Hi all! Today I want to talk about such a material as external drywall. Recently a friend asked me if it was possible to sheathe a façade with it. I said that aqua panels would be more reliable, and that drywall, even moisture-resistant, should not be used for exterior decoration. It copes with humidity, but only in buildings and rooms. If you still bought drywall, then make the facade in 2 layers, and treat the joints with silicone-based putty. It is also possible to increase resistance to moisture by painting. But you also need to buy silicone-based paint. Let's take a closer look at how to carry out all the steps of the process.

What is the difference between external drywall and regular drywall?

Special sheets are used to decorate the façade of a house with plasterboard. They are treated with hydrophobic impregnation. GCR has the following properties:

- energy saving - heat remains in the house, cold does not enter the room;

- moisture resistance – this drywall does not allow moisture to pass through. Fungus and mold do not appear on the interior walls of the room;

- sound insulation – noise from the street is practically inaudible in the house;

- façade plasterboard does not deform under the influence of weather conditions.

On the practical side, there are the following properties:

- the smooth surface of the plasterboard makes the facade beautiful and attractive;

- there are a lot of finishing options;

- working with plasterboard does not take much time;

- the insulation laid between the walls and drywall is not exposed to external influences of temperature and moisture;

- façade plasterboard is safe for people and the environment;

- at low temperatures, drywall does not deform or burst.

With all the positive properties there are some disadvantages:

- The facade of the house cannot be covered with any other type of plasterboard, except for façade gypsum plasterboard.

- If drywall is constantly exposed to water, it will become deformed.

- If the drywall sheets are constantly exposed to high temperatures, the structure will collapse.

- GCR is fragile and breaks easily, so work should be carried out carefully and carefully.

When a set of deficiencies occurs, it is necessary to handle the gypsum board accordingly.

Comparative characteristics of gypsum board and gypsum board

Despite the similarity of composition, the materials differ in all respects.

Geometric parameters

GCRs are produced in a wide variety:

- Thickness - 6.5, 8, 10, 12.5, 14, 16, 18, 24 mm.

- Length - from 2 to 4 m in increments of 50 mm.

- Width: 600 and 1200 mm.

Wall and ceiling gypsum plasterboards are available in only 2 versions:

- 2.5x1.2 m;

- 1.5x1 m.

GCRs are produced in a wide variety of thickness, width and length.

The thickness of both types is 10 or 12.5 mm.

The floor-standing version is available in 1 format: 1200x600x20 mm.

Weight

Gypsum fiber is produced by pressing, so its density is approximately 1.45 times higher than that of gypsum plasterboard. So, the weight is 1 square. m of sheet 12.5 mm thick is:

- GVL - 14 kg.

- GKL - 9.6 kg.

Thus, a gypsum fiber sheet can have a mass of up to 44.5 kg (with dimensions of 2500x1200x20 mm). The weight of gypsum boards of the same size is 29 kg.

GVL manufacturers do not always indicate the weight of the slab.

The buyer needs to focus on the following data: the weight of the sheet is in the range of 1.08-1.25S, where S is its thickness in mm.

Strength

Gypsum fiber sheet is superior in strength to plasterboard due to its higher density.

GVL has a higher density and can be used in floor construction.

This provides the following benefits:

- The material cannot be penetrated by a kick or hand.

- The shelves are attached to the sheathing.

- Gypsum fiber can be used in floor construction.

A special butterfly dowel, screwed into the GVL in compliance with the rules, can withstand a constant load of 80 kg.

Plasterboard sheathing breaks easily. Shelves can only be attached to the frame.

Flexibility

Without special treatment, plasterboard bends along a radius of 3 m. A sheet lying on the floor can be lifted by pulling the short side. It will bend, but will not crack.

GCR can be given a curvature with a smaller radius if you first pierce the cardboard with a needle roller and saturate the core with water. This is how arches, columns and spline transitions in multi-level ceilings are made.

GVL is tougher. If you try to lift a lying sheet by the short side, it will break or become covered with cracks. It is impossible to bend it by wetting or in any other way.

Flammability

Cardboard burns, so all brands of gypsum board, including gypsum board, belong to the following groups:

- Flammability - G1 (low-flammability).

- Flammability - B2.

- Tendency to smoke formation - D1.

- Toxicity - T1.

GCR refers to non-combustible materials.

Fire-resistant sheet (GKLO) retains its integrity longer during a fire: 45 minutes versus 20 for GKL.

In GVL, fibers from cellulose and other organics are located under a layer of gypsum. Therefore, this material is classified as non-flammable (NG group).

Soundproofing and thermal insulation

The sound absorption coefficient of GVL is only 2 dB higher than that of GCR. But due to the outer cardboard layer, the second type has a higher reflectivity. A room sheathed with gypsum plasterboard becomes echoey, whereas when gypsum plasterboard is used, the sounds go out.

The materials have the following thermal conductivity coefficients, W/(m°C):

- GCR - 0.21-0.34.

- GVL - 0.22-0.36.

The energy-saving effect is almost identical.

Both materials cannot compete with insulation materials having a coefficient of 0.028-0.04 W/(m°C).

Water absorption

During the control time, the materials absorb water in the following quantities:

- GCR - 20% of the sample volume. Moisture-resistant variety - no more than 10% (GOST requirement).

- GVL - no more than 1 kg/sq.m. m. With a thickness of 12.5 mm, this value is 7% of the volume. GVLV has a lower figure.

GKL and GVL have low water absorption.

The low water absorption of gypsum fiber is explained by its high density.

Frost resistance

In a water-saturated state, materials can withstand the following number of freeze-thaw cycles:

- GKL - 4;

- GVL - 15.

The difference is explained by the increased specific gravity of gypsum fiber.

Such frost resistance indicators are considered low. Therefore, standard gypsum fiber sheets and plasterboard are not suitable for use in unheated areas.

Environmental friendliness

Both varieties do not contain phenol-formaldehyde resins and other components harmful to health. All components of gypsum plasterboard and gypsum fiber board are completely environmentally friendly. Materials are allowed to be used without restrictions in premises with constant occupancy of people, incl. children's institutions.

GKL and GVL are environmentally friendly materials.

During installation and operation, plasterboards emit gypsum dust, but due to the small amount it does not pose a threat to health.

Ease of operation

Due to its lower density, drywall is more convenient to work with:

- Due to its low weight, delivery and installation are simplified.

- To fasten the sheets, a thin-walled frame is sufficient.

- Trimming can be done with a utility knife.

- To screw in the self-tapping screws, no pre-drilling is required; the head is easily recessed into the cardboard. A lot of force is not required; on the contrary, it must be controlled. Otherwise, the head will break through the cardboard and destroy the gypsum core.

Dense, heavy GVL is characterized by the following:

- Reinforced frame required.

- A special disk tool is used for cutting.

- You have to pre-drill a hole for the screw. The exception is hardware with a self-tapping head in combination with a powerful screwdriver.

- To recess the cap, you need a countersink (drilling a hole with a tool of larger diameter).

GCR is more convenient to use because it has a lower density.

When screwing into double skin without pre-drilling, the screw, having reached the second panel, pushes out the first.

Price

Minimum price 1 sq. m of material:

- GKL - 70 rub.;

- GVL - 180 rub.

For example, one of the companies offers sheets of format 2500x1200x12.5 mm at the following price (rubles):

- GVL - 633.

- GKL - 269.

Material with improved properties is more expensive. For example, a sheet of moisture-resistant plasterboard of the specified size will cost 369 rubles, soundproofing - 645 rubles.

Which profile to use when sheathing a house with plasterboard on the outside

To prevent the profile from rusting, use an aluminum type.

For exterior finishing, use a special aluminum profile coated with an anti-corrosion compound. It is produced by pressing. There is a profile of normal and increased strength.

Properties of aluminum profile:

- The weight is light.

- Durability – able to withstand a certain weight.

- Rigidity – does not bend during installation and operation.

- Aluminum profiles are available in different sizes.

- The frame made of profile lasts a long time.

- Using this profile it is possible to manufacture curved structures.

- Working with this building material is simple and easy.

- Aluminum profiles do not contain toxic substances and are therefore safe for health.

When creating a frame from a facade profile, it should be taken into account that the fasteners must be treated with an anti-corrosion compound. After installation, the space should be filled with thermal insulation material. This is mainly polystyrene foam or construction wool.

If the house is made of natural stone, the frame is not mounted. After fixing the heat-insulating material, the sheets are attached to the wall with special fasteners.

GKLO

Fireproof, marked red (GKLO), it is used mainly in dry places or with high air temperatures. Typically, this type of drywall is recommended to be installed in ventilation shafts, attics, and other places where there is a risk of fire.

It should be noted that thanks to reinforcing additives, such drywall is able to withstand very high temperatures, and possibly even an open flame of fire. The color of the plaster is pink.

Materials for covering a house with external plasterboard

Primer. To treat the surface outside, a soil mixture is used:

- façade primer – anti-corrosion. Prevents rust;

- antiseptic – prevents the appearance and spread of fungus and mold, fights the appearance of beetles and other pests;

- primer with deep penetration - for greater adhesion of building materials;

- hydrophobic composition – prevents the penetration of water and moisture;

- universal primer - has many properties and is widely used in outdoor work

Putty. It has the main task of withstanding temperature changes and alternating high humidity and dryness.

Putty can be of 3 types:

- starting – base;

- finishing – main. With its help, the surface is leveled and prepared for subsequent decoration;

- universal - can be used as a base or finishing finish.

When finishing exteriors, it is important to choose the right plaster.

The qualities that universal putty has: elastic, frost-resistant, durable, breathable, quick-drying, does not contain toxic impurities. This putty is easy to work with and sands well. The composition of putty mixtures is:

- polymer – suitable for outdoor use;

- cement – there is shrinkage;

- polyurethane - universal composition;

- gypsum - not recommended for street work, because does not tolerate moisture well.

With the right choice of building materials, finishing the facade of a house with plasterboard will not be difficult and will not take much time.

History of the creation of drywall

Who invented drywall? Three people can be considered the inventors of drywall: Augustin Sackett, Clarence Utsmann and Stefan Kelly. The material was first invented more than 130 years ago. His homeland is the USA. During this time, gypsum plasterboard underwent some changes until it became a modern building material.

- 1881, USA. Augustine Sackett, a paper mill owner, received a patent for the first prototype of modern drywall. At that time, the sheet consisted not of two, but of ten layers of paper. The gypsum in such a sheet served more as a glue than as a durable core.

- 1917, England. Between 1910 and 1930, drywall evolved into its modern form. Now there are two layers of cardboard, and the layer of gypsum has been significantly increased. The second version of the gypsum board was patented by Clarence Utsmann and Stefan Kelly. They also came up with a folded edge made from cardboard. Production of this variant began at a factory in England in 1917.

Since then, only the composition of the gypsum has changed slightly, new additives have been introduced, but there have been no fundamental changes in the structure of the drywall.

How to properly use drywall for exterior use

To create a beautiful individual house facade, you will need to create a metal frame. Elements must be galvanized to prevent rust. Before installing frame parts, you should prepare the surface. The facade must be clean and without hanging finishing materials. If there is a “belly” in the plaster or “fur coat” of the house, it should be removed. It is also necessary to remove the old whitewash. There should be no dust, cobwebs or dirt.

The surface is primed to prevent the occurrence of fungus and pests. After the primer has dried, this process is quick in the open air; markings should be made. Stretch the fishing line and hang plumb lines (to make the surface even). Installation of profiles begins along the perimeter of the wall, do not forget about windows and doors. After fixing the guide profiles, you should work on the vertical posts and horizontal struts. Each mounted element is checked for evenness with a level.

The metal frame should be made under the very roof and with a slight approach to the foundation line. Once the roof is sheathed, the top edge of the plasterboard wall will be hidden. Below, when insulating the foundation, the lower edge of the facade trim is sealed.

After installing the metal profiles, a corrugated wire is laid on top to illuminate the street. The entire surface is insulated with insulating material.

Drywall sizes

When choosing the size of drywall, two parameters should be taken into account:

- Lenght and width

- Sheet thickness

Lenght and width. The standard width of a plasterboard sheet of any thickness is 1200mm. The length can vary from 1500mm to 3000mm. When choosing sizes, you should start from the finishing area. Work with the sheet that is most convenient for your space. For large rooms, choose the longest sheets, this will speed up finishing. In small rooms, it is more convenient to work with small sizes, since cutting and moving large sheets in cramped conditions will be problematic.

Sheet thickness. Depending on the thickness and application, plasterboard can be divided into three groups:

- Wall. The thickest sheet, 12.5 mm, is used for wall decoration. It is durable and can withstand various shelves, paintings and other interior attributes.

- Ceiling. 9mm sheet is intended for simple finishing of ceilings. It is convenient to finish large, flat areas with this material. The weight of the sheet is reduced due to the thickness, but the strength remains at a high level, eliminating sagging. A ceiling with such a sheet will look perfectly smooth.

- Arched. 6.5mm sheet is used for complex figured decoration of ceilings, arches, niches in walls, domes, columns and other design figures. It lends itself most easily to radial molding. With the wet method, the radius can be reduced to 300mm, with dry molding - up to 1000mm. You can't do this with thick sheets.

If there are no thin sheets, you can, of course, finish the ceiling and arches with plasterboard, but this will require additional time and putty.

How to install drywall on exterior surfaces

Drywall is attached to different surfaces:

- Tree (log house).

- Brick walls.

- Concrete walls.

- Cement board.

- Cinder block surface.

Almost any building material from which the house is laid out is made of a metal frame from galvanized profiles. After creating the frame, the strength and evenness of the surface are checked. Sheets can be fastened both longitudinally and transversely. Drywall sheets should be attached first to the corner of the house.

Fastening occurs according to the rules:

- Fasteners must be galvanized or have a special anti-corrosion coating. The hardware is screwed in by hand.

- Self-tapping screws should have a sharp tip and a semicircular head.

- Fasteners are installed every 20 cm.

- The screws should be turned in a level position.

- There are 15 hardware for 1 square meter.

Knowing these rules, attaching drywall to the frame will not be difficult.

Drywall. Characteristics, types, application and price of drywall

New standards for drywall . Consumers and industrialists are getting used to the updated GOST number 32614-2012. The international nomenclature states EN 520:209. In 2016, new rules were applied in parallel to the old ones.

Since the beginning of 2017, GOST 6166-97 has been cancelled. Not only quality parameters and size ranges have been clarified, but also terminology. What used to be called gypsum board sheets have now become gypsum building boards, abbreviated as GSP. But first, let’s look at the very concept of “drywall.”

What is drywall?

The essence of the material is clear from the title. The boards are a combination of cardboard and gypsum. The latter is located between the sheets. There is a cardboard edge. Initially, paper was added to the plaster. This happened more than a century ago.

New material was invented by Fred Kane and Augustine Sackett. Both are Americans. Augustine owned a paper factory. The desire to expand the business gave birth to the idea of alternating sheets with gypsum.

The dimensions of the slabs were brought to squares of 91 by 91 centimeters. The thickness of the first drywall was 6 millimeters. This is the 1884 standard. This is the date the patent was granted.

The new material was called Sackett boards. The advertising company declared the material a replacement for plaster. The advantages were the perfectly smooth surfaces of the walls, the absence of cracks and the ability to move into the house immediately after installing the Sackett boards.

The description is close to the modern version of drywall. The installation of his first samples was not widespread. Fame came to the sheets of Stefan Kelly. He resumed Sackett's work 2 years after his invention.

It was Kelly who replaced the paper with cardboard, but did not think of covering the sides of the slabs with an edge. This was already done by Clarence Utsman in the 1910s. In 1917, the first full-fledged production was launched. The plant was built in England.

Modern drywall, like its predecessors, is a sandwich-like composite material. The slabs are used as a rough layer of walls and for the construction of false structures, for example, arches, fireplaces, columns, interior niches.

In the first case, technical purposes are pursued, and in the second, decorative ones. Depending on the purpose of the sheets, additives may be mixed into the gypsum. They complement the properties of the material, which is related to its classification.

Types of drywall

There are 8 types of drywall sheet Previously there were 4 of them. New designations have also been introduced. The usual one is close to historical samples. It is gray in color and marked with the letter A. Sheets with a given density are hidden under the D-marking.

In particular, the load supported by the material depends on it. I is a designation for slabs of increased hardness, and F is for fire-resistant ones. In the latter, for example, fiberglass is added. It reinforces the slabs and reduces flammability.

The photo shows colored drywall

True, plasterboard walls are not flammable even in their usual form. The filler of the sheets is stone. His flame does not take him. It can absorb cardboard, but there is no layer of air between it and the plaster. At most, the paper will char. But, for rooms with a high fire hazard, it is still customary to take F slabs.

GOST 32614-2012 separately identified facade slabs. Impregnation of cardboard makes them resistant to moisture. It also does not pass in the form of steam. The sheets are designated by the letter E.

Marking H is reserved for waterproof plasterboard. It has a green color and 3 subtypes. H3 has the highest moisture absorption coefficient. H2 has less. The most resistant plates are H1.

It remains to describe the P and R-plates. The first are suitable for applying gypsum plaster, fastening stucco moldings and ceramic slabs. Hidden under the R-marking are sheets of increased flexibility.

The thermal insulation properties of the material can also be increased. The plasterboard partitions the brick . Polystyrene foam comes to the rescue.

A slab made from it is attached to the hero of the article, resulting in a combined drywall with increased thermal insulation, worthy of a brick. Here is another classification into separate slabs and those combined with other materials.

There are several options for each destination. Thus, you can increase the thermal insulation of drywall not only with polystyrene foam, but also with mineral wool.

Characteristics and properties of drywall

There may be environmental issues with combined slabs. But, in its pure form, drywall is completely safe. The inside is natural stone, the outside is recycled wood pulp. In its normal form, the material perfectly absorbs moisture and just as easily releases it when the air dries out.

Arches made of plasterboard and other semicircular structures allow its flexibility to be erected. The slabs are pliable, and as for the R-type, they work miracles of gutta-percha.

The photo shows drywall installation

At the same time, drywall is lightweight, which makes it easier to install. It is also convenient to work with the fact that the slabs are simply cut. However, this same property indicates the fragility of the sheets.

Ordinary drywall does not boast of increased strength. For example, the material does not support weight. To the design from the hero of the article, they try to relieve the load of televisions and shelves.

The disadvantages of drywall include its sound insulation. Visually the structures are there, but audibly they don’t seem to be there. Sounds from neighboring rooms penetrate almost unhindered.

However, if the ceiling is made of plasterboard , or the material is used for rough straightening of walls, the minus does not matter. Sounds are blocked by the main masonry of the building.

If plasterboard is chosen for partitions, it is better to purchase combined sheets with reinforced polystyrene foam or mineral wool. The latter is as safe as the base.

Cotton wool is made from threads of natural minerals, hence the name. This material is not susceptible to mold, fungi, does not interest rodents, in general, it is an ideal insulation material. The only problem is the price. There are better options.

A special feature of drywall is that it cannot be installed without a special frame. It's called a profile. For drywall, it is divided into types. Thus, CD is used in suspended ceilings and wall cladding.

The photo shows a profile for installing drywall

UD – profile is horizontal guides. The main ones are inserted into them. Parts are needed for screwing and fixing drywall. Its sheets, by the way, measure 2.5-4.8 meters by 1.2-1.3 meters.

The new standard adds slabs 40 centimeters wide. The size of the drywall also received a variation in the edge. Appeared with a cut corner. When finishing walls with putty, it helps to strengthen the end joints.

Application of drywall

Some ways of using the material have already been discussed. Now, the details. Communications are easily hidden behind the drywall. True, sometimes the boxes have to be redone. Let's take, for example, a new building.

Builders rarely cut sheets of drywall to cover pipes. They take a standard slab without wasting time on dividing it. As a result, the box turns out to be larger than necessary. You can redo it, saving about 1 square of living space.

Drywall boxes are simply opened. This is convenient in case of pipe leaks and other emergency situations. The material allows for quick repairs, achieving ideal shapes and the ability to easily dismantle structures.

There may be decorative plasterboard on the walls and ceiling. Its surface is covered with ornaments. Any paint is ideal for laying on them, as well as on simple sheets. There are also laminated blocks. They don't even require painting, much less plaster.

The ease of cutting the material has made it a favorite when installing multi-level ceilings of complex shapes. A construction knife along the marked lines easily divides drywall into zigzag, round and other elements of fantasy geometry.

Price of drywall and reviews about it

Standard sheets of drywall cost from 220 rubles. If the slab has fiber reinforcing it, the cost already rises to 440-500 rubles. to buy moisture-resistant drywall for 530-590 rubles.

Fire-resistant is about 30 rubles cheaper. There is no shortage of orders. The material has long been a public favorite. But, to be fair, let’s read a couple of reviews.

Among the negative responses, there are often opinions that drywall does not breathe. The statements are based on the stuffiness of the air in many of the rooms decorated by the hero of the article.

Those knowledgeable in construction counter that it’s not the drywall, but the incorrect ventilation system. The cause of stale air is also the use of synthetic insulation and non-breathable facades.

Sometimes the cost of the hero of the article also causes criticism. Its specialized types, taking into account profiles, screws and installation, cost a pretty penny. However, simple sheets remain a budget option for beautiful and simple repairs.

How to cover external wooden walls with plasterboard

This type of interior work is carried out using the frame method of installing gypsum boards on the walls, and you can choose either a wooden or metal frame. It all depends on the complexity of the design. After installing a frame made of wooden mounting strips or a galvanized metal profile, sheets of drywall are installed on it using standard self-tapping screws.

The advantages of such finishing can be considered the usual list - ideal alignment of the walls, simple and quick installation, the ability to lay communications into the thickness of the wall, elimination of complex preparatory work, relatively low cost of the process, installation by yourself is quite possible.

What is drywall in construction?

Drywall is a material used in almost all types of interior decoration.

For brevity, the material is abbreviated as GKL. Its interpretation is plasterboard sheet.

Structurally, it is a gypsum core, covered on both sides with thick, smooth cardboard.

Used for the following tasks:

- Alignment of walls.

- Construction of frame partitions.

- False ceiling devices.

- Manufacturing of curved decorative elements: arches, columns, multi-level ceilings, etc.

For most models, the sheet thickness on the long side is reduced. Due to this, to level the surface it is necessary to putty only the joints between the gypsum boards.

The popularity of drywall is explained by the absence of dirt and difficulties inherent in “wet” technologies.

Properties and types of material

They produce several types of gypsum boards with different properties. To facilitate recognition, cardboard is painted in different colors:

- GKL - gray. Suitable for use under normal conditions.

- GKLV - green. Moisture-resistant, used in bathrooms, kitchens and other wet areas. The cardboard is impregnated with food-grade paraffin, and hydrophobic and antibacterial additives are introduced into the core.

- GKLO - red. Fireproof, used in rooms with increased fire safety requirements.

- GKLVO - green with red markings. Combines the properties of the 2 previous types.

- GKLZ - blue or purple. With increased sound absorption. This type is often called acoustic. It features increased core density and cardboard perforation.

They produce several types of gypsum boards, painted in different colors.

According to GOST 6266-97, according to the magnitude of permissible deviations from the nominal dimensions and external defects, plasterboards are divided into 2 groups: A and B. The first includes higher quality products.

External plasterboard: installation on a brick facade

All that is needed to start work is to choose the method of installing drywall, tools and materials, the correct dimensions and markings of the walls.

In this case, it is possible to finish the walls with plasterboard without a frame, if the difference in its plane is small and it is possible to use the adhesive method. If the difference is slightly different from the permissible one, you can always level the transition with special beacons made from pieces of plasterboard. If the difference is large, or the wall has significant defects, then it is better to use a frame.

Try to follow the algorithm, accurately take measurements and mark the wall for the frame and drywall sheets, install the structure efficiently and do not forget about the final finishing.

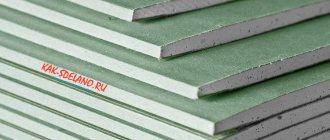

Types of plasterboard sheets

Let's look at the main types of drywall used in the interior decoration of apartments and houses. There are only 4 types:

- Ordinary. GKL. The sheet is gray, the markings are blue.

- Water resistant. GKLV. The leaf is green, the markings are blue.

- Refractory. GKLO. The leaf is pink, the markings are red.

- Waterproof and fireproof. GKLVO. The leaf is green, the markings are red.

Main types of drywall

Waterproof and waterproof fireproof drywall have the same sheet color - green, but differ in the color of the markings. Waterproof is marked blue, while fireproof waterproof is marked red.

All other types of drywall are highly specialized and are rarely used in domestic construction. For example, this rare type includes façade plasterboard with yellow sheets. In Russia it is used very rarely; they treat it with distrust. But in other countries this material is used for exterior work; the main thing is to follow the technology when finishing walls.

Drywall for external facade finishing

Exterior walls take on a stylish look.

A popular trend in cladding materials in construction is various façade panels. Plasterboard systems are a practical and modern way of finishing a facade.

Plasterboard panels for facades are an acceptable and optimal option for insulating external walls

buildings, reliable, highly effective protection from winds and moisture. Drywall for facade work has a unique, special structure that resists moisture, ensuring the moisture resistance of the material.

Features and technological data of external drywall

Due to hydrophobic impregnation, drywall for facing work outside the house becomes a reliable protective screen from natural, weather and climatic influences. Such slabs for external use are a productive energy-saving coating that is used for water and thermal insulation, leveling the effects of wind and air currents.

The material prevents the blowing out of fibers of heat-insulating materials, heat loss from the heat-insulating layer, and the penetration of moisture into the insulation.

Operating data of gypsum boards for external work:

- Aesthetically attractive appearance of facade finishing;

- Individuality of finishing;

- Resistant to moisture absorption;

- Long service life;

- Simplicity of exterior arrangement;

- Wind protection for any wind rose;

- Wear resistance;

- Resistance to temperature changes;

- Prevents the insulation from drying out;

- Environmental Safety;

- Frost resistance;

- Thermal insulation abilities.

Drywall for facade finishing is a means of wind protection. It adjusts the air pressure without reducing its vapor-permeable qualities.

Features of façade gypsum boards

Facade plasterboard panels serve not only to give an aesthetic appearance, but also to insulate buildings, protect against wind and exposure to atmospheric moisture. Therefore, facade gypsum boards have a special structure - the outer cardboard layer is impregnated with a special hydrophobic composition, due to which moisture does not penetrate into the cardboard.

In addition to protecting the house from the effects of precipitation and air currents, plasterboard sheets serve as an energy-saving coating that prevents warm air and insulation fibers from blowing out. Particular attention should be paid to the beneficial performance characteristics of this building material:

- treating the walls with plasterboard makes them perfectly smooth;

- contains only natural ingredients, which is why it is considered environmentally friendly;

- not exposed to temperature changes;

- We are vapor permeable, which prevents moisture from accumulating in the insulation;

- easy to install;

- fireproof material;

- serves for many years without repair;

- does not require special care during operation;

- affordable.

When choosing a gypsum board you need to know:

- For façade cladding, only special moisture-resistant boards are used;

- prolonged contact with water leads to destruction of the slabs;

- cuts well and is highly flexible.

Disadvantages of drywall for outdoor use

Despite all sorts of advantages, advantages and affordable cost, plasterboard has a number of limitations in its use for outdoor work:

- Facade cladding is performed exclusively with material specialized for this type of work;

- Prolonged contact with water leads to deformation of the sheets;

- Prolonged exposure to elevated temperatures leads to destruction of the structure of the slabs;

- Installation work and processing of gypsum boards is carried out carefully, due to its fragility.

Features of gypsum fiber boards and gypsum boards from Knauf

- one of the world's largest manufacturers of building materials. It has a number of its own developments in the field of gypsum-based sheet products.

Main dimensions and characteristics

GKL are produced in the following formats (m):

- 1.5x0.6;

- 2x1.2;

- 2.5x1.2;

- 3x1,2.

Knauf is a manufacturer of gypsum boards.

Sheet thickness: 6.5, 9.5, 12.5 mm.

All drywall from Knauf belongs to group A according to GOST 6266-97 (highest quality).

Sheets are available with the following types of edges:

- Direct (in the brand it is designated PC). Designed for installation without joint finishing.

- Refined (UK). It is planned to seal the joint with Fugenfüller putty with reinforcing mesh.

- Semicircular on the front side (PLC). The joint is sealed with Uniflot putty without reinforcing mesh.

- Semicircular thinned on the front side (PLUK). Universal, suitable for any putty.

- Rounded (ZK). For installation of plastered surfaces.

Characteristics:

- Strength is 20% higher than required by GOST.

- Thermal conductivity coefficient is 0.15 W/(m°C).

GVL are produced in sizes 2.5x1.2 m, thickness 10 and 12.5 mm.

Characteristics:

- Brinell hardness - from 20 MPa.

- Thermal conductivity coefficient is 0.22-0.36 W/(m°C).

- Bending strength is from 5.3-5.5 MPa.

- Vapor permeability coefficient - 0.12 mg/(m.h.Pa).

offers polished gypsum fiber boards. The cost of this material is higher than that of traditional gypsum fiber, but it does not require putty before finishing.

GCR with special properties

The assortment includes non-standard plasterboard:

- Frost-resistant. Designed for finishing unheated rooms.

- Flexible. Used without pre-treatment for the manufacture of arched and other curved structures.

Flexible plasterboard is reinforced with fiberglass on both sides of the gypsum core.

Exterior finishing with plasterboard

Installation work involves the construction of a frame. The façade material and base are marked. This type of drywall is easy to cut and can be processed; it is installed on the surface:

- Wood and lumber;

- Covered with siding;

- Brick walls;

- Cement slabs.

Installation of slabs is possible in the longitudinal and transverse directions to the sheathing of the metal frame. Installation of sheets begins from the corner of the house. In this case, make sure that the vertical joint above the door frame or window is above the opening, and not the vertical post that limits it. With the longitudinal installation method, the vertical seams are shifted by one step of the frame posts. To achieve the highest possible air permeability, joints along the horizontal axis are avoided. To do this, attach drywall as long as the height of the wall.

A non-hardening type of sealant is applied to the joints. This measure will protect the core of the sheet from moisture and increase breathability. With high-strength masonry walls of the house, drywall is attached directly to the wall with screws.

Features of façade cladding with plasterboard

When performing outdoor work, it is worth remembering some simple rules that will help speed up the work process and achieve maximum efficiency from the use of drywall.

· Drywall can be mounted both vertically and horizontally. Regardless of the chosen option, do not forget about the slight displacement of the slabs.

· If there are no horizontal joints, this will have a positive effect on breathability. Therefore, it is best to use sheets of material of the same height as the height of the building.

· All joints between plasterboard sheets must be treated with a special non-hardening sealant. The material will protect the cladding of the house from moisture and allow it to “breathe”.

· To protect exposed edges, you can additionally use a PVC profile.

Facade cladding can make any building unique and beautiful. It is important to choose the right material and carry out installation in compliance with all rules. Drywall for exterior use is popular due to its excellent characteristics and relatively low cost. On sale you can find several different options for material that are suitable for cladding any home.

How to use drywall for exterior work

Fastening is carried out with galvanized hardware or screws coated with an anti-corrosion compound. The size of the screws is selected in accordance with the thickness of the structure frame. Hardware is screwed in manually or using a pneumatic tool. Features of external work on covering the frame with plasterboard:

- Self-tapping screws with a sharp end and a semicircular head are used;

- The head of the screws should not damage the integrity of the cardboard;

- The step for attaching the slabs to the frame slats is 20 cm;

- The screws are screwed in at an angle of 90 degrees;

- The approximate consumption of hardware is 15 pieces per square meter of gypsum plasterboard.

A few words about installation

Facade gypsum plasterboard has its own fastening features:

- Facade plasterboard is mounted on a finished frame, which can be cement slabs, brick walls, lumber and wood, or a specially prepared metal frame. The slabs can be installed both lengthwise and crosswise.

- The installation should begin from the corner of the house so that the vertical joint does not fall above the vertical post of the doorway. Therefore, before starting work, markings are carried out on the base and gypsum board slabs.

- To ensure tightness, the joints must be sealed with non-hardening sealant.

- The slabs are fastened to the base using galvanized hardware or screws that have an anti-corrosion coating. You can carry out the work manually or use a special tool.

Drywall is also successfully used for interior decoration. We talked about this here.

Façade profiles: for external mounting

For external work, an aluminum anti-corrosion profile is used. It is made by pressing. The composition includes aluminum and its magnesium alloys.

The strength of the product depends on the chemical composition of the alloy. By indicator:

- Normal strength;

- Increased strength.

Performance characteristics of aluminum profile:

- Ease;

- High load-bearing strength;

- Sufficient rigidity;

- Large selection of sizes and models;

- Durability;

- Versatility;

- Plastic;

- Resistance to aggressive environments;

- Does not accumulate static charge;

- Possibility of implementing designs of any complexity;

- Smooth surface;

- Easily amenable to all types of processing;

- Easy installation;

- Thermal conductivity;

- Does not deform under the influence of temperature changes;

- Fire safety;

- Not high cost;

- Environmentally friendly material.

Moisture resistant exterior drywall

A moisture-resistant analogue for facade finishing (GKLV) is widely represented on the construction market by various manufacturers. The material is not afraid of water and has high water-repellent properties. GKLV for external work differs:

- Contains antiseptic components;

- Reinforced with fire-resistant properties;

- Huge range of standard sizes;

- Versatility of use;

- Sufficient plasticity;

- Simplicity of installation work;

- Thermal insulation qualities.

Moisture-resistant boards are installed in a double layer. The first layer is attached with dowels, the second is glued. For additional protection, they are coated on both sides with a hydrophobic spray. The joints are filled with a hydrophobic insulator.

Finishing the balcony with external plasterboard

The cladding of the open-type balcony is made with moisture-resistant plasterboard. The balcony is pre-insulated and protected from atmospheric influences. Double-glazed windows are installed, taking into account the following factors:

- A frame is built under the glazing and secured to the load-bearing wall of the building;

- Insulate the balcony floor;

- The glazing must be airtight.

Sequence of work:

- Lay electrical wiring for lighting;

- Install the frame sheathing under the insulation and on the ceiling;

- All cracks, seams and joints are filled with polyurethane foam that does not contain toluene;

- Drywall is installed, fastening is carried out with self-tapping screws;

- Seal the seams;

- Treat with primer and putty the surfaces;

- They begin to carry out the final decorative finishing work.

What is drywall

From the name of the material you can understand that this is a gypsum sheet of certain dimensions, and it is covered with paper, although most likely it is cardboard.

Its popularity and demand is due to the fact that drywall is very practical and versatile, while it is very easy to work with, since it is a pliable material.

It is used mainly for making various figures on ceilings, it is good to use when constructing interior partitions, and it is good to use when constructing decorative arches in a room.

As a rule, a standard type of drywall can be used for all these works. However, it can have different colors and different dimensions, as well as its technological application.

Today, drywall manufacturers produce four types of products. Therefore, we will briefly look at each of them.

Decorative columns made of external plasterboard

Drywall for facade finishing is flexible, easily takes the desired shape, so its scope is varied. Owners of private housing construction can experiment and look for non-standard ways of exterior design.

Facades with columns are always an impressive type of decoration. Gypsum plasterboard columns perform an exclusively aesthetic function. They visually increase the height of the building. Types:

- false columns are a decorative design to give your home an individual style. They are hollow inside, this space is used for original lighting, water pipes and other communications are hidden in them;

- Support columns are unattractive concrete products that are sheathed with plasterboard.

Tips for decorating residential buildings:

- Several columns are installed - one column is not acceptable, the symmetry of the elements is important;

- The style is maintained by the columns in the same style that was used to decorate the entire house.