Ventilation of a septic tank made of concrete rings is carried out to eliminate unpleasant odors and ensure safe living for people in the country or in a private household. Typically, energy-dependent septic tank systems are created in areas adjacent to private buildings, designed to effectively process sewage waste and wastewater due to the bacteria living in them.

A septic tank is a structure in which bacteria live. They develop and multiply quickly during the active processing of organic waste discharged through the sewer system. Processing is accompanied by the release of gas, as a result, silt deposits remain in the septic tank, and clean water goes into the ground. The main problem and danger for people living in households is the possibility of gas poisoning. Therefore, the ventilation system needs to be equipped and done correctly.

Ventilation device for a septic tank built from concrete rings - purpose and rules of arrangement

When thinking about whether ventilation is needed in a septic tank made of concrete rings, it is worth, first of all, taking into account the safety requirements for operating the system. Special bacteria live in the septic tank, which “eat” all the waste, producing clean water and sludge at the exit. But they cannot process sewage without producing harmful gases. Therefore, for the normal operation of the system and ensuring the safety of people living on the territory, the installation of ventilation is a mandatory step.

Uninterrupted operation of a septic tank is impossible without creating optimal living conditions for microorganisms. The main element at all stages of processing is the supply and exhaust air supply system, which provides the bacteria with oxygen in the required volume.

The supply and exhaust system consists of a pipe for supplying oxygen to the wastewater collection tank so that the bacteria feed and work properly (without air, microorganisms die) and a pipeline for removing gases that appear during the work of the bacteria.

The main stages of operation of the ventilation system in a septic tank:

- The flow of air into the pipe along with the volume of wastewater and waste.

- Drain the waste into an external storage tank to allow the coarse fraction of waste to settle; oxygen should immediately enter the chamber.

- Delivery of air to other tanks through internal channels.

- Nutrition of bacteria.

- Removing gases through a hood.

In order for the ventilation for a septic tank made of concrete rings to work correctly, for microorganisms to live and perform their functions, and for the residents of the house not to be poisoned, you need to remember certain principles of system design. In some cases, the septic tank ventilation system is combined with the home ventilation system, but this must be done correctly.

Rules for arranging a ventilation system in a septic tank:

- The diameter of the pipeline should be 30% greater than the expected volume of wastewater, so that a vacuum plug does not appear during flushing and oxygen flows in a normal volume.

- To ensure air flow, the end of the pipe is led directly through the roof of the premises so that there is no resistance and circulation is normal.

- To prevent birds, insects, and rain from getting into the pipe, it is covered with an umbrella and a net.

- The joints of the main are sealed to prevent odors from entering the house.

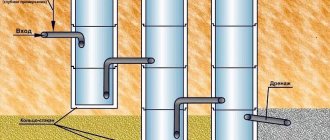

- When air circulation is organized inside concrete rings, the pipes connecting the containers are mounted so that the air channel does not become clogged and water does not enter.

- The pipeline for air exchange located inside the container is treated inside and outside with waterproofing materials, and the joints are sealed.

What is a fan boner?

It is needed to ensure communication between the sewerage system and the external environment, that is, to ensure that the sewerage system is not closed.

Most often this is a plastic or polyethylene pipe of the same diameter as the sewer. However, sometimes cast iron and metal are still used.

The sewer pipe is actually a continuation of the sewer pipe, except that water should not flow through it; this is the so-called dry pipe.

Ventilation of a septic tank without a drain pipe

In a sewer system that does not provide for a drain pipe, organizing the flow of atmospheric air is also a prerequisite. To do this, ventilation branches are cut into the main pipe, which emerge from the ground to a height of at least 30 cm, and it is better to raise them along the facade of the building at the base of the roof. Through these pipe sections, air will flow into the main pipeline and then through the channel into the sump itself. The upper inlet socket must be covered with a mesh and a protective umbrella. Recently, special plugs with built-in valves have become very popular, which allow oxygen to pass in one direction and prevent odors from the tank from entering the atmosphere.

With such a system, the inflow pipe riser performs two functions at once, ensures proper flow circulation and, if necessary, can serve as an inspection hole for cleaning the sewer.

Why is septic tank ventilation needed?

A septic tank purifies wastewater using bacteria that need air for normal life.

At the same time, in the process of eating waste and cleaning drains, bacteria release very dangerous gases - they are not only unpleasant for people (hydrogen sulfide smells very bad), but can also cause serious health problems, even trigger explosions (methane, for example, stands out and may well be the cause).

In addition, without a ventilation system, the sewer septic tank will not work properly. Indeed, at the moment of draining water through the pipe, a vacuum appears, which often causes a plug to appear. To avoid this, a ventilation pipe must be installed in each riser in the chambers, providing air inflow and outlet, thus neutralizing the resulting vacuum.

General information about aerators for wastewater treatment plants

If you want to choose a compressor for a septic tank, you should know that not every similar device is suitable for this. Therefore, this issue must be taken seriously. If you choose the wrong device, the septic tank will not be able to provide the proper level of cleaning, which will negatively affect the environment and the performance of the equipment.

It is necessary to select a unit taking into account the fact that it must withstand sewage and aggressive environmental factors. If this is not the case, then the compressor equipment will require repair within a few days after the start of work.

The procedure for constructing septic tanks from concrete rings

To build a septic tank with your own hands, you will need the following materials: reinforced concrete rings with a diameter of 1 meter - 3 for each of the 3 chambers (9 pieces), 3 cast iron hatches, 3 reinforced concrete slabs (there must be a hole in the slab for the hatch), a PVC pipe with a cross-section of 12 centimeters the required length (the distance from the house to the septic tank well and the length of the connecting pipes are considered), liquid glass or bitumen for reliable waterproofing, a concrete slab for the bottom of the pit (or mortar to make a concrete base).

Tools for arranging a septic tank: shovels for digging a pit, buckets for removing soil, strong ropes, ladders, a hammer drill, a lifting mechanism that will install the rings on top of each other, because their weight is at least 400 kilograms.

Main stages of septic tank construction:

- Digging a pit - carried out before delivery of reinforced concrete rings to the territory, the required depth, is designed with a slope towards the house so that each subsequent settling chamber can be located lower than the previous one.

- Installation of rings, after which the pipeline can be assembled.

- Sealing the entire system, with special attention to the bottom of the chambers.

- Installation of ventilation risers that will eliminate unpleasant odors.

- The final stage is backfilling and compaction.

During the implementation of all tasks, you should not smoke, it is better to carry out maintenance with someone’s help, and when performing work you need to think about reliable insurance.

Types of equipment

In terms of themselves, all septic tanks are the same thing, although they are divided into:

And, in fact, they are an ordinary container, impenetrable both from the inside and from the outside. Contaminated water from your dacha is pumped there and processed to purify it at the primary level.

Just according to the above-mentioned chambers, and septic tanks are also distinguished by size. So single-chamber and double-chamber can accommodate different numbers of drains. But whatever the design, the treatment properties still depend on the processes that occur inside the septic tanks, and with the help of which the wastewater is cleaned.

Bacteria in a septic tank

Ventilation in a septic tank made of concrete rings is the best option. Despite the fact that installing the system will entail additional costs, ventilation cannot be abandoned, as this is fraught with serious consequences.

The following bacteria live in a septic tank:

- Anaerobic

– located in the first chamber of the system, in the water column, they process all household waste (various types of detergents, organic matter, etc.), releasing explosive methane, which is not noticeable to the bike.

- Aerobic

- live in a film directly on the surface of the water and process waste that was not eaten by the first bacteria. They emit hydrogen sulfide, which is poisonous and smells bad.

In addition to hydrogen sulfide and methane, septic tanks also emit volatile arsenic salts, carcinogens, and various types of phosphorus compounds. If ventilation for the septic tank is not provided or performed incorrectly, all the products of the “work” of bacteria go through the sewer system back into the house, at best creating a stench, at worst – severe poisoning and an explosion.

Limitations and recommendations

If, after familiarizing yourself with the regulatory requirements, you are still full of doubts as to whether you need ventilation of the sewer system or not, we offer simplified explanations:

- If you are designing a house, then know that the district architect will not approve your project without drain outlets if the future building has more than 2 floors;

- If the number of floors is 1-2 floors, then the number of toilets and bathrooms matters. A fan output is not needed if there is only 1 of them.

But that’s not all - even if your project includes only 2 floors with one bathroom and one bathroom, their location will play a role:

- A drain pipe is needed if the bathtub and toilet are located at different levels;

- A connection to the roof is needed if a pipe with a diameter of less than 100 mm will be used to lay the sewer;

- A connection between the sewer system and the atmosphere is required if there is a swimming pool in the house;

Ventilation system design

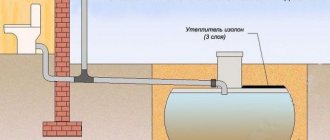

Before you begin work, you need to carefully plan and think through everything. The installation of a ventilation system is inseparable from the construction process of the entire septic tank, so all stages of work must be completed in the correct order and in accordance with standards.

Design

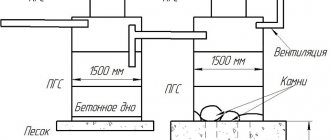

Any septic tank for a private home consists of three chambers: wastewater enters the first tank of the septic tank and settles, the second chamber is installed as a secondary settling tank, and filtration takes place in the third. The volume of the chamber is calculated in accordance with the expected volumes of wastewater and waste.

According to standards, on average a person uses about 200 liters of water per day, so for each family member you need to “book” 600 liters in the cells. But usually septic tanks are built with a reserve, adding 15-20% to the total value.

Installation of septic tank chambers

First you need to dig a pit - it is dug before installing the concrete rings. The depth corresponds to the total height of the three rings plus 40 centimeters for the sand cushion and screed under the structure. Under the drainage well, crushed stone is poured into a layer at least 70 centimeters thick. You can dig drainage channels and lay drainage pipes in them in a star shape. The bottom of the ditch is made with a slope towards the house in order to place subsequent chambers 20 centimeters lower than the previous ones.

Installation of septic tank chambers is simple - the rings are simply installed vertically, evenly or using ready-made grooves. On top there are plates with holes (inspection hatches). Holes for pipes designed to move wastewater are made in advance. Holes for ventilation are made above the second septic tank, connecting pipes are inserted, and sewerage is connected to the first tank.

The pipes should have a slope of about 3 degrees. The pipes must be sealed, as well as the bottom of the chambers. The bottom is sealed several times with geotextile or bitumen, and strengthened with concrete mortar. Pipe inlets are protected with liquid rubber. For the purpose of insulation, various materials are used.

Installation of ventilation pipes

When installing the ventilation of a septic tank from concrete rings, you need to pay special attention to the installation of pipes. The ventilation risers are plastic sewer pipes with a cross-section of 100 millimeters, which are intended for installation outside.

In a single-chamber septic tank, the pipe is installed in the top hatch; the length of the pipe is calculated so that the protective device at its end rises 50 centimeters above ground level.

In a two-chamber design, a pipe for drains is installed in the first chamber, and a riser is installed in the second for air exchange and ensuring pressure balance. The second chamber of the septic tank goes into the filtration fields or the third chamber. There must be a pipe in it to ensure ventilation and fill the filter field or third chamber with purified water.

Ventilation riser

Hydraulic seals of plumbing fixtures, which cut off the unpleasant odors that accompany wastewater treatment, work correctly provided that there is a constant presence of water, coming regularly during drainage. If there is no water in the seal, the smell spreads throughout the room.

The background (ventilation) riser is connected to the ventilation system of the septic tank, compensates for the vacuum that creates the volume of drained water, and guarantees the correct operation of the water seal.

The riser is connected to the septic tank and ensures constant air movement, removal of carbon dioxide and methane, and allows bacteria to live and work.

Final stage

The final stage of creating a septic tank and ventilation system is carefully backfilling the soil. They fall asleep in small portions; you can use sand instead of soil. Particular care must be taken to fill the passages of ventilation pipes and the connections of plastic elements with concrete, so that no gaps appear in the joints.

Backfilling is carried out in layers of 10 centimeters, followed by compaction of each layer so that the sand or soil becomes more dense. You can tamp with a hand tool or any other suitable device, but very carefully and consistently.

Arranging a ventilation system in a septic tank made of concrete rings is not at all as difficult a task as it might seem at first glance. It is quite possible to do all the work yourself, paying due attention to the design stage, the technology of system design and the selection of high-quality materials.

Overview of species

An aerator cannot fully operate without a compressor. The latter differ in the principle of air injection used in their operation. The following options are available.

The screw contains a working element consisting of a pair of rotors, having a multidirectional surface profile. The rotors engage and rotate in a sealed chamber. The incoming air volume is compressed by reducing the distance between the pair of screws and the housing. After this, the exhaust valve opens and air moves to the compressor pipe. Among the advantages of this design, it is worth noting the long service life due to screws made of high strength steel. The disadvantages include the need to replace the entire device if a breakdown occurs inside the camera.

- The membrane works due to the fact that the membrane, whose edges are fixed, vibrates. Movements occur due to the armature under the influence of a magnetic field or a hydraulic piston. A pair of valves is located above the membrane. As it moves downwards, the inlet flap opens and the working chamber is filled with air. When moving up, the valve closes, and the compressed volume of air opens the exhaust valve and exits to the nozzle.

The device is economical, easy to maintain, low cost, quiet during operation, and compact. At the same time, it is also resistant to aggressive environments. However, the membrane often becomes inelastic and needs to be replaced.

- The piston works due to the fact that the air above the piston is alternately compressed and rarefied. Due to the movement of the working element and the actuation of the valves, air moves between the inlet and outlet pipe. This version of the device impresses with its simple design, reasonable cost and convenient maintenance. However, it makes excessive noise during operation, consumes a lot of electrical energy, and vibrates strongly. In addition, such devices must be stopped periodically to cool down, so they are rarely used for septic tanks.

Installation of pipes along the external wall of the building and on the roof

It is desirable that this be a gable wall. Before entering a bathroom or room, especially if the plumbing fixture itself is still a few meters away from the outer wall, you need to stretch an additional air duct along the outer wall, which also runs above the roof. This measure will ensure better circulation within the system.

When the sewage system inside the house is assembled at the highest point, after the plumbing fixture, a tee is installed in the pipeline with the socket facing up. Then a pipe of the same diameter is inserted into it and brought out through the ceiling to the roof. If there are various obstacles along the route (rafters, chimneys, etc.), they will have to be bypassed without changing the angle of inclination using bends.

Products from the store often do not fit in size. You'll have to cut it with a grinder and then chamfer the end to make it easier to join the bell of the next piece.

On the roof itself, the shaft exit should protrude at least 50 centimeters above the roof. Then a headband is put on its end, which will prevent moisture and snow from getting inside.

Moreover, it is unacceptable to install a weather vane or deflector; this can lead to the formation of ice and subsequent blockage of the pipeline. It is enough to put a small umbrella or visor

Throughout the entire external ventilation, inspection fittings must be installed, which look like a standard tee with a socket and an inspection window with a lid. This part is necessary to solve problems of diagnosing the internal state of the highway and performing preventive maintenance. If a blockage occurs or a foreign body enters, through such a unit it is possible to accurately determine the clogged area and eliminate it.

Important! The rubber bands must be left in the sockets and lubricated with oil or sanitary sealant. Also, if the length of the pipe was changed by cutting, a chamfer must be made at the end of the part, otherwise the cut end will rest against the sealing ring and lift it inside the socket.

How does the aeration process occur?

Aerators are used to distribute the oxygen that the compressor can supply to the total volume of water.

And it is in septic tanks that it is used most often.

Well, if we consider various types of aeration, from the point of view of efficiency, then the most effective is aeration with fine bubbles.

But if you want, for example, to save money, then it is not always necessary to buy a professional aerator for yourself; no one is stopping you from making it yourself. To do this, we need to understand from the very beginning how aerators work.

The need for cellar ventilation

The lack of good ventilation in the cellar is fraught with the appearance of condensation and fungal plaque. The air in such a room is stagnant and the smell is unpleasant.

In unventilated storage, vegetables quickly rot, which causes the release of methane and carbon dioxide, which are dangerous to life and health.

Even a slight accumulation of these substances can cause loss of consciousness and poisoning for those inside the cellar, and in severe cases, death is possible. In addition, methane is a flammable gas that explodes at the slightest contact with an open flame.

It's not just food that spoils due to poor basement ventilation. In such conditions, structures and objects made of metal quickly rust, and shelves and boxes made of wood are affected by fungus and destroyed.

Initial conditions

The house stands on a bolt, the floating foundation is a caisson until it leaks. High water: off-season – 30 cm; in summer - 70 cm, in drought, it went up to 1.5 meters. Five people live in the house, sometimes seven. It had to be done in winter. I refused to pour concrete. In addition, pouring concrete into a swamp requires good pumps for pumping. According to calculations, the volume of discharge is 7×150=1050 liters, in total – cubic meters. Safety factor (cleaning time) – 3.5 days. The volume of the septic tank (more correctly, local treatment station, VOC) is 3-3.5 m³.

After studying the forum, aazinus chose a design scheme with aeration:

- the first cube is a settling tank;

- the second is aerated;

- the third is aerated, but weaker, so that the sludge settles.

Vacuum valve

(hereinafter referred to as VK)

In a one-story house, as well as in a building where plumbing fixtures are installed only on the first floors, it is allowed to use VK instead of FS.

In order to provide ventilation, a special mechanism can be installed in a small system, which is mounted using a tee connection.

It works on the reverse principle. The device has a sealed curtain with spring resistance. When a vacuum occurs in the sewer, the vacuum draws in the valve and with it the air from the room, and when the balance is restored, the spring closes the valve again, preventing the smell from leaving the pipe.

How to install

The installation of an air duct can be combined with the laying of an air duct, but you need to remember several nuances with this combination:

- The valve should not be higher than the fan riser.

- In some cases, it is possible to install the mechanism not only on a vertical, but also on a horizontal pipe.

- If the length of the horizontal section of the shaft with plumbing fixtures is more than 8 meters, install two valves at an equal distance from each other.

How to make it yourself

To do this, a plastic plug is inserted into the tee, in which several holes are drilled in a circle. So that they can be closed, a flat disk with a diameter slightly larger than the halo of holes is cut out of foam rubber.

Then you will need a simple wood screw and a loose return spring. In order for the foam rubber to press down and close the holes after the valve operates and the pressure in the system normalizes, a plastic or iron plate is inserted between the spring and the disk.

Now the screw is screwed into the cover from the reverse side. It is worth considering that the performance of a valve made independently will be several times lower than a factory one. In the factory, all calculations and drawings are carried out, which are based on all the indicators of the future sewer system, and the volume of air required to be supplied inside is calculated. It is unlikely that such actions will be possible to perform under domestic conditions.

Note : You can combine the use of a vacuum device and the FS system. In this case, the valve is installed at the end sections of the sewer pipeline.

Making your own aerator

The simplest aerator can be easily made from a plastic pipe yourself. Execution of work:

- take a PVC pipe with a diameter of 50 mm:

- We put a plug on one side of the pipe, and on the other - an adapter for connecting the compressor hose;

- Numerous holes are drilled across the entire surface of the pipe using a small-diameter drill.

The homemade aerator is ready for installation.

Water supply maintenance rules

A correctly installed system rarely fails, but preventative maintenance and inspections can prevent some breakdowns.

To do this, we recommend paying attention to the following system elements:

- pump - monitor the operation of the pump, clean it on time and replace consumables, for example, rubber gaskets;

- sealing - if the composition of the water changes, check the sealing of the well (surface water may enter);

- pressure - monitor the pressure in the system (the norm is from 2.5 to 4 atmospheres);

- filters - use filters that purify water from large particles and impurities, thereby preventing mechanical breakdowns of equipment.

Automating the process will allow you to control the system even in your absence. In the event of a sudden change in pressure or emergency drying out of the source, the triggered relay will stop the operation of the station.

Modernization of the settling chamber

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank. To do this you will need:

- determine the location for the new section;

- dig a hole where to install a container or concrete ring;

- install a homemade or purchased compressor made for a septic tank;

- Be sure to install a perforated pipe sealed at the bottom into the aeration tank.

Important! Such a pipe can be made from any suitable length. Drill holes, spacing them evenly and observe the appearance of air bubbles on the surface during startup - this means that the compressor installed for septic tanks is working normally.

By adding a mixing structure to the entire installation, it is possible to improve the distribution of masses so that the air flow flows evenly, this will improve the process of decomposition and recycling of accumulations. As a means of post-treatment, it would be a good idea to install an additional chamber where the wastewater will settle and be clarified.

What is the operating principle of the device

Scheme of operation of a septic tank with an aerator. (Click to enlarge) On what principles does the aerator work:

- Under strong pressure, oxygen is pumped through any perforated materials that have a large number of pores.

- Because of this, a large number of oxygen bubbles begin to form in the liquid.

- They, in turn, begin to move under the force of Archimedes towards the water surface.

- The water begins to gradually become saturated with air.

- The air stops supplying as unnecessary.

- And after completing the entire oxygen saturation process, the pores close to prevent the entry of foreign bodies.

With such a simple diagram, it is quite easy to make an aerator yourself.

Read an article on how to make a septic tank from a Eurocube with your own hands here.

After reading this article, you will learn about the benefits of using sewage pumping stations.

Advantages of autonomous water supply

Residents of megacities who are not puzzled by the problem of private water supply may be surprised to learn that the well water supply system has many advantages.

The largest is contained as a liquid. It has almost spring purity - its composition is completely free of harmful impurities such as chlorine or rust.

The second advantage concerns saving the family budget - you freely use natural resources without paying monthly bills.

And another nice bonus is control over the operation of the system. For example, you can independently regulate the pressure or lay pipelines to a garden plot or flower bed.

Many doubt the feasibility of installing a water supply system from a well to a house, arguing that a water supply system with a well would be much more efficient.

Perhaps, but if you have a strong, deep well with a sufficient water level in your dacha area, there is no need to drill a well for the following reasons:

- registration of permits for an artesian well, drawing up a project and drilling work take a lot of time;

- the cost is high and not everyone is happy with it (about 130 thousand rubles for a well up to 30 m);

- setting up a well system is a little easier (especially the summer version);

- the presence of a well does not require permission from government agencies.

If minor repairs or cleaning of silting are required, it will take much less effort and money than cleaning a well.

In case of temporary power outages, there is always a backup option - a bucket on a rope or a special lifting mechanism (the narrow borehole does not allow the use of improvised devices).

There are a number of difficulties, but they can be solved. For example, an old wooden structure becomes unusable over time - it is better to replace it with concrete rings.

If the structure has lost its tightness and allows water and domestic waste to pass inside, it is necessary to thoroughly seal the seams on both sides, internal and external.

Features of operation

In order for the installation to last for a long time and without unnecessary problems, a number of rules must be followed. Of course, you need to start by carefully reading the operating instructions included with the unit. Before using the device, it must be grounded. The compressor can only be located in a box protected from moisture. During installation, it should be taken into account that the suction zone, as well as the cooling part of the unit, must be fenced off from vapors and various gases that emanate from the container.

As for the electrical component, it is important that the circuit is reliably protected from sudden voltage drops, which are often found in the network.

Do not forget that the device has an air filter at the inlet, which needs to be cleaned in a timely manner. The device must be handled carefully so that it does not fall or be subject to mechanical damage. Particular care must be taken during operation, as well as when removing the aerator before the septic tank is mothballed. It is necessary to constantly monitor the condition of the cleaning tank. It must not be allowed to overflow or flood.

When using membrane-type devices, it is necessary to replace the working element with a new one at certain intervals. This is due to the fact that during operation it loses its elasticity and wears out. While the warranty is valid, the replacement can be made by a specialist, and then you can do it yourself. It is advisable to always have a membrane aerator repair kit at hand. You can make a replacement, guided by thematic videos from the Internet and recommendations of professionals.

If the unit overheats quite often and the thermal relay trips, you should check the device for contamination. Most often this occurs due to organic deposits that can penetrate inside with gases and fumes from sewer water. In this case, the device will have to be completely disassembled, cleaned and rinsed thoroughly.

How to aerate a septic tank with your own hands, see the following video.