The choice of technology for building a future home should be taken as seriously as possible. It is necessary to take into account such factors as cost, speed of construction, technical feasibility and much more. If you haven't decided yet. look at the technology of permanent formwork “Technoblock”.

Durable construction requires certain knowledge and skills. In the modern world, a lot of technologies have appeared that make life easier. This technology is permanent formwork (decorative cladding). It has become popular due to its durability and practicality. This formwork is available to all categories of developers.

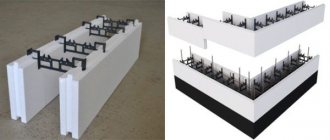

Fixed formwork technoblock

What is permanent formwork and where is it used?

Formwork is individual elements in the form of slabs or blocks, assembled into a single frame structure, which acts as a form for laying a monolithic reinforced concrete sheet.

Two types of formwork are used in construction: removable (this structure is disassembled after the concrete has completely hardened) and permanent .

Fixed formwork has two main differences:

- As the name implies, it is not removed after the concrete solution has hardened.

- A similar frame for pouring concrete is made using insulation (most often polystyrene foam). Thanks to this design, houses under construction receive additional insulation even at the stage of wall construction.

An example of the use of facing (decorative) formwork in construction Source keodom.ru

The technology of permanent formwork is universal , suitable for both private and multi-storey construction.

In the construction process, the use of a permanent frame is used:

- during the construction of the foundation;

- during the construction of the walls of the building;

- when carrying out certain types of finishing work.

Currently, this design allows concrete to be poured into a wide variety of shapes and designs. Permanent formwork is used for the foundation, construction of arches and columns. And the presence of insulation in the frame increases the thermal insulation of monolithic concrete walls and makes it possible not to carry out insulation during finishing work.

Choosing a foundation when using facing permanent formwork

Foundation for permanent formwork

Particular attention should be paid to the choice of foundation. This is a very important stage in construction. A big plus is the fact that such work can be carried out at sub-zero temperatures. Naturally, it is very important that the work happens faster and after pouring the foundation, you can proceed to the next steps. Such as installation of further construction. Any type of foundation, made taking into account all the technological requirements of the region, is suitable for permanent formwork.

Types of material for the frame

Today, there are several types of permanent formwork, each of which has its own fundamental assembly features and functional characteristics.

Here are the types that are most popular for country house construction:

- Expanded polystyrene formwork is assembled from two parallel foam boards, the rows are superimposed on each other and fastened together using tenons and grooves located along the edges of the panels. Additional strength of the structure is provided by iron reinforcement installed inside the structure. Currently, permanent formwork for foundations made of polystyrene foam is most often used; its price is usually low, which adds to its popularity.

Expanded polystyrene formwork Source spokostromskoe.ru

- Facing (decorative) formwork . Special prefabricated modules consisting of facade cladding plates, inside of which insulation and fittings are laid. Such a frame requires neither insulation nor finishing.

Decorative formwork Source stroyrom.ru

- Wood concrete formwork involves the use of wood concrete slabs (panels consisting of wood chips mixed with concrete mortar) for the frame. This design has higher thermal insulation rates than a polystyrene frame, but the price of such formwork is very high, so it is used less often than others.

Construction of a house using permanent wood concrete formwork technology Source opalubka-stroy-spb.ru

See also: Catalog of companies that specialize in the construction of country houses.

Step-by-step construction instructions

Foundation slab

The foundation slab has already been made at the site, but before starting work you need to carefully check its horizontalness. If there are abnormal deviations, they must be eliminated during installation of the first row of formwork. It is necessary to take height measurements and accurately determine the location of problem areas.

Measuring heights, checking horizontality

Step 1

. Start work from the corner of the building, place the first two blocks, connect them with a lock.

Laying starts from the corner

Apply a layer of special polystyrene glue to the studded surface; you can use cheaper polyurethane foam. Adjust the amount of foam so that, after hardening and increasing in volume, it does not reduce the clearance of the internal chambers of the permanent formwork.

Application of polyurethane foam

Important. Do not glue the first row of blocks to the foundation; this operation is done over time. The fact is that the assembled structure will need to be slightly shifted in one direction or another according to the working drawings of the building project.

Second row of blocks

Further laying on the corners, third row

Step 2

. Make technological cutouts for pre-installed utility connections. If they are not there, then carefully study the installation drawings of the project and make such holes when installing the blocks.

When laying formwork, trim the height of some blocks to accurately level the plane horizontally. You have data on differences after preliminary measurements have been taken. It is recommended to cut the blocks with an ordinary hacksaw with fine teeth. To make making shaped holes easier, use a tool with a narrow blade.

If necessary, polystyrene foam is cut with a hacksaw with a narrow blade

When assembling the formwork, you need to use three types of blocks:

- privates;

- end;

- corner.

Types of blocks

The first ones are used for installing main walls, they are laid with an overlap of half a block, and have locks on both sides that do not allow lateral movement. The latter are required when creating window and door openings; they have one flat wall. Still others (corner) are left or right and are mounted in the corners of the walls.

Block laying

Linings are used to level the rows

The blocks must be installed in such a way as to prevent the free fall of concrete from a great height; the mass can damage their walls. It is recommended to move the jumpers; due to this, large volumes of solution are crushed, and the kinetic energy of the fall due to the reduction in weight is greatly reduced.

Block joints should not match

Correct concrete pouring scheme

What does block masonry look like, top view

Step 3

. Install and secure special scaffolding. This should be done when the wall height reaches approximately one meter. Scaffolding is a home-made device designed to accurately install formwork and prevent it from moving during further installation or pouring concrete.

Scaffold

The device consists of several separate elements that allow adjustment in three planes and then fix the selected position.

- Vertical support bar. It is attached to the wall and gives it stability.

- Horizontal. It has a special metal ear, with which it is firmly attached to the foundation. Dowels of appropriate sizes are used for fixation.

Horizontal part

Fixing the racks - Horizontal support for decking. Boards for workers are installed on it.

All elements are connected to each other by corners; they are welded in such a way as not to restrict the movement of parts.

Elements are connected by corners

The displacement is done by threaded rods with adjustable ties. By twisting/unscrewing it, you change the angles of the vertical stand.

Adjustable tie

When the required parameters are achieved, the device is attached with a wooden plank on the inside of the blocks. The racks should be located at a distance of approximately 3 m, while at the locations of the doorways they should be placed at each end. The use of adjustable scaffolding completely eliminates the possibility of the assembled formwork moving during further construction work.

Scaffolding to prevent the formwork from moving

Continuation of masonry

Plaque installation

Fixation with polyurethane foam

Appearance of masonry

Connection of rack and masonry blocks

Step 4

. Continue working according to the described algorithm. If a large load on the walls is expected or the building is located in regions with a high risk of earthquakes, then reinforcement must be done. The rods are inserted into the holes of the blocks before pouring concrete and significantly increase the ability of the walls to resist static and dynamic multidirectional loads.

For reinforcement, technological holes are provided on the blocks; they are located in the upper part of the lintels. Each row is connected or through one; the specific solution is indicated in the building design and calculated by specialists.

Step 5

. A cut must be made where the sewer pipes exit the block. The pipe is lubricated with plumbing grease and connected, and the cut hole is foamed and a piece of polystyrene foam is inserted.

Engineering hole and pipe installation

The next check of the correct position of the assembled formwork should be done when the height reaches approximately 1.5 m. First, the location of the corners of the structure is controlled, then a rope is pulled between them and the wall lines are aligned. If all dimensions exactly correspond to the design data, then firmly attach the devices to the foundation. Make sure that the position does not shift; if problems are found, the alignment work must be repeated.

It is mandatory to fasten structures; permanent polystyrene foam formwork weighs so little that even moderate gusts of wind can move the assembled structures. In addition, accidental impacts may occur as people move around the construction site.

Step 6

. Install wooden decks on the posts and seal the seams and cracks between the foundation and the first row of blocks. This will prevent concrete from leaking during pouring.

Practical advice. If you made a mistake in calculating the number of end blocks, then they can be made from ordinary ordinary ones. To do this, you need to insert any material of appropriate size with a flat surface from the inside and secure it with polyurethane foam.

Step 7

. When the design height of the openings is reached, install lintels. They can be made from pre-glued wall elements. In order for them to withstand the weight of liquid concrete, a formwork stand should be placed in the lower part; they are precisely adjusted in height with screws. Remember that all lintels must be reinforced; these structural elements, despite their relatively small dimensions, must withstand significant loads.

Installation of jumpers

Support for lintels

Appearance of assembled formwork

Step 8

. Continue installing the formwork until the last row. Next, it is imperative to reinforce it with horizontal bars made of periodic profile construction steel. The number of rods is at least two.

Step 9

. Secure the single outer halves to the ends of the row. These elements must be cut out from whole blocks.

Fastening the halves in the uppermost row

Now everything is ready for concreting the frame.

Advantages and disadvantages of technology

Using permanent formwork technology in construction allows you to get a lot of advantages:

- Speeding up the construction process . Assembling the formwork does not take much time, which means the overall construction time of the walls is reduced.

- Possibility of monolithic construction at air temperatures below zero . Concrete can be poured into a frame with insulation at temperatures down to -10 C, while conventional concrete work at subzero temperatures is impossible.

- Reducing the total weight of the building leads to the opportunity to reduce the cost of the foundation (use a lighter foundation for construction).

- The absence of the need to use heavy construction equipment significantly simplifies and reduces the cost of construction.

- Improving the sound and thermal insulation of a building .

- Increasing the service life of a monolithic structure.

- Facilitation of finishing work.

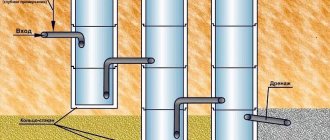

- Possibility of hidden installation of utilities . All communications can be built into the frame and brought out in the required places through special holes in the formwork.

- Absence of biological and natural threats (buildings do not rot, do not become moldy, and are unattractive to rodents and insects).

The most serious shortcomings in most cases are:

- The need for interior and exterior finishing (with the exception of formwork made from cladding panels).

- Poor vapor permeability of the insulation , so houses require the installation of high-quality forced ventilation of the room.

- The need to ground the house due to iron reinforcement inside the walls.

House using permanent formwork technology based on an individual project Source transsib6.ru

Do-it-yourself permanent formwork

You can install the formwork yourself. The main thing is to choose the right material that is suitable for the specific foundation of the project. It is also important to purchase components for corners, transitions and mates. This may require qualified advice from a hardware store manager.

Installation procedure

- Before you begin installing the foundation blocks, you need to build a foundation for it. This is done by backfilling with a gravel cushion up to 15–20 centimeters thick. The layer must be carefully leveled and watered to compact it. For foundations for heavy buildings, preliminary concreting is carried out with a solution 10–12 centimeters thick.

If the foundation will bear heavy loads, a slab of lean concrete (with a reduced percentage of cement relative to sand and filler) is first poured onto the ground

- The second mandatory operation is waterproofing. The bulk layer is made of roofing material or polyethylene. After preliminary filling, you can use bitumen mastic.

Before installing the formwork, a waterproofing layer is laid at the bottom of the trench. It can be made from plastic film or roofing felt

- The bottom layer of the foundation is formed from blocks with bottoms. You need to start from the corner, carefully placing the block. Straightness control is carried out using a pre-tensioned cord between the corners.

Blocks of permanent formwork with bottoms are laid down, starting from the corner

- The second and subsequent layers are assembled from blocks with through openings.

Orienting these parts is not difficult, since the blocks are installed in the tongue and groove. The following rows are formed from end-to-end blocks and fit into the grooves of the elements of the previous level - The space between the formwork walls is reinforced with steel rods.

A reinforcing frame is installed inside the assembled formwork - To ensure high-quality filling, you need to complete its first part already at this stage. In this case, it is necessary to use a deep vibrator to avoid the formation of air pockets in the concrete mass. The “bayonet” method using a pin is not always effective.

The installation of further layers up to the design height level is carried out in a similar way.

Making blocks yourself

The easiest way is to make your own concrete-based permanent formwork blocks. The fillers in this case are wood chips or polystyrene foam balls in an amount of up to 70% by volume. Concrete is poured into collapsible metal forms. The final formation of the blocks is carried out on a vibrating table, then the products in the molds are placed under a canopy until they are completely ready. The process is lengthy, so the preparation of blocks begins in advance. The long hardening time is the main disadvantage of the procedure for self-manufacturing permanent formwork from concrete blocks.

Video: DIY production of concrete blocks for permanent formwork

The use of technology for casting foundations into permanent blocks can significantly increase labor productivity during their construction. This eliminates the need to perform other operations, in particular, installing insulation or waterproofing. As a result, the seemingly high costs are offset by the refusal of additional expensive work. In addition, carefully developed designs of formwork elements make it possible to obtain sufficient quality even when performed by unskilled builders.

- Author: Vitaly Kalugin

64 years old, retired, higher education, metallurgist engineer. Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Some features of the construction process

Construction of the foundation . Since houses with permanent formwork are relatively light in weight, they do not require a heavy foundation. Typically a tape-type base with a small recess is used.

A shallow strip foundation is the basis for a house in the form of a concrete strip buried 20-30 centimeters into the ground, which runs under the load-bearing walls and along the entire perimeter of the building.

However, the choice of foundation depends not only on the features of the structure being built, but also on the specific conditions of the area (soil quality, air humidity and many other factors).

When using permanent polystyrene foam formwork for the foundation, it is also worth considering the need for additional waterproofing of concrete, because polystyrene foam has high moisture absorption rates and does not protect the concrete inside the frame from the destructive effects of moisture.

Finishing work . Permanent formwork technology allows the use of any finishing materials, both inside and outside the house. You just need to remember that the temperature when performing work must be positive. Materials are applied directly to the surface of the frame.

One-story cottage using permanent formwork technology Source stroyka.radiomoon.ru

Features and technical characteristics of the Velox system

Velox is a leading Australian brand of permanent formwork made from wood chips (95%) and cement (5%).

Peculiarities:

- a unique system that allows you to build a house from the foundation to the roof, including floors and walls;

- liquid glass with additives that envelops wood chips makes the material resistant to environmental influences;

- construction time is minimal;

- there is no need for additional insulation;

- high sound insulation characteristics;

- environmentally friendly materials.

Specifications:

- average density no more than 800 kg/m3;

- humidity 22%.

- thickness swelling over 24 hours is no more than 1.15%;

- water absorption in 24 hours no more than 32%;

- specific resistance to pulling out screws is not less than 1.3 kgf/mm;

- bending strength of at least 1.8 MPa;

- thermal conductivity coefficient 0.11 W/m °C;

- specific effective activity of natural radionuclides is not more than 27 Bq/kg.

Prices for permanent formwork

When determining the cost, you need to take into account that permanent formwork is a prefabricated structure, which means that the costs of constructing a monolithic house or foundation will depend on the construction area. In addition, it is worth considering the type of frame used.

Prices for elements of permanent formwork made of polystyrene foam are presented in the table:

| Element type | Price |

| Wall block (main frame element) | From 300 rubles, depends on the thickness of polystyrene foam, the width and length of the element |

| Opening lintel element (lower base of the structure) | From 300 rubles |

| Corner block | From 250 rubles |

| End block | From 700 rubles |

| Additional structural elements (plugs, connections, fittings, clamps, etc.) | From 30 rubles |

Depending on the material from which the permanent formwork for the foundation was made, the price can vary significantly. For example, the cost for 1 m2 of polystyrene foam frame can reach 3 thousand rubles. Almost all companies that use a similar frame in the construction of houses offer services for calculating the cost based on the presented project of the future house.

Which profiled sheet to take for permanent formwork

To make permanent formwork, use only load-bearing corrugated sheets with a wave height of at least 60 mm and additional stiffening ribs. If you take a less embossed corrugated sheet, it will bend under the weight of the concrete pour and the ceiling will turn out to be uneven.

For permanent formwork, choose the following types of corrugated sheets (all these options are available in “Metal Profile”):

- N-60;

- N-75;

- N-114.

The number in the name of the profiled sheet brand means the wave height: 60, 75 or 114 mm. The letter “N” indicates that the corrugated sheet is load-bearing, i.e. it can withstand a lot of weight.

These grades of corrugated sheets are made from steel of increased thickness - from 0.5 to 1 mm. For formwork, choose a material with a thickness of 0.6 mm.

Design, types and their differences

The developers of permanent formwork Technoblock, Durisol, and Arbolita were able to come up with and implement a rather interesting concept for a prefabricated structure. Velox permanent formwork, like the others, consists of two sheets that form the edges of the supporting structure.

Inner sheet is usually cheaper and simpler. It is made of ordinary concrete, but of a cast system. That is, the profiled sheet is immediately ready for applying putty or a finishing layer of plaster . And this is a big plus, because you will be able to save on thoroughly leveling the walls, especially above the attic.

The outer profiled sheet, especially if we mean a facing model, consists of foam plastic slabs, which are then covered with a concrete slab made of “cast marble”. The peculiarity of the outer slab is its texture and the ability to select a specific texture of the profiled sheet.

Since the Arbolite formwork is already insulated, all you have to do is apply a layer of thin putty to the concrete, prime it, and then paint it.

Agree, if you compare the financial and time costs with conventional facade work, the advantage will clearly not be in their favor.

Moreover, this entire system is assembled in an elementary way. All slabs have pre-drilled holes for fasteners. If your model does not have holes drilled, then you will have to do it yourself.

Main types of formwork Technoblock

The fasteners themselves are also available. These are special screw L-shaped hooks.

Plastic spacers are attached to the hooks. The spacers are made using such technology that even their dimensions can be changed, and quite simply. With the help of plastic spacers you can change the final thickness of the future structure.

Using the same formwork you can create both a wall with a thickness of 50 mm and a load-bearing structure with a thickness of 250 mm.

Having understood the design of permanent formwork Technoblock, let’s turn to its popular varieties. Here are a few of them:

- Technoblock standard.

- Technoblock combi.

- Technoblock without insulation.

- The technoblock is removable.

Standard models are permanent structures insulated on both sides, which are used most often. They are used when it is necessary to create walls of plinths, foundations, powerful external load-bearing structures, etc.

The technoblock combi has insulation on only one side. Variations of finishes can be combined. For example, leave the finishing and insulation only on the outside, and install a regular enclosing concrete slab from the inside.

Models without insulation differ from standard ones only in its absence. They are often used for pouring columns, pool bowls, internal load-bearing walls or partitions.

Construction of walls from facing permanent formwork Technoblock

Well, removable systems consist of two durable plywood sheets. The corrugated sheets are mounted and fixed using a similar technology; only after the concrete has hardened, the plywood is removed . The spacers and screws are left inside the concrete structure, since they are consumable elements.

The convenience of Technoblock removable formwork lies in its practicality and readiness for work. You can assemble such a structure in a matter of minutes, while with homemade models you will have to seriously tinker. However, we note that such a system cannot be rented.

Reviews about Technoblock formwork

Now we recommend that you pay attention to reviews about permanent formwork of the Technoblock type. Reviews from customers always help to better understand the situation. After all, nothing gives such a clear picture as reviews from a person who has already used this product.

Valentin, 29 years old, Kharkov:

At work we were building a house using Technoblock formwork. We used standard models with external insulation. I can say that I have never seen anything more convenient in my life.

My colleagues and I calculated that by using this system we saved money on rent and about a week of time. And this is according to the most conservative estimates. If you are willing to pay more for such material, then take it without hesitation.

Anton, 42 years old, Penza:

I used Technoblock formwork to fill the outer walls of a large cottage. After work I had only pleasant impressions. However, I will note in advance that the internal slabs will have to be trimmed, and this is not so easy. Otherwise, the material and technology are thought out to the smallest detail. It is very convenient to work.

Kirill, 39 years old, Kamenka:

I was very pleased with this formwork. I have never seen anything more convenient in my life. Not only can you adjust the thickness of the walls and select insulation, but you can also change the facing panels the way you want.

Technoblock wins by a huge margin over all other models of factory formwork.

Formwork assembly process from the Technoblock company (video)

Advantages of technoblocks (decorative formwork)

Reusable formwork plates provide maximum economic effect during construction. They are required much less than facing ones. After such plates are removed, a smooth and even wall surface remains, ready for finishing. Such plates are used for the construction of partitions or internal walls. With their help, subfloors and ceilings are arranged.

Minslab is sometimes used as insulation instead of polystyrene foam. The technoblock is assembled from two formwork plates on a special stand. Next, the first row of Technoblocks is installed on the foundation. checking the horizontal and vertical installation using a building level. After installation, concrete is poured into the internal cavity of the Technoblocks. The next day, another row is installed and concrete is poured. Reinforcement, engineering communications, and embedded elements for technological holes are installed in the internal space of the formwork in the right places.

Reinforced panels (SOTA).

Reinforced panels are slabs made of polystyrene foam or other thermal insulation liner, equipped on both sides with steel reinforcing mesh. This structure is separated by a special wire route connecting welded reinforcing mesh. After installing the insulation panel and securing the mesh, several layers of special concrete are applied to the structure using a special installation. Such a wall is similar to a sandwich, consisting of concrete - polystyrene foam - concrete. It does not require additional polystyrene foam protection.

Figure 6 – Reinforced SOTA panel

Pros:

- High installation speed;

- Good heat and sound insulation;

- The internal and external walls of the building are concrete;

- Does not require additional finishing, only putty and painting.

Minuses:

- High price;

- Rare and expensive equipment;

- A wall made using this technology is not considered self-supporting; floor slabs cannot be supported on it.