One of the most common materials for making stairs in a private home is concrete. A do-it-yourself concrete staircase to the second floor made of reinforced concrete has a number of advantages compared to other options:

One of the most common materials for making stairs in a private home is concrete. A do-it-yourself concrete staircase to the second floor made of reinforced concrete has a number of advantages compared to other options:

Despite all their attractiveness, concrete stairs have a number of disadvantages, which may make it impossible to install them in a particular home:

The platform is also reinforced with 2 meshes. When reinforcing the site, it is imperative to secure it to the load-bearing wall (Figure 5). If the design of the house does not allow the platform to be secured to the load-bearing wall, then an additional column should be made that will serve as support for the platform.

DIY concrete staircase. Formwork drawings and reinforcement of a monolithic staircase.

A staircase is an architectural structure used to move between floors. The staircase can be either internal (located inside the house) or external. In addition, the staircase is subject to such requirements as reliability, durability, safety, ease of use and aesthetic design. It is due to its durability and design qualities that concrete has become so widespread.

For convenience, the article is divided into sections:

- Advantages of concrete stairs;

- Calculations and drawings of stairs;

- Correct installation of formwork, formwork drawings for stairs;

- Monolithic staircase, reinforcement.

Advantages of concrete stairs.

Technological advantages. The concrete staircase is erected during the construction of the house, which facilitates further construction and the supply of materials.

Reliability during operation. A properly reinforced staircase has a long service life and does not require repairs. In addition, the reinforced concrete staircase will be an integral element of your house and will be securely connected to the foundation and floor slab, thereby strengthening the structure of the building.

Aesthetics and design. When working with concrete, it is possible to implement any of the customer’s ideas, from ordinary flight stairs to complex spiral ones. Wide selection of finishing materials.

Calculations and drawings of stairs.

Figure 1 – Dimensions of stair steps.

When designing a staircase, it is better to make all calculations on paper, but it is good if you make a working drawing of the structure. When making calculations, it is necessary to take into account the clean height of the floors, taking into account the finishing of the floors and stairs (Figure 2, 3).

Figure 2 – Landing drawing of a monolithic staircase.

Figure 3 - An example of landing the first step of a staircase, taking into account subsequent finishing.

Reinforcement of a monolithic staircase.

Reinforcement of the stairs is usually carried out using reinforcement with a diameter of 10 mm, this is done after the formwork has been placed. The reinforcement is cut to the length and width of the flight of stairs and tied into a mesh with a square of 150-200mm. A second mesh is knitted on top of it. The distance between the grids is 100 – 120 mm. The grids must be connected to the outlets that come from the base (floor) and from the floor slab (Figure 4). The outlets must be at least 400 mm long.

Figure 4 – Connection between a monolithic staircase and a slab.

The platform is also reinforced with 2 meshes. When reinforcing the site, it is imperative to secure it to the load-bearing wall (Figure 5). If the design of the house does not allow the platform to be secured to the load-bearing wall, then an additional column should be made that will serve as support for the platform.

Figure 5 – Additional securing of the landing.

After completing the reinforcement, it is necessary to raise the mesh above the formwork by 25 - 30 mm, thereby providing a protective layer for the reinforcement.

Correct installation of formwork, formwork drawings.

Figure 6 – Formwork for straight stairs.

Figure 7 – Staircase with two flights. Ceiling height - 2800 mm, step length - 300 mm, step height - 165 mm, number of steps = 2800 / 165 = 17 pcs.

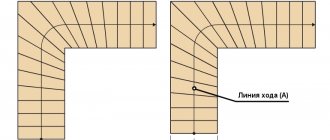

A flat staircase with a spiral bend for climbing.

It differs from the previous one in that it does not have a platform (Figure 8). This design is less convenient when moving furniture, but has a more attractive design. More suitable for a private home, as it takes up less space and allows you to maximize the usable area.

Figure 8 – Semi-spiral staircases.

When installing the formwork, the first step is to install the panels (bases) of straight flights of stairs, to which the base for turning, assembled with thin plywood 8 - 10 mm, is attached. After assembling the base of the staircase, it is reinforced. To tie the meshes, you should use long rods of reinforcement along the entire length, without interrupting them at the point where the stairs turn. Then the sides for the steps are installed.

Stairs with rounded steps.

Rounded steps can be made on any staircase, but they look more beautiful on a staircase with a wide step or entrance. If the width of the staircase is small, a plywood template is made under the step, according to which the thinner (6 mm thick) plywood of the step is bent. The plywood is screwed together with screws (Figure 9). The reinforcement of such a staircase does not differ from the standard one. Concrete is poured into specially left technical holes.

Figure 9 – Assembling formwork for a monolithic staircase.

Figure 10 – Entrance group with rounded steps.

The entrance group with wide steps is made without a top cover. For steps you can use an inch board. The main thing is to clearly maintain the radius and fasten the steps together. (Figure 10) If the entrance group rests on columns, then additional reinforcement must be laid between the supports.

Spiral staircase.

The most difficult design to install. Due to the rounding of the steps, such a staircase takes up the most usable space, about 9.5 square meters. More suitable as an interior decoration in a large hall or as an external staircase. A spiral staircase is attached only to the floor and ceiling and has no additional supports. When reinforcing, the reinforcement must not be allowed to break. Recently, special iron formwork has been used for spiral staircases (Figure 11, 12).

Figure 11 – Assembly of a spiral staircase.

Figure 12 – Concrete staircase after finishing.

Pouring concrete.

Concrete for pouring stairs can be prepared on site (by yourself) or ordered ready-made. Often, to facilitate work on the second floor, the stairs are poured immediately along with the floor slab. The staircase must be poured in one stage, starting from the bottom level and going up. It is desirable that the concrete is thick and does not slip. A vibrator is used to compact the concrete (it must be used carefully so that the concrete does not slide down). After pouring, the steps must be carefully smoothed with a trowel. (Figure 13).

Figure 13 – Pouring the stairs.

A monolithic staircase, like any concrete structure, requires maintenance (spillage with water) in the first days after pouring. The formwork from the steps can be removed after 3 days; the formwork can be completely disassembled no earlier than 2 weeks after pouring.

Do you have any questions?

You can ask your personal manager by calling:

The main advantage of welding is the speed of action; with welding you can perform a larger amount of work than with a bundle.

- Concrete stairs

- Wooden

- Frame

- Forged

- Cast iron

- Glass

How to make a concrete staircase to the second floor with your own hands

- Manufacturing of formwork

- Installation of formwork

- Reinforcement

- Pouring concrete

- Finishing concrete stairs

- tree

- Porcelain tiles

How to make a concrete staircase to the second floor of a private house

Manufacturing of formwork

Installation of formwork

ADVICE! Before directly filling the formwork with concrete, it should be moistened generously with water to expand and compact the boards, which will also provide additional tightness.

Reinforcement

Reinforcement is a method of increasing the strength of a supporting structure using reinforcement or reinforced mesh.

Before you begin to reinforce the formwork, you need to check the quality of the reinforcement. The first thing you should pay attention to is rust, if the reinforcement is slightly covered with rust in places, it can be used for reinforcement, but if, when exposed to a hard metal brush, the shape is at least slightly deformed, then such reinforcement is not recommended.

Next we need to make a frame from reinforcement. To create a frame, you need to lay reinforcement along the formwork and connect it with transverse reinforcement. It is advisable to lay out 2-3 reinforcement cages at a distance of 50-100 mm. from each other. The cells between the reinforcement should be +-100 mm.

Reinforcement with reinforcement can be divided into 2 types: 1. Viscous 2. Welding

Viscous For this type of reinforcement, we will need pre-cut 25-35 mm. and steel wire folded in two layers with a diameter of 1 mm. Next, we connect each joint as shown in the figure.

Welding The weld itself is very fragile, which means that at the slightest bend it can be damaged, for example, by vibration of the solution or by the pressure on the reinforcement that the solution creates during pouring.

To ensure a better quality construction, we recommend using reinforcement with index C (only for this type of reinforcement).

The main advantage of welding is the speed of action; with welding you can perform a larger amount of work than with a bundle.

Pouring concrete

Secondly, you need to prepare: cement 1 part (preferably brand M400), sand 2 parts, crushed stone 1.5 parts, water 1 part. Next, we begin mixing the solution, as a rule, the “ingredients” are added and mixed in the following sequence: water - cement - sand - crushed stone, if you feel that the solution is too “dry”, you need to gradually add water.

When the solution is ready, you can start pouring it. Concrete stairs are poured from top to bottom. Afterwards, the solution is compacted tightly and thereby the air is released. Once the solution is poured and compacted, it must be leveled using a trowel. When everything is ready, it is advisable to cover the future staircase with plastic film so that the concrete gains the necessary strength. The time for complete hardening of concrete is 28 days.

- cement grade PC 400 – 10 parts;

- sifted construction sand – 20 hours;

- crushed stone, fractions 10-20 mm – 30 hours;

- filtered water – 7 hours;

- plasticizer S-3 - in some instructions, liquid soap can be used instead - 0.1 part.

Varieties

The design can be monolithic or combined.

1. Concrete monolithic stairs are installed in any part of the house through simple installation - these can be both interfloor and, for example, stairs to the basement, to the porch and others.

2. Combined ones are a mixture of concrete and a metal frame of increased complexity, as well as more varied shapes. Such a concrete staircase is suitable for construction to the second floor and will serve as a real decoration for a private home.

There are options when only stringers are made of concrete - supporting structures on which wooden or concrete steps are subsequently erected. They are cast in a special formwork using reinforcing material, crushed stone, granite and marble chips. After hardening they are polished.

Selection of type and sizes

The appearance of a concrete staircase depends on the built-in space and the imagination of the developer. The more intricate the design has to be made, the more difficult the installation will be.

1. Direct march structures are most often in demand; for convenience, they can be equipped with a platform. But if there is not enough space in the room, then a staircase with winder steps is installed, where in the turning area there will be irregularly shaped steps instead of a landing. Thanks to its original appearance, it will not only save useful space, but will also fit perfectly into any room design.

2. Separately, it is worth noting the exquisite spiral and curvilinear (patterned) concrete staircases, which can be built into every space, but they will have a rather high price.

3. The first stage is taking measurements and developing a drawing of the concrete structure. It is worth first of all taking into account the possibility of installing a march, fences, handrails and other important details. This issue is especially relevant in private homes with small children and elderly people.

4. When calculating dimensions, you need to know the height of the span between floors. The required width is usually 80-90 cm. The angle of inclination is taken into account, which for a concrete interfloor staircase is from 25 to 45°.

The dependence of the span length on the angle of inclination based on a ceiling height of 3 m is:

- 25° – 6.3 m;

- 35° – 4,3;

- 45° – 3.

The height and depth of the steps are calculated based on the average step length of an adult 60-64 cm. The calculation is made using the formula:

64 cm, where H is the height of the steps, L is the depth.

The optimal height of a concrete step varies between 15-17 cm, excluding finishing, the depth is 28-30 cm.

If in the end the number of steps exceeds 14, it is recommended to install two spans.

5. In a situation with a winder staircase, carrying out an accurate design yourself is quite a labor-intensive task, so you should entrust this process to professionals.

The concrete solution must have the necessary characteristics, because the level of reliability, safety and strength of the staircase structure in the house depends on this. The strength class must be at least B-15.

Finish lining

A DIY concrete staircase can have different finishing options: wood, laminate, tiles, carpet, acrylic stone or porcelain stoneware. Any material must be laid on a level base. After dismantling the formwork, uneven areas may remain on the site, which are recommended to be removed by sanding and plastering. The end parts are usually finished with plaster and painted. After this, the steps are covered with one of the materials.

The surface can be covered with tiles, artificial or natural stone with a rough surface. The material is laid on cement mortar or tile adhesive. Using the same technology, mosaics are laid, creating original compositions from small elements.

Photo instructions for installing clinker steps

The finishing can be done with wood panels that are resistant to abrasion. For this purpose, larch and exotic species that have undergone antiseptic treatment are selected.

Installation of larch wood cladding

An excellent treatment option is laminate, which is abrasion-resistant, easy to install and durable.

Installation of special stair laminate

If children or elderly people live in the house, then you can choose carpet, available in different colors.

The final stage is finishing with carpet

To save money, you can simply paint the steps with high-quality concrete paint.

Painting is a cheap but interesting option

In any case, the appearance of the staircase is associated with the taste preferences and financial capabilities of the owner.

Installation stages and features

Accurate calculations and professional design allow you to create a reliable staircase design with your own hands. It is also very important to use high quality materials that will ensure reliability.

In this case, preliminary calculation of all design parameters, correct installation technology, quality of materials and compliance with the requirements for the staircase structure are important.

Any type of concrete stairs requires the construction of formwork. With your own hands it’s enough to simply create a primitive version of the staircase that does not have complex turns and protrusions. In other cases, it is best to entrust the complex of work to professional craftsmen. In any case, the optimal solution for creating formwork is plywood, which is 20 mm thick and water-resistant. The following items and materials will also be required for the work:

- Edged board, the thickness of which is 30 mm;

- Wood beams 100×100 mm;

- Thin plywood for patterns;

- Self-tapping screws intended for wood and having a diameter of 3.5 mm;

- Metal rods with a diameter of 15 mm for reinforcement.

The ground screed is designed so that the weight of the monolith does not exert a pressure on it exceeding 1 kg/cm². The weight of the finishing material is also taken into account; if the load exceeds the permissible standards, then it makes sense to finish it with lumber.

Principles of reinforcement of concrete stairs and construction diagram

Structurally, a flight of stairs is a self-supporting structure. Additional support is necessary only when the march turns more than 180 degrees. In other cases, load compensation is needed in the form of constructing columns or fastening to walls.

The base loads fall on the reinforcement, so its amount is about 2-3% of the cross section along the entire length of the span. They mainly use ST-5 rods, which are laid along the march in increments:

- With a rod cross section of 10 mm – 120 mm.

- With a rod diameter of 12-14 mm – 160 mm.

- With a reinforcement cross section of 16 mm – 180 mm.

- With a diameter of more than 18 mm - 200 mm.

In the lateral projection, the frame is assembled in increments of 220-300 mm. Platforms need to be reinforced in increments of 200 mm in all directions. Fixing the reinforcement to the embedded units aims not only to provide additional support, but also to prevent cracking of the monolith during shrinkage. However, any drawing of a monolithic interfloor staircase must take into account its rigid attachment to the ceiling. For this purpose, embedded rods are produced at 70-80 mm.

Metal rods form a mesh, laid without clearance and placed on special clamps, which install a layer of concrete 30-50 mm from the edge of the formwork. Typically, two rows of mesh are sufficient for spans of up to 18 steps; as the length increases, a third row of longitudinal rods is installed. They are placed longitudinally and 50 mm above the main mesh.

The mesh frame at the intersections of the rods is tied with steel wire or nylon clamps. For those who know how to reinforce a strip foundation , the procedure is not particularly difficult. It is desirable that the reinforcement be continuous along the entire length of the structure. But this is not always feasible, so there are tolerances when merging embedded components:

- overlap knitting in 24 nominal sections;

- with an overlap of 12 diameters, welding with a one-sided seam is allowed;

- An overlap of 6 diameters can be fixed with a double-sided weld.

Important! There is no need to reinforce the steps, however, to prevent chipping, it is recommended to lay a 4x50 mm metal mesh under the concrete layer.

Formwork organization

To work, you will need moisture-resistant plywood or OSB, from which a gutter with vertical walls is assembled. The latter are fixed together with strips, one per step. Adjacent walls can act as walls. Further actions are performed in the following order:

- On the inside of the walls, mark the height of the load-bearing surface of the span, which, according to the reinforcement drawing for a monolithic reinforced concrete staircase, corresponds to the thickness of the reinforcement frame and the protective layer of concrete.

- Use a ruler to mark the vertical boundaries of the steps. On a radius march, a cord of a certain length is used for this. According to Pythagoras' law, the length of an inclined segment is determined from the square root of the sum of the squares of the length and height of the steps.

- Draw vertical lines along the marks made to indicate the height of the steps.

- Install the vertical formwork of the steps according to the marks, attaching them to the walls of the gutter. Adjacent boards are secured with spacer wedges, one for every 800 mm of span width.

- The formwork must be supported from below with racks, their number is one for every 1.2 square meters of the ramp plane. To securely fix them, transverse bars are screwed to the bottom of the formwork from the outside.

It is necessary to draw a detailed project and carry out all the calculations. If a simple type of structure is selected, which will be located between two walls, then the drawings can be applied directly to the walls. The project takes into account the dimensions and installation locations of railings or other fences.

Choice of design and types of stairs

It is necessary to draw a detailed project and carry out all the calculations. If a simple type of structure is selected, which will be located between two walls, then the drawings can be applied directly to the walls. The project takes into account the dimensions and installation locations of railings or other fences.

According to building codes, the width of the stairs must be at least 80 cm. The standard height of steps is 17 cm, width is 30 cm, so that the step is comfortable. When calculating the height, you need to take into account the future height of the finishing coating (the entire pie) of the floor.

The angle of inclination of the stairs to the second floor is selected in the range from 30° to 45°. 30° is considered the best option, since going up and down it will be as comfortable as possible. An angle of 45° is made when it is necessary to save space, for example, in a small private house. It is not recommended to build it even steeper, as it will become unsafe.

You can pour a staircase for a private house yourself during its construction or buy a prefabricated one. The latter option is delivered ready-made to the construction site and assembled on site. It can also be made from combined materials: the stringer is made of metal, and the steps are made of concrete.

According to the type of staircase design, there are the following:

- outsiders;

- screw;

- with straight march;

- two-flight with a platform.

Straight one-march is the simplest type. Connects the first and second floors without bends, just straight. Screw ones are installed if the house has a small area. Winder stairs are structures that have winder steps and one or more turns (bends). They are also installed when it is necessary to save space, since they do not require arrangement of the site.

This is a minimum set of accessories that will help you carry out the measurement process efficiently and quickly.

Video description

This video clearly shows how to install formwork for a concrete staircase:

Formwork is done in several steps:

- First, prepare the boards. To ensure a smooth concrete surface, the inner sides of the formwork are ground.

- The base is assembled and supports are installed from below so that the formwork for the steps does not fall.

- Then they put up fences on the sides, which are reinforced on the outside with boards.

- Reinforcement is placed inside.

- Mount the risers by securing them to the sides of the formwork or to the wall.

- They check whether the formwork for the stairs is assembled correctly, whether all supports are in place, and whether the calculations are correct. The staircase itself will be the same size as the formwork.

Formwork and reinforcement

Metal staircase on stringers

After all, the design must fit the parameters of the space allocated for the stairs. A ladder on metal stringers will help even inexperienced craftsmen complete the installation task.

The main thing is to correctly make drawings of the stairs with a mark of the place where the gangway will be located. And also have on hand the tools and materials necessary to implement this idea in your own home.

Advantages

Due to the fact that gangways equipped with stringers have earned their vocation, the positive aspects of this solution are obvious:

- This makes the work process easier;

- Allows you to easily organize the order of actions;

- Such structures are strong and durable;

- Thanks to stringers, even an inexperienced specialist or just a home owner will be able to realize his plans and make them a reality;

- This element allows you to devote more time to details and design experiments that will decorate the staircase project to the second floor.

These are not all the positive aspects of staircases on stringers; each owner of a private house finds his own independent advantages.

Flaws

It is necessary to correctly determine the size of the base for the steps so that the structure fits clearly into the interior. It is not difficult to make such calculations. Simply measure the height, angle and width of the required installation.

The procedure for filling the formwork:

On-line calculator

| Name of material | Unit | Quantity | price, rub. |

| Formwork | PC | 1 | |

| Armature | mp | ||

| Concrete | m3 | ||

| Hardware and consumables | PC | 1 | |

| Fare | PC | 1 | |

| Operation of machines and mechanisms | PC | 1 | |

| TOTAL price of materials | |||

| TOTAL price of work | |||

| TOTAL price of work and materials | |||

Discount on stairs less than RUB 105,000.

does not apply. * From the clean floor of the 1st floor to the clean floor of the 2nd floor. ** The width of a trapezoidal flight of stairs is taken as the arithmetic mean. *** The pump is rented for a shift (up to 7 hours); it is possible to fill 1, 2, 3 stairs at one site. Make a copy by clicking the (PrtScr) button and receive a full staircase estimate by sending a scan in the feedback form.

Get a full estimate

Types of staircase structures

The main division is into entrance (front) and high-rise. In the first case, they are used to simply get into the house, and high-rise ones are used for direct access to the second floor or to the cellar (basement). Each of them, in turn, has its own varieties and forms.

Even a standard concrete staircase in a private house can be of any geometric shape: usually rectangular, but there is no difficulty in creating rounded, multifaceted or combined structures, the choice of which depends on the overall design of the building.

Depending on the height to which you need to ascend or descend, the second type of staircases is divided into single-flight and rotary, with two or more landings. A separate category are rotary semicircular or screw varieties. If you are making a concrete staircase to the second floor with your own hands, then you must take into account the need for an exit platform. The only exception is if there is already a terrace on the top floor, to which the upper flight of stairs will be adjacent.

Various types of structures in the following video:

This option will fit well into any interior; it requires careful selection of dimensions during installation. It is relatively inexpensive, but you will have to tinker with it when installing it.

SNiPs, GOSTs, SP.

Any of these SNiPs and GOSTs will provide you with invaluable assistance in quality control and pouring of a monolithic concrete staircase.

- GOST 9818-2015 Reinforced concrete flights and landings of stairs. General technical conditions

- GOST 9818-2015 Reinforced concrete flights and landings of stairs. Are common

- SP15.13330.2012 Design of stone and reinforced masonry structures.

- SNiP 52-01-2003 Concrete and reinforced concrete structures.

- SP 63.13330.2012 Concrete and reinforced concrete structures Updated edition.

- SNiP 2.03.01-84 Manual on the design of reinforced concrete structures

- SP 52-101-2003 “Concrete and reinforced concrete structures without prestressing reinforcement”

Any of these regulations will become an indispensable guide to pouring a concrete foundation.

All the best and solid support under your feet!

The materials on this site are for informational purposes only and do not constitute a public offer as defined by the provisions of Article 437 of the Civil Code of the Russian Federation.