Home / Electric boilers

Back

Published: 05/31/2019

Reading time: 3 min

1

9603

Using electricity for heating is a common way to heat a home. This method is environmentally friendly (no impact on the environment) and convenient.

The only factors limiting the spread of such heating are:

- Electricity tariffs and their growth in the future.

- Consumer expenses for supplying and connecting to housing the electrical power necessary to ensure comfort.

When the user decides on fuel for the boiler, he is limited in choice. There are no natural gas or district heating networks near his home, and there is no market for wood or agricultural waste.

Photo source: buildingwork.net

Then the electric boiler becomes the only alternative and the main source of heat. In bivalent heating systems it becomes a backup in combination with gas, solid/liquid fuel boilers or heat pumps.

- 1 Advantages and disadvantages of electric boilers

- 2 Electric boiler design

- 3 Operating principle 3.1 Boiler with heating element

- 3.2 Electrode boiler

- 3.3 Induction

Selection and features of an electric boiler

In the process of choosing an electric boiler, you need to be guided by what area needs heating, so the power of the electric boiler is selected depending on the area of the heated room, approximately 1 kW per 10 m² of a well-insulated house with a ceiling height of no more than 3 m.

The most popular are double-circuit devices with a power of 6-15 kW, and among household floor-standing electric boilers, most of which are used in the construction of cottages, the most popular are models whose power is 20-30 kW.

The operating principle of modern electric boilers is extremely simple: to heat the coolant, i.e. water, the principle of its ionization is used.

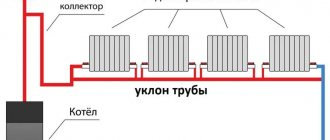

Electric water heater installation diagram.

The bottom line is that the energy of the electric current is directly transferred to the molecules of the coolant, as a result of which its temperature instantly increases. In turn, the heating device of the type in question very quickly reaches its rated power level. If the flow of water stops for any reason, the heating unit also immediately stops working. This reduces the risk of explosion, fire or thermal damage to the system. Boilers of the type in question have a collapsible design, which makes it possible to replace an old electrode, which for some reason no longer works, with a new one without any problems.

One of the most effective ways to reduce financial costs for heating when using an electric boiler is the principle of multi-tariff electricity metering. It is quite obvious that the need of users of various electrical appliances for electricity is constantly changing throughout the day. Thus, maximum consumption, when many different devices are operating, occurs in the periods from 08:00 to 11:00 and from 20:00 to 22:00, half-peak periods - from 07:00 to 08:00 and from 11:00 to 20 :00. It is precisely these time periods of the day that account for the bulk of the operation of household electrical appliances and the maximum industrial consumption of electrical energy. The minimum electricity consumption occurs at night, i.e. from 23:00 to 06:00. Therefore, it is advisable to use this electricity for domestic purposes, and specifically for heating with an electric boiler. This principle of energy distribution makes it possible to save up to 30% by maintaining optimal indoor air temperature throughout the day.

The principle of combined use of the “night” tariff when operating electrode boilers and other devices is very effective and economically justified. The use of such combined heating systems as: an electric boiler and a gas boiler, an electric boiler and a solid fuel boiler is widely practiced. This gives users the opportunity to minimize natural gas costs and ensure maximum ease of use of solid fuel boilers.

Calculation of power for the area of the house

We present a simplified calculation of power, since this issue is a topic for a separate article. Approximate calculation usually always gives results as close as possible to real needs.

If the electric boiler performs an auxiliary heating function in addition to the main gas or other unit, or fireplace, then for 120–150 m² a power of 3–6 kW will be sufficient.

Comparative table of average statistical electricity consumption by electric boilers

| Electrode | heating elements new | ||||

| Boiler power | Heating area, m² | Consumption, kW/hour | Boiler power | Heating area, m² | Consumption kW/hour |

| 3 kV 1 phase | 50 | 0.5–0.6 | 3 kV 1 phase | 30 | 1.5–1.8 |

| 5 kV 1 phase | 80 | 0.9–1.2 | 5 kV 1 phase | 50 | 2.0–2.5 |

| 9 kV 3-phase | 120 | 1.8–2.3 | 9 kV 3-phase | 90 | 3.6–4.2 |

| 25 kV 3-phase | 350 | 4.5–5.5 | 25 kV 3-phase | 240 | 9.5–11.0 |

If an energy-saving boiler is the main source of heat, then it is necessary to carry out calculations taking into account heat losses, which for an average private home with two-brick masonry and 2.7 m ceilings in the climate of the Moscow region is 1 kW/hour. It is recommended to select power with a margin of 10–20%, and for heating element heaters - by 20–30%, since their efficiency decreases due to scale. For 80 m² you will need an electric boiler of 9.6–10 kW (8 kW + 20%).

For SAV boilers, a power of 2.5 kW is 2100 kcal/hour, which is enough to heat 25–30 m². The calculation is affected by the required temperature. If you need to maintain 15–20 degrees in a room of 120 m², then a 6 kW unit will suffice.

An economical ion-type electric heating boiler with a power of 3 kW is suitable for heating 50 m². The same product with a heating element will heat 30 m².

Installation of a manufactured boiler

Before installing the boiler, you need to choose the most suitable location for it. It should allow the following manipulations to be performed correctly and easily:

- Laying out the necessary heating system pipes.

- Convenient to connect.

- Control the work process.

- Maintain and carry out repair work as necessary.

To achieve this goal, it is necessary to first draw up a detailed diagram of the placement of the radiator and the layout of all pipes belonging to the heating system

In addition, it is very important to choose the best option for the location of the manufactured boiler. As a rule, such equipment is compact in size, so they can be placed on the ground floor of a residential building; many install it in the basement

Experts recommend mounting heating element boilers on the wall using special dowels. If we are talking about electrode boilers, they must be installed on the pipes of the heating system; they can also be secured to the wall using clamps. Due to their heavy weight, induction boilers are recommended to be mounted on the floor, strictly in a vertical position.

The process of connecting a self-made electric boiler is carried out strictly to a separate machine, which is located in the electrical panel and to the grounding circuit. The shield should be designed for the highest boiler power ratings, and it is advisable to entrust the quality check of the grounding circuit to a specialist.

It’s quite simple to make a high-quality electric boiler with your own hands and save money. All that is required is just to approach the process of assembling it as responsibly as possible.

The quality of the work performed is very important, since the boiler operation process is based on the circulation of water, which can leak if there are problems. This will automatically lead to serious waste of material resources.

A responsible approach to the construction of an electric boiler will ensure that it operates as long and efficiently as possible.

No. 3. Connection type

Before purchasing a boiler of a certain power, you need to find out the features of the electrical wiring in the house. Among boilers with a power of up to 10-12 kW, you can find models that can be connected to both single-phase (220 V) and three-phase networks (380 V). It will not be possible to use more powerful boilers with a single-phase network - you will need to connect the house to a three-phase network.

To connect the boiler to the panel, it is better to use a stranded copper wire, which, with higher conductivity, will heat up less.

Making an electrode boiler with your own hands

To assemble an ion boiler with your own hands you need: a pipe, an electrode, and hot metal.

If you have become familiar with the operating principle of ion boilers, as well as the features of their operation, and still want to make it yourself, then you will need:

- welding machine and skills to work with it;

- steel pipe of the required dimensions;

- electrode or group of electrodes;

- neutral wire and ground terminals;

- insulators for terminals and electrodes;

- coupling and metal tee

- desire and perseverance in achieving the ultimate goal.

Before you start assembling the boiler with your own hands, you should pay attention to several important points. Firstly, the boiler must be grounded

Secondly, the neutral wire from the socket is supplied exclusively to the outer pipe. And thirdly, the phase must be supplied exclusively to the electrode.

The technology for assembling a boiler with your own hands is quite simple. An electrode or a block of electrodes is inserted into a steel pipe with a length of about 250 mm and a diameter of 50-100 mm on one side using a tee. The coolant will enter or exit through the tee. The other side of the pipe is equipped with a coupling for connecting the heating pipe.

An insulator is placed between the tee and the electrode, which will also ensure the tightness of the boiler. The insulator is made of any suitable heat-resistant plastic. Since it is necessary to ensure tightness and at the same time the possibility of a threaded connection with a tee and an electrode, it is better to order an insulator from a turning workshop in order to withstand all structural dimensions.

A bolt is welded onto the boiler body, to which the neutral wire terminal and grounding are attached. It is possible to secure it with one more bolt. The entire structure can be hidden under a decorative coating, which will also serve as an additional guarantee against electric shocks. Restricting access to the boiler is the first and most important task to comply with safety regulations.

As you can see, assembling an electrode boiler with your own hands is an achievable goal for almost any person. The main thing is to know the principle of its operation and follow safety precautions. Warmth for your home!

Operating principle of electric boilers

Heating boiler wiring diagram.

An electric boiler can be connected anywhere, it works normally where there is power supply, it does not require purchasing and storing fuel or setting up a special room. It is enough just to connect to the electrical network and remove the pipeline. For many people, such boilers have become an indispensable assistant. Thanks to its compact size, the electrode boiler can be installed even in a very small room, while the modern design of the equipment will allow it to fit seamlessly into any interior. The basic package includes an expansion tank, a heating element, elements for regulating and controlling the operation of the heat generator.

The operating principle of the equipment is extremely simple: coolant is supplied to the expansion tank, which is heated by electricity and then distributed through radiators and pipes. Electric heating boilers are characterized by high efficiency, which often reaches 100%; ease of operation, affordable cost of units, silent operation, safety and environmental friendliness are also undeniable advantages of such heating equipment. Of course, in addition to the advantages, heating boilers powered by electricity also have certain disadvantages, which are largely associated with the domestic organization of the electrical system. It is imperative to remember about the cost of electricity, which is increasing all the time, about frequent interruptions in the supply of electricity, power surges, which negatively affect the functional part of the equipment and its service life.

Electric heating boilers are endowed with a stylish and modern design, ease of maintenance and stepwise power switching. The equipment can be connected in cascade to create a powerful installation. Electric boiler: advantages and disadvantages

Electric boiler design diagram.

Like any other equipment, an electric boiler has its advantages and disadvantages. Among the undeniable advantages, one can highlight, first of all, compactness. This equipment is really very compact and almost invisible in the overall design of the system. Such boilers are low in cost, have a smooth ramp up to rated power and, among other things, the peculiarity of their operation eliminates the possibility of an emergency in the event of a water leak. If water suddenly disappears from the system, the equipment simply will not work.

Among the disadvantages are the following points:

- the need for water treatment. The equipment will operate effectively only if certain values of water resistivity are ensured, which very often cannot be independently measured and brought into compliance with standards;

- ensuring optimal coolant circulation. If the circulation is weak, the water in the electric boiler may boil. If forced circulation is too fast, the equipment may not start;

- Non-freezing liquids cannot be used as a coolant.

Thus, having become familiar with the operating principle of an electric boiler, everyone will draw their own conclusions: whether to buy it or not.

Reviews

“I decided to heat my house with electricity, solid fuel is too much of a hassle, and there is no way to connect to gas. Electrode boilers seemed like a way out to me. Unfortunately, they only seemed so. It is necessary to constantly monitor the condition of the water in the system, which is an almost impossible task with constant electrolysis and corrosion. After suffering for a couple of years, I switched to a boiler that runs on solid fuel.” Andrey, Yaroslavl.

“I installed a dacha for heating, where, after retiring, I began to live all year round. My house is insulated, in a good location, not blown by all the winds, so my boiler does not work continuously. I turn on the electrode boiler as needed. Everything suits me. True, I have already cleaned the tank of scale. But nothing is perfect." Olga, Moscow.

“We installed it at a dacha, which is very far from the city. We heat in early spring and don’t live there in late autumn in winter. Everyone is happy. It’s a little expensive, of course, since we get electricity from a diesel generator, but it’s not much more expensive than firewood and coal, and there are a lot fewer problems.” Vitor, Kaluga.

“The old stove has completely collapsed, and I’m no longer able to constantly tinker with firewood and shovel out the ash. It’s too expensive to connect to gas, so we decided to switch to electric heating at home. We chose an electrode boiler. Not to say that we haven't taken care of heating since then. It is necessary to constantly monitor the condition of the water that has to be purified and where antifreeze needs to be added. However, this is still better than chopping wood and cleaning the ceiling from soot.” Ivan, Syzran.

“I read the manufacturers’ recommendations and decided to purchase such a boiler for my home. Installing a table is not expensive, operation also had its own nuances. And electricity is quite expensive, it burned up especially a lot in cold weather, even insulating all the walls of the house didn’t help much.” Arseny, Tver.

Advantages of electrode heating devices

The operation of an autonomous heat source allows you to control not only the microclimate and thermoregulation in the house, but also heat costs. At the same time, electrode boilers have a number of obvious advantages compared to heating elements and induction devices.

All water that enters the electric electrode boiler is heated almost instantly and in full. Due to the absence of uncontrolled inertia of heating the coolant, the design achieves a very high level of efficiency - up to 98%.

Constant contact of the electrodes with the coolant liquid does not lead to the formation of a layer of scale. And, accordingly, rapid failure of the heater. This is due to the fact that in the design of the device there is a constant change in polarity - alternating movement of ions in different directions at a speed of 50 times per second.

The principle of electrode heating of liquid makes it possible to reduce the volume of the heat generator several times compared to heating elements of similar power. Small size and light weight of the equipment are very advantageous features that characterize electrode boilers. Reviews from experienced users confirm the ease of use of household appliances, ease of installation and the possibility of their location in any room.

The presence of a digital adjustment unit on the external panel of the devices allows you to intelligently regulate the intensity of the boiler operation. Operation in a given mode helps save up to 40% of electrical energy in the house.

In case of depressurization of the system or water leakage, there is no fear of electric shock. Without coolant, there will be no current flow, so the boiler simply stops working.

The absence of sound vibrations ensures quiet operation.

The operating principle of an electrode boiler implies the complete absence of combustion products or other types of waste. There is also no need for a reserve of fuel resources.

Conclusion

Heating with electricity is unprofitable - only diesel fuel is more expensive. But if it is possible to implement a scheme with a heat accumulator, the energy resource's costs will reach the level of coal and will be comparable to natural gas (the difference will be 25%). This makes sense, especially when you consider the many benefits of electric heating. In any case, each user decides for himself whether to install an electric boiler or convectors as an alternative.

Design features

A double-circuit heating boiler has a simple design, although it performs the function of a mini-boiler room. Both of its circuits can work either individually or in pairs, heating the house and providing hot water at the same time. The equipment in question consists of the following components:

- heat exchanger;

- boiler;

- heating elements;

- expansion tank;

- circulation pump;

- air vent;

- safety valve;

- automation;

- control unit.

Electric double-circuit models differ from single-circuit models by the presence of a built-in boiler in the design.

In appearance and main design features, electric boiler models can be:

- wall-mounted – compact and relatively light;

- floor-mounted – massive, with a high power rating (more than 60 kW).

As the name implies, heating equipment of the first group is mounted on walls or on specially installed metal frames. The second group of boilers is placed directly on the floor in a specially designated area. It should be noted that modern electric boilers are quite aesthetic and in no way can spoil the interior of the room.

According to the heating method, they can be divided into three groups:

- Heating elements - highly reliable, having one or more heating elements in the form of a metal tube inside the container;

- electrode (or ionic) – heating the coolant as it passes through a liquid alternating current medium. They have the ability to switch off independently in the event of a short circuit, a maximum increase in temperature and a decrease in the volume of water to a critical value;

- induction - operating thanks to inductance coils. Refers to energy-saving devices.

The first option refers to indirect heating of the coolant, and the second is considered as direct heating.

In terms of power, electric boilers intended for heating needs can be:

- single-phase (up to 12 kW);

- three-phase (more than 12 kW).

It is recommended to select power with the help of specialists, since only they can make a competent calculation. The method of selecting a boiler based on the area of the house is incorrect, since in addition to this parameter, a number of others are also taken into account (wall thickness, number of openings, orientation to the cardinal points, etc.).

As a rule, household heating units operate from a 220V network.

Video description

In the video, a specialist talks about the Protherm Panther KTV wall-mounted boiler:

Floor standing gas boilers

They are presented on the market from the same manufacturers, so the range is wide. And yet we have to choose the best floor-standing double-circuit gas boiler.

Vaillant atmoVIT VK INT

First place again goes to German equipment. There are several types in the model range of this unit, differing from each other in power. This figure varies in the range of 16-56 kW. Basically, a boiler is required to heat hot water, but one model has an instantaneous heater installed inside.

Boiler features:

- atmospheric injection burner without fan;

- cast iron heat exchanger;

- Efficiency 92%;

- flame, temperature and draft control sensors.

Boiler Vaillant atmoVIT VK INT Source mostszh.ru

Viessmann Vitogas 100-F 29-60

This brand is one of the most extensive in terms of model range. It contains 15 models with a power from 29 to 60 kW, which is very convenient if you need to select the required unit. Experts say that if the consumer is faced with the task of choosing an economical gas boiler, then this is it.

Moreover, all models easily cope with gas pressure differences in the main pipeline. That is, it is not a problem for them.

Design features:

- the burner is made of stainless steel, it is rod type;

- heat exchanger made of gray cast iron;

- full automation of equipment;

- gas control relay.

Viessmann Vitogas floor standing boilers Source static.wixstatic.com

Installation procedures

To hang the device, you need a mounting plate, which is included in the delivery package: it is attached to the wall with four dowels or anchor bolts with mandatory horizontal and vertical alignment. If this is a floor-standing boiler, then it is installed on a special stand.

The device must be grounded, inspected and made sure that it is in the correct position, the water pressure in the system is normal, and all communications are connected.

Electric heating units must be connected with a wire whose cross-section is indicated in the documentation for the equipment. Wires are carried in special protective boxes.

Scheme options

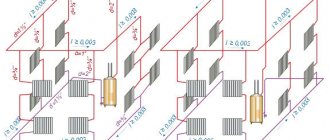

There are various diagrams: a diagram for connecting an electric boiler with heating radiators, diagrams with the possibility of installing a cascade. The latter option is used if it is necessary to heat large areas. To operate devices in a cascade, the terminals of the control unit are connected to the terminals of the controlled unit. If the installation system is controlled by a room regulator, then its control contacts are connected to the terminals of the leading equipment.

Heating apparatus piping

Tying can be carried out using a direct or mixing scheme. The direct scheme involves adjusting the temperatures with a burner, the mixing scheme involves a mixer with a servo drive. The binding is carried out as follows. The boiler manifold is installed, a pipe of the required diameter is connected to the boiler.

A three-way mixing valve is installed at the inlet, which will regulate the temperature. A circulation pump is installed on the return line and a control unit is mounted. After piping, you can fill the system with coolant and test the operation of the equipment for correctness.

Do not underestimate this stage: in reality, it is not as simple and insignificant as it might seem. Normal piping allows you to use equipment without an automation system, and this greatly reduces costs. Therefore, it must be performed at a professional level and taking into account the design features of the system and boiler.

The wiring of an electric boiler must be done by a specialist. If you still have to do it yourself, then you need already assembled distribution units. General diagram of the implementation of a heating system in a house.

EVAN S1 18

Russian single-circuit high-power boiler. This model allows you to maintain a comfortable temperature in large areas. The retail price of the boiler ranges from 21,000 to 25,000 rubles.

Specifications

The main equipment indicators include:

- base power – 18 kW;

- required voltage – 380 V;

- Efficiency at 93%;

- maximum coolant temperature – 85 0С;

- minimum temperature in the system – 30 0С;

- heating area – 180 m2;

- maximum operating pressure in the system is 0.3 MPa;

- circuit pipeline cross-section - 1 ¼ inches;

- there is no expansion tank;

- weight no more than 24 kg;

- body dimensions – 645x250x180 mm.

Model features

This boiler is characterized by its simplicity of design and ease of operation and maintenance. It does not have an automation system, but the developers took care of the possibility of connecting its elements. Thus, the boiler circuit has built-in connectors and sockets for connecting a circulation pump and an air temperature sensor, which are necessary to automatically maintain a given temperature level in the room.

The small dimensions of the model allow it to fit into any existing circuit as an additional heating element, and also to be used as an independent heat source. One circuit provides space heating, so a storage boiler must be installed to supply hot water.

All boiler elements are made of materials that are not subject to corrosion, which significantly increases the service life of the equipment. Protection systems against power surges and pressure surges ensure trouble-free operation of the model.

Boiler installation

Installation of this model does not require special skills due to the simplicity of the design. But taking into account the network voltage requirements, an autonomous heating project should be drawn up and agreed upon with the electricity distribution organization.

The pipe supply must be carried out in such a way as to ensure natural circulation of the coolant. This connection reduces the pump load and contributes to more economical operation of the equipment. The maximum coolant level in the pipeline should not exceed 30 m; with a higher value, the boiler pump will not be able to circulate it. The best option for working with developed pipeline systems is the additional installation of a circulation pump.

It is also necessary to install an expansion tank to allow the excess volume of coolant or steam to be discharged. It is not allowed to install shut-off valves at the junction of the circuit and the expansion tank. Ball valves are installed at the inlet and outlet of the circuit from the boiler for repair and dismantling work.

Clearances from obstacles are left along all sides of the body of at least 5 cm on the side edges, at least 50 cm from the floor and ceiling, as well as the front surface of the boiler with the control unit.

Flaws

The biggest inconvenience in working with this model is the need to install a large amount of additional equipment. As a result, the total cost of the system increases by 20–35%.

What ensures the efficiency and reliability of ion heating devices?

In any case, electrode boilers for a private home are a profitable purchase. High efficiency in their work consists of a combination of several indicators:

- reduced heating inertia;

- uniform increase in temperature of the entire coolant volume;

- construction of a two-pipe closed type system;

- use of automation to control the temperature of the coolant and ambient air in the room;

- simple design using innovative materials;

- high efficiency of the boiler.

What other savings occur in the operation of electrical appliances?

Efficient methods of heating with electricity

Heating with electricity in a private house has the main advantages over all others - these are simple and accurate methods for monitoring and regulating the operation of all components and elements. Even the sensors and display of information about operating modes are more accurate than those of equipment using other types of energy carriers.

When we are talking not just about local heating, but about the heating SYSTEM, this means the following:

- Heating works not only when there is someone in the house (therefore, a wood stove is not a system).

- You can manage the system (set up, regulate), including remotely. Therefore, an oil radiator or fan heater simply plugged into an outlet is not a heating system.

Individual electric heating of a private house has four options for heating systems:

- autonomous water heating systems based on electric boilers:

- use of infrared ceramic heaters;

- electric convectors with electronic thermostats;

- electrical converters with inverter thermostats.

All these systems can be adapted into a smart home system and controlled remotely.

Construction of electrode boilers

Electric mini-boilers "Galan" of electrode type are available in three modifications:

- single-phase CHAGS have a power of 2, 3, 5 and 6 kW;

- three-phase GEYSER and VULCANO - 9, 15, 25 and 50 kW.

They are compact in size and light in weight. The most powerful device weighs 11.5 kg, its diameter is 180 mm with a length of 570 mm, and it can heat a space up to 1650 m3. The smallest boiler has a diameter of only 35 mm and a length of 275 mm, its weight does not exceed 0.9 kg, and the heated room can reach 120 m3.

Ion boilers consist of several elements. On the metal body there are inlet and outlet pipes, allowing unhindered circulation of the coolant (water or antifreeze). Thanks to the housing, ionic processes occur, as it acts as an ionizer. The top of the case is protected by a plastic casing, which improves the electrical insulation of the device and reduces its heat transfer. Inside a single-phase boiler there is one electrode, and a three-phase boiler there are three electrodes with a terminal group brought out.

Galan electrode boilers are supplied assembled. The automation system that allows you to control and monitor the heating system is not included in the equipment package, so it must be purchased additionally. In addition, you need to buy an expansion tank and, if necessary, a pump.

Without installing automation, the GALAN company does not provide a warranty period for the operation of the boiler.

The manufacturer also declines responsibility in the event of improper installation or operation of the electrode heat generator, mechanical damage or the presence of foreign objects in the system.

Prices: summary table

| Manufacturer and model | Type of fuel | Power, kWt | Efficiency, % | Gas consumption, m3/hour | Cost, rub. |

| Teplodar Cooper Praktik 8 | Firewood, coal, peat, pellets | 8 | — | — | 16 100 |

| NMK Sibir KVO 10 TPE | Firewood, wood briquettes | 10 | — | — | 23 000 |

| Protherm Wolf 12 KSO | Gas | 12 | 92,5 | 1,5 | 21 300 |

| Lemax Premium-10 | Gas | 10 | 90 | 1,2 | 21 000 |

| HEPHAESTUS VPR KSG-10 | Gas | 12 | 85 | 0,7 | 17 100 |

Gas boilersBoilersWays to save Solid fuel boilers

Models of electric boilers

The principle of any electric boiler is the conversion of electricity into heat. Electric units are not the most cost-effective, but the efficiency of their use is 95-99%, which is quite good for such units. Such boilers are divided into three types according to the type of coolant. Let's talk about each of them in more detail.

Electric heating element boiler

Electric heating boilers equipped with heating elements operate on the principle of an electric kettle. Water passes through tubular heating elements - heating elements. Acting as a coolant, it passes through the entire heating system, circulating using a pump.

One of the advantages is its compactness, neat appearance and the ability to be mounted on a wall. The installation process will not cause any particular difficulties, and operation is comfortable and simple, thanks to thermostat sensors. Automation allows you to maintain the required heating, focusing on data from sensors that measure the ambient air temperature.

The coolant can be not only water, but also a non-freezing liquid, thanks to which scale will not form on the heating elements, which cannot be avoided by using water.

Attention. Scale formed on heating elements impairs heat transfer and energy-saving properties of an electric heating boiler

This option for heating a house is also good because it has a low cost. For the convenience of regulating electricity consumption, it is equipped with several heating elements that can be turned on separately.

Electrode electric boiler

The operating principle of an electrode electric boiler for heating a house is completely different from the previous model. The liquid is not heated by a heating element. An electrode installed in the housing gives the liquid an electrical charge, under the influence of which the molecules are split into negatively and positively charged ions. The coolant has its own resistance, which provides intense heating. Either water or a special compound (similar to antifreeze) is poured into the system.

This type of electric unit for heating a house is completely safe; if a liquid leak occurs, it will simply turn off. Electrode models are very compact (looks like a small cylinder with pipes), equipped with sensors for measuring ambient air temperature, and controlled automatically.

Maintenance of this model comes down to replacing the electrode, since they gradually dissolve as they work, which worsens the heating of the house. It is also necessary to ensure that the circulation pump is working properly so that the liquid in the system does not boil. Correct and efficient operation of an electrode electric boiler for heating a private house is only possible with prepared water - it must have the required resistivity value. Measuring them yourself is not always convenient and easy, just like preparing water. Therefore, it will be easier and more reliable to buy a liquid specially designed for use in electrode boilers.

Electric induction boiler

This type of electric heating unit for the home operates on the basis of induction heating of liquid with ferromagnetic alloys. The inductive coil is located in a sealed housing and does not have direct contact with the coolant, which flows around the perimeter of the device. Based on this, not only water, but also antifreeze can be used as an energy carrier for heating a house. This electric boiler for home heating is not equipped with a heating element or electrode, which improves its efficiency. Also, the absence of heating elements ensures complete safety during operation. This version of the boiler for heating a home is not subject to scale formation, practically does not break and does not leak.

The only disadvantage of induction models is their higher cost and larger dimensions. But over time, the size problem is eliminated - the old ones are replaced by improved models.

In addition to this classification, electric boilers for heating a private home are divided into:

- single-circuit (intended only for heating the entire house);

- double-circuit (provide not only heating throughout the house, but also water heating).

You also need to highlight:

- wall-mounted boilers;

- floor-standing boilers (high-power models are produced).

No. 4. Number of circuits

Among electric boilers, single-circuit models . They are only responsible for the heating system. To provide yourself with hot water supply, you need to retrofit the system with a water heater or take a double-circuit boiler . The latter has two independent circuits for heating water. Double-circuit electric boilers consume a lot of electricity, so they are used quite rarely.