The cost of energy resources in our country is constantly growing, as a result of which we have to pay more and more for heating and hot water. To reduce costs, it is necessary to take care of high-quality thermal insulation of the building envelope. However, its effectiveness directly depends on the correct choice of insulation, and the most popular types in this group of materials are mineral wool and polystyrene foam.

The concept of mineral wool covers three types of insulation - slabs or mats made from:

- fluffed basalt fibers;

- glass;

- slag waste.

In order for the comparison of cotton wool with polystyrene foam to be correct, only basalt slabs can be considered. The fact is that the other two insulation materials are hygroscopic and actively absorb moisture, while slag wool also releases toxins when wet.

With polystyrene foams it’s not so simple either. Plain white foam is flammable and cannot be used for thermal insulation of buildings. Conventional molded polystyrene foam has a porous surface and partially absorbs moisture. Therefore, to insulate the external walls of residential buildings, only extruded polystyrene foam boards with a waterproof smooth surface can be used.

Insulation of the house

To live comfortably in a private home, the walls of the house need to retain heat well. The indoor atmosphere depends on several factors:

- season;

- house construction technology;

- type of heating;

- climatic conditions.

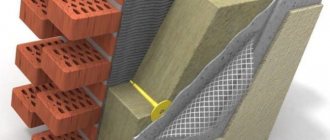

To ensure the required temperature in the rooms, most often it is necessary to install walls with the installation of various building materials in several layers, this is called a “wall pie”. If the pie is selected and installed correctly, the indoor atmosphere will be comfortable at any time of the year.

Insulating the walls of a frame house with mineral wool Source www.landlordzone.co.uk

- In rare cases, it is possible to completely meet the heat demand with just one external wall, so it is necessary to use additional thermal insulation. Typically, the search for the right insulation is narrowed down to the choice between polystyrene foam or mineral or stone wool. Each of them has its own advantages and disadvantages. To understand which one is needed for your home, you need to understand what each insulation is.

Soundproofing

- Mineral wool, due to its weight and specific structure, has excellent sound dampening ability. By using it to insulate walls, the acoustic comfort in the room also improves. Therefore, mineral wool is often used in the construction of internal partitions, for example, made of plasterboard. Mineral wool slabs, which have the lowest density, are fluffier, well insulate sound traveling in the air, while hard and semi-solid slabs suppress noise caused by the operation of appliances well.

- Expanded polystyrene has mediocre acoustic characteristics, especially when it comes to sounds traveling through the air and vibrations emanating from devices. It should be noted that there are special types of polystyrene that dampen impact sounds.

Styrofoam

When the question arises about insulating the walls of a house or outbuildings, people most often think about polystyrene foam. Actually, polystyrene foam is the general name for a group of foamed plastics (polymers), which includes EPS (expanded polystyrene foam) and XPS (extruded polystyrene foam). Expanded polystyrene consists of many balls with air inside. The cavities are sealed, so air masses are not able to move. This leads to the fact that the material has high thermal insulation rates.

The percentage of air in the total mass of the material is about 98%. During the manufacturing process, polystyrene beads are filled with a pure carbon compound, pentane, which has foaming properties, and then heated.

Expanded polystyrene insulation Source st26.stpulscen.ru

An increase in temperature provokes a change in the state of pentane to a volatile one, and as a result, the polystyrene beads increase in volume. The cavity of each ball is filled with air. After this, gluing occurs using steam. The sizes of the cavities range from 5 to 15 mm. Developers love expanded polystyrene for:

- high thermal insulation performance;

- Possibility of use in places with high humidity;

- light weight, which greatly facilitates transportation;

- long service life;

- high sound insulation rates;

- resistance to fungal diseases.

Expanded polystyrene has high diffusion resistance. This means that during installation there is no need for an additional vapor barrier membrane. Expanded polystyrene of standard sizes has a thickness from 2 to 10 cm. The length of standard plates is from 100 to 200 cm, width from 50 to 100 cm. Non-standard sizes are produced according to individual orders with specified parameters. Since the slabs have a dense structure, there is no need to use windproof films.

Insulation of internal walls with polystyrene foam Source otdelka-expert.ru

The main disadvantage of polystyrene foam is its high flammability. Upon contact with fire, it ignites quickly and, when burned, releases toxic chemicals with a strong pungent odor. However, now in the production of this material, to increase the material’s resistance to fire, fire retardant additives are used during the manufacturing process, which provide the possibility of self-extinguishing. Another disadvantage of expanded polystyrene is its low resistance to solvents and chemicals: when they enter, the structure and geometric shape of the foam are disrupted. In addition, polystyrene foam is highly fragile, which leads to damage to the material.

Expanded polystyrene

Expanded polystyrene is a material obtained by foaming. It consists of 98% air and 2% polystyrene with various additives. Essentially, many air bubbles are enclosed in a polystyrene shell. Since the static sealed air layer is an excellent insulator, this material is widely popular among insulation materials.

Here are some characteristics of polystyrene foam:

- The thermal insulation coefficient ranges from 0.028 to 0.036 W/(m K).

- Vapor permeability - 0.015-0.05 Mg/(m h Pa).

- It is resistant to alcohol and ether.

- Mechanical tensile strength - no less than 20 MPa.

- Soundproofing effect. A sheet of polystyrene foam 3 cm thick can reduce noise penetration by 25 dB.

- Low moisture absorption - no more than 6%.

Expanded polystyrene is produced in sheets measuring 1 m * 1 m. The thickness of the sheet can be different, depending on the needs of the buyer. The most commonly used sheets are 5 and 10 cm thick; they are also available in 3 or 2 cm thick.

Foam plastic in different sizes

However, sheets of greater thickness or different sizes can be produced to order. To increase the thermal insulation qualities, 12 cm polystyrene foam can be used.

Types of material

In addition to differences in size and thickness of the material, it is also distinguished by density. One special type is extruded polystyrene foam. It has a very fine structure and is produced by extrusion. This material has high compressive strength. It is more durable.

Extruded polystyrene foam

One of the characteristics of expanded polystyrene is density. It varies from 15 to 35 kg/m3.

Advantages

Here are some reasons why polystyrene foam is preferred to mineral wool in certain cases:

- If polystyrene foam needs to be plastered (this applies to façade finishing), it is much more convenient to work with it rather than with mineral wool. It is much easier to glue sheets of foam plastic evenly due to their smooth surface, and when applying the adhesive mixture, it will not roll off.

- Polystyrene foam is safe for health. When working with it, you do not need to use a respirator, long sleeves and glasses, as is necessary when working with mineral wool.

- Polystyrene foam has a low water absorption coefficient.

- Low price.

- Light weight.

Flaws

In addition to the advantages, polystyrene foam also has disadvantages:

- It is susceptible to rodents and other animals. If the material is not protected from external influences (for example, by plastering), mice can chew it. Another pest is geese, which can significantly damage an unplastered façade.

- Flammability. If a fire occurs, it will help the fire spread by slowly smoldering. And the substances that are released when polystyrene foam burns are very harmful to health.

- It is vapor-tight, so to maintain a comfortable microclimate in the room you will need to ventilate frequently.

- Foam plastic is negatively affected by the sun's rays - it begins to collapse. An unplastered facade can become 0.5 cm thinner over a few years.

Therefore, when choosing polystyrene foam, you should weigh the pros and cons.

Stone wool

There is an opinion that stone wool is a synthetic material. This is wrong. On the contrary, stone wool is based on natural materials. The idea for the production was the principle of a volcanic eruption, in which molten rock under the influence of high temperature turns into lava and is thrown out of the crater. The production process of basalt wool is based on a similar principle. In factory conditions, in industrial furnaces, basalt rock is heated to a temperature of 1500 degrees. A molten mass is formed from which filaments are made. From these, using a pendulum spreader and synthetic binding components, an insulation sheet of the required density and size is formed. At the final stage, it is subjected to heat treatment up to 200 degrees to polymerize the binder, after which the web is cut to standard sizes and packaged for transportation.

Stone wool production Source express-china.ru

The material can have different densities. Low-density insulation materials include stone wool with a density of 25 to 50 kg/m3. Medium density material has values from 60 to 80 kg/m3. High-density boards include material with a density from 90 to 175 kg/m3.

Stone wool in rolls Source fasad.guru

Stone wool has a number of important advantages:

- high thermal insulation rates;

- ability to pass steam;

- environmental friendliness;

- good noise insulating properties;

- resistance to bacterial and fungal infection;

- non-flammability;

- durability.

Stone wool slabs from Paroc Source eurodach.lutsk.ua

Installation of stone wool for internal wall insulation Source paneligid.ru

See also: Catalog of house projects made from aerated concrete blocks

When installing mineral wool slabs, it is recommended to use personal protective equipment during installation. In addition, since stone wool is not a closed-loop insulation and has the ability to allow vapor to pass through, during installation it is necessary to additionally install a vapor barrier layer. If this is not done, then over time the insulation may become damp, which will lead to subsidence and deterioration of the thermal insulation ability. It is also impossible not to note the cost of stone wool, which significantly exceeds the cost of PPS insulation. In addition, the need to purchase a vapor barrier further increases the cost of purchasing materials for insulation.

Foam insulation Source prouteplenie.com

Fire safety

Looking ahead, let's say that mineral wool does not burn at all, and basalt fibers successfully withstand temperatures of +1000 degrees, so it has a significant advantage. Polystyrene foam not only melts, but burns on its own, and even fire retardants cannot stop this process.

The active substances only slightly slow down the effect of fire, but over time their effect fades away. In this category, basalt insulation wins a convincing victory.

Main Differences

Due to its sealed structure, polystyrene foam does not have the ability to remove air masses outside. Therefore, if we compare whether polystyrene foam or mineral wool is warmer, the answer will be in favor of expanded polystyrene.

Vapor permeability

Vapor permeability is the main difference between these two types of thermal insulation. For expanded polystyrene it ranges from 0.13 mg/(m*h*Pa) to 0.03 mg/(m*h*Pa). Stone wool indicators range from 0.4 mg/(m*h*Pa) to 0.6 mg/(m*h*Pa).

Comparative characteristics of insulation materials Source moybalkon.com

This clearly demonstrates that mineral wool insulation removes vapors much better. During the operation of insulation when heating a house, vapors are retained on those layers of the wall “pie” that have the lowest vapor permeability. This means that when using mineral wool alone, the dew point will most likely be located inside the insulation, which will lead to moisture accumulation inside the insulation. If the insulation becomes damp under the influence of vapors, this will lead to a significant deterioration in its properties. Therefore, it is necessary to install a vapor barrier layer inside the house on top of mineral wool. While polyurethane foam thermal insulation itself is non-hygroscopic and does not require the installation of additional membranes.

Fire safety

In the case of comparing non-flammability indicators, the clear victory will be for stone wool.

Consequences of neglecting fire safety Source avatars.mds.yandex.net

See also: Catalog of companies that specialize in home insulation

All types of polystyrene foam insulation quickly ignite and maintain flammability. Stone wool can withstand high temperatures up to 1000 degrees, does not ignite or burn, which makes its use more preferable in rooms with a risk of high temperatures.

Price

When deciding whether to use polystyrene foam or stone wool to insulate a house, the question of the cost of materials arises. Currently, one cubic meter of stone wool will cost about 2.5 thousand rubles. The same volume of polystyrene foam insulation will cost more - at least 2.6 thousand. However, it is worth taking into account the price of vapor barrier (from about 15 rubles per 1 sq.m.)

Choice of insulation Source scientificarab.com

Operation and installation

Installation of polystyrene foam thermal insulation is not associated with the release of airborne particles and dust, so for the installation of EPS layers it is not necessary to wear personal protective equipment. It is important to remember that when joining polystyrene foam slabs, there will be a small distance between them, or in other words, a cold bridge. To avoid heat loss in such places, it is necessary to carefully foam each of them. In this case, stone wool will again have the advantage: when joining mineral wool slabs, such gaps or cracks do not arise.

Comparison of characteristics

When comparing which insulation is better, polystyrene foam or mineral wool, let’s consider several basic technical and operational characteristics:

- environmental cleanliness;

- thermal conductivity;

- lifetime;

- ease of installation;

- resistance to biological effects;

- price;

- insulation density;

- water absorption;

- strength;

- Fire safety;

- soundproofing properties.

Which is more environmentally friendly?

Under normal operating conditions, both insulation materials are absolutely harmless to human health. But with increasing temperature, and even more so when exposed to an open flame, polystyrene foam can become dangerous.

When polystyrene melts, the active release of toxic and poisonous gases begins. And therefore, in most European countries, the use of PPS boards for insulation is prohibited by law. Although in our country it is used everywhere.

Which retains heat better?

Both insulation materials have excellent thermal insulation characteristics. But if we compare the thermal conductivity coefficients, we can say for sure that polystyrene foam is a more effective insulation material.

Which is cheaper?

The cost of basalt mats ranges from 1400 to 2300 rubles/m3. Expanded polystyrene is sold for 1900-2300 rubles/m3, i.e. the price is almost the same. But, as mentioned above, polystyrene foam is warmer and will require 40-50% less of it. It turns out that PPS slabs are cheaper than mineral wool.

Which will last longer

When considering the technical characteristics, it was already said that the service life of PPS slabs is 25, and that of basalt wool is 50 years. Here the clear leader is cotton wool. However, when choosing insulation, you should take into account the finishing method used. Thus, a facade plastered using the “wet” method will last no more than 25 years. Therefore, the use of expensive durable cotton wool simply loses its meaning.

The easier it is to insulate

The installation technology for both insulation is identical. The insulation is initially placed on glue and then additionally secured with plastic mushroom-type nails.

What is less attractive to pests

Both polystyrene and mineral wool are not susceptible to mold and mildew. But rodents very willingly make burrows in polystyrene foam, which is significantly inferior in this regard to basalt fibers.

Which material is more harmful to health?

Under standard operating conditions, both materials are not harmful to humans. However, when the ambient temperature rises or an emergency situation occurs (fire), the foam becomes extremely dangerous for humans.

In the heat, it releases harmful styrene, which accumulates in the body, and in the event of a fire, toxic substances that can quickly render people unconscious in a room on fire. Therefore, the Stockholm Convention on Hazardous and Poisonous Substances directly prohibits the use of foam plastic for attic insulation. In Russia little attention is paid to this, but in the West there is a categorical ban.

Conclusion: under standard operating conditions, both materials do not pose a health hazard. However, you should refrain from insulating walls with foam plastic from the inside of the apartment (house) in the nursery and kitchen, where the risk of fire is higher than in other rooms. And also do not put your health at risk when insulating the attic. Here basalt wool has no competition.

Resistance to microorganisms and rodents

Both types of insulation do not serve as a basis for the growth of mold and mildew. But their relationship with mice and rats is different: they avoid basalt, and polystyrene foam serves as their favorite habitat. Nests are made in it. Adding special additives to expanded polystyrene does not solve the problem.

Conclusion: basalt wool is completely protected from adverse biological effects. Polystyrene foam should not be used where there is a high probability of mice and rats (dacha).

What's worse is burning

Basalt wool belongs to class NG (non-flammable materials), and polystyrene foam belongs to class G3 (normally flammable). Attempts by manufacturers to reduce the flammability class have been successful. Products from BASF, Polimeri Europa, Styrochem, etc., after the introduction of fire retardants, go into class G1 (self-extinguishing). Most Russian manufacturers are unable to do this, which is most likely due to semi-handicraft production.

Conclusion: basalt wool, unlike polystyrene foam, does not burn. Therefore, if there is a high risk of fire, it is better to avoid polystyrene foam.

Vapor permeability

The vapor permeability indicator is especially important when insulating wooden walls. They actively “breathe”, regulating the water balance inside the log or timber. Blocking the wood's ability to remove excess moisture with vapor-tight insulation provokes rotting processes. During the hot season, the tree does not rot, but rots. To a lesser extent, but the above is also true for brick and concrete - condensation forms on the surface of the wall, followed by the growth of mold or mildew.

Comparing the vapor conductivity of basalt (about 0.3 mg/(m.h.Pa)) and polystyrene foam (0.03 mg/(m.h.Pa)), it should be noted that they have exactly opposite properties: polystyrene foam is practically vapor-proof, while basalt wool allows the walls to breathe.

Conclusion: the vapor-tight properties of polystyrene foam give a huge advantage to cotton wool: it can be used on any type of wall material. The use of polystyrene foam is undesirable when insulating the walls of a wooden house, and when insulating brick and concrete, it is necessary to calculate the dew point so that it does not end up on the surface of the wall. If such calculations are not carried out, then the problem can be solved by increasing the thickness of the thermal insulator layer (you need to bring the dew point inside the insulation, where there will be no harm).

Which is easier to install?

Insulation of a building with polystyrene foam and basalt wool is carried out using similar technologies, which does not provide an advantage to any of the types under consideration.

Conclusion: the technology of thermal insulation by any of the materials being compared does not give any of them any advantage.

Other criteria

When choosing insulation, it is recommended to pay attention to such comparative qualities as:

- polystyrene foam is much lighter than mineral wool;

- expanded polystyrene absorbs moisture less and does not lose its properties when wet;

- basalt mats have greater bending strength, which makes it possible to insulate surfaces with complex configurations;

- the fire protection characteristics of polystyrene foam are significantly lower than those of its competitor;

- Polystyrene has virtually no vapor permeability.

Video description

To learn how to inexpensively insulate a frame house, watch the video:

Important! It must be remembered that the walls, inside of which basalt wool is laid, must be well vapor-insulated with careful gluing of the seams with special construction tape.

Expanded polystyrene is not the best option for laying inside walls: according to the experience of homeowners, mice gnaw passages in it and move around the perimeter of the house. But because of its “prickliness,” rock wool is not to the taste of rodents.

When heated, polystyrene foam can emit a chemical odor, so it is better to use it in outbuildings. For example, inside the walls of a bathhouse, polystyrene foam will help avoid installing a vapor barrier, which will reduce the cost of the construction process.

When choosing between expanded polystyrene or mineral wool, you need to correctly evaluate a combination of factors:

- insulation is installed in residential or non-residential premises;

- will there be exposure to humidity and high temperatures;

- Is it possible to install a vapor barrier layer?

It is recommended to use low-density stone wool inside wooden interior floors.

Laying rolled mineral wool insulation in floor joists Source znatoktepla.ru

How to glue mineral wool?

How to glue mineral wool? It is important that there is no air movement under the layers of mineral wool, because... this may reduce its thermal insulation capabilities. Therefore, it is necessary to fix it tightly. Adhesive compositions will help with this. Adhesive compositions that can be used with mineral wool are dry mixtures and foams.

Moreover, foams are more convenient to use; foam allows you to avoid smearing on the surface of the waterproofing.

Video description

How to properly insulate the external walls of a house with penoplex, watch the video:

Therefore, to insulate the walls of a house from the outside, the best choice would be to use pegopolystyrene. Due to the lack of ability to absorb moisture, this material will last a long time without the use of additional construction membranes.

Therefore, when choosing the best way to insulate the walls of a house from the outside, penoplex or mineral wool, the best choice for insulating facades will be the use of PPS. Due to the lack of ability to absorb moisture, this material will last a long time without the use of additional construction membranes.

Installation of facade insulation with stone wool Source 478879.ru

Mineral wool is used to insulate the facade of a private house or outbuilding in cases where it is possible to install a special sheathing. Often, insulation of this kind is combined with the installation of siding, since sheathing is also needed to prepare the walls. Therefore, when choosing stone wool or polystyrene foam, which is better for insulating the facade, what the exterior finish will also matter.

Hygroscopicity

Hygroscopicity is the ability of something to absorb water. It is measured as a percentage of absorbed moisture per day relative to its own weight.

This factor determines the scope of application of the insulation. If the indicator is high, it means that the material needs additional insulation from moisture.

| Material | Hygroscopicity |

| Styrofoam | 1% |

| EPS (extruded polystyrene foam) | 0,04% |

| Mineral wool | 1,5% |

What is better to use for foundation insulation?

The construction of the foundation of a house is often associated with the need to insulate it. If the walls of a private house are well insulated, but the foundation and floor of the first floor are cold, then heat leaks are inevitable, as well as a violation of the comfortable atmosphere in the house. A foundation protected from heat loss provides:

- reduction of heat loss;

- reducing home heating costs;

- preventing dew point changes;

- stabilization of temperature values in residential premises;

- protection from environmental influences.

Insulation of the foundation is possible in two options. The first is placing a heat-insulating layer around the perimeter of the house on top of the foundation.

Foundation insulation with foam plastic Source static.tildacdn.com

Ecological cleanliness

At the very beginning of production, polystyrene foam was produced from styrene using freon. This material released toxic compounds and was prohibited for internal use. Now environmentalists have become more demanding, and manufacturers around the world have abandoned freon, replacing it with more harmless components. But, despite this, it is better not to get carried away with internal insulation using this insulator. And it is perfect for outdoor work.

Basalt-based mineral wool is made from natural components, therefore it meets all the requirements of environmental friendliness and, accordingly, wins in this category over its opponent.

Video description

For a detailed comparative review of insulation, see the video:

To summarize, we can say with confidence that when choosing expanded polystyrene or mineral wool, which is better for insulating a house, there cannot be a definite answer; you need to select the type of insulation in accordance with the set of parameters of the structure itself and the subsequent exploitation. It is important to remember that there are neither bad nor good insulation materials, but there are materials that were incorrectly selected and poorly installed.

When choosing, it is important not to chase the lowest price, but to give preference to trusted manufacturers who have proven themselves well in the building materials market.

High-quality insulation of house walls Source www.promstan.com.ua

After all, even the best material, if installed unskilled, has a high chance of losing its performance properties and characteristics. When choosing, it is important not to chase the lowest price, but to give preference to trusted manufacturers who have proven themselves well in the building materials market.

Professional advice on choosing insulation

The problem of choosing between polystyrene foam and mineral wool insulation for insulation often arises. Below there are two useful tips that can help even a beginner make a quick decision:

- basalt wool is suitable for thermal insulation of various facades before finishing, thermal insulation of gables, the main thing is to provide vapor and waterproofing;

- polystyrene foam is relevant for thermal insulation of facades of brick and wooden houses.

You can always reconsider your options and choose a building material that is suitable in terms of cost and characteristics.

The given recommendations serve as the result of an economic calculation and have been verified empirically. For each specific situation, a heat insulator is selected separately - it is recommended to take the advice of experienced consultants in construction stores.

Briefly about the main thing

To insulate a private home, two types of insulation are most often used: polystyrene foam or stone wool. Each of them has a number of advantages and disadvantages.

Thus, polystyrene foam insulation retains heat better and does not absorb moisture, but is fire hazardous and fragile.

Mineral wool insulation has the ability to release vapors, which entails the installation of a vapor barrier layer, but is non-flammable and does not leave cold bridges during installation.

Taking into account these functional characteristics, you can choose the best option for insulating different parts of the house. It is better to insulate the foundation and external walls with expanded polystyrene. Stone wool is ideal for insulating interior walls, ceilings and attics.

Ratings 0

Installation

Both extruded and regular foam have greater strength and elasticity than insulating wool. It is easy to cut and sanded without problems, but gluing it without joints at which cold bridges form is very difficult. The solution in this case is an L-shaped edge on sheets.

In the case of felt insulation, sufficient elasticity is present only where the mineral wool is produced in the form of mats laid in the frame or on the facade surface. But you don’t have to think about cold bridges here, because the joints between the materials are negligible. And again we can state a draw.

Moisture accumulation

Ordinary expanded polystyrene foam (foam) can become moisturized and accumulate moisture. It cannot just be in the ground or in a damp basement. On the wall it must be protected from sunlight and sediment by a continuous layer of plaster.

But mineral wool can absorb water like a sponge. A prerequisite for its use is constant ventilation with outside dry air.

Those. it is closed either with hanging panels, under which the air stream moves, or with a particularly vapor-transparent thin layer of plaster. Embed cotton wool into concrete (heavy) structures without ventilation. gap with the jet is always questionable and not a recommended option here.

The best manufacturers on the market

One of the first manufacturers to enter the Russian market with offers of mineral wool insulation is URSA. Later, products from Knauf, Rockwool, and Isover appeared. These manufacturers are still considered the best. Analogs from other companies are cheaper, but the quality may not be for the better.

Trusted manufacturers

The most famous manufacturers of extruded and conventional foam plastic today are Penoplex, Elite-Plast and TechnoNIKOL. Any of the presented brands guarantees decent quality insulation based on polystyrene foam.

Scope of application

We have already become familiar with the main characteristics of expanded polystyrene and mineral wool. All that remains is to figure out which material is best to use in certain conditions so that its thermal insulation properties can be fully demonstrated.

teaching staff

Due to its endurance in humid environments, polystyrene foam is suitable for areas where the air is characterized by high humidity. They are often used to finish multilayer and monolithic foundations, as well as underground structures.

When installing a monolithic base, polystyrene foam slabs are laid on a flat plane and filled with a layer of concrete. After complete drying, a house is erected, the floors of which will be sufficiently warm and dry.

Walls made of brick or concrete blocks are also effectively insulated using such insulation. By insulating interior spaces, it is possible to avoid the phenomenon of dew point.

Non-ventilated roofs are treated with polystyrene foam of the PSB-S brand, and covered with waterproofing material on top. Ventilated roofs are insulated with foam plastic on the inside, with a mandatory gap to prevent condensation.

Floors and interfloor ceilings are insulated with foam plastic, which is laid on top of the insulating material. The top of the structure is filled with concrete mortar.

Basalt material

Wooden houses cannot be insulated with polystyrene foam, otherwise they will stop “breathing”; mineral wool will be indispensable here. In buildings made of other materials, ceilings, interior partitions and floors are treated with such an insulator. If it is necessary to insulate the facade, a suspended ventilation facade is constructed using a vapor barrier membrane.

Basalt wool works great in attics, attics and pitched roofs. It is often used to fill the space between masonry in brick low-rise buildings. It is also very effective in three-layer concrete panels.

An excellent solution would be to insulate with fibrous material those places that come into contact with heated objects, because mineral wool can easily withstand temperatures of 1000 degrees. It is used to wrap pipes of heating plants, gas mains and industrial equipment. This material can be attached to surfaces of any shape and configuration.