To fully enjoy the fruits of civilization, living in a suburban area far from urban life support systems, you can organize them yourself. For example, drill a well for water supply, build a septic tank for sewerage. The latter becomes an important element of life outside the city, because it ensures maximum purification of sewage effluents coming from the house. Septic tanks are different, and they are built from different building materials: brick, stone, blocks and reinforced concrete finished products. Here we will consider a septic tank made of concrete rings.

Septic tank made of concrete rings for a private house

The term “septic tank” is clearly defined by the state standard under number 25150-82. This document clearly states that a septic tank is a structure in which mechanical wastewater treatment is carried out, where processes such as sedimentation and anaerobic fermentation of the resulting sludge are used. That is, to a greater extent, cleaning is carried out precisely by settling.

Such facilities purify contaminated water by 65%. To bring this figure to 100%, additional filtration elements are built: fields, wells, ditches, trenches, etc., which are laid in the ground. It is the latter that performs the functions of a filter.

For septic tanks made of reinforced concrete rings, standard products with a height of 0.9 m and a diameter of 1, 1.2, 1.5, 1.7 or 2 m are used.

Pros and cons of the system

Let's start with the advantages:

- High structural strength that can withstand loads from frost heaving of the soil.

- The service life is almost unlimited.

- This is a non-volatile structure if the wastewater is supplied by gravity.

- Easy to install. Can be done manually if the installation is carried out at a shallow depth.

- Small cash outlay.

- A septic tank of this type can be used in houses where people permanently live.

- Almost zero maintenance. It is recommended to clean the septic tank of sludge once a year.

Flaws:

- Cannot be installed at a high groundwater level - not lower than 1.3 m.

- If special equipment is used during the installation process, the costs increase sharply.

- Additional filtration structures take up a lot of space on the site. Plus there are additional costs.

- If wastewater is forced into the septic tank, the structure immediately becomes volatile.

Attention! Unpleasant odors will not be a problem if ventilation is properly organized.

We install overflows

We can find out the installation depth of a pipe with a 50-centimeter cross-section by referring to SNiP 2.04.03–85, which recommends installation of communications 30 cm deeper than the point of penetration of negative temperatures into the ground, but not deeper than 70 cm from the point of the ground surface to the top point of the pipe. Based on the above, the smallest depth of penetration of negative temperatures into the soil for the Moscow region will be 110-120 cm, varying by type of soil.

Pipe sealing details

The difference between the bottom cut of the drain pipe and the top of the bottom filter element should be below 100mm. The end of the drain pipe must be located in the center of the well.

The overflow slope should be about 0.02 m/1 m to ensure the free movement of large particles, reducing the possibility of clogging communications. With a lower slope, such particles will remain in the pipe.

The inlet pipe is 10cm in cross-section and is installed 5cm above the overflow. The use of plastic pipes outside can lead to the system being out of service earlier than expected.

Along the edges of the overflows, tees are installed in a vertical position, directing the incoming flows downward.

Design features, nuances of use

Purely structurally, a septic tank is a well assembled from reinforced concrete rings installed on top of each other. If the volume of sewage discharged is no more than 1 m³/day, then one well is sufficient.

If the wastewater volume is 1-10 m³/day, then two wells are installed. This type of septic tank is called a two-chamber septic tank. If more than 10 m³/day of sewage is discharged into the sewer system, then there can be an infinite number of wells, depending on the volume of wastewater. On suburban private plots, structures of more than three wells are usually not used.

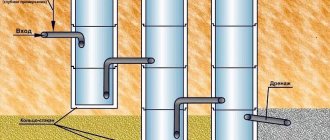

The arrangement of the latter relative to each other can be as follows: sequential, circular, letter “G”, etc. Here it is important to correctly connect the wells to each other, for which a regular plastic sewer pipe is used.

Attention! The number of chambers does not affect the quality of cleaning. The larger influence is the volume of the structure. The larger it is, the more intense the sedimentation of sewage occurs.

Types of wells

In most cases, a sewer well is made simply: a hole is dug, concrete rings or a plastic container are lowered into it, a pipe is brought in, covered with earth and a lid is placed. There are many types of sewer wells:

- Inspection – linear, rotary, nodal. Their goal is to make it easier to maintain underground sewers. Installed in the most inconvenient places, where the system turns or several pipes converge at one point, or in a straight line every 15 meters.

- Drop wells are installed to change the level of sewerage. The inlet and outlet pipes are located at different heights. Such models also have several varieties.

- Filtration systems are made of perforated concrete rings. There is usually no bottom, since they receive partially treated wastewater.

- Accumulative collections collect all household waste.

Nodal

Cumulative

Perepadny

Filtering

In order for sewer pipes to last longer and to be able to carry out repairs or clear a blockage at any time, in addition to the storage septic tank, you need to install an inspection shaft into which a person can get in and do the work.

It’s good if household waste is collected in one septic tank, and rainwater in another. It can be used to water the garden in hot weather or simply pumped outside, outside the site. If there is one sewer well, an overflow may occur, and then the foul-smelling liquid will spread throughout the area.

How to correctly calculate capacity

To do this, two indicators are taken into account:

- The number of people permanently living in the house. Guests are not included.

- The amount of water consumed by one person per day. This is a standard value - 200 liters or 0.2 m³. This indicator includes: using the toilet, washing dishes, showering, washing and other procedures related to water.

For example, if there are 4 people living in a house. Then you need to build a septic tank with the following volume:

4 x 0.2 = 0.8 m³.

But there is one more indicator that is recommended to be taken into account when making calculations. This is the number of days during which bacteria process organic matter in sewage, turning it into activated sludge. Its value is 3 days. The final result will be like this:

0.8 x 3 = 2.4 m³.

How to choose a concrete ring

The dimensions of reinforced concrete products are known. And each has its own standard volume. For example, if a diameter of 1 m is selected. It turns out that the volume of one ring is:

0.9 x (πD²)/4 = (0.9 x 3.14 x 1)/4= 0.7 m³

The same can be done with other sizes:

| Diameter of reinforced concrete products, m | Volume, m³ |

| 1,5 | 1,6 |

| 1,7 | 2 |

| 2 | 2,83 |

The required volume of the septic tank is 2.4 m³. For it, either 4 rings with a diameter of 1 m, or two rings with a diameter of 1.5 m, or 2–1.7 m, or one two-meter are suitable. That is, the total volume of the rings should not be less than the required value.

The choice of diameter is also influenced by the groundwater level in the area. If it is tall, then it is better to give preference to a wide product, the depth of which will not be large.

Subtleties of purchasing material

When choosing a material for arranging wastewater communications, several points must be taken into account:

- reinforced concrete is characterized by high hygroscopicity. The surface of the tanks must be waterproofed;

- The concrete ring is heavy. Installation requires additional special equipment;

- low-quality material can easily crumble. Therefore, when choosing material for sewerage, it is better to choose trusted manufacturers.

All the disadvantages of sewer rings are easily corrected in the process of stage-by-stage arrangement. How to properly design and build drainage is the main question for owners of dachas and country houses.

How to choose the optimal location for a septic tank

There are strict requirements for the location of septic tanks of various types. All requirements are the same, and they are specified in construction legislation.

- The distance from the septic tank to the foundation of the house should not be less than 5 m.

- To the border of the neighboring plot - 1 m.

- Minimum 15 m to a well or borehole if the septic tank is located along the flow of groundwater. If not, then the minimum distance is 30 m.

- The same parameters apply to open bodies of water: lake, pond, river. But more often the distance is determined depending on the type of reservoir, its size and other characteristics. This is done by specialists from water protection organizations.

- If a gas pipe is laid underground on an area, the distance to it should not be less than 1 m.

Attention! Many suburban villages have their own standards for the location of certain structures. When building a septic tank, you must adhere to them.

And other recommendations:

- If a house is being built on a site with a slope, then the septic tank must be built in the lowest place. In this case, the water intake point should be located higher.

- If there are situations with flooding on the site, then it is better to place the septic tank higher. That is, at a point where it will not be flooded.

We are building a foundation pit

The permissible depth of groundwater from the earth's surface when installing filtration wells should not be less than 3 meters, and when making filtration fields or on loamy soils - 1.5 meters.

When digging a pit, when using a shovel you begin to notice intense moisture in the soil at a sufficient depth, you should stop, since the goal has been achieved. But, if you went no more than a meter deep and came across water, then you should forget about the filtration well and bury the hole.

When building a system of several containers, they are installed on a concrete base, with the exception of the last one, in order to prevent drainage from leaking into the soil and to increase stability.

The diameter of the pit is dug 30 cm wider than the diameter of the container being installed. Slag, crushed stone or gravel with a fraction of 1.5-3 cm is poured into the resulting voids between the walls of the tank and the soil. When installing a multi-section system, such filling is carried out only with the outermost container, the rest are filled with ordinary soil.

The specified backfill is the “working part” of the filtration well.

Construction options

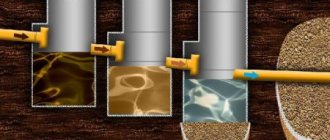

Most often, one-, two-, or three-level septic tanks are used in suburban areas. In this case, the first septic tank is always sealed. This is where the majority of sewage solids settle.

The remaining wells serve as filter elements. They are not sealed, that is, they do not have a bottom. Secondly, manufacturers today offer perforated concrete rings. Through holes are formed in their walls during the production process.

Single level

This is one well for which filtration fields will need to be built. Or at least a filtration ditch. Not the most effective cleaning option, so it is recommended to construct it from large diameter rings.

Two-level

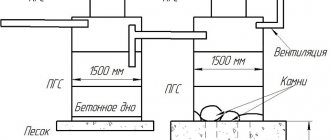

Ideal for a small country house. Usually the wells are the same size, but this is not necessary. The first one is sealed, the second one is not. They are erected on the same level. But you can lower the second lower than the first.

Three-chamber

From the name it is clear that this is a septic tank of three compartments, which are connected to each other in series, regardless of their location. The arrangement scheme can be as follows: in one line, in the form of the letter “G”, in a triangle.

Typically the first element has a larger volume than the other two individually. Moreover, it is the latter that perform filtration functions. The first is a collection of sewage, where heavy sewage settles.

Benefits of concrete

A septic tank for receiving household waste can be made of brick, polymer materials, stone, metal, concrete. The resulting structure is not overly loaded; its durability is affected by the resistance of the source material to aggressive substances and constant humidity. Constructing the walls of a sewer well from concrete rings is considered an ideal option for the following reasons:

- Concrete elements are used when constructing a septic tank on various soils; their resistance to compressive deformations allows them to withstand pressure from displacement of soil layers and groundwater.

- Availability of material.

- High speed of sewerage installation using concrete products.

- Sewerage made from concrete rings is durable and easy to maintain.

- Rings allow you to make a device of the desired depth and diameter.

- Resistance of the material to aggressive substances, groundwater composition and temperature changes.

- Easy to install yourself.

- A large selection of waterproofing materials to protect the walls of the future well.

- Thanks to metal reinforcement elements, concrete products are highly durable.

- Factory-produced products are designed for tight joining.

Concrete products are durable, but they also have their disadvantages.

The main disadvantages during operation: weight, certain difficulties with delivery and loading, the possible need to use lifting equipment and additional labor.

Stages of building a septic tank from concrete rings, how to do it yourself

The main process of forming a septic tank from concrete rings with your own hands is digging a pit for reinforced concrete rings. There are two options: manual using shovels and mechanical. For the latter, you will have to use a drill truck, the services of which increase the construction budget by two or three times.

The manual method can be carried out using two technologies.

- A well is dug with a diameter larger than the diameter of the selected concrete rings by 20 cm on each side. The depth is determined by the number of reinforced concrete elements. Subsequently, the rings are lowered inside using a crane or a hand hoist mounted on a tripod.

- A well is dug 50 cm deep. A ring is lowered there. Afterwards, you need to climb inside and select the soil with a shovel, without touching the soil located under the walls of the ring. In this way, the pit is deepened to a depth of 30 cm. Next, soil is removed from under the walls, which makes it possible to lower the reinforced concrete product. As soon as the first element has disappeared underground, the second is installed on it. And the process repeats.

The first option is used if the soil on the site is strong clayey. The second, if it is fragile, for example, sand or with a large amount of sand impurities.

It is this technology that is used to construct a filtration well, which has no bottom. For the assembly compartment you will have to form a bottom. There are two options here:

- Buy a finished product in the form of a round reinforced slab at the same factory where the concrete rings were purchased. To install it you will need to use a crane.

- First, formwork is installed in the prepared pit, into which a reinforcing frame is laid. Next, the form is filled with concrete mortar. The thickness of the slab is 10 cm. This is done if concrete rings are installed in a dug pit.

If the septic tank is formed by removing soil from inside the rings, then the bottom is poured directly inside the finished concrete well. In this case, the formwork will be the lower ring. A reinforcing mesh or lattice is also laid here.

Regardless of which well is being constructed, a cushion of medium or fine crushed stone is formed at the bottom.

After all the rings are installed, the neck is installed. This is a finished product that is mounted on top of the upper concrete ring. A lid is placed on top of it: plastic, cast iron or cement-polymer.

In the first sealed well, before installing the neck, the joints between all elements of the structure are sealed. To do this, use a standard cement-sand mortar. The same mixture is used to close the gaps in the holes for sewer pipes.

And the last stage is filling the soil into the gap between the wells and the walls of the pit. Ventilation pipes are installed.

Installation

For example, let’s look at what a two-chamber sewer system will look like. A sand cushion 0.1-0.15 m thick is laid on the thoroughly leveled bottom of the pit and irrigated with water for maximum compaction. If it was not possible to lay a slab under the concrete rings, then the base of the pit should be concreted and waterproofing should be done at the junction of the structures to avoid contamination of the surrounding soil by runoff.

Concrete rings are laid on a sand-cement mixture in a ratio of 1:3, diluted with 0.1 part of liquid glass. The solution is prepared in small quantities, since its setting time is 30 minutes.

To eliminate deformations during possible ground movements, the concrete rings are additionally fixed with metal plates or brackets. The top slab with a lid is attached to concrete rings with a solution of cement and sand.

1 — rings of the working part; 2 — insulating cover; 3 — neck rings; 4 — hatch body; 5 — hatch cover; 6 — ventilation riser; 7 - floor slab; 8 — bottom plate; 9 — crushed stone cushion; 10 - waterproofing; 11—sediment zone; 12 — running brackets

Waterproofing of a settling tank in comparison with a filter well is carried out in two layers of hot bitumen on a previously primed surface. Penetrating water-repellent compounds or a mixture of gasoline and bitumen are used as primer. The outside of the tank is insulated with rolled bitumen material.

Typology

Since reinforced concrete rings are used for a wide variety of purposes, there are several types of reinforced concrete rings adapted for a particular task.

Rings of reinforced concrete products

In particular, wall rings are needed if it is necessary to equip a water supply system. Their diameter ranges from 0.7 to 2 meters, height from 0.69 to 0.89 meters, thickness - 70-100 millimeters. A more modern solution, but not yet sufficiently tested in practice, is VG rings, which can also be used for gas pipelines.

Monolithic rings are used to strengthen the bottom, while sewer rings are distinguished by their large height - up to 0.9 meters, with a diameter of up to 2 meters.

Filter well

You don't have to use concrete rings for the well. To save money, it can be made from an ordinary iron barrel.

The well should be located at least 1 m above the groundwater level. Where the well comes into contact with the soil filter, make holes in its walls with a diameter of no more than 6 cm, which will occupy a tenth of the walls. This will increase the absorption area.

1 — water barrier; 2 — neck rings; 3 — hatch cover; 4 — insulating cover; 5 — hatch body; 6 - floor slab; 7 - ventilation riser; 8 — blind rings; 9 — perforated rings; 10 - filter media; 11 — holes in the rings; 12 — concrete base; 13 - supply pipeline

The filter is a layer of small stones, broken bricks and other solid materials at the bottom of the well. The thickness of the words should be from 20 to 30 cm.

We recommend reading the instructions for building a drainage well.