Here you will learn:

- Eight ways to increase efficiency

- Integrated approach and technical solutions

Traditional potbelly stoves are not characterized by the highest efficiency. Up to 30-40% of the heat they generate flies into the chimney. Simple technical devices will allow you to increase the efficiency of a potbelly stove. In this review, we'll look at eight ways to increase the efficiency of these furnaces. They differ in level of complexity, but all work is done with your own hands using auxiliary tools. Let's go through these methods in more detail.

Principle of operation

People who have their own workshops, garages, houses, install potbelly stoves. This is a device that first appeared in the 1917 revolution. They named it because of the high consumption of fuel for the firebox, but the advantage is that the stove is unpretentious.

A potbelly stove made from disks has an advantageous design; it is simple and also has a low price.

The main disadvantages include low efficiency - only 15-20%. Insufficiently thick metal walls conduct heat poorly, and the device quickly cools down during processing. This happens because the main volume of heat produced by the stove evaporates into the chimney - that is, it heats the street.

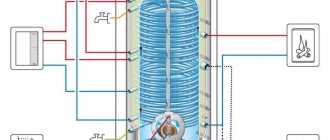

Heat exchanger

To increase efficiency, you can try to increase the area of the heat-conducting surface. For this purpose, a heat exchanger is needed. It is mounted in a place where heat is concentrated to a greater extent, significantly increasing efficiency.

The heat exchanger for the building is a device for indirectly heating water. The essence of the operation is that the liquid circulates in a confined space due to the convention. Water warms up under the influence of heat.

Hot layers rise and are replaced by cooler ones. Mixing water against the background of heat is called circulation. Heated water or other coolant, rising, transfers heat to the water. The stove becomes a heat exchanger as it creates heat.

Working a potbelly stove in your home

The main functions of the device are:

- The heat exchanger becomes an additional heating circuit. As it runs, the fuel burns out and at the same time warms up the walls of the firebox. In this case, when interacting with air, hot bricks give off their heat, which evaporates through the flue.

- Thanks to the device, the air transfers excess heat to the liquid, thereby increasing efficiency, receiving an increased coefficient for each unit of fuel at the output.

- In accordance with its purpose, the device allows you to heat water for showers and heating fluids.

Where is a potbelly stove used?

Although the potbelly stove is a simple design that you can assemble yourself, it is still very popular and is in great demand. The design works on any type of solid fuel.

A potbelly stove for a garage with your own hands is considered the optimal solution and a very effective unit for heating a room. This is justified by the fact that the design takes up little space and is the cheapest heating option. To operate the stove, it is enough to purchase firewood and use it for a long period. And as everyone knows, wood is the most affordable type of fuel.

If you make a potbelly stove from a gas cylinder yourself, then it can effectively heat a small utility room. And this is very useful, because it is simply impossible to repair something when your hands are cold and the room is cold.

Stoves of this type are relevant for country houses. Not every person may be at the dacha every day, but when he comes to see what’s going on, he needs warmth, especially in winter. Having made a potbelly stove and installed it in a country house, you will be sure that when you arrive and light the unit, you will immediately feel the heat, which will quickly spread throughout the entire building.

Types of devices

Among air types, the classic model for self-assembly is a tubular heat exchanger. But there are also a large number of other types. They remain relevant for chimneys of long-burning stoves, small-sized potbelly stoves, and stoves undergoing mining. Their heat converted from combustion energy is called dry heat. Pipes can be welded to the firebox horizontally and vertically. Vertical localization is many times more effective because the air flows better through the channels. The material is usually steel.

Another type of heat exchanger is a pipe that wraps around the firebox. For proper heat transfer, 2-3 curls are required. They move apart a little, increasing the heating area. The performance corresponds to the difference in the level of inlet and air supply. The draft corresponds to the temperature difference, so the hole for the fence is often exposed to the street.

Coil

Partitions in the housing are also a type of heat exchanger. The characteristic labyrinth is constructed from vertical metal plates. The optimal thickness of each part is 6-8 mm. The inlet and outlet openings of the air duct are formed opposite each other, and a cover is welded on top to seal the housing.

Partitions in the housing

The next option is pipes that pass through the firebox. The structure is constructed already at the stage of assembling a home-made device, before welding the walls. The channels are located parallel at the same distance. The cross-section of the pipes is not less than 50 mm.

Pipes through the firebox

In vertical channels, air moves more actively, therefore increasing productivity. Less commonly, horizontal channels or partitions are appropriate. Any described scheme is suitable for design, provided you have welding skills.

How to check traction?

Expert opinion

Pavel Kruglov

Stove maker with 25 years of experience

Initially, the traction force is determined with a burning match. With a cold chimney, the flame of a burning match or newspaper should deviate towards the firebox. Then we preheat the chimney pipes. To do this, light a fire in the firebox using a small amount of dry paper. If the flame burns brightly and the smoke goes into the chimney, therefore, all the conditions for burning a fire in the firebox are met. The presence of a smoke smell in the room indicates a lack of cravings.

Checking traction

Which material to choose

Using classical technology, the coil is constructed from a pipe. Its length and diameter are set depending on the required heat transfer. The exact operating efficiency depends on the thermal conductivity of the materials. Usually pipes are taken from:

Steel

- copper – thermal conductivity coefficient 380;

- steel – 50;

- metal-plastic – 0.3.

Do-it-yourself copper heat exchanger for a potbelly stove

With the same heat transfer rates and the same transverse size of pipes, the length of metal-plastic pipes is 11 times longer, and that of steel is seven times longer than copper. For this reason, annealed copper pipes are chosen for the coil. They are plastic, so they easily take the required shape with the help of deflection. It is also easy to connect a fitting to such a pipe using a thread.

Solving backdraft problems

If there is reverse draft in a stove heating system, an accident with fire hazardous consequences and carbon monoxide poisoning is possible. This situation can only arise if the chimney design is incorrect.

Installing the deflector

The deflector is designed to ensure a continuous process of removing burnt gases in any weather. It is installed at the upper end of the chimney. The design of the deflector does not allow air to mix with smoke in the pipe itself. It prevents backdraft.

Installation of the draft regulator

Installing a draft regulator does not solve the problem of smoke backflow in the chimney. Rather, it is designed to establish an economical fuel combustion mode. The same function is performed by a standard valve in the pipe.

Increasing the length of the chimney

The problem of reverse draft can only be solved by reconstructing the chimney. To do this, it is necessary to increase the length of the chimney and take measures to prevent clogging of the chimney pipelines, as indicated earlier. The pipe should be at a height of 500 mm from the roof ridge. If backdraft occurs at this height, then it is necessary to increase the length of the chimney.

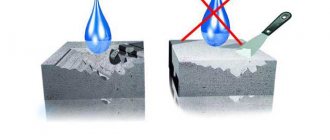

Improving the quality of the chimney

The best material for pipes may be the use of asbestos-cement and ceramic pipes up to 4 m long. Such chimneys have less resistance to smoke movement than brick pipes with a plastered surface. Even pipes made from sections of monolithic reinforced concrete have a worse throughput than asbestos-cement ones. Metal pipes rust in air and fail after a few years of use.

Use ceramic pipes

Options for making devices yourself

When selecting, the main role is played by the price of the heat exchanger. The design will depend on the material. Another important nuance is manufacturing capabilities.

You also need to understand where the stove will be placed. It is important to take into account the purpose of operation - heating and cooking, for heating a bathhouse, a house. Each type has differences.

For heating a private home

The main thing is to correctly calculate the area that needs to be heated, also clarify whether hot water is required, and calculate how many units of fuel will be consumed per season. The results of the calculations are the selection of the most suitable and affordable materials for the budget.

For a bathhouse you will need a comprehensive option. The main goal is to warm up the water, two rooms at once - a dressing room with a steam room, and sometimes a shower. It is recommended to use a heating coil for stove heating and water heating. Additional heating will improve the quality of the steam.

For the bath

For the home, the functional requirements for the device must be taken into account. The final choice will depend on this. Usually in villages they try to make universal heating and cooking structures; they install the most commonly used heat exchangers, simple ones that solve at least three problems - heating, cooking, water heating.

For garage

The garage is the easiest place to choose, here heating the liquid carrier is an optional function, the main thing is heating the room. These conditions will make the choice easier. Various homemade heat exchangers made from scrap materials are suitable - car radiators, cast iron batteries, etc.

What is a potbelly stove

A potbelly stove, like a barbecue and a smokehouse, is considered optimal for heating, since it has a large combustion chamber. A chimney pipe is installed at the back of the stove. In the front part there is a door for closing the combustion chamber and a small door for the ash pan, which must be periodically cleaned of collected ash.

Scheme of rectangular potbelly stoves

If you construct a potbelly stove for a wood-burning garage with your own hands, then it is worth noting that the bottom door will perform several functions at once. The first function is to open the space for cleaning, and the second is the ability to adjust the combustion intensity and temperature in the room. That is, if the door is opened all the way, the stove will burn much more powerfully than when the door is ajar. Based on this, the temperature in the heated room will increase.

As for the sizes, they can be very diverse, but the efficiency and efficiency of the unit depend on them. This is especially important if a potbelly stove is being made for a summer residence.

To facilitate the manufacture of a potbelly stove, choose a gas cylinder with a volume of 50 liters. A potbelly stove of this size can warm up a garage or small outbuilding. If a more efficient stove is needed, then a 200 liter metal barrel is used as a base. You can also make a stove out of sheet metal. Well, naturally, the cost will increase due to the material.

Heat exchanger from a cylinder

To use already exhaust gases for additional coolant in the heat exchanger, you need to slow down the exit of smoke by creating a barrier in the chimney. For construction you will need three empty gas cylinders, sheet metal and scrap metal. The sequence is:

- Build a firebox from a cylinder - cut out the top so that the diameter of the hatch reaches 200-250 mm.

- Mark a rectangle measuring 50 by 20 cm on the wall, apply a mesh with cells 30 by 40 mm. Make holes in the crosshairs.

From a cylinder

- Build an ash pan slightly larger than the area with the holes. It must have a lid. This is a collection for ash. Supports are welded to the wall at the corners.

- At a distance of 4 cm from the bottom of the cylinder, at the rear wall of the firebox, a hole is first marked, then a hole 3 cm smaller than the cylinder itself is cut.

- It is better to make the door for the firebox from the head of the second cylinder, cutting a hole in the center of it. A piece of pipe with a diameter of 7.6 cm, equipped with an adjustable damper, is attached to the hole. The mobility of the sash is supported by hinges and locks of inventory drawers.

Balloon frame design

- Construction of a heat exchanger from the second cylinder. Make 3 bulkheads from 4-5 mm metal so that they cover the internal size of the cylinder. They cannot fit around the edges of the hole according to the diameter of the chimney pipe and for a margin of another 2 cm.

- Cut off the bottom of the cylinder, cut it in the shape of a fit on the firebox at an angle of 90 degrees.

- Cutting a hole for the chimney in the valve part.

- Installation of the bulkhead - holes in a checkerboard pattern.

- Installation of the heat exchanger, scalding, welding of the pipe.

Advantages and disadvantages

Having decided that a potbelly stove is the best option for your dacha, you should not immediately purchase the material. First, let's look at the advantages and disadvantages of the unit.

Advantages of the stove:

- Low cost. To make a potbelly stove, you can use the cheapest materials. You can ask your neighbors or relatives about them.

- Works on any type of solid fuel. The potbelly stove performs its functions on any type of solid fuel. After all, even the cheapest type, such as wood, can be used for heating.

- Simplicity of design. If you look at the drawings, you can see that the oven consists of only a few elements.

- Possibility to design a hob. If you include a hob in the model, then it is quite possible to cook food on the stove.

- Ease of use. If you organize a high-quality chimney, there will be no interruptions in operation; all you need to do is add fuel regularly.

Scheme of a potbelly stove from a cylinder

Unfortunately, a potbelly stove, which is made by hand, also has disadvantages. For some they are insignificant, but for many they can prevent them from making a choice in the direction of these devices.

Main disadvantages:

- not aesthetic appearance of the finished product;

- increased temperature of the base, during operation and if you accidentally touch the body, you can get burned;

- high fuel consumption, but it is cheap.

The disadvantages are much smaller than the advantages, and besides, they are not so serious.

Economizer Fehringer

The device is used to improve efficiency. It works by extracting heat from the chimney. It has 4 pipes, 60 mm each, with spiral-shaped swirlers.

The passing gases from the smoke swirl, resulting in maximum heat release. The device is made of black steel. It is designed for the entire period of operation of the stove. It allows you to quickly warm up the steam room.

Feringer is valued by bath lovers as one of the best models. They are produced in different versions, but in two main categories:

- Steam - the heater is closed, creating a steam room atmosphere - temperature up to 50-70 degrees, humidity reaches 40-75%.

With closed heater

- Golden ratio - the heater is open, suitable for saunas, where at a temperature of 80 degrees, low humidity is needed - 10-15%.

With an open heater

Since 2011, the company has developed a new line - Lamel. It has a natural stone cladding and small innovations in the design that allow you to confidently heat log steam rooms.

Lamella

The system for securing the decorative stone of the stoves is unique - a holder is installed on the cut plates of the stone. Its hooks are fixed in a groove. The design is simple, at the same time very effective, installation work is simple, it will take no more than 1 hour.

How to determine the quality of draft by the color of the flame?

The quality of draft in stove heating is the main factor. It is necessary to evaluate it according to various criteria. When kindling (chips, birch bark, newspapers or papers) lights up, it is not yet clear whether there will be real draft or not. And only when the main fuel lights up and all the valves are closed in working order can it be determined whether there is good traction.

Two factors will determine the thrust:

- The fuel cap must be opened. The sound of combustion should become dull and calm. The color of the flame is red in the center and purple at the top.

- By closing the fuel cap, the flame will hum sharply and glow brightly in daylight.

Air convector

There is not always enough finance to purchase a ready-made heat exchanger. In principle, it is not difficult to make a heat exchanger for a heating furnace. For this, copper and aluminum are used; if desired, you can completely do without welding. With proper preparation and accurate calculations, the budget is significantly saved.

First, a location is selected, parameters are calculated, and you need to decide what material to choose to make the heat exchanger. You can build a structure from an old cast iron radiator, a radiator from a car. The main thing is to take into account the conductivity of heat. It is also important to think over a set of tools, prepare everything in advance, each detail makes installation much easier.

Assembly must begin with drawing up a drawing taking into account the dimensions. If the stove is weak, a disproportionately large heat exchanger will do harm. When using copper for the coil, its length is maximum 3 m. The speed of heating depends on the length of the pipe and the number of curls. It is important to remember that distortions reduce the life of the equipment.

Air convector equipment

To twist the pipes into a spiral, a template is required. This is any available part in the shape of a cylinder. Its diameter must fit into the size of the firebox.

The sequence of actions is as follows:

- bend the pipe, wind it around the workpiece to form a spiral;

- keep the dimensions to fit the coil;

- the average design power of the heat exchanger is 1 kW per 10 m2.

Conclusion

The widespread use of stove heating in our country is explained by the low cost of fuel material and the emergence of efficient equipment with an efficiency of up to 20%. Comparing solid fuel stoves with gas heating equipment, we can conclude that there is no need to build expensive gas pipelines to a house in the village.

If we take into account the costs of obtaining technical conditions for connection, design work and attracting the gas industry trust for construction work, then the tractor driver’s salary is not enough even for a gas meter. And how many problems there are with bureaucrats when coordinating the entire project. Until prices level out, the potbelly stove will be used for heating.

Installation

It is most convenient to install the heat exchanger at the masonry stage. This helps to build it more correctly with strict adherence to dimensions and gaps. This makes it much easier to fit the given dimensions. After installing the heat exchanger on the stove foundation, it is covered with bricks. This is easier than disassembling the existing structure, although this approach is not excluded.

To increase operating time, you need to pay attention to the following nuances:

- do not fix pipes with metal fasteners;

- do not fill the system with too cold water, otherwise strong condensation will form;

- observe the ratio of the sizes of the furnace and heat exchanger, the difference should not be large;

- use seals with good fire resistance;

- compliance with fire safety measures.

These simple settings will help prevent the occurrence of situations dangerous to the life and health of people, increase service time, and remember safety.

Why do you need furnace modifications?

Every model, and not just stoves, is imperfect, and you always want more and better. So it is in this case with heating partings. Any modifications are carried out in order to obtain maximum effect without reducing the service life of the heating device.

For example, with the help of improvements, you can achieve maximum proper combustion, with a good level of heat transfer, without heating the potbelly stove to the limit so that the metal turns red.

Watch the air damper. It must be at a level so that the flame does not enter the chimney. The fire should not exceed the level of the top of the stove. The heat must be distributed evenly throughout the device in order to properly warm the room.

There are many options for modification; you should choose the optimal one for yourself in order to ensure a comfortable temperature for being in the room.

Chimney maintenance

Despite the apparent simplicity and unpretentiousness of the design, the chimney for a potbelly stove will need periodic attention. First of all, this will have to be manifested in regular inspection of the pipes for the appearance of rust, signs of burnout or cracks.

The presence of any of these defects should be a signal to immediately replace the damaged section of the chimney. Left unattended, it will sooner or later turn into a source of danger for the residents of the house. In the best case, smoke will leak through the cracks; in the worst case, a burnt-out pipeline may simply collapse.

It is equally important to take care of the internal surface of the chimney, on which soot and ash will invariably accumulate during operation. The presence of a thick layer of soot can have several negative consequences:

- Craving decreases.

- Normal smoke removal is impaired.

- The chimney structure becomes heavier.

Accumulated soot can be removed using special chemical compounds that are applied to the firewood. Their components are completely harmless to human health, but for soot they are a truly formidable weapon.

Ordinary aspen firewood has almost the same effect. It is desirable that the aspen smolder little by little and not burn out quickly.

In structures equipped with additional elements, it will be enough to just cover the vent.

But traditional cleaning methods (metal brush, core, brush, high temperatures) will not work here, since thin iron may simply not withstand it.

In order for the potbelly stove to always have good draft and to avoid smoke in the room, it is necessary to carry out preventive measures that will help keep the chimney in order.

Any chimney requires periodic preventative maintenance:

- In order to keep the pipe clean from soot deposits, it is necessary to periodically add chemicals specifically designed to loosen carbon deposits to the wood being burned. Aspen firewood is also used for the same purposes, which helps clean the internal walls. To clean the pipe with their help, only aspen firewood is used for preventive combustion. It is advisable that they do not burn out quickly, but smolder for as long as possible in the firebox. To create such conditions, the draft is artificially reduced by closing the ash pit after the wood has burned well.

- The pipes are mechanically cleaned annually to remove carbon deposits and rust. To do this, you can use a special cleaning brush with a weight.

- After each cleaning, be sure to inspect the surface, carefully lowering the switched-on light bulb into the chimney. This is necessary in order to detect burnouts or cracks in time.

The process of installing a chimney from ready-made segments is quite simple, and you can easily handle it yourself. If you want to make parts of the pipe yourself, then it is better to abandon this immediately, especially if you have no experience in such work.

Since any chimney must be extremely reliable, and all segments must perfectly match each other when joined to seal them, it is recommended to install parts manufactured exclusively at a professional level. It must be remembered that the entry of carbon monoxide into a room from poorly sealed seams or burnt holes is, without exaggeration, a mortal danger.

We invite you to read: What are the disadvantages and advantages of a bathhouse made of expanded clay blocks?