature of hot water only by changing its pressure or using the regulator on the column.

- The heat exchanger is clogged with scale somewhere. This also leads to a decrease in water consumption with subsequent overheating. You can guess what happened by the clearly weakened pressure of hot water, despite the fact that cold water flows properly. To prevent such troubles, the heat exchanger must be periodically washed with special anti-scale compounds.

If the mesh filter (dirt filter) installed on the water supply in front of the column is clogged, the flow rate in this case will drop with all the ensuing consequences.

What is the reason for the speaker turning off during operation?

Sometimes the user is faced with a situation where the column lights up, but goes out during operation. This may indicate a problem with the device's security system. The fact is that inside the column there is a temperature control sensor, which is triggered when it overheats. It consists of two plates. When the temperature inside the device rises sharply, these parts open, the electricity supply ends, and the column turns off.

If you have the necessary device (multimeter, tester) at home, you can check the resistance of the sensor. The operating device will display an infinity sign. If this is not the case, then it is better to call a specialist to repair it.

Soot accumulates on the heat exchanger

During operation, soot, soot, and scale may accumulate on the heat exchanger. As a result, it will simply clog. This can be determined by the changed color of the flame: it will change from yellow to blue. You can clean the heat exchanger yourself by performing the following work.

- Remove the casing.

- Remove the screws and turn off the water supply.

- Drain any remaining hot water in the system.

- Disconnect the heat exchanger.

- Prepare a 3% hydrochloric acid solution.

- Pour it into the heat exchanger and wait a while.

- Drain the solution, rinse the tube with water and replace it.

- Place the casing in place and tighten all screws.

Clogged hose and shower head

Some speakers owners are faced with the fact that it works fine, but immediately turns off when switching to a shower. This may be due to a clogged shower head or shower hose. To eliminate the problem, you need to wash these parts or soak them in a solution of citric acid. It's also worth checking the faucet. If it is clogged, clean it.

Attenuation immediately after switching on

The reason that the fire goes out after being turned on may be a malfunction of the flame ionization sensor. The signs of this are as follows:

- The flame goes out after 3-6 seconds.

- After switching on again, the device works longer.

- After 5-6 times the column starts working normally.

- After cooling, everything repeats.

First of all, you need to check the contacts between the control unit and the sensor. Also move the ionization sensor closer to the flame. If these manipulations do not help, the part will have to be replaced.

If the water heater lights up, runs for a few minutes, and then goes out, then the exhaust gas protection is triggered. This happens in the following cases:

- The chimney is clogged and the exhaust gas does not have time to escape. In this case, you need to clean the chimney of soot and foreign objects.

- At the same time, active ventilation operates. Then combustion products can escape through the kitchen into the ventilation. You need to turn off the ventilation while the speaker is running or set it to a lower power.

- The radiator is clogged. When using the water heater for a long time, the spaces between the radiator fins become clogged. A sign of this is the yellow color of the flame. You need to disassemble the column, remove the heat exchanger and wash it in the bathroom using detergents and a long-hair brush. Also, over time, the igniter wick becomes clogged with dust. You need to remove it and clean it with wire.

- The window is closed. According to the rules for using gas water heaters, the window must be open during operation. This is done so that the draft works well, and new oxygen is supplied, which is necessary for combustion.