Installation according to GOST. The whole truth and... not entirely true

Having decided to install a plastic window, you carefully choose a company: having your own production and certified products guarantees that the window will be of high quality.

But 70% of a durable window is its installation. In advertisements and advertisements you can often find a phrase like “Installation of plastic windows according to GOST.” Theoretically, such installation is a guarantee of quality, reliability and durability of installation work, but.

What is “installation of a plastic window according to GOST”?

- GOST 30674-99 “Window blocks made of polyvinyl chloride profiles”, art. 9;

- GOST 30971-2002 “Mounting seams of junctions of window blocks to wall openings. General technical conditions"

- GOST R 52749-2007 “Window installation joints with vapor-permeable self-expanding tapes.”

- Requirements for the properties of the construction seam filling.

- Requirements for the dimensions of the installation gap.

- Requirements for the size of the window opening.

- Requirements for window opening surfaces.

- Requirements for securing the window structure.

- General requirements for the performance of work.

- GOST requirements and recommendations for documentation of work.

- Contractor's warranty obligations.

Errors when sealing and insulating window openings

Practice shows that in order to seal and insulate window openings, in the vast majority of cases today, special polyurethane foam is used. This is due to a number of well-known factors, the main of which are maximum tightness and speed of installation.

When using spray foam, inexperienced installers often introduce too little or too much spray foam into the gap around the window frame. Thus, in the first case, the gap space around the window is not completely filled and does not provide a tight seal. The result is the absence of a thermal circuit, freezing in winter and possible blowing. In the second case, excessive use of polyurethane foam can lead to deformation of the window profile.

Lack of sealing or poor quality sealing can be caused by other reasons. Premature start of processing of polyurethane foam, before it has completely dried, can lead to a decrease in the volume of the insulating layer, and as a result, to a deterioration in sealing efficiency.

The main part of the window and the components used in the assembly. 1. Outer layer of insulation (PSUL) 2. Inner layer of insulation (vapor barrier) 3. Central layer of insulation (foam) 4. Glass 5. Fasteners 6. Frame 7. Slope 8. Spacers 9. Wedge

Filling gaps

Fill gaps around window units using polyurethane foam, expansion tape and vapor barrier. The insulation pie consists of three layers! Before using foam, it is necessary to insert spacers (mounting wedges) between the window frame posts to prevent their deformation due to the expansion of the foam. Choose foam with minimal expansion, thereby reducing the risk of making a mistake in its dosage

Sealing with polyurethane foam

Before you start sealing, thoroughly moisten the window openings with water, which will increase the adhesion of the foam. Fill the gap between the frame and the opening to 1/3 of its volume. After applying the foam, be sure to allow time for it to dry completely in accordance with the manufacturer's instructions. Once dry, remove excess foam using a sharp knife.

Using mounting tape

If you choose the option of finishing window slopes with plastering, then use a special tape to prevent scratches and dirt from appearing on the window profile. Upon completion of the work, do not forget to remove the tape as soon as possible; after 2-3 months this will be very difficult.

Myths about plastic windows

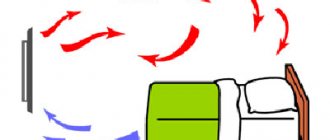

Myth 1. Plastic windows block the opening and “don’t breathe”

Modern designs are equipped with high-quality fittings and rubber seals around the perimeter of the sash and frame, which prevents drafts from entering the room. For a user who is not accustomed to such tightness, at first it seems that the apartment has become stuffy. Compared to old wooden frames, which “breathed” thanks to cracks and dried wood, plastic windows really do not allow air to pass through. To avoid stuffiness and ensure access to fresh air, it is necessary to ventilate the room at least 2 times a day for 15 minutes. New wooden windows also do not “breathe” naturally. The surface of the frame is treated with special impregnations and varnishes, through the pores of which wind does not pass. Wood products require daily ventilation for a comfortable indoor microclimate.

Myth 2. Plastic windows are not environmentally friendly

There is a widespread belief that plastic structures are hazardous to health. Most often, the buyer reacts to the mention of lead in the PVC profile. For rigidity, strength, increased service life, beautiful appearance, and reliable protection against moisture absorption, various stabilizers are added to the plastic. These additives may be lead based or calcium and zinc compounds. Only the material does not contain lead itself, but its compound, which has absolutely no effect on human health. The same table salt is sodium chloride. If we said that salt consists of chlorine, would we eat it? But the compound is strikingly different from the chemical element itself. The same goes for profile additions. The safety of plastic has long been studied and proven. We use this material every day for things such as a toothbrush, glasses, and dishes. Baby bottles are made of plastic and even in medicine you cannot do without it; the same vessels for donor blood are made of PVC.

How to care for your seal so it lasts longer

There are special kits for caring for plastic windows.

Twice a year, the products need to be cleaned and lubricated . There is no need to dismantle them for this.

Soapy water and detergents that do not contain alcohol are suitable for cleaning The sash and frame contours need to be processed. The elastic sides are then wiped dry (lubricants are hydrophobic, so water may interfere with absorption).

Silicone compounds are well suited for lubrication Do not use mineral oils (they are harmful to rubber) or other mixtures that can react with seal components. The lubricant is distributed over the product, the excess is removed with a napkin.

GOST for installing PVC windows in a wooden house: brief information

Installing plastic double-glazed windows in old wooden houses requires certain knowledge. State standards regulate the requirements for installation work, without compliance with which the geometry of the window opening itself may change. This is due to the properties of the wood material, which shrinks over time. To prevent the formation of cracks and the occurrence of unbearable loads on the windows, the owner is required to comply with GOST for the installation of PVC windows, as can be seen in the photo. In particular, we are talking about the need to correctly perform casing and place a seal. We'll talk about how to do this correctly below.

Rubber

Material – vulcanized rubber. Rubber bands are only black due to the color of the filler - soot.

Advantages of a rubber seal:

- reliable window sealing;

- low price.

Flaws:

- cracks and shrinks due to temperature changes;

- short-lived.

GOST requirements

We list the main requirements that are specified in provisions 30971-2002:

- The glass frame should be several cm smaller than the window opening. If 4 cm is enough for the width, then the length of the opening should be 6-7 cm longer. Only such values can allow a wooden structure to move unhindered;

- The error limit when installing the structure should not exceed one and a half mm per 1 m of window length. Installation is carried out strictly in a horizontal position with a building level;

- Since the use of polyurethane foam is prohibited, only mechanical fastening is used;

- Serious requirements are placed on the installation seam: if a waterproofing layer in the form of a film is installed outside, then a thermal insulation layer (polyurethane) with an aluminized vapor barrier is installed inside the room.

TPE

It is a thermoplastic polymer—a modified plastic—that at normal temperatures has the properties of rubber.

Advantages:

- A high degree of elasticity ensures good sealing.

- Excellent resistance to welding, non-flammable.

- It can be any color, most often gray.

- It is installed automatically in production, so the defect rate is lower than that of other types.

Flaws:

- At temperatures below -20 ˚С it loses its elasticity – it “turns tan”.

- At temperatures above +35 ˚С it softens.

- Unresistant to mechanical damage.

- A soldered seal is more difficult to replace, so this service will cost more.

Description of installation work

Before installing a plastic double-glazed window, it is necessary to dismantle the old window structure and prepare the workspace. This involves cleaning work and adjusting the opening parameters, if the situation requires it. However, it should be remembered that too large dimensions of the window opening can affect the strength of the structure. And sometimes, on the contrary, beams are used to narrow the opening.

The box is placed on special mounting wedges, which should secure it firmly. Additional plates are often used between the gaps. Fixation is carried out using glazing beads with a tenon joint (you must wait for a slight click for fastening). Then adjustment is made with the building level and further glazing. After placing the fittings, they begin to create the assembly seam. At the final stage, the window sill and external slopes are installed. Excess foam must be carefully cut off so that the decorative trim with platbands or other accessories does not look rough.

In what ways is it possible?

There are two common ways to install a PVC frame without a stand profile and with a stand.

Without stand profile

In the first option, a number of through holes for anchors are drilled in the frame for fastening in the opening, using a 10 mm drill with the direction of the holes perpendicular to the profile.

I place such holes along the profile axis, with a gap of 180 mm to the inner corner, and 150 mm at the point where the impost is attached.

The drilling direction is maintained from the outer wall to the inner one, this will help create holes of the correct shape.

Sometimes there is no reinforcing liner in the frame profile in the drilling area. When drilling from inside the room, this defect will not be identified, but if on the contrary, then the absence of the liner can be detected.

In this case, you need to make a new hole in the frame, moving 40 mm. These measures are necessary to avoid installing the anchor without a liner, otherwise it will fall inside the chamber.

For standard two- and three-hung windows, fastening is carried out with 11 anchors. In this case, you need to pay attention to the drill; it must be pre-sharpened in order to drill through the internal reinforcing liner.

Advantages of installing metal-plastic windows without a support profile:

- faster installation;

- low installation cost.

Disadvantages of installing a frame without a support profile:

- the ebb is attached to the frame, which creates conditions for moisture to enter the room;

- the tightness of the installation is broken, the wall will freeze;

- the fastening of the window sill is broken;

- The thermal density of the window is disrupted.

With stand profile

When installing a PVC frame, a special profile is attached to the lower end - a stand; after installation, this element cannot be seen, but it fulfills the very important energy-efficient characteristics of the window. In addition, a slope is attached to it from the outside, and a window sill from the inside.

The stand profile is placed in a specially designated groove at the bottom of the frame and secured in it with self-tapping screws and special clamps.

Advantages of a wildcard profile:

- provides thermal protection of the seam together with construction foam;

- increases the service life of the PVC block;

- strengthens the structure of the installed frame;

- protects the opening from moisture and biological damage by mold.

Oddly enough, many experts believe that when installing PVC windows this element is not required, since the main heat and moisture protection is provided by foam. The disadvantages of installing a PVC window using a substitution profile include:

- high cost of installation work;

- extended installation time.

Creating a casing

The arrangement of the casing (edge) is carried out in the form of a box with a special fastening. The support system is created from medium-diameter timber (from 50 to 100 mm). Longitudinal grooves are installed in the side walls for free sliding of the ridges. The latter are fixed on the sides of the casing.

Attention! Since wood shrinks over time, a powerful box cannot be attached directly to the logs.

The fastening is otherwise called tongue-and-groove, since it does not involve the use of self-tapping screws. It is imperative to leave technical gaps, which will subsequently be filled with tow. Since the already mentioned GOST does not encourage the use of plastic windows in wooden buildings, its requirements for the installation seam should be strictly observed. The three-layer seam includes the following components:

- External means moisture removal from the insulating layer;

- The insulation is filled with polyurethane foam;

- The inner one should protect the insulation from exposure to steam.

If all conditions are met, the natural deformation of the structure should not affect the design of the plastic double-glazed window. Sometimes they are limited to finishing casing instead of façade cladding.

Errors in the accuracy of geometric parameters

A very common mistake when ordering and installing products is errors in measurements. Ideally, this procedure is carried out on empty window openings during the construction stage of the building.

In practice, plastic windows are installed as a replacement for old wooden ones. The presence of an installed frame prevents accurate measurements. In turn, this leads to an erroneous geometry of the finished double-glazed window. How can you understand at the installation stage that the measurements are incorrect?

At a minimum, it is worth remembering that the distance between the frame and the wall of the building should be 3-4 cm. In the lower part, such a gap may be larger, taking into account the installation of an external ebb. A distance less than that specified is unacceptable, because in this case the expansion and contraction of the plastic becomes difficult. This occurs due to changes in air temperature: at positive temperatures the frame will increase, and at negative temperatures it will shrink.

The frame has no choice but to rest against the wall. Because of this, curvature occurs and it can deteriorate ahead of time. Sometimes cracks even appear in the glass unit. For the installer, narrow gaps also have disadvantages, because they are quite difficult to fully fill with foam. The empty spaces thus obtained violate the tightness of the seams.

It is important to choose the optimal distance to the wall, because large openings also negatively affect the quality of installation. There is no normal fastening, and the structure turns out to be shaky.

Such defects can be corrected in rare cases. If the error is a few centimeters upward, then it is corrected with polyurethane foam. In other situations, it is necessary to order new products.

General recommendations

- PVC windows are checked for compliance with the load before the start of all work. It is strongly recommended to entrust installation work to specialists from the company from which the plastic windows were purchased. In this case, there will be a guarantee for possible errors during installation;

- Installation in accordance with GOST implies compliance with a number of conditions, in particular, the mandatory sealing of the window structure using slopes. For sealing, various sealants, silicone sealants such as Steez or polyurethane foam are used. It is important that the insulating elements are unable to change under the influence of climate. Bitumen mastics are also not suitable for the reason that they interfere with the breathing of wood. Rotting and dampness are unlikely to be part of the owner's plans;

- The installer must draw up a work plan indicating all materials so that the owner can control its quality and compliance with GOST;

- According to fastening requirements, the use of adhesives or liquid nails is prohibited. Only special fixings with crossbars are used to reliably resist shrinkage of the house;

- The protective film from PVC products is removed no earlier than after a week;

- It is not recommended to paint joints.

In order for PVC windows to be used for a long time and without complications, installation work is recommended to be carried out in accordance with the requirements of GOST. Since many conditions must be met, it is better to entrust the installation of double-glazed windows to professionals. Otherwise, there is a high risk of incorrect installation. The latter may lead to unnecessary material costs.

Replacing the seal yourself

Changing the seal is not difficult; you can do the job yourself. To do this, it is recommended to remove the sash from its hinges and lay it on a smooth, flat surface. after this you need to perform the following steps:

- completely remove the old gasket;

- clean the grooves or seat from dirt. Residues of glue or sealing material;

- apply special glue to the profile groove;

- insert a new gasket into the grooves;

- The gasket is cut at the corners and the joint is glued at 90°.

Attention! Installation of several pieces in one groove is not allowed. A solid profile must be installed along the entire length, otherwise its performance will be significantly reduced.

Advantages of installing windows according to GOST

In addition, installation of wooden and plastic windows in accordance with GOST provides the following advantages:

- minimizing the freezing effect;

- protection against mold on slopes;

- tangible economic effect – reduction of heating payments during the heating season;

- preventing the appearance of microcracks on internal slopes;

- Reducing the amount of condensation to an absolute minimum.

Installation of window structures in accordance with GOST not only allows you to extend the service life of products, but also ensures the possibility of their trouble-free operation. The requirements for the selection of fastening elements and the distance between them specified in the standards make the likelihood of various kinds of deformations and distortions that interfere with the normal opening/closing of the sashes and can cause depressurization of the windows insignificant.

If the contractor guarantees compliance with standards, and this is reflected in the contract, then if problems arise, the customer has a better chance of correctly formulating his claims to the installers. Thanks to this, it is easier to prove the violation of technology by the installer and bring him to justice.

What is the essence of installing windows according to GOST and what is the sequence of work?

Thanks to the installation of windows in accordance with GOST, it is possible to bring the microclimate in the premises as close as possible to the requirements of SanPin 2.1.2.1002-00, which regulate humidity, ventilation, optimal temperature, and so on. Subject to compliance with the parameters specified by accepted standards, installation work is carried out step by step in the following sequence:

- Unevenness on the inner sides of the opening is eliminated and all surfaces are cleaned of construction debris, including dust and dirt. If necessary, it is recommended to level the opening using building mixtures. Then the surfaces are primed.

- After marking and preparatory work, a vapor-permeable self-expanding tape is fixed on the inside of the opening to protect the assembly seam from moisture penetration. A tape is glued to the outside of the frame's outer ribs to ensure complete waterproofing.

- A window structure is inserted into the opening, which is leveled in all planes using cushions and blocks.

- The frame is secured using anchor dowels.

- The sashes are hung.

- The seams between the inner sides of the opening and the frame are gradually filled with polyurethane foam, the choice of which is determined by the time of year and climatic conditions at the time of installation.

- Installation under the window sill and casting of special tapes. A vapor barrier material is used on the inside, and a vapor-permeable diffusion tape is used on the outside.

At the same time, full installation in accordance with GOST is carried out not only taking into account the requirements for the installation process, but also taking into account the correct selection of all the main elements of the window structure. Everything important about the characteristics of the profile, double-glazed windows and fittings can be found on the website aggregator of plastic and wooden windows OknaTrade.

Execution options

vaster

The discussion turned out to be constructive at the seams. I would also like to hear from the installers what you think about the materials for installation and the technology described below.

- Pre-treatment of aerated concrete: primer, then STIZ-D.

- Window fastening: mounting plates, pitch up to 700mm, terrace exit with anchor bolts.

- Support pads: plastic.

- Waterproofing (from the street): vapor-permeable sealant STIZ-A or analogues.

- Assembly seam: polyurethane foam.

- Vapor barrier (from the room): vapor barrier tape.

- Additional sealing of connectors and expanders with PSUL tape.

technologistSPK

Apart from support pads, plates and mounting foam, everything else is a waste of money. I will give my reasons.

- Polyurethane foam has negligible vapor resistance.

- Polyurethane foam is negligibly hygroscopic.

- For interior and exterior applications, the foam will be sealed inside and out, creating the same barrier as sealants. The internal slope will be denser, which means that the rule is more dense on the inside than on the outside.

Of course, you can do what you plan, it won’t be bad, but it won’t be just as bad without extras.