- home

- Switches and sockets

When you come to a construction store, you can see 2 categories of sockets: with and without grounding. This causes some difficulties with the choice, because... a person far from electrical engineering may not know the basics of connection.

Why this is necessary and for what purposes a PE contact is needed - you will find out in this article.

Grounded sockets

The main visual difference between a grounded outlet is 2 additional contacts above and below the holes.

They are necessary in order to connect to similar pads on the plug. Using them you can quickly determine whether there is grounding in the outlet.

Why is this necessary? A person consists of more than 70% water and salts. Skin, muscles and nerve endings are excellent conductors of current, so even 220V can lead to cardiac arrest or “sintering” of the brain.

Moreover, this can happen, for example, when the power wire is short-circuited to the housing of household appliances.

The problem is solved by conventional grounding (PE). Unlike human te, PE has absolute zero potential.

And because Since electricity always follows the path of least resistance, it is easier for electrons to enter a grounding device than into the human body.

Connecting a grounded outlet is not much different from a regular one. The only difference is that in modern electrical networks there is a grounding wire, which is connected to 2 additional contacts.

Kinds

Below are the main types of sockets with and without grounding.

By installation type

- External. Essentially, it’s a cover socket for which no grooves are punched. It is connected by external wiring, which is convenient in garages or utility units. To install the socket, you need to disassemble the housing, pass the wires through the holes, and then screw the back plate to the wall.

- Internal socket. The usual form factor, found everywhere in apartments. The socket block is inserted into a groove on the wall, after which it is fixed with metal wedges. Grounding is often carried out to the frame.

By number of holes

- Single and double. Sockets for 1-2 beds are installed in one socket box. The contacts are usually connected in parallel to each other.

- Multi-sectional. In this case, each individual block requires its own socket box. Moreover, contacts are made individually to each section. Please note that connecting them with a cable is prohibited!

When is grounding necessary?

So, when is it necessary to install sockets with grounding? They are needed for:

- Kitchen equipment connections: ovens, hobs, etc. This is due to the fact that the power of the equipment often exceeds 2.5 kW. In the event of a short circuit to the frame, the electric shock can be fatal. Moreover, often the surface of ovens is not painted, but covered with a thin layer of varnish, which quickly wears off, making the surface conductive.

- Connections of industrial equipment and machines. The problem with them is similar, although their body is often plastic. Their cables can fray, especially if used carelessly. In the event of a break, a grounded outlet will prevent a strong electric shock.

- Installation of equipment requiring grounding. Some, usually European brands, require a mandatory PE contact when connecting. Otherwise it won't work.

It is also highly recommended to carry out grounding in the children's room.

This is especially true for lamps and computers.

It is also advisable to connect the bathtub to a grounding device if it is made of steel or cast iron.

Please note that the apartment must have a grounding wire! It makes no sense to install Euro sockets in houses with two cables without grounding to the charger.

Test method

Checking the ground loop is carried out according to a single algorithm:

- Cleaning the tire area for good contact.

- Driving 2 additional pins into the ground 50 cm.

- Connecting the busbars to the pins using the device clamps according to the diagram.

- Perform measurements according to the instructions for the device.

Place electrode “C” at a distance 5 times the length of the vertical ground electrode. Remove pins from underground utilities for data accuracy.

Technology for working with the M-416 device

Checking wires with the M416 device for resistance compliance

If a visual inspection does not reveal any faults on the ground line, you can find out the condition of the circuit using the M-416 device. The work is carried out as follows:

- Power supplies are checked. The device must have 3 batteries of 1.5 V each.

- The device is placed horizontally on a flat surface.

- Calibration in progress. The range switch is set to the “5Ω Control” mode.

- The arrow is set to the zero position. You need to press the red button and turn the rotor handle. The scale displays 5±0.3 Ohm.

- The meter is located at a minimum distance from the ground electrode. This will help prevent the resistance of the connecting wires from affecting the overall result.

- The test is carried out according to the diagram under the cover of the device. The main and auxiliary electrodes will need to be driven into the soil to a depth of 50 cm.

- Calculations are being carried out. If the resistance is less than 10 Ohms, the total must be multiplied by 1, and the switch must be moved to x1. If the measurement result is more than 10 ohms, the switch is switched to x5, x20, x100.

Sockets without grounding

They are often found in houses built before 2000 that have not undergone major renovations. Ungrounded sockets work simpler: there is only zero and phase, and there is no third contact.

They are produced without a grounding contact, therefore, if the wires are shorted to the body or the cable is broken, electric shock is guaranteed. In addition, an ungrounded outlet does not have lightning protection.

In the event of a collision with a power line pole, all connected equipment may burn out.

However, they also have their advantages:

- cost less;

- easier to install;

- more durable.

In general, you can still use sockets without grounding, because... When handled carefully they are quite safe. Moreover, they are more convenient when connecting small equipment, such as nail lamps, lamps, soldering irons, etc.

Often, manufacturers do not equip them with grounding cables, so problems do not arise.

Many chargers for laptops and phones also do not have a PE contact, which means you can choose a cheaper outlet - this does not pose any danger.

It is appropriate to connect an outlet without PE in non-residential premises, such as a garage or utility room.

Connection nuances

Connecting a socket without grounding involves fixing the zero and phase in the contact grooves. It is important to consider only 3 nuances:

- The mains voltage is variable, so it makes no difference in what order you connect the wires.

- The contact between the clamping screw and the wire should be maximum. Because there is no grounding, an electric arc may form in the socket.

- You cannot connect sockets using a daisy chain method. Higher chance of short circuit and overload.

- If protection is necessary, it is possible to reset it. In this case, the ground contact is connected to zero. In the event of a short circuit or penetration into the housing, the machine is switched off.

Determining the purpose of conductors

When working with electrical wiring, be sure to double-check the assignment of the outlet conductors. There is no guarantee that the electrician or the previous owner of the premises did not mix up the wires. Therefore, if the tester shows a voltage of 220 V relative to a terminal that appears to be grounding, this does not mean that it is such.

This means that one of the contacts is a phase, and the second is a zero or ground. If the tester shows 0, then there is a neutral and ground conductor. It is impossible to understand exactly what is what.

If you are not 100% sure of the purpose of the grounding terminal, the sockets operate differently. First you need to exclude the presence of two phases. Check the voltage between all contacts. If the device does not show 380 V anywhere, but only 220, it means that one phase conductor is connected to the socket. Now you need to start looking for grounding.

First you need to disconnect the grounding conductor in the floor panel. It is connected through a bolted connection to a special bus welded to the body of the electrical panel.

After this, the voltage between the socket connectors is measured.

If the device shows 220 V, then the socket contacts are the phase and neutral wires, and the ground terminal really is. Now knowing exactly where the ground is, you can determine the remaining connectors, but first you need to reconnect the “ground” to the ground bus.

If the multimeter shows 0, then the ground has been connected to one of the socket contacts, and the second is neutral or phase. Now we take measurements between the socket and ground contact of the socket. If there is no voltage, then this socket is the real ground.

The readings at 220 V speak for themselves.

Summary: what is the difference between sockets with and without grounding?

And so, we can give the main differences between different types of sockets:

- Safety. The PE contact allows you to prevent electric shock if the cable is short-circuited to the housing or broken. Conventional sockets require careful handling and regular inspection.

- Form factor. A grounded outlet has 2 additional contacts on the front side. Please note that they are spring loaded, so a regular plug can be inserted here.

- Zeroing. A method of protection similar to grounding, if it is not provided for by the wiring. In this case, the PE contact is connected directly to zero, which allows you to simulate grounding.

- Price. At the moment, there are sockets with grounding that are cheaper than regular ones. This is due to the fact that their production is more widespread and affordable.

Why is it necessary to install an RCD?

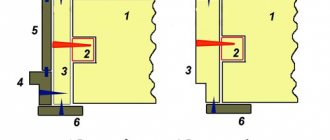

Let's look at this issue using a simple example. Let's say there is a washing machine in the bathroom. Electrical wiring in the apartment is made only with neutral and phase wires, there is no protective grounding, and the RCD is not installed.

Let us present the situation further. The insulating layer inside the machine was damaged, causing the phase to come into contact with the metal body. Some potential has appeared, that is, the body of the washing machine is now energized. If a person approaches it and touches it, it will play the role of a conductor through which electric current will flow. The effect of the current will continue until the person withdraws his hand from the washing machine, because the damaged area will not be turned off by any device. Unfortunately, under the influence of current, a person’s muscles are paralyzed, and it is not always possible to pull the hand away.

There are two options here - either the person loses consciousness and gives in, or someone else helps him by turning off the input machine for the room.

If, in the example considered, there was an RCD in the distribution panel, it would react to the appearance of a leakage current, turn off and protect human life. It is for this reason that in an apartment equipped with a large number of powerful household appliances, the installation of an RCD is simply necessary.

Useful video on the topic

A lot of interesting information is in the video.

Leave a comment Cancel reply

Similar posts

We make holes for sockets in concrete and tiles ourselves

Height and placement of sockets in the kitchen in a modern apartment A socket with a remote control is an indispensable help at home

Installing sockets in a wooden house with your own hands. Is it difficult?