Installing a wooden staircase with your own hands is a labor-intensive and quite complicated process for a beginner, as it requires certain training, skills and abilities.

It is obvious that securely fastened and perfectly adjusted staircase elements make the structure as stable and reliable as possible, eliminating creaks, swaying and deformation. However, novice craftsmen often neglect simple rules, which leads to distortions, premature destruction and other extremely unpleasant consequences.

In this article we will try to talk about the key points of assembling and installing rotary flight stairs so that you do not make mistakes in practice.

If you don't have a finished project, we recommend that you use our online staircase calculator . It allows you to receive a ready-made estimate, a set of drawings, a 3D model and recommendations for manufacturing the most convenient design.

Content

- Introduction

- Wood grain direction

- Wall stringers

- External stringers

- Attaching the stringer to the ceiling

- Connecting stringers to each other

- Attaching steps to a string - methods

- Methods of fastening balusters

- Installing railings on stairs

- Attaching the handrail to the pole

Conclusion

Now that you know how simple straight staircase structures are built, especially if you have had practical experience after reading the information described above, you can move on.

For example, study more complex types of stairs for the home, understand how they are made, and then try to make them yourself. In the video presented in this article you will find additional information on this topic.

The main thing in spiral staircases is the main support, which must be securely fixed to the floor and ceiling of two floors

Introduction

Installation of a staircase, like any other structure, is carried out in stages. First of all, parts are always installed that perform the function of load-bearing elements and access to which will be difficult in the future.

However, each master has his own exact sequence of assembling individual elements, and any of these methods does not claim to be the only correct one.

To avoid asymmetry, after each stage of work, check with a level that the horizontal and vertical projections are observed.

Wood grain direction

When manufacturing staircase elements, you should pay special ATTENTION to the direction of the wood grain . Drawings must be transferred to the source material, taking this feature into account, along the greatest direction of the template.

Wood has such a quality as anisotropy - that is, its physical and mechanical properties differ depending on the direction within the medium. For example, the compressive strength of wood along the fibers is 3-4 times greater than across the grain, the tensile strength is more than 30 times greater, and the indicators for fracture and chipping are similar. Professional carpenters know these nuances and produce products in accordance with certain rules that allow them to achieve the highest possible reliability of the final product.

For example, the winder step at the junction with the turning post has a rather small support surface, as a result of which an increased load is applied to this place. If the wood fibers are located parallel to the front edge (that is, along the larger side), the load is distributed evenly over the entire element , and if perpendicular, then near the attachment point, a break will soon occur along the direction of the fibers in the narrowest place.

The situation is similar with stringers in places where steps are cut - the direction of the wood fibers must be parallel to the upper and lower edges of the board. Otherwise, unreasonable arrangement of fibers will definitely lead to the appearance of a defect.

Building plan

Typically, a staircase drawing is part of a building or floor plan. We will begin by introducing the concept of a plan.

It is worth clarifying: of course, when manufacturing any complex structures, a detailed sketch is also drawn up, indicating those dimensions that are usually absent on the building plan. However, the staircase is in any case indicated on the general plan.

So, a plan is a projection of a horizontal section of a floor or an entire house onto a plane. What information does it contain?

- The location of all rooms on the floor, indicating their sizes.

- Location of staircases and flights.

- The location of window and door openings also depends on their dimensions, of course.

- Building structure (including location of supports and floor spans).

- Thickness of load-bearing walls and columns.

Drawing up plans is subject to certain rules:

- The main facade is at the bottom of the plan.

Cottage floor plan. The façade is below.

- If there are plans of several floors on one sheet, they are arranged in ascending order of the floor number from left to right or from top to bottom.

- The plan indicates the direction in which the doors will open.

- The drawing of a flight of stairs is supplemented with an arrow indicating the slope from bottom to top: the beginning of the arrow is always at the bottom of the flight.

Attaching support posts to the floor

Support pillars are vertically located load-bearing elements that form the basis of the frame of the lower part of the staircase. They provide support for the winder steps (landing) and the stringer (string).

There are no special requirements for the wood of the part - the main thing is that it is uniform, without cross-layers and large knots. Typically made from the same type of wood as the rest of the staircase.

In order for the future structure to be strong and reliable, the pillars must be firmly secured. This can be done using steel angles, studs, zip bolts, wood glue and other devices - there are a lot of options.

Finally, it is recommended to connect the columns with supporting stiffening beams.

Of course, by this time, all the technological holes and grooves for other elements of the staircase should already be made in the pillar structure.

Installation of a stringer

Stringers are the main load-bearing elements of a flight of stairs, which are mounted at an angle to the adjacent floor. Do-it-yourself installation of stair steps is carried out directly on the stringers, in pre-prepared recesses.

Wall stringers

Installation of the supporting structure begins with the installation of a wall stringer. For convenience, it is recommended to make markings on the wall in advance and, immediately before assembly, additionally double-check the accuracy of the structure with a level.

It is highly recommended to glue all connections and fastenings of parts with liquid nails or glue.

Usually the installation process begins with fixing the lower part of the stringer. To do this, the beam is installed and pressed into the groove connection or groove on the support column. A temporary support structure can also be made if it is planned that the stringer will be supported on the outside of the support column.

Then they begin to attach the upper part of the stringer. Depending on the type of floor: wooden, metal, concrete, different types of fasteners can be used. For example, in wooden houses, it is preferable to use angles, bolts, studs and anchors.

To strengthen the structure, it is also recommended to install stringers in the cuts of the load-bearing floor beam.

At the final stage, the main section of the beam must be pressed against the wall with pre-prepared dowels or anchors. If necessary, the attachment point of the stringer and support beam is additionally reinforced with a metal corner.

In order to prevent squeaks from adjacent structures in the future, all joints should be generously rubbed with paraffin, except for those where glue will be used.

External stringers

Installing an external stringer is practically no different from a wall stringer. By analogy, it is necessary to secure the lower part of the beam in any convenient way and then fix the upper part, which is adjacent to the ceiling.

During work, you need to ensure that the stringers are positioned exactly opposite each other, otherwise the design will turn out crooked and many manufactured parts will have to be modified.

After installing both beams, you will end up with something similar.

Attaching the stringer to the ceiling

You should dwell in more detail on attaching the upper part of the stringer to the ceiling, if the upper step is below the level of the second floor . In such a situation, there are quite a few ways of reliable fixation between elements and all of them are almost universal. The stringer can be connected using angles (both internal and lower), supporting steel plates, special clamping U-shaped fasteners; for wooden floors, a tongue-and-groove connection can be used; to fasten the staircase to a concrete slab, fixing it to a reinforced furniture board is acceptable.

Connecting stringers to each other

There are options for non-standard designs, when the stringers are not fixed in the grooves of the support posts, but are attached to them from the outside, or when only one support post is used, and the internal stringers are held only by fastening to the wall. In this case, the question often arises: how to fasten the stringers together?

The most common and universal method is the tongue-and-groove connection. This is quite simple to manufacture, but the most reliable unit that allows you to rigidly fix the parts. If, in addition, you treat the joints with PVA glue, then if the standard loads are observed, such a structure will be almost impossible to destroy.

together using ordinary self-tapping screws, screws or flush bolts (shown schematically in the figure with the screw head protruding outward). This connection also makes it possible to achieve high structural strength, but it can only be used if the stringers are planned to be attached to the support beam.

The second method involves cutting down the grooves in the support column, cutting one of the stringers to the thickness of the other, installing them in the appropriate holes and tying them together with any hardware. The resulting connection will firmly secure the elements of the staircase, and is also guaranteed to protect the structure from creaks and loosening.

On our website you can also calculate the length of the stringers and the amount of materials for their manufacture.

Design Features

To build a high-quality, reliable two-flight staircase, you need to adhere to certain standards:

- the width of the flight of stairs is calculated based on the number of people living in the house, but it should not be less than 80 cm;

- It is better to design the product with reliable railings with a height of at least 90 cm;

- dimensions, method of connecting parts, type of material must correspond to the operating load;

- the installed structure must comply with sound insulation and fire safety standards.

Attaching steps to the stringer

The next stage of building a staircase to the second floor with your own hands is attaching the steps to the stringer.

In cases where the design of the staircase also requires the presence of risers, it is recommended to install them first.

Let us remind you that the height of the risers should be approximately 1-2 mm less than the height of the steps. This is done so that in cases of increased humidity, when the wood swells, deformation of the entire structure does not occur.

After this, you can begin to directly install the steps. Straight elements along the stringer are installed simply and there is no point in going into detail, but the installation of winder steps should be considered in more detail.

There are two main ways to install winder steps:

- tongue-and-groove connection (classic);

- connection with the cut of the support column.

The first method assumes that in order to install the rotating elements, you will need to make blind grooves in the main support column. The vast majority of experts recommend making grooves slightly smaller than the thickness of the step, as this will allow the elements to be connected as tightly as possible and prevent their movement. In turn, this will prevent deformation of the structure and eliminate the appearance of squeaks.

The second method involves cutting through the support column to a thickness equal to the thickness of the step. The entire structure is fixed using wood glue or a pin wound inside the support column. To strengthen the selected connection, it is also practiced to create small grooves (locks) in the rotary stage to securely fix the entire assembly.

The outer side of the step, in both cases, must be attached to the frame made of winder stringers or supporting stiffening beams using PVA glue or self-tapping screws. If necessary, all connections are reinforced with metal corners.

Our website has a program for calculating winder steps - you will have access to drawings with actual dimensions, technical specifications and the amount of materials for manufacturing.

How the idea came

In summer there are mosquitoes, in winter it is cold. And if you have to go several times, and even go to the toilet at night, then the problem becomes insoluble.

In order not to experience the inconvenience of going into “outer space,” it was necessary to build a staircase inside the house. The problem is that it takes up a lot of space.

And I came up with an idea: to make the stairs steeper, and underneath it to arrange a toilet room, install a toilet, a sink and a sink.

As you can see in the photo, there is quite enough space, thanks to the steep stairs.

It turned out pretty good!

If you like such a table for a circular table, then you can make it from the drawings and materials below.

Simple do-it-yourself entrance staircase made of timber

It's so easy to make an entrance staircase! It’s not easy to do, but very simple!

A couple of photos of how it was done.

It turned out pretty good!

A simple and reliable ladder!

See also:

- A simple staircase on a metal frame to the basement with your own hands

- Wooden staircase on a metal frame from Mikhail Alexandrovich

- Multifunctional homemade bed for son

- Carved front pillar in the shape of a cat for the larch staircase

- Homemade staircase to the garage

EuroSamodelki.ru is a huge number of homemade products, which are accompanied by detailed illustrated instructions for self-production. There are already more than 4,500 homemade products in our catalog. Join us, join our social groups VKontakte and Odnoklassniki. We are waiting for you! Do something useful for yourself, for your home, for your loved ones.

Make homemade things with your own hands like us, do better than us!

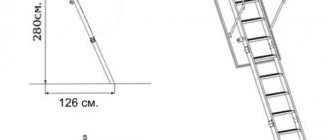

Before starting assembly, you need to make a preliminary calculation and make at least an approximate drawing, indicating on it all the dimensions of the stairs.

Installation of ladders on a bowstring

The string is the main load-bearing element of the staircase structure, which is located in an inclined plane relative to the surface of the floor/ceiling.

The main difference between a bowstring and a stringer is the method of installing the steps. On the bowstring, the steps are installed from the inside into pre-cut grooves, and on the stringer they are placed on top in special recesses.

When assembling the entire structure, it is assumed that first the treads and risers are installed on one string and only then the second one is pressed on the other side using a special hammer.

This design feature predetermines some difficulties when installing a staircase, since you first have to assemble a whole flight (string along with steps) in one place, and only then secure this bulky structure in another.

The remaining stages of installation exactly coincide with the stairs on stringers.

It should also be noted that bowstring ladders have greater bending strength, but due to drying of the wood and the lack of uniform lateral adhesion, the sidewalls are able to move slightly apart over time. Therefore, this type of structure is often reinforced with cords, which can be made of wood or metal. They are recommended to be installed at the beginning, middle and end of the flight or every five steps.

Attaching steps to a string - methods

The classic version of assembling a wooden staircase with your own hands implies that the steps must be assembled before the march structure is installed in a given location. In this case, at the initial stage of assembly, all joints of the elements are lubricated with a special adhesive, risers and treads are inserted into the grooves, and, if necessary, reinforced with self-tapping screws.

However, recently designs with overhead bars and corners have become increasingly popular. In this case, specially placed stops are attached using nails or self-tapping screws directly to the body of the bowstring, and the tread, in turn, is installed on them.

In this case, the assembly of the stairs is carried out by analogy with the structure on stringers, that is, there is no need to first assemble the entire flight and only then install it at a given position.

A bowstring staircase is an excellent solution for a spacious home; try our tool to get a finished design project.

Calculations

This stage is the most critical. Modeling is the process of finding the optimal relationship between the dimensions of a structure and the ease of its use.

This is interesting: how to make calculations for a wooden staircase?

For a comfortable ascent, the width of the steps must correlate with the angles of inclination of the flights of stairs. Here it is necessary to take into account that the steeper the angle of inclination, the higher the height of the riser should be.

On average, this characteristic should be 150-180 mm. The width should not exceed 250-300 mm. If the angle of inclination exceeds 45° or, conversely, does not exceed 20°, then the described ratios will have completely different figures. However, it is recommended to adhere to the specified parameters, since they provide proper comfort.

What to do if these conditions cannot be met? Well, in this case, why not build a rotating structure? The main thing is not to reduce the width of the tread, otherwise the staircase will be dangerous.

Important! Another mandatory requirement is maintaining the same width of all steps. The only exception is the rotating elements.

DIY installation of balusters and railings

Assembling the staircase railing is the last and one of the most important stages of installation. Durable railings ensure safe operation of the structure; they must protect people from accidental falls and must withstand the weight of people when leaning on them.

To achieve this effect, there are certain recommendations that determine the most optimal location of the balusters. For example, the clearance between the columns should be in the range of 15-20 cm; this does not make the structure much heavier, but prevents a child from falling from the second floor. It is also recommended to maintain the height of the handrail at 90-110 cm, since this is the most optimal value that will be convenient for the average person to support.

Methods of fastening balusters

To ensure that the railings are safe, stand firmly and do not wobble during use, several proven methods of attaching balusters are used:

- metal studs;

- metal platforms;

- dowels;

- self-tapping screws

Steel studs

Steel studs are one of the most popular fastening methods, as they provide the greatest strength of the connection. Experienced specialists recommend using studs when installing support balusters.

Based on the type of rod, they are divided into smooth and threaded.

In the first case, to create a strong connection, you need to drill a hole in the baluster at least 4 cm deep, add some liquid nails, carefully hammer in the existing pin and wait until the glue dries completely. After this, you need to make a similar cavity in the floor surface, also lubricate it with glue and connect the parts.

In the second case, you will also need to make a hole, but with a diameter 0.5-1 mm smaller than the diameter of the pin so that the wood does not crack when twisted. You can screw the rod into the support post using a lock nut.

It is also worth noting that mounting the structure on studs is only possible when the elements are placed perpendicularly, so it is impossible to use this method for a bowstring.

Metal platforms

Metal platforms (hidden gear fasteners) are a fairly modern type of connection, which also allows you to completely hide all fastening elements.

The principle of operation of the mechanism is extremely simple - there is a steel platform in the shape of a lock, with four fastenings for self-tapping screws around the perimeter. In the middle there is a widened hole into which the bolt head is inserted, and a narrower elongated hole has a beveled side on the inside. Thus, by driving the head of the fastener inward and hammering it to the far side, we obtain a strong locking connection.

A fence completely installed in this way cannot be moved after all the supporting columns have been installed, but individual elements can be easily replaced if broken if you tap a mallet in the direction of the lock extension.

The main disadvantage of this connection is its applicability only in the horizontal plane - for a beveled march, it is necessary to use other types of fastening.

Wooden dowels

Dowels are cylindrical fastening products in the form of a short rod, most often made of wood.

They are used for fastening intermediate fencing elements or in cases where a threaded connection cannot be used, for example, on beveled surfaces.

The installation method is similar to installing smooth studs - first, a hole equal to half the length of the dowel is drilled in the end of the baluster, then it is filled with wood glue, and only then a wooden rod is installed there. After one connection has acquired the necessary strength, the pole is attached to the stairs.

The disadvantage of this type of fastener is the inseparability of the resulting assembly and, as a result, possible damage to adjacent structural elements during dismantling.