In this article we will look at the general rules for installing an electric floor, and also give some practical tips for successful installation of the structure.

So, a modern electric floor consists of a heating cable, a thermostat, and a temperature sensor .

Sensors and thermostats are standard and, by and large, it is enough for them to simply work; the main role in high-quality heating of the room is given to heating cables.

Resistive cables, single-core and double-core, are very popular. It is believed that two-core cables provide better protection from electromagnetic radiation, which is why they are more expensive .

Self-regulating ones are less popular. They are more expensive than twin-core ones. Self-regulating cables are considered the safest.

Choosing a heated floor

When choosing a heated floor option, be guided by your financial capabilities . What is more expensive is not always the best option.

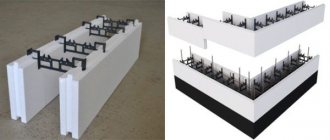

Conventional cable floors, the most economical option, the second most expensive option, are thermal mats (mesh). These are the same cables, but built into a reinforced mesh.

Installation is greatly simplified and accelerated; each cable does not need to be routed and secured separately. Thermal mats have an adhesive backing; you just need to stick them to a flat floor surface .

The advantage of a regular cable is that you can adjust the installation depending on the heating power per square meter you need.

There is also a film option, here the main role in heating is played not by the cable, but by thermal (infrared film) . The difference is that the film is laid on top of the screed, and not filled with it, as is the case with cables and thermal mats.

Let's consider the most popular options with conventional cables and thermal mats and a concrete base.

Installation of thermomat

Installation of Thermo Thermomat

The process of installing heating mats with your own hands is much simpler than cables, since the wire is fixed to the sheet:

- Draw a diagram of the location of the mat on paper; we must remember that they are not placed under heavy furniture.

- The power of the heating device and the amount of material required are calculated - this is done by analogy with cable floors, taking into account the usable area.

- A place on the wall for the temperature sensor is determined, a recess is made for it, as well as grooves from this area to the sensor.

- The base is prepared - it is leveled and cleared of debris. Then it is covered with a primer - this will improve the adhesion of the floor to the solution.

- The sensor is installed - placed in a corrugated pipe and placed at a distance of at least 50 cm from the wall. It should be placed between the floor turns.

- Mats are laid - they are laid directly on the subfloor to avoid overheating; additional insulation is not necessary. The product is equipped with adhesive tape, so no fasteners are required. Mats should not overlap each other. If you need to trim the fabric, you need to be careful not to damage the electrical wire.

- The connection is made and the system is checked - the resistance of the cable in the mats is checked with a multimeter. The thermostat is installed, the floor and sensor wires are connected to it, after which it is connected to the power supply. A test run of the system is performed.

- The mats are poured with tile adhesive - a layer of 8 - 10 mm, and time is given for it to dry. The grooves are also sealed with this composition.

It is possible to lay mats in concrete or dry screed; this process is the same as when installing a heating cable (described above).

- The finishing coating is laid - when filling the mat with glue, it is often tiles.

Turn on the electrical system only after the glue has completely dried.

Thermal mats can be laid on an old base, similar to a heating cable.

Warm floor scheme

We would like to warn you once again - the electrical circuit of the system is made by an electrician!

He will also connect the system and conduct reinforced wiring lines from the distribution board.

You act as the brute physical force necessary for installation work. When drawing up the diagram, both the characteristics of the cable itself and the characteristics of the base and floor covering are taken into account .

Here is the required network voltage for individual rooms:

- bathroom and toilet – 150-180 W/sq.m;

- bedroom - from 110 to 140 W/sq.m4;

- corridor, kitchen and hallway – 130-160 W/sq.m;

- loggia or balcony – 180-220 W/sq.m;

Heating system control

The thermostat allows you to control the underfloor heating system

The temperature in a room heated with underfloor heating is regulated by a special device - a mechanical or electronic thermostat.

Indicators are read by sensors that monitor:

- air temperature (if the cable is the main heating element)

- temperature of the floor covering (if heating a nursery or bathroom)

The selected control type depends on:

- comfort of people in the room

- duration of operation of the heating system

- floor heating efficiency

- saving energy resources

The algorithm for maintaining a comfortable atmosphere in the room is such that the floor temperature on the thermostat must be set in the calculation: the required air temperature plus 5 degrees.

Modern control systems allow you to turn the heating system on and off at the appointed time, interact remotely and monitor indicators in different rooms.

Preparing the floor surface

Note that the work that we will perform is well described in two articles - “Leveling floors with a self-leveling mixture” and “Laying laminate flooring and the cost of work”, but there are slight differences.

Let us briefly describe the whole process.

- Standard removal of debris and dust using a construction vacuum cleaner.

- Primer treatment of the base.

- If there are large differences and unevenness, we perform leveling with a cement-sand screed. This is the most economical option. If you need to get the job done faster, use a self-leveling floor. In both cases, the thickness of the screed itself must be at least 4 cm.

- The thermostat is installed after laying the cables, so when preparing the base you only need to mark the location of its future location.

- Then you need to lay a layer of thermal insulation to minimize heat loss.

- After this, we mark the places where floor installation will not be necessary (locations of stationary furniture)

The distances from the walls to the cable must be at least 8 cm.

- We install fasteners if you use regular cables and not thermal mats.

Peculiarities

As a rule, heated floors under ceramic tiles are installed in rooms with high humidity, for example, in the kitchen, bathroom, saunas, and swimming pools. Thanks to heating, the floor covering in these rooms becomes comfortable and warm, even if you walk on it barefoot.

Floor tiles themselves are a material that is resistant to moisture and mechanical abrasion. Combined with heating, it becomes even more functional and in demand.

An electric floor heating system is one of the types of heated floors. There are also water heated floors, which are heated by water. This system is only suitable for private houses, since when used in an apartment building, there is a high probability of flooding of neighbors below, as well as interruptions in heating of neighboring apartments.

DIY cable laying

After completing all work on preparing the base, we proceed to the installation of heating cables or thermal mats.

Let us clarify: the option with heat cables is more labor-intensive; each cable will need to be installed separately and secured with fasteners.

One way or another, we double-check everything again according to the installation plan, clarify the details, order and step of installation. We carry out a standard cable resistance test.

We enter the resulting value into the warranty card. The difference should be no more than ± 10 percent of the value indicated on the cable label .

Safety requirements for operation

Before using electric floors, read the manufacturer's instructions included in the kit.

Basic safety requirements that apply to all types of electric floors:

- Do not shorten the heating element;

- It is necessary to take only a screed solution or tile adhesive intended for warm polos;

- Opening heat-shrinkable sleeves at the junction of the heating and installation parts of the floor is prohibited;

- Do not lay carpet on heating sections or place furniture without legs.

Laying process

Let us consider in detail the option with a two-core cable.

We begin laying the cable from the place where we will install the thermostat ; the coupling and cable are secured to the floor with fasteners or mounting tape.

The cable is laid using a so-called snake. Do not forget to ensure that the cables do not touch; we clearly measure each laying step on all segments.

The bending radius of the cable, where it is necessary, is made at least 5 cm . The end sleeve of the cable, like the connecting sleeve, must be completely covered with a tie.

Nothing particularly complicated, we clearly control the installation.

Installing a temperature sensor and thermostat

After laying the cable, we proceed to install the temperature sensor. The temperature sensor is located along the cable near the thermostat.

Before the final pouring, you need to make sure that the electric floor is working . You need to turn on the heated floor and leave it for a while.

The thermostat is installed only when three wires are connected to the junction box:

- heating cable supply wire;

- network wire;

- temperature sensor wire;

- pouring screed onto the cable system.

Layed floor cables must be photographed. The thickness of the final screed is at least 5 cm. When the screed is dry, you can begin laying the floor covering.

Advantages over other types

What are the general advantages of electric heating over other types?

- This is an ideal additional heating that will evenly heat any surface from tiles to laminate, and provide a pleasant, comfortable temperature in cold and damp weather.

Advantages of electric heating systems over convective ones - Its operation in an apartment building does not depend on central heating; it can be turned on at any time.

- Installation of such heating is simpler than water heating; you only need to correctly calculate the cable pitch to prevent cold zones. Modern industry produces ready-made cable mats, which do not require cable pitch calculations.

Typical electrical heating installation diagram - The layer of screed during installation is much thinner (minimum - 5 cm) than when laying water pipes; it does not raise the height of the floor in the premises too much. There are options that do not require screeds at all.

- Burst of pipes and flooding of neighboring premises are excluded.

- No special permit or design or approval is required for the installation of the system.

- If all installation norms and rules are followed, such heating can last up to 50 years.

Electric cable heating has many advantages. The main task during installation is to choose the option that is suitable for you in terms of energy consumption, installation method, and budget.

How to lay and connect an electric heated floor

[ads-mob-1][ads-pc-1]

Flaws

What are the disadvantages of this option?

- In the harsh climatic conditions of the middle zone, a warm floor cannot be the main source of heating in an apartment or house.

Types of heated floors and their descriptions - Only professionals can solve the issue of installation and connection of some types.

- Warm floors should be placed in open areas; furniture can reduce free heat transfer and cause overheating, which will lead to system failure.

- A heated floor is considered effective if it covers more than 70% of the entire heated area.

- When overheated, the entire system fails.

Cost of work

The exact cost of the work is difficult to calculate; a lot depends on the materials and the cost of installation work . So, we can only talk about the approximate cost - 2000-9000 per square meter, this is for the material.

For laying the cable you will pay 300-500 rubles per square meter, for installing a thermostat and other related devices, you will need to pay separately.

If we add up the prices for everything, then on average it will be 700-1300 rubles per square meter of area.

Example prices for some components

Thermostats:

- digital thermostat Nexans MILLITEMP CDFR-003 – 2500-2800 rubles;

- thermostat OCD-3 – 4000-4500 rubles;

- thermostat TR 510 (mechanical) – 1500-1800 rubles;

- thermostats for heated floors RTC 70.26 – 500-800 rubles;

- thermostat UTH-150 (invoice) - 1200-1500 rubles.

Warm floor:

- Teplolux floors 20TLOE2-170 (3.40 kW) – 10,000-12,000 rubles;

- Teplolux floors 20TLOE2-75 (1.40 kW) – 4000-6000 rubles;

- Teplolux floors 18TLOE2-38 (0.70 kW) – 2000-3000 rubles;

- floors Heating mat Thermo Thermomat TVK-130 – 4000-4500 rubles;

- Arnold Rak floors Heating mat FH-2107 120W 0.5×1.5m (0.75 sq.m.) – 1700-2200 rubles;

- floors Gulfstream heated floor set MGS2-75-0.5 – 2000-2400 rubles;

- floors Twin-core heating cable Nexans TXLP/2 – 4000-5000 rubles.