A wooden frame is a type of residential building construction that constructed from solid logs without the use of metal floor elements. Such construction does not provide for initial external or internal finishing, so you should immediately think about how and with what to insulate the log house from the inside, because it is very susceptible to drafts and dampness.

A wooden house is very beautiful and provides coolness in the room in summer and retains heat well in winter. Insulating the log house from the inside will help make your stay more comfortable and retain heat, while saving on heating costs.

Internal insulation can act as a vapor barrier, protecting the wood from moisture and preventing condensation from forming on the walls.

In order to understand how to properly insulate a house made of timber, you need to pay attention to the physical quantity “thermal conductivity”. This is a unit that quantifies the thermal resistance of a material. You should pay attention to this parameter when purchasing and installing insulation. The higher this value, the higher the thermal resistance due to conduction.

Also, you need to pay attention to such a parameter as the dew point. This physical quantity shows to what temperature the air must be cooled to become saturated with water vapor. This indicator also applies to the insulation surface of a timber house from the inside.

If the insulation is insufficient and the walls freeze, the water vapor in the air will constantly condense on the walls.

What is a wooden house

Before you start talking about insulating the log house of a wooden house , it is necessary to clearly define what will refer to the concept of “wooden house”. It would seem that we can figure it out! But, thanks to marketers who are trying to sell us even what we don’t need.

As a result, frame houses, houses using SIP technology, double beams, insulated beams and other technologies are all trying to be subsumed under the concept of a wooden house. After all, they have wood in them. Yes, there is a tree. But it is also present in the wooden ceiling of a brick house, and in the wood concrete block. These are not wooden houses!

We can talk about a wooden house only when the tree acts not only as a structural part, as a frame, but also as the main heat insulator (and there is no need to include frame houses with ecowool made of paper here).

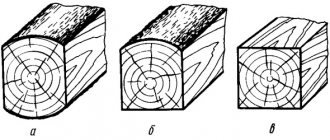

Thus, only houses that are built from rounded or chopped logs, planed, profiled or laminated timber can be classified as wooden houses. These are houses where wood is a monolith, serving as both a frame and a heat insulator.

In my article, I will call wooden houses made of logs and beams a log house. Maybe someone will argue with me, but I do this for a reason. Yes, indeed, such houses were not cut down, but, firstly, they are a modern development of the construction of houses using hand-cutting technology. For examples, what is the difference between a Norwegian log house made from a carriage and a house built from profiled timber. In both cases, both manual cutting and machine processing may be present.

Secondly, the log house is not just cut down with an axe, it is assembled using interlocking connections of solid wood parts (logs, beams). But there is no concept to characterize this phenomenon in wooden architecture. Who knows, tell me. Well, it's not a castle!

So, I think we've agreed. We will talk about the insulation of a log house as a general structure made of logs or timber.

Finishing the bathhouse outside with a block house

- Natural

. Made from deciduous and coniferous wood. - Metal

. Galvanized steel is used for its manufacture. - Acrylic

. Based on polymer resin. - Vinyl

. It is melted from PVC powder.

best option

Before starting the cladding process, you need to treat all the wood with an antiseptic and fire retardant.

Next we carry out the work step by step:

- We attach the vapor barrier film horizontally with an overlap of 10–15 cm. We fix it with staples and a construction stapler.

- We also install the sheathing in a horizontal position. Fastening to a wooden base is carried out using self-tapping screws or nails. We fix it to the brick wall with frame dowels in the pre-drilled recesses.

- We lay insulation between the beams.

- Using a construction stapler with staples, we attach the waterproofing material.

- We build a second sheathing on the main frame clearly vertically.

- We cover its surface with block house elements from the bottom up in a horizontal position.

- We fix the panels with clamps.

- After finishing, we hide the heads of the screws. To do this, we use wooden paste made from sawdust and PVA, ready-made plugs or the remains of a block house.

- We trim the corners with baseboards, and window and door openings with cash elements.

Is it necessary to insulate a log house?

In any wooden house made of rounded or chopped logs, assembled using caulking, shrinkage of the logs occurs in the very first years. In addition, the annual seasonal movements of the house lead to the appearance of gaps between the logs.

The answer is clear: YOU NEED TO INSULATE. Of course, if you want the house to last a long time, to be warm, and at the same time there will be no extra heating costs, if you want to avoid drafts, high humidity, mold, fungi and insects in the walls of the house.

Log caulking

As for caulking, this is a time-tested method of insulating roof joints and connections between logs. It is mainly used for houses made of rounded logs and hand-cut logs. It is hardly possible to caulk an entire house made of profiled timber, although individual elements, such as gaps between the wall and the casing, corners of cuts and places where beams and rafters are inserted, can be insulated. High-quality caulking avoids loss of thermal energy, protects seams from moisture and blowing and, in the end, does not violate environmental harmony.

Unfortunately, one of the main disadvantages of caulking is durability. Without elasticity or any damping properties, it can last 4-5 years at best. Deformation movements of logs during subsequent shrinkage force inspection and repair of the seam between the crowns. The tightness of the junction gradually weakens, blowing occurs and moisture enters the seam. The linen wool is no longer tightly packed, but simply hangs and, as a result, becomes good material for the nests of agile birds.

Modern natural materials

Jute fabric

- Easy installation. Rolls out on a beam or log;

- Uniformity. Uniform stripe;

- Doesn't puff up from under the crowns;

- Durability of consumer properties;

- Hygroscopicity;

- Impeccable environmental friendliness. There are no harmful additives;

- Economical. No double caulking required.

A jute product is perhaps one of the best in terms of price-quality ratio.

Available in several sizes. Width varies from 2 to 100 cm, thickness from 4 to 12 mm, density ≈700 g/m². You can conveniently and quickly roll it out directly into the groove, securing it with a stapler along the way. After laying, the jute fabric is compacted and becomes resistant to moisture and wind. Excellent for timber. The seam looks symmetrical, and its golden hue harmonizes pleasantly with the color of the wood.

“Jute fabric is practical for a bathhouse, since its fibers remove moisture well.”

Warm seam technology concept

The “warm seam” technology

is designed to simplify this procedure. In its concept, it repeats the idea of caulking with the additional use of clay, but it is simpler and more durable. And modern materials provide a better thermal insulation effect.

The essence of the technology is that instead of moss or tow (or other materials), a polymer cord is laid, which is easily compressed, but at the same time holds its shape well, maintaining it over time. Thanks to the constant filling of the gap and good thermal insulation properties, a very good effect is obtained.

From the influence of external factors and giving better aesthetic properties, a sealant is applied over the cord, which prevents moisture from getting inside, decorates the cracks of the log house, and is plastic, thanks to which it can withstand minor movements of the log house of a wooden house.

Thanks to the insulation of the house using the “warm seam” technology, the house loses less heat , and the difference in wall temperature in the thinnest and thickest parts of a log frame is only 1-2°C. The use of warm seam technology is highly recommended when building a house from rounded logs, as it allows you to decorate all the cracks that form and eliminate the shortcomings of rounded logs.

Purpose of interventional insulation

Inter-crown insulation is a special type of heat-insulating materials that are laid between the crowns of a wooden building (house, bathhouse, utility room) to eliminate gaps. They can be loose (tow, moss) or in the form of ribbons (felt, batting).

The main task of such insulation is to create comfortable living conditions inside the house. Interventional insulation creates a favorable microclimate only if it can:

- keep the house warm in winter and prevent it from overheating in summer;

- avoid drafts;

Insulation of a log house with moss.

- compensate for changes in the linear dimensions of wood that appear during drying or swelling during changes in environmental humidity (so that cracks do not appear);

- protect owners from unnecessary noise;

- prevent insects from appearing in the house;

The main functions of interventional insulation.

- prevent the colonization of inter-crown space by microorganisms.

In order to perform its assigned functions, inter-crown insulation for timber (logs) must have a certain set of quality characteristics.

Traditional methods of insulating a wooden house

Our ancestors used natural fillers, which could fill voids relatively easily and were also good insulators.

Fillers were “hammered” into the cracks, thereby filling the voids. This method was called caulking. Moss, linen tow, and wool were used for caulking. These materials had disadvantages. They harbored various insects that attracted birds. Birds, trying to get insects, pulled out the insulation. A number of birds took out the insulation for building material for their nests. In addition, the insulation dried out over time, resulting in voids forming again. As a result, we had to caulk every year or two. From the outside, the cracks could be covered with clay. This temporarily protected the insulation.

How to insulate a log house from the outside and inside

Today, the following insulation technologies and materials are offered in construction and finishing:

- Caulking Traditional insulation technology, invariably used at the stage of construction of a log house. The material used is tow, jute, linen or moss.

- Insulation with mineral wool (mineral wool), ecowool, isover and other sheet materials, of which there are now many with different properties and under different names.

- Insulation with polyurethane foam and other materials in the form of foam.

- Warm seam Insulation (caulking, sealing) of seams between logs (inter-crown) with acrylic-based sealant. The sealant can be used both outside and inside a house or bathhouse.

Now let's try to understand the presented technologies.

Let's make a reservation right away:

- We discuss only the insulation of the walls of the house and do not discuss the insulation of the roof, basement and basement.

- You can find a detailed description of insulating a house with sealant on our website in the article “Warm seam technology.”

- A detailed comparison of the insulation technology with caulk and warm joint sealant can be read here. In short, at the construction stage we use caulking, and after shrinkage we use a warm seam.

Insulation with mineral wool or foam implies continuous closure (insulation) of the walls, with the following consequences:

- The house stops “breathing”

- The natural humidity regime disappears. The material either does not allow moisture to pass through at all, or accumulates it within itself, forming a dew point inside the walls of the house, followed by rotting, mold and fungi.

- Insulation with mineral wool requires an additional ventilation system.

- To install mineral wool, additional structures are required, which makes the walls thicker and “eats up” the internal space of the house.

- The environmental friendliness and safety of such insulation often raises questions.

Bathhouse exterior finishing

It is necessary to carry out external cladding of the bathhouse not only to improve the aesthetic appearance. It is also needed to improve thermal and waterproofing performance, since a bathhouse is a place with high humidity. In addition, if it is located in close proximity to other residential buildings, it is worth choosing a finishing material that will ideally suit the general style of the area on which the bathhouse is located.

Materials for exterior finishing of baths

Depending on the material from which the hygienic building is made, your preferences and finances, the following materials are used to decorate the outside of the bathhouse:

Vinyl or metal siding. It is environmentally friendly, lightweight, durable and affordable. It is easy to install, resistant to atmospheric, mechanical and temperature influences. Available in a wide color palette. They are usually used to cover frame and brick buildings.

Features of the exterior finishing of a log bathhouse with your own hands

Log houses usually do not require external finishing. However, to increase the heat-saving characteristics and service life, the wood must be further processed.

- We make caulk. To do this, hammer the tow into the cracks between the crowns with a hammer and spatula. It is used as insulation.

Finishing the outside of the bathhouse with siding

This method is optimal for brick buildings. Installation on wooden baths is undesirable, since the material will interfere with the natural ventilation of the wood. For cladding we will need: siding panels (from 150 rubles per piece), joining parts, 5*8 cm boards or slats for sheathing, brackets, vapor barrier film (optional), insulation (optional), waterproofing material (preferably isospan).

We attach a vapor barrier layer to the wall to protect the heat insulator from condensation.

Finishing the bathhouse outside with a block house

Several types of this material are used for cladding buildings:

Natural. Made from deciduous and coniferous wood.

The finishing of the bathhouse can be done using any type of block house. Additionally, for this you also need: self-tapping screws, clamps 6–7 mm high, insulation (the best option is mineral wool), timber for lathing, vapor barrier membrane, waterproofing agent, antiseptic impregnation, fire retardant.

Next we carry out the work step by step:

- We attach the vapor barrier film horizontally with an overlap of 10–15 cm. We fix it with staples and a construction stapler.

Finishing the outside of the bathhouse with warm plaster

This method is used for buildings with a solid foundation. Most often, brick baths are finished with cement-sand mortar. For wooden structures it can only be used after caulking all the cracks. For effective insulation and aesthetic cladding, we will need the following materials: 3*5 cm timber for sheathing, umbrella dowels, polystyrene foam, construction adhesive for polystyrene foam, plastic reinforcing mesh, base for “warm plaster”.

We stuff the sheathing. To do this, we use bars 3–5 cm thick.

External cladding of the bathhouse with clapboard

Such material is considered less reliable because it is damaged due to atmospheric influences. To cover a room with wooden or plastic lining, you need to stock up on brackets, mineral wool mats, dowels, construction adhesive, guides, waterproofing film, and lining.

- We install the brackets horizontally at a distance of up to 50 cm from each other.

Instructions for decorating the outside of a bathhouse in different ways and photos will help you independently implement any stylistic decision on the facade of the building. Carved details on the openings of windows and doors will help decorate the walls of a traditional Russian bathhouse. You can also decorate the building with openwork cornices and platbands.

Pros and cons of technology

Insulating a wooden house with sealant has become widespread today due to its undoubted advantages, among which are:

- high speed of insulation, subject to professional performance of the work;

- absence of dust, dirt and noise during installation;

- the material is not of interest to insects, rodents and birds, fungus and mold do not form on it;

- a warm seam is made once, its service life is about 50 years;

- The sealant withstands high and low temperatures well and is not afraid of moisture and dampness;

- The material is resistant to both mechanical stress and aggressive chemicals.

However, this insulation method has some disadvantages that also need to be mentioned:

- high cost of material;

- artificial insulation is used;

- a warm seam on a rounded log outdoors can only be done in above-zero and dry weather;

- For complete drying, the sealant requires from twenty days to a month.

Synthetic insulation

Synthetic thermal insulation for the gaps between the crowns of the wall is represented by polyester fibers. The general advantages of this type of insulation include:

- durability - manufacturers talk about a service life of 100 years;

- low thermal conductivity coefficient;

- vapor permeability;

- elasticity (volume is restored by 90% after prolonged compression);

- frost resistance.

There are two disadvantages:

- high cost of 1 linear meter;

- do not absorb water, as a result of which a greenhouse effect occurs indoors, and the wood becomes moldy. Therefore, good ventilation of the house and careful wood processing are needed.

The result of using low-quality synthetic inter-crown insulation is fungus at the joints of the crowns.

The best representatives in the segment of synthetic insulation are “Holofiber” and “PoliTerm”.

"Holofiber"

Inter-crown insulation “Holofiber” (translated as “hollow thread”) is one of the varieties of padding polyester known to everyone. It is a springy polyester fiber molded into a tape that perfectly adapts to changes in the linear dimensions of wood during deformation due to shrinkage or changes in humidity. This property is especially valuable for a log house made of sawn timber without grooves. The insulation perfectly holds the volume, ensuring complete tightness, so that re-caulking is not done.

Holofiber insulation.

It goes on sale in rolls and sheets of different densities and elasticity, which allows you to make a choice based on the characteristics of the wood.

Among the advantages :

- excellent elasticity;

- good noise and thermal insulation properties;

- long service life;

- simple installation;

- no need for re-caulking;

- environmental cleanliness;

- resistance against negative biological factors (birds do not carry, insects do not appear).

Negative include :

- “biting” price;

- artificial origin;

- there is a risk of mold or a special type of rot, about which people say: “the tree is rotting.”

"PolyTerm"

Insulation of gaps between the crowns of a wooden house "PoliTerm" is the result of the work of Finnish technologists. Let us immediately note two features:

- when developing the heat insulator, “Holofiber” was taken as a basis, as a result, the result was a type of padding polyester insulation;

- short production period (appeared on the market about 10 years ago), and therefore we cannot give an objective assessment of the advantages and disadvantages of the material (manufacturers can say whatever they want).

What is beyond doubt is:

- convenient release form - in the form of an adhesive tape;

- resistance to any vagaries of nature;

- high price (10-12 times more expensive than jute tape);

- lack of vapor permeability.

Insulation "PolyTerm".

Sold in the form of tapes with a width of 30 to 250 mm and a thickness of 80-200 mm.

What difficulties can you encounter when working independently?

The technology for applying warm joints to wooden houses and log houses, at first glance, seems simple. In fact, this is quite a complex job, the quality of which largely depends on the knowledge and experience of the master. When faced with sealing for the first time, unprepared people will probably experience many problems, which begin already at the very first stage. It is very important to choose the right sealant and tool for the job, and choose the right cord size.

Particular attention should be paid to surface preparation; if it is done poorly, it can negate all further work. Laying insulation and applying sealant also causes difficulty. Both must be done very carefully. It is necessary to strictly adhere to the technology; any violation can lead to undesirable consequences.

Sealing seams between logs

Technological process of insulating a wooden house

, according to the

“warm seam”

consists of several stages:

- removing old caulk if necessary and cleaning the surface;

- laying a heat-insulating cord;

- filling the seam with sealant;

- final cleaning and sanding of the seam.

For those who are planning to insulate themselves with sealant, the article “warm seam with your own hands.”

Beautiful and even seams

We have developed our own application nozzles, and thanks to them we make seams of the same width

Uniform application of sealant

We use pneumatic guns that fill the seam evenly and do not leave hidden cavities

Optimizing sealant consumption

We optimize the consumption of sealant by correctly selecting the cord, and not by “stretching” the sealant, violating the technology

Wood sealants

For warm joint technology, special wood sealants are used, which are usually made on an acrylic base. The main feature of sealants is their elasticity, due to which constant sealing occurs, even when the size of seams and cracks changes.

Price

As already said, the tube is more expensive. One tube of 600 ml is enough for an average of 4-6 linear meters. It depends, of course, on the thickness and unevenness of the seam, as well as the experience of the finisher. The cost of a tube of German Remmers, for example, is 430 rubles. In this case, in the best case scenario, the cost of 1 meter of seam will be 72 rubles. A 25 kg Eurotex bucket costs approximately 7,300 rubles. When using such a sealant, the cost of one meter will be 28 rubles.

By the way, a warm seam for a wooden house can be ordered from a contractor. However, the price of such a service will cost 150-170 rubles per linear meter. In a day, a novice specialist can do 50-200 meters. (Much depends on the size/evenness of the seams and personal abilities).

If you decide to apply it yourself or check the craftsmen for lice, the technology for applying the sealant is described below.

Precautionary measures

Many sealants are fireproof for wood, and also do not pose any risk of explosions, and are non-toxic. Still, when working with them, it is worth protecting the skin of your hands with gloves, but not allowing the product to get into your eyes or mucous membranes. When treating the surface of walls inside the room, ensure good ventilation.

Is it possible to do the sealing yourself?

The production of a warm seam is carried out once and for many years, so special care and strict adherence to technology are required. Non-professionals, beginners, as well as those who ignore important rules, will often make mistakes that will lead to a significant decrease in the quality of the finished seams.

The most common mistakes are:

- Wrong choice of sealing agent.

- Carrying out work in cold and damp weather.

- Applying seams with low thickness.

- Poor base preparation.

- Making interrupted and rough seams.

- Poor smoothing of joints.

If the technology is violated at each stage, the sealing layer may crack, swell or even rupture. This can cause depressurization and the entry of cold air into a wooden house. Moisture will also get into the cracks, and this will cause the materials to rot and the appearance of fungus and mold. As a result, if you completely follow the technology and buy only high-quality materials, then you can do the work yourself.

Final Recommendation

By the way, recently (on the eve of the New Year) a fellow colleague of mine bought flax-jute fabric at. He liked the conversation with the consultant (in his words, he understands issues of wooden house construction very well) and the price of the product was quite reasonable. This is not an advertisement - just a consultation, which is always useful. I recommend this company for residents of Moscow and the Moscow region. Moreover, the company is specialized and has been on the construction market for several years.

Well, perhaps he said everything he wanted. If it was informative, then do not miss the release of new information. Do you have friends who are building a bathhouse or a house? Recommend the article to them.

Good luck and warm, well-caulked walls. Bye!

Quote of wisdom: This is how men are made: they can resist the smartest arguments and cannot resist a single glance (Bazzak).