Any owner always strives to ensure that his home is both comfortable to live in and attractive in appearance. And both of these factors directly depend on the quality of the roof, so special attention is always devoted to the selection of roofing covering. It is necessary to try to settle on an option that would combine high reliability, an elegant appearance (preferably “with a twist” that makes it stand out against a monotonous background), durability of the roof, guaranteed by the manufacturer and proven by the practice of using the material, and, finally, a relatively affordable price .

Composite tiles pros and cons

The task, as you can see, is not an easy one, but with the modern range of roofing coverings, it is still solvable. So, among the relative new products on the Russian building materials market, we recommend taking a closer look at composite tiles.

The combination of a “classic” appearance with the versatility and durability of modern construction materials, coupled with a convenient installation system (much simpler than that of piece tiles), is gradually bringing this type of roofing to the “top” of popularity. Interestingly, some potential homeowners do not even know exactly about the availability of such materials, or have insufficient information about them. First of all, this publication is dedicated to this category of users - composite tiles pros and cons, a review of the most popular brands and tips on selection.

What it is?

The base is a sheet of steel, which is protected on both sides by an aluminum-zinc alloy. The outer side of the material is covered with natural stone granules of different colors. The stone chips are covered with a special glaze on top. The roof does not have a characteristic shine; the metal is well hidden from the eye of the observer. A metal sheet coated with granulate reliably insulates the roof from rain and wind.

Tile surface granules

Modern roofing made of composite tiles is a multi-layer complex structure. It includes components such as a vapor barrier film, wind protection, a layer of insulation, roofing, etc. In addition, the structure of the roof provides ventilation of the space underneath and reliable protection against heat loss. A set of measures is being taken to prevent the formation of condensation. If you want to purchase high-quality composite tiles at manufacturer’s prices, then https://www.icopal-russia.ru/kompozitnaia-cherepitsa-decra/ can help you with this.

Structure of composite tiles

Installation

Polymer sand tiles have protrusions on the sides, with the help of which they are secured to the frame. Side locks secure the individual roof elements together. For additional fixations, there are additional holes on the tiles.

Installation work on laying tiles begins from the bottom of the slope. The fastening of the tiles to the sheathing should not be rigid, which will help to further prevent deformation of the elements.

Installation is quite easy and can be done even by a non-professional. The main thing is to follow the steps of work:

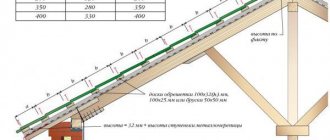

Roofing work on sheathing at intervals of thirty-five centimeters;- Next comes the installation of lower tides;

- Then the rows are laid out from bottom to top;

- Side and ridge elements are installed.

Characteristics of composite tiles

The colors can be monochromatic, variegated, with stains or textures. Often sheets of composite tiles imitate some natural material.

- The length of the sheet is regulated by the standard - it is 140 cm, and the width varies.

- According to GOST standards, fluctuations in the thickness of the steel sheet should not exceed 0.1 mm.

- Stone granules + protective acrylic glaze provide additional strength.

- Durability depends on the thickness of the aluminum-zinc layer. This option varies depending on the brand. For example, if the volume of aluminum-zinc coating reaches 190 g per 1 m2, then the manufacturer guarantees a service life of 50 years.

- Metal and stone chips are completely fireproof. The acrylic polymer coating contains silicon, which allows it to withstand temperatures up to 135 C. In practice, this acrylic coating can withstand open fire for 6 hours.

- The materials are selected so that when heated by sunlight they do not emit any toxic fumes.

- Metal has a high coefficient of thermal conductivity, so when installing the roof it is necessary to insulate it.

- It bends well, so it is very convenient for designer roofs with a large number of bends.

Table of characteristics of Dekra composite tiles

| Characteristic | Classic | Stratos | Novel |

| Sheet size, mm | 1324x410 | 1300x360 | 1100x375 |

| Usable area, sq. m | 0,465 | 0,390 | 0,368 |

| Number of sheets per sq. m | 2,15 | 2,54 | 2,72 |

| Steel thickness, mm | 0,43 | 0,43 | 0,45 |

| Weight of one sheet, kg | 3,10 | 2,80 | 2,70 |

| Weight of one sq. m, kg | 6,70 | 7,20 | 7,46 |

| Permissible roof slope, degrees | from 12 to 90 | from 15 to 90 | from 15 to 90 |

Manufacturers of metal tiles and criteria for their selection

Despite the comparative novelty of composite tiles, a list of branded manufacturers has already formed on the domestic roofing materials market. Trustworthy Products:

- Metrotile is a Belgian manufacturer that produces composite tiles under the brand name of the same name. It is one of the most popular brands in Europe. Metrotile composite tiles are produced using the highest quality raw materials, using several exclusive technologies. The company offers the buyer many collections in a variety of colors;

- Decra is a trademark owned by the Danish concern Icopal. The products of his enterprises are of high quality and reliability. This is confirmed by the manufacturer himself, guaranteeing the integrity of the composite tile coating under harsh operating conditions for 30 years;

- Gerard is a brand of the New Zealand company AHI Roofing. Offers the buyer five main collections. Positioned in the segment of luxury building materials, which have a fairly high cost;

- Grand Line is a Russian-made composite tile produced on imported equipment. The company offers three types of profiles with various external coatings. Their wide range of models causes significant differences in the performance characteristics and cost of roofing products;

- Tilcor is another brand from New Zealand. It entered the roofing coatings market relatively recently with two collections, Bond and Shingle. Its products are distinguished by high quality, affordable cost, and increased resistance to dynamic deformation. Due to this, Tilcor composite tiles are recommended for use in areas with increased seismic activity, as well as in buildings near busy transport routes;

- Feroof is a South Korean company that produces luxury composite tiles. The high cost of its materials is fully compensated by their impeccable quality and durability. Feroof offers a wide range of products. It consists of 7 collections, each of which is available in 12 single-color and 6 two-color options.

- Luxard - TechnoNIKOL composite tiles. This is a branded domestic manufacturer that produces fairly high-quality products. Composite tiles Luxard from Technonikol are offered in 6 colors with two types of profiles.

How to choose composite metal tiles

Considering that there are other manufacturers of composite tiles on the roofing materials market, when choosing their products you should be able to determine their quality. Particular attention should be paid to the following aspects:

- the surface of the inner side of the sheet must have a protective coating based on acrylic primer. Its absence, and even more so the absence of an anti-corrosion coating, indicates that this is a low-class product, most likely counterfeit. The inner surface of the branded composite tiles is, in addition, additionally covered with a protective polyethylene film;

- high-quality mineral granulate has a homogeneous fraction (unless otherwise provided by the product design). The accompanying documents must indicate the type of material from which the powder is made. You should avoid purchasing composite tiles that use colored sand as the outer layer;

- products of any branded manufacturer must have a full set of accompanying documents. It should include factory warranties and certificates, ranging from ISO to its domestic counterparts, as well as fire safety certificates. If the seller is unable to provide such documents, then most likely he is selling counterfeit composite tiles. It is unlikely that it will meet the declared quality parameters.

Production Features

The steel sheet serves as the basis of the product. It is coated on both sides with a layer of aluminum-zinc (an alloy of zinc and aluminum). This is necessary to protect against corrosion and minor scratches that the granulate can cause.

Next, on top of the aluminum-zinc, a protective layer is applied against heating by the sun's rays - the SPT composition. Its second function is protection against the rooting of mosses, lichens and the formation of colonies of microorganisms. Finally, the SPT coating provides UV protection.

Then a decorative layer of stone granules is applied. The chips are made from natural stone of the desired shade. The stone chips are strengthened in a layer of acrylate, selected in composition so that it does not evaporate when heated by the sun. If necessary, the stone chips are tinted to achieve the desired color of the roof.

Tile production

The introduction of dye into natural stone and its protection with a layer of acrylate ensures complete resistance to ultraviolet radiation, moisture and temperature changes. Thanks to this, the surface is able to maintain its original appearance for decades.

The final stage of manufacturing is the application of pure acrylate without styrene. The layer turns out completely transparent. The coating protects the stone chips from falling off under the influence of rain and wind.

We take into account the shortcomings

It is recommended to purchase products only from well-known manufacturers. And in the case of polymer sand tiles, this is very important.

Tiles made by hand, as a rule, have dimensional errors, do not fit well and cannot provide protection against leakage, and after a short time they begin to crack and crumble.

It is easy to recognize low-quality products made in violation of production technology and non-compliance with the recipe at the purchase stage: they are not certified. And complaints about plastic tiles are caused precisely by the use of such material.

Layer structure

To understand how the material is structured, as well as what function each layer performs, you need to look at the structure in more detail. As an example, the Dekra brand is considered.

- The base is a steel sheet about 0.43 mm thick.

- The metal is protected from corrosion on both sides by an aluminum-zinc coating up to 275 g/m2. It is applied by hot galvanization.

- A special primer is applied over aluminum-zinc. Its purpose is to ensure adhesion with subsequent layers. Also, acrylic primer allows the metal to withstand sudden temperature changes without deforming.

- Next, the surface is covered with basalt chips. It performs a decorative function. A layer of stone chips protects the steel base from mechanical stress and solar radiation. In addition, stone chips improve sound insulation.

- The final stage is to protect the stone chips with transparent acrylic glaze. This measure prevents shedding under the influence of wind and rain.

Experts also recommend paying attention to:

- for uniformity and uniformity of color. In the photographs presented, which depict the work performed by the company, you can notice either a uniform color (and this indicates good quality), or changes in shade from tile to tile, which indicates low quality dyes or polymers;

- on the surface texture - it should be smooth;

- for the correct geometric shape and smooth edges of the tiles;

- by weight Too much weight indicated for this type of coating indicates an insufficient amount of the polymer component. Normally, the weight should not exceed 22 kg/sq. m.

In addition, aesthetically attractive tiles are superior in many respects when compared with natural ones; at the same time, they are much heavier than metal tiles and more expensive than sheet roofing materials.

pros

- Visually no different from natural tiles.

- Relatively light weight compared to natural tiles. This allows it to be used even on light structures without reinforcing the load-bearing elements.

- The roof surface has a much higher noise absorption coefficient than conventional metal tiles.

- The stone chips are recessed in the acrylic mass, so they do not crumble from rain and wind.

- Compact dimensions make installation easy.

- The metal under multi-layer protection is not damaged by corrosion.

- Does not accumulate static charge.

- All components are non-flammable, only if exposed to open fire for more than 6 hours, the acrylic may melt slightly.

- There is no deformation of the canvas during sudden temperature changes.

- The roof is very well protected from destruction by ultraviolet rays.

- The color saturation remains for decades - the dye does not fade.

- It is cheaper on the market than clay, but looks just as good.

- The surface is immune to the destructive effects of acids and alkalis.

- Flexibility allows you to accurately finish even roofs with complex geometric configurations.

- The mount is designed so that water cannot enter there. Self-tapping screws + special locks securely fasten the sheet to the base.

- The manufacturer provides a 50-year warranty.

What does the material consist of:

- quartz sand;

- polymer;

- mineral pigments – dyes;

- flame retardants and UV stabilizers.

Actually, optimal properties were achieved in the following way: in the composition of cement-sand tiles, the binder - cement - was replaced with a thermoplastic polymer (polyethylene).

Thermoplastic composite obtained by mixing the components is used to form tiles of specified sizes and geometric shapes. The stamping method allows you to produce tiles of the same size and proportions.

Consumer Reviews

Kucherenko Ivan:

“We put this much-praised “miracle” on the roof of the dacha in 2010. Immediately after installation, the difference became visible: some tiles are lighter, others are darker, some are more matte, others have a glossy shine. However, the real problems began two winters later, when I climbed onto the roof to adjust the antenna: the tiles simply crumbled under my feet! Fortunately, the waterproofing held up and there were no leaks. We completely changed the entire covering on the TsPCh: the same problem was typical for the entire roof, especially for the southern part. Then the roofers said that these were clearly omissions in the production process - the components were mixed in the wrong ratio.

Olga Mamedova:

— I see only advantages: price, ease of installation, and beauty - by the way, there are many color options. First they checked it on the barn - they waited for three years for a loss of quality, it didn’t happen, and then they just decided to cover the house. After 7 years, there are no visible changes on the roof of a house located at mid-latitude.

Rostislav Pichuga:

— Of course, metal tiles cannot be compared with plastic ones in terms of beauty. But as for reliability... It was not difficult to find real reviews from those who had it installed, and I understood that depending on your luck: some have had it for 10 years, others have problems in the first year. And it all comes down to the manufacturers. I decided not to trust anyone, but checked it myself. I ordered a prototype (they sent it) - I liked everything, the shape, the lock, the smoothness, and the color. I covered the roof myself: it’s been worth it for 5 years, so far I don’t regret it.

For which buildings is plastic roofing suitable?

Basically, a plastic roof is an attribute of those buildings for which the transparency of the roofs is important:

- carports, terraces, verandas;

- gazebos;

- greenhouses and winter gardens;

- galleries;

- swimming pools and sports grounds;

- visors;

- greenhouses;

- balconies.

Sometimes in cottages they make separate rooms with transparent roofs, but most often in residential buildings we are talking about individual elements: skylights, translucent inserts in the roof, which replace attic windows.

Opaque plastic roofing is most often found in warehouses, hangars, garages, outbuildings and other buildings, during the construction of which it is important to fit into a minimum budget.

Let's sum it up

A plastic roof is practical, holds a distributed load well, is not subject to corrosion and can be 90% transparent. At the same time, most plastic panels for roofs do not have very high resistance to point loads and a short service life, although there are materials that stand out in terms of these characteristics compared to other polymers.

Here's what the roof plastic is called:

- Polycarbonate. This is a whole family of materials, which includes:

- especially durable, even bulletproof, monolithic polycarbonate;

- lightweight and cheap cellular phone that effectively prevents heat loss;

- thin, but profiled to hold up to 350 kg/m2 load.

- Profiled PVC . Less durable than profiled polycarbonate, but with biaxial orientation it is more elastic and better able to withstand impact loads.

- Composite plastic . Specialized multicomponent materials, difficult to produce and therefore expensive. They are used for constructing roofs in aggressive conditions and for vandal-proof structures.

The roofs of gazebos, verandas, greenhouses, winter gardens, greenhouses, galleries, and canopies are usually made of plastic. Monolithic polycarbonate is used for glazing the atriums of commercial and public buildings, and sometimes for partially covering the roofs of private houses.

orders russiabrandsqualityaddluxardevengotoexpensescartshowcalculationsguaranteebuylinegrandclassicmetrotilesiding

Roof operation

Polymer sand or plastic varieties of tiles are much more practical to use than clay products. This is due to the high strength of modern elements. At the same time, you can extend the service life and preserve the appearance of the roof by following simple operating rules. Roof maintenance is carried out taking into account the following principles:

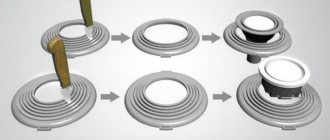

- If during installation the screws are screwed very tightly into the tiles, then deformation of the coating is possible. Therefore, the fastening of the parts should be loosened, since the tiles move during thermal expansion;

- materials for hydro- and vapor barriers must be durable and of high quality, which will ensure that the roof does not need to be dismantled to replace them for many years;

- when installing a weather vane, snow guards or other additional roofing parts, it is important to take into account the preservation of the tightness of the coating and carefully seal holes and cracks;

- a drainage system is necessary to minimize the effect of moisture on the roof structure.