The rafter system is the load-bearing frame of the roof, supplemented with sheathing. There are several ways to structure it, but in private housing construction the most popular is the option with two symmetrical slopes.

The thing is that the installation of a rafter system for a gable roof is the simplest structurally and most expedient option in terms of cost.

Log bathhouse with tiled gable roof

Plan and drawings of a gable roof

It is difficult to imagine a building without a reliable roof over it. Any roof is the basis, the main guarantor of the inviolability of things in the house and the safety of property. It is the main protector from rain, snow and wind. After its construction, you can move on to the next stage, which involves internal work. Having made this part unreliable, there is no need to talk about a full-fledged home. A do-it-yourself gable roof is the simplest and most functional option among other types of roofing.

Parts of the roof

There are several roof options, one of which is gable. Construction does not require a lot of talent, since this type of roof is the simplest. The housing element consists of the parts indicated in the figure: » alt=»»> The structure consists of the following parts: Ridge. The upper part that will connect the 2 slopes. Rack. An installation used to redistribute weight from the top to the bottom of the roof. It must be made from quality materials. Sill. A beam located horizontally. Connects the rack and the load-bearing wall.

View of the roof from the inside

Start of the skate

Beginning of the ridge Struts. These boards are fixed at a slight angle. Serve to redistribute weight from the rafters to the load-bearing elements below.

» alt=»»> Rafter leg. These elements form a visible outline in the shape of a triangle. Serve to hold the roofing covering. The heavier it is, the more often it is necessary to lay rafters. Fillies. Boards that extend the rafters. Necessary for creating an overhang from a gable roof, which according to building codes must be at least 0.5 m.

Simple gable roof

Fillies in schematic form

The difference between the rafters The roof plan for a gable roof and the drawing can be completed on your own. All elements can be constructed in several ways. The difference is the rafter system used for construction. There are the following types of rafters:

- Layered. Here it is necessary to install additional support beams located in the middle of the load-bearing walls. The rafters will transfer part of the load to internal devices to lighten the weight. The type of rafters is used if the roof, built by yourself, is heavy, with large areas of the home, significant distances from the walls (more than 10 meters).

Types of rafter systems

- Hanging. The only support for them is the side ceiling. When constructing such systems, it is necessary to tighten them to prevent the beams from bursting with other materials. They can be done both from above and from below. It is worth considering that when installing the top puffs, an indentation of no more than half a meter is made.

- In case of strong winds in the construction area, the angle is set to about 10-12° so that the roof is not torn off.

- With significant winter precipitation, the slope is within 30-40o. the snow will easily slide off the surface. There are no difficulties in the calculations, but if the roof is made with a complex shape, this will make it difficult to calculate the required values.

The systems are used in many homes, and both are of sufficient quality for comfortable use. When constructing an attic roof, they are used together. In this case, hanging and inclined types of rafters are combined. It is worth creating rafter drawings that will show the location of each element of the roof, built with your own hands, so that there are no incomprehensible moments. It will help you calculate the amount of materials needed. Any element of the house must be created, understanding how it will all look as a result. For clarity, a drawing is created, and so that everything fits perfectly, it is calculated in advance. The plan takes into account the length of the roof along the ridge, the length of the slopes, and the length of the plumb lines is shown separately. The angle of inclination of the roof is determined. The angle is determined taking into account the following points:

What you need to know about flat roofing

Roof slope made of corrugated sheets

Below we list the main requirements that are put forward for this type of design, namely:

— Since precipitation should under no circumstances accumulate on the roof surface, there must still be a slope. To ensure the durability of the structure and the reliability of the roof itself, it must be no less than 2%. The best option is 10-15 degrees.

- If your area is characterized by prolonged and heavy rains or large amounts of precipitation in the cold season, then in this case slope alone will not be enough

It is important to consider creating a complete drainage system. It can be both external and internal

One riser can serve an area of about 150-200 square meters. In suburban housing construction, external drains are often created using special overflow windows, which are installed at the level of the roof storm drain. If the drain lines do not intersect, it is strongly recommended to show the perimeter of the facade in the roof plan.

It is important to note that projects of private cottages often do not contain information about the angle of inclination; in this case, to correct the designer’s error, there is no need to redo the entire work again, but simply need to form a slope using various bulk materials, as well as screeds or slabs polystyrene

Roof construction

After making calculations and purchasing the necessary parts, the Mauerlat is installed. After this, the sheathing is created. The element is the basis for a do-it-yourself roof, made from pine or other coniferous wood. The material is durable and lightweight, capable of distributing the weight of all elements over the entire plane. Placed along the roof slopes, between the rafters, and on the top of the walls.

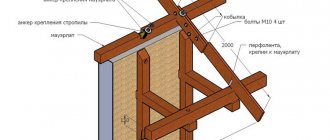

Mauerlat

In order for the element to last longer, an insulating layer is necessary between the wall and it. Roofing material is suitable for this. The Mauerlat can be secured using any fasteners that are convenient. To erect a roof, you must follow the plan:

- Fastening the rafters. If hanging ones are used, they must be assembled in advance, using fasteners to stiffen this part. The outer elements are made first, then the inner ones. With a layered system, a bed is first created where the supports will be installed. If the length of the elements is insufficient, you can add it by installing fillies.

Installation of sheathing. You can use any materials for construction, but it is important to get rid of bark from the boards in order to increase the service life of the elements. If you plan to use a soft roof, the sheathing is made continuous. A rigid base is required here so that there is no deformation during operation.

Continuous sheathing

Lattice. It is done using hard types of coating: slate, metal tiles.

Lattice system

Roofing. There are many coating materials, each of which involves the use of different coating methods. Do not neglect the recommendations of the material manufacturer. It is important to make a slight overlap between the elements. The structure must not be disturbed to prevent leaks. Do not forget that a reliable roof, built with your own hands, is a guarantee of the safety of property in the house. You shouldn’t neglect its construction, so that you don’t have to make complex repairs later.

Video description

An example of creating a flat roof plan in a computer program is shown in the video:

How to create a flat roof plan

When drawing up a roof plan for a flat roof, a specialist performs the following actions:

- all important details are indicated using thick lines;

- the drawing indicates the contours of the main walls ;

- when dividing a building into separate figures, the roof must be drawn under each of them ;

Plan of a flat roof of complex shape Source cont-market.ru

- indicate the places where the ventilation ducts and chimney .

Roof truss system design

So, every building has a roof that is supported by something. It is this support, without which installation of the roof simply would not be possible, that is called the rafter system. It consists of many structural elements, these include braces, racks, ridge girders, battens with counter-lattens, etc. In fact, its importance is comparable to the skeleton in the human body.

Wood is mainly used as a building material. However, you should not think that absolutely any wood will do, as long as the dimensions are maintained. For this purpose, only high-quality materials are taken, preferably coniferous. In addition, they must be well dried in natural conditions. Also, before use, all elements must be treated with a special antiseptic to prevent the appearance of fungus, mold, rotting and termite damage. Also worry about fire safety; various types of special solutions are also sold for this.

Related article: Laying gable roof rafters

A feature of all new buildings will certainly be shrinkage, so many builders advise installing floating rafters. Their design is not fundamentally different from the one you have chosen; modifications are carried out only for attaching the leg and ridge beam. The installation is carried out without rigid fixation, and during the shrinkage process, the rafters can slightly change the location of their elements, without changing or losing strength. Otherwise, parts of the structure may bend or even break.

Other programs

If we talk about roof design, then Arkon is the best program for this. But if your goal is not to design the roof down to the smallest detail, but just want to see an approximate three-dimensional result, then you can use the following available software:

Google SketchUp is designed for modeling three-dimensional objects, including roofs. There are virtually no presets, so you can develop a custom design. Different planes can be moved laterally and along a given curve. Envisioneer Express is software that is used for three-dimensional modeling. In this software, you can first make a two-dimensional plan of the future structure, and then convert it into a three-dimensional image

After creating a three-dimensional image, the future structure can be viewed from different angles in a photorealistic form and as a translucent frame, which is very important when designing roof structures. Home Plan Pro is distinguished by the fact that its database contains many ready-made elements and objects (windows, doors, dormers, roof parts). When working in the program, you can use the multi-layer mode, standard shapes and metric systems.

- Dom-3D is most often used for three-dimensional design of interiors, houses and their individual structural elements. This software is constantly being improved, new convenient functions and capabilities appear.

- FloorPlan 3D features simple graphics and clear functionality. In this software, your possibilities for creating a three-dimensional image are practically unlimited. The most important advantage of this program is that it can be used not only by specialists, but also by beginners who want to see a model of a future house, its roof or other structural part of the structure.

- Another software that can be used by people without special knowledge is VisiCon. Here you can not only quickly create a model of the future roof, but also select different textures of the roofing covering. Thanks to its simple and understandable functionality, the program can be quickly mastered.

If you need more serious software for free, you can use NanoCAD software. Essentially, this is the basic level of computer-aided design systems.

Gable roof and types of rafter system for it

As the name implies, a gable structure involves two wings, i.e., inclined planes connected to each other at the very top. What about the bottom, it rests against the walls of the building. The front and rear gables can be brick, cinder block or other building material. In addition, they are often decorated, especially since today there are many ways to give this element a unique look.

This design of the roof truss system has many advantages, for example, the ability to arrange an attic space. Of course, it is not suitable for living, but storing things there is quite possible. Also, the resulting space is often used as an attic. In addition, this is a fairly economical option, and the likelihood of leakage is minimal.

Now it’s worth dwelling a little on what options for gable roof rafter systems exist. So, there are hanging and layered types of structures. In the first case, the support is the ridge of the roof, and in the second the walls of the house, as well as an additional intermediate support, for example, the middle load-bearing wall. These rafters also differ in the principle of service.

Beams of a suspended system work simultaneously in both compression and bending, but what about layered beams, in this case the emphasis is only on bending.

The best option is a combined gable roof arrangement (alternating layered and hanging rafter elements ). Using this method, you can not only save building material, but also make the structure somewhat stronger, and this is useful. After all, this part of the house is subject to heavy loads, for example, sometimes a person is forced to climb onto it in order to restore it; in addition, one should not underestimate the power of winds, snow, rain, etc. So, regardless of the type of gable roof rafter system chosen, the design is mandatory must be sufficiently reliable and strong.

Floor slab installation technology

To install prefabricated reinforced concrete slabs, it will be necessary to rent a crane and 4 workers: a driver, a slinger and 2 installers.

Load-bearing walls should be calculated taking into account the need for a 5 cm gap on the street side. Insulation is placed in the recess; it prevents drafts through the cracks in the ceiling. Wear of thermal insulation in such houses leads to cold, dampness and drafts.

Installation procedure:

- Concrete is laid in a layer of 15-20 mm on the prepared cement mortar cushion on the supporting walls.

- The panel is lifted with a crane and placed on top of the installation site.

- Installers rotate the slab to guide it to the desired position. Crowbars will help to accurately position the slab before removing the slings. The correct location implies a contact point between the wall and the slab of at least 15 cm on each side.

- The slings are released and a final check of the installation is made.

There are no temperature restrictions for reinforced concrete

How to make a rafter system for a gable roof with your own hands - step-by-step diagram

Step 1: Arrangement of the base for the rafters

Direct installation of the roof truss system can be started only after the pediment, ridge, mauerlat, and floor beams have been installed (for the attic, beams of a larger cross-section are taken). In addition, you should lay boards on the ceiling, which will serve as the floor of the attic or attic, depending on the purpose of the room.

Step 2: Preparing the Material

Of course, you need to prepare the workplace first, but how strong the structure of the rafter system of your gable roof will be largely depends on the quality of the material. So we buy only high-quality timber - the most suitable beams for this purpose with a section size of 50x100 mm. A smaller size is not always able to serve for a long time, and during strong winds or snow melting you will hear the pitiful creaking of the wood. Do not forget to treat them with all the necessary means, they have already been discussed above. Next, we cut out the elements for the rafter system. It is much more convenient to do this on the ground and then lift the finished parts. Cuts should be made on the ridge where it will connect to the legs of the rafters.

Step 3: Installation

Having installed the ridge, you should also mark the places where the beams are attached to the Mauerlat and make grooves there. The outer beams are installed first. Then a strong thread is stretched between them (a fishing line will do) to make it easier to position the intermediate legs. The beams are attached to the ridge with long nails, but to secure them to the Mauerlat, you will need anchor bolts. To increase the reliability of the gable structure, additional spacers should be installed; they are also nailed.

Sequence of installation of floor slabs

Initially, you need to complete 2 steps:

- Preparation. It is important to create the correct level between all the supporting walls of the structure. The permissible difference is 1 cm, it is not necessary to eliminate it. To check the horizontal plane, use a building level. A beam is laid between opposite walls and the evenness is checked. If there are small irregularities, they can be eliminated with cement mortar.

- Next, a distribution belt is made to level the wall. The reinforcing belt is made of cement M500 1 to 3 with sand. It is important to ensure the cleanliness of the sand, rinse and sift if necessary. A solution of medium viscosity is prepared. The mixture is poured into the formwork and pierced or tamped to remove voids. The solution takes up to 3-4 weeks to dry.

The main qualities for which reinforced concrete is valued are always called strength and good resistance to bending moment.

House with a gable roof: project + Photo - rafters before price calculation

Often, when building a roof, people have to make a rather difficult choice - which option to prefer.

The fact is that modern technologies provide the opportunity for such a choice, allowing you to install any type of roof in a fairly short time. In Russia, gable rafter roofs have always been more popular.

When thinking about which design is more suitable, the homeowner is guided by many factors: its functionality, reliability and durability, and the ability to prevent precipitation from entering the building.

Perhaps this was facilitated by the peculiarities of the climatic conditions of our fatherland.

In winter, much less snow accumulates on such roofs, because it rolls off the surface, reducing the load on the structure.

The number of slopes does not in any way affect the parameters of the house, so the specific choice depends on the preferences of the owners.

The gable roof of the rafter system is quite easy to install, it is durable and reliable in operation. Its structure allows the use of many different materials as roofing: from the usual, well-known slate, to fashionable metal tiles.

How to Design a Roof

Published by the author of this blog / January 17,

The main element of any home #8212; this is the roof. After all, it is precisely this that provides maximum protection to the premises inside and gives a refined appearance to the entire building. In order to properly design a roof, you need to become familiar with its main functions and types.

The main functions performed by the roof

Before you begin construction, there are a few important features you should understand. Any roof must effectively protect the house from the effects of adverse precipitation. It must also have all the necessary fire-fighting characteristics and be stable. In the project, the roof is given an individual appearance, which allows it to stand out among many others. In order to design correctly, it is necessary to take into account the fact that the roof is the completion of the appearance of a newly built house. And a properly executed design can make a building unique and attractive. Therefore, before erecting a rafter system, you should find out in more detail everything about roofs on the website stroimkryshu.ru. The shape and appearance will depend on factors such as the presence of internal supports, architectural design and expected loads.

Roof project: main varieties

Most often, two types of structures are erected - flat (the angle of inclination does not exceed 2 degrees) and pitched (the angle of inclination is much greater). Pitched roofs are considered the most popular because they can more reliably protect a home. Snow and rainwater do not accumulate on such structures. From the point of view of architects, pitched structures are more extravagant and unusual structures.

The estimated number of stingrays will depend on factors such as operational requirements, climatic conditions of the region and personal preferences of the owners. Roofs are often designed with one or two slopes. In rare cases, conical, domed and vaulted structures are built. The most difficult project is considered to be a multi-tongue project, as it has a large number of intersecting internal angles.

Roofs with one slope are an inclined surface that is fixed on all walls at different angles. Gable structures are built from two slopes directed in different directions. The main advantages of the design: reliability, ease of construction and long service life. Recently, hipped structures, which are built mainly on square houses, have become very popular. It is quite difficult to build, but the excellent characteristics make up for this difficulty.

Another type is hip roofs, built on rectangular buildings. The hips are triangular slopes that are located at the ends. The other two slopes, in the form of a trapezoid, are located on the long walls of the rectangular building. Thanks to this form, the appearance of the house improves, while its protective functions increase. The roof project may have a non-standard shape, for example, multi-level. Such structures can bring practical benefits - they are often equipped with sleeping quarters.

House with a gable roof: advantages

Such a roof looks like two surfaces inclined towards each other, oriented along the long sides of the house, connecting at the top into a ridge. It goes well with a classic house that has a familiar rectangular shape.

Among the advantages are:

- sufficient strength and slope height, allowing the use of almost any roofing material;

- light and simple design;

- well ventilated attic;

- the slope of the slopes, preventing the accumulation of sediments.

Related article: How to make a pitched roof at home with your own hands

The roof slope is an important parameter for this type of roof. For arid areas, its optimal value is up to 45 degrees. Where the amount of precipitation is high, it increases to 60. When designing a roof, the prevailing winds in a given area should also be taken into account: after all, with an increase in the angle of inclination, the windage of this part of the structure increases.

The choice of the appropriate type of roofing also depends on its slope.

Tiles and slate, for example, can only be used if the temperature is at least 22 degrees. The final cost of the roof will also depend on the slope of the slopes. The larger it is, the more you will have to spend on coating materials, and the higher the overall price will be.

Common mistakes when designing a roof

House with a gable roof project Photo

The created project must be checked several times, since correcting errors at this stage will cost much less than if the defects are identified at the construction site or during the operation of the house.

Design errors can be divided into:

- Architectural;

- Constructive.

Architectural errors. The main mistake of this type is ignoring the issue related to ensuring ventilation of the elements of the roof “pie”.

When installing an insulated roof, it is important not only to protect the insulation as much as possible from moisture, but also to take care of removing the amount of water that the mineral wool still absorbed, that is, it is necessary to plan such elements as eaves and ridge ventilation vents, weather vanes, etc. For operation These devices are influenced by various architectural elements (attics, parapets, etc.), which greatly limit the possibilities of air intake

Therefore, you have to either increase the height of the vents or abandon some decorative elements

The functioning of these devices is influenced by various architectural elements (attics, parapets, etc.), which greatly limit the possibilities of air intake. Therefore, you have to either increase the height of the vents or abandon some decorative elements.

Another common mistake is improperly organized removal of water from the roof that falls on it in the form of precipitation.

Errors are constructive. This type of error most often concerns the insulation of the roof (especially its attic version).

Gable roof rafters: device diagram

What does any rafter system consist of? These are the rafters themselves, the roof plate, the struts and the sheathing. The rafter legs with their upper ends must be overlapped using special overlays. The lower ends are connected to support beams made of logs, as well as to the mauerlat.

According to the project, a gable roof can be made in two ways: with hanging rafters, or with sloping ones. This or that method is selected based on the size of the frame house or gazebo structure itself.

It is extremely important that the calculation of the gable roof (rafter system structure) is carried out correctly. The best way to handle this is to hire a professional.

Fastening the support beam (aka Mauerlat)

It can be done using various methods:

- The most reliable of them (also the most common) is as follows. When the walls are installed, onto which the support beam is then planned to be attached, a concrete belt (continuous) is created along the perimeter of the building. It can be replaced with a concrete beam.

Thick studs, at least 12 mm in diameter, are inserted into this armored belt. The studs must penetrate the axis of the Mauerlat when attaching it. From its edge to the edge of the armored belt you need to leave about five centimeters. The distance between the studs should be from one and a half to two meters, so that each part of the support beam is securely fastened along the edge.

We should not forget at least about the minimum required roof slope. Otherwise, you may experience leakage or damage from strong winds.

- During laying, the studs are embedded directly into the wall. They will have to be walled up much deeper, so the studs themselves must be much longer. Not as reliable a method of fastening as the previous one, but for a gable roof with an area of less than 250 square meters (with or without an attic) it is quite suitable.

- The most affordable way. A soft but thick wire is laid in advance in the masonry, with the help of which the Mauerlat is then secured. How it's done? Shortly before the end of the laying, when several rows remain, the middle of the wire is placed between the rows so that its ends protrude evenly on both sides.

Mounting diagrams for the Mauerlat

Their length must be sufficient to attach the support plate. To prevent the wire from being too noticeable, its outer end is passed through the mortar joint between the bricks. This method is quite common and very reliable, especially if we are talking about a building of modest size (for example, 10 by 10)

If the walls and beams have undoubted strength, then the rafters can be attached directly to the beams without using a support plate. plan for a gable roof may include the use of the upper crown of the house (chopped) instead of the mauerlat. In some cases, a separate support beam for the roof is required.

Between the purlins and racks, to enhance the stability of the rafters, struts are made. The necessary parameters for the struts and rafter legs are calculated using the roof calculation. The usual width of simple rafter boards is approximately five centimeters, but their height is up to 20.

To form an overhang, which will become a reliable protection for the outer wall from precipitation, the tie rods or rafters are extended at least half a meter beyond the plane of this very wall. It is necessary to lay a good layer of waterproofing under the Mauerlat, otherwise the service life of the structure will be greatly reduced. You can use good old roofing felt or other similar material.

Several layers of insulation are laid between the rafters, always with offset seams. Materials with low thermal conductivity, for example, ordinary mineral wool, are used as insulation. In addition to thermal insulation, it is also necessary to install a vapor barrier. To do this, a well-stretched polyethylene film is fixed on the inside of the insulation.

A special vapor-proof waterproofing film is used. This is a diffuse membrane with a special perforated structure. It is capable of releasing steam entering the insulation from the interior to the outside, but prevents moisture from entering it from the outside.

Lathing: assembly order

After this, you can begin the direct installation of the gable roof according to the drawing. The final (before roofing) stage of completing the gable roof structure will be the assembly of the sheathing. It is usually made from a wooden beam 6*6, 5*5 or 4*4 cm. It is installed perpendicular to the rafters, as provided by the design. The sheathing serves to transfer and redistribute the weight of the roof to the rafters, which, in turn, direct it to the load-bearing walls of the building. The pitch of the sheathing can be different, and it depends on the type of roofing material chosen.

Some of them generally require the installation of a continuous covering-flooring. These are, for example, flat slate or soft roofing. And under soft bitumen tiles, an additional underlay carpet is required, mounted on top of the flooring. It not only levels its surface, but also protects it from unnecessary moisture when laying roofing materials.

To do this, you can use specially treated fiberglass with bitumen impregnation.

A DIY gable roof is a wonderful choice for responsible homeowners who aren't afraid to get their hands dirty and are ready to get to work. A simple structure representing an isosceles triangle in section is not at all difficult to build yourself. The height of the descent and the angle of the roof can be varied, but certainly within the limits of correctly made calculations.

General installation information

Prefabricated reinforced concrete slabs are installed with a minimum gap between each other. Installation will require special lifting equipment. The seams of the floors are filled with cement mortar. Metal anchors that are mounted to the hinges of the slabs will help create a complete and extremely rigid horizontal floor. In places where the panels come into contact with the internal slabs, composite anchors are used, which are fastened by welding.

If precast slabs are based on external walls, it is recommended to attach their end parts to the masonry using L-shaped anchors. After installation, they are filled with cement, it will prevent corrosion. If gaps appear between the slabs and partitions, they can be eliminated with brickwork.

An important rule is that reinforced concrete slabs are laid exclusively on load-bearing walls; other self-supporting structures and partitions are laid after the slabs are installed.

When laying slabs, a foundation is formed under load-bearing and self-supporting walls with a thickness of over 250 mm. Additionally, the base is installed under ventilation ducts and individual supporting elements. To create a foundation sketch, you should take into account the size of the base under the walls and determine the connection of the base of the foundation to the modular alignment layers. When using columnar and prefabricated foundations, the width of the foundation slabs is determined according to the strength required to withstand the loads.

In addition to the good economic effect in terms of construction costs and speed of building construction, the use of reinforced concrete provides a number of other advantages

The thickness of the rubble concrete and rubble strips is determined 8-10 cm wider than the wall. The size of the prefabricated foundation is determined equal to the thickness of the blocks (30-60 cm), but the wall itself is sometimes 4-5 cm wider than the base. Common block lengths: 80, 120, 240 cm To reduce pressure on the soil, the foundation can be made with an expanded base with 1-2 ledges, dimensions (HxW) - 30-40x15-25 cm. In a prefabricated foundation for widening, a foundation slab-cushion with reinforcement with a width of 60 cm to 1.6 m is used , height 30 cm.

Construction of a gable roof truss system: assembly and installation

The roof is the structural element of a house that gives it a unique look. There are a great many options for constructing such a structural element. But among them there is one, gable, the appearance of which changes remarkably depending on the angle of inclination of the slope.

Related article: Do-it-yourself construction of a pitched roof

In order for the structure to be as strong, reliable and durable as possible, the design of the gable roof rafter system must be thought out at the stage of developing the house project. A properly executed structure must be able to cope with permanent loads, say, the weight of the roof, as well as temporary ones presented by nature - snow, wind, rain. The most optimal plan is considered to be a gable roof plan, in which the rafter legs rest with their ends against a support beam, the so-called Mauerlat, and are fixed in a special way. In this case, the load can be evenly distributed around the perimeter of the house.

Tips for creating a roofing project

Example of a completed roofing project

Here are some useful tips to consider when designing a roof:

Not everyone has the ability to draw and draw, so to develop a project it is worth using computer programs created for design. For example, Arkon or AutoCAD

In this case, it will be enough just to select the required type of roof, and the program will select standard blanks into which you can make the necessary changes. It is necessary to approach the development of the rafter system with special attention, because the strength and reliability of the structure depends on it. When choosing roofing materials and the color of the coating, you must adhere to the general style in which the house is built.

Rafter system design ↑

As already noted, the key to the strength of any roof is its rafter system. According to their design, they are divided into layered and hanging.

Hanging ↑

Hanging rafters are beams that have only two points of support, namely the walls of the house. In this case, each leg is subject to mainly two types of loads - bending and compression.

Hanging ones transmit horizontally the load bearing on them (the weight of the roof, snow, wind) to their support points, that is, to the walls, as a spreading force. To reduce its influence, the rafters are connected with a wooden or metal tie. In the truss structure of a sloping gable roof, similar ties are the floor beams. With a span of 8 m or more, headstocks with struts are additionally installed under each truss.

Layered ↑

Layered rafters are beams that have an intermediate support that rests on additional supports or the internal wall of the house. The main effect of this system on supports is bending. In the supporting structure of the roof, only layered ones can be used if the intermediate supports are located at a distance of up to 6.5 m from each other.

The layered structure is lighter than the hanging or combined system.

The scheme may also contain elements of a future attic. Vertical racks, reinforced with struts and crossbars, which are installed in this case, can serve as part of the attic in the future. They are supported by floor beams. Read: Installation of a gable roof rafter system.

Floor slab plan

An important step in drawing up a diagram is calculating the number of slabs. The indicator is defined as the sum of the floor areas and the area of one slab. When dividing, the result may be a non-integer value; rounding is carried out upward.

When considering the plan, you can choose several types of floors for different floors. Differences are often made for rooms below grade level, but changes can be made for each floor separately.

It is better to leave the drawing of the floor plan in the hands of a professional. The work itself can be done by a beginner or an unskilled worker, but the drawing requires an understanding of the properties of reinforced concrete slabs and correct calculations. Any mistake can result in the destruction of the structure. The architect will take into account the building's features and help determine the best plan.

Floor plan - a graphic representation of horizontal structures that perform load-bearing and enclosing functions

For flooring, reinforced concrete beams with a T-section and inter-beam filling are used (lightweight concrete slabs or hollow liners). The length of the beams ranges from 2.4-6.4 m. Support on the wall - from 150 mm. The ends are anchored into the wall on both sides. The pitch is defined as the size of the aggregate, usually 60, 80 cm or 1 m.

If you plan to lay wooden floors, the situation is greatly simplified, since you will not have to operate with heavy structures, but with easily movable beams. If errors are made in terms of overlaps, they are easier to eliminate; the result of the error is not disastrous. Even a beginner can perform flooring with wood. It is important to choose impregnated beams, and their installation is a simple procedure.

Wooden beams are capable of covering a span of up to 4.8 m. The height of the beam is selected in the range of 5-10% of the span, and the width is in the range of 60-120 mm. The support for the interbeam shields are 40-50 mm cranial beams, which are attached to the sides of the beams. The pitch of the beams is taken from 600 to 1500 mm, this has a decisive effect on the width of the boards. The length of the shields is calculated based on the length of the boards.

Installation of the rafter system ↑

Methods for installing the Mauerlat ↑

In houses made of logs or beams, the lower part of the rafters is supported by the upper crown, and in brick or stone houses - a special support beam, Mauerlat. It is laid on a waterproofing pad on the inside of the wall along the attic.

The Mauerlat is fixed to the wall:

- by means of a reinforcing belt (on concrete with studs), on studs embedded in the masonry of the walls, using wire rod.

A hairpin is a metal rod with a thread. Its length is chosen on the basis that one half of the stud will be embedded in the wall, and the protruding part should be enough by 3–4 cm to tighten the nut on top of the Mauerlat.

Ridge run ↑

The upper part of the gable roof structure rests on the so-called ridge girder. It is a log or timber to which the upper ends of the rafter legs are attached. It is this run that will subsequently serve as the ridge of the roof.

- With a house length of up to 6 m, it is permissible to prepare a ridge run from a single beam or log. At the same time, it can rest on two pediments without additional supports. When the length of the house is more than 6, construction trusses are used to install a composite ridge girder.

Additional elements ↑

- The side girders serve as additional support for the system itself. They are supported either by building trusses or by the gables of the house. If the structure is heavy, the purlins are made in the form of a “construction lift” or a rocker. Struts help relieve the rafters in the center. They are installed under all “legs” at an angle of 45° or more. In this way, you can build a gable roof up to 14 m. Braces (diagonal beams) strengthen the rafters and help the gables withstand strong wind loads. The support of their upper part is the corner of the pediment, the lower part is the central floor beam.

Installation order ↑

Rafters can be installed in two ways:

- assemble the truss on the ground and lift it up; assemble trusses directly at the installation site.

The choice of installation method, of course, is up to the contractor, however, in any case, when creating trusses of the same type, it is more convenient to use a template according to which the rafters will be cut and connected.

Making a template like this is not at all difficult.

- To do this, take two boards, slightly longer than the rafters, lift them up and install them like the future structure. Align them vertically so that the top of the ridge is installed in accordance with the drawing, the boards are connected with one nail. By lowering or raising the ends of the boards, achieve the required angle of inclination and connect the boards using a transverse strip and thus fix them in the desired position. The finishing version is adjusted to this template and connected.

Floor slab layout plan

After drawing up sketches regarding the approximate location of the slabs, it is important to determine the axes and overall dimensions of the panels along the axes. The dimensions of the slab will help determine the height of the building and the number of panels. Vertical dimensional values take into account relative heights from the finished floor level.

To draw up a plan, it is important to take into account the location of the load-bearing walls to which the floors will be attached.

When laying out the load-bearing elements of the floor, you will see that the selection of their width is as important as the length

Development of a rafter plan

Ready rafter plan

When developing a rafter plan, the following procedures are performed:

- Drawing modular coordination axes to which the thickness values of the main walls of the building are attached. In this case, the extension of the crowning cornice of the structure used is displayed on the plan of the external walls in the form of a contour line;

- Smoke and ventilation ducts and pipelines are drawn on the plan, the location of which is necessarily taken into account in the process of placing elements of the designed rafter system;

- A plan of the selected roof shape is developed in the form of a sketch, which should also take into account the location of the walls. The ridge, valleys, ribs, as well as the following elements are drawn on the plan in the form of lines:

- The shape of the roof slopes;

- Slope direction;

- Location of dormer windows;

- Location of gables, etc.

Using the roof plan, a plan of the rafter system is drawn, which should indicate the placement of the following elements:

- Rafter beam;

- Mauerlats;

- Rafter legs with fillies and tie rods, resting on mauerlats;

- Racks, as well as longitudinal struts, providing the necessary spatial rigidity of the rafter system (displayed as a dashed line);

The cross sections of the various elements take approximate values depending on what type of wood will be used in construction (boards, beams or logs). The pitch of the rafters, that is, the distance between them, is selected depending on what kind of scaffolding is used in the construction of the roof, as well as on the weight of the material used for covering:

- The pitch of wooden rafters is 100-120 cm;

- The pitch of rafters made from beams is from 150 to 180 cm.

In addition, the distance between the rafters can change when chimney or ventilation pipes are passed between them.

In addition, these pipes can be passed by interrupting the rafter legs; for this, their free ends rest on wooden jumpers located between adjacent rafters, for the fastening of which a special rafter cut is performed.

In the case of gable or gable roofs, dormer windows are placed in the gables located at the ends. This increases the efficiency of ventilation of the attic during the warm season.

When developing a project for a hipped roof, you should display on the plan such elements as the slanted diagonal legs of the rafters, the flanges resting on them, as well as the dormer windows located on the hips.

If an attic floor is installed in the under-roof space, the plan should also show the upper beams of the framing walls on which the rafters will rest.

It should also be taken into account that the development of a plan for the rafter system should be carried out in parallel with the development of a plan for the various structural sections of the designed building, which must be interconnected.

On the rafter plan drawing, the values of the distances between the modular axes of the designed building are indicated, to which the wall thickness values are attached. Dimensional lines, which mark the chain of steps between the rafter axes, are drawn on the plan closer to its outline. Inside the plan, the distances between the racks, ventilation and chimney pipes, as well as between the various structural elements of the rafter system are indicated. In addition, it is necessary to display callouts on the plan, which will indicate the values of the lengths and cross sections of the listed elements.

The rafter system is the most important element of the structure of the roof being erected, on the correct design of which indicators such as the reliability of the roof, its safety and the length of its service life depend.

Therefore, without having the required skills and abilities, it is better not to start drawing up a rafter plan, but to entrust this work to a qualified specialist with the necessary experience.

Installation and assembly of rafters

Before installing the rafters, the Mauerlat is attached to the longitudinal walls using anchor bolts. Then the optimal cross-section of the rafter legs is determined, taking into account their length and the pitch between them. If lumber is required that is not the same width and length as is available, then the required dimensions are achieved by splicing them together using fasteners. When using insulation, the distance between the rafters must be selected in such a way that the heat-insulating material has to be cut as little as possible. Installation of gable roof rafters is carried out in the following order:

- A template is made that will be used to create roof trusses. To do this, two boards (length equal to the length of the rafter leg) are connected to each other with a nail at one edge.

- The free ends of the boards of this structure (scissors) are placed on supports in those places where the rafter legs will rest. This will create the angle of inclination of the roof slope, which is fixed with several nails. To better fix the angle, a crossbar is fixed between the boards.

- A second template is made (preferably from plywood) for making mounting cuts on the rafters.

- Using this template, mounting cuts are cut on the rafters. Then the rafters are connected at an angle of inclination of the slope. This results in a triangle, which is called a roof truss. It is lifted onto the roof using auxiliary structures (ladders, joists, etc.) and attached to the Mauerlat.

- First, the two outer gable trusses are installed. To perform correct horizontal and vertical installation, temporary struts are attached to them.

- A cord is stretched between the tops of the outer trusses, indicating the future ridge and indicating the level for the remaining intermediate rafters.

- After this, all other trusses are lifted and installed at an appropriate distance from each other (minimum 0.6 m).

- Bulky structures, if necessary, are strengthened with struts, crossbars, supports, etc.

- The ridge beam is installed on special supports. Diagonal, intermediate and short rafters are attached to it.