The mid-90s of the last century was a turning point for the building materials market. Practical and inexpensive types of thermal insulation began to appear, for example, mineral wool, glass wool, and cellulose-based insulation. These materials attract the attention of buyers with their affordable price and relatively good characteristics.

However, there are also significant drawbacks. In particular, these are quite large materials, and the thickness of the insulation board “conceals” the interior space of the premises. In addition, such thermal insulation can dry out and become painted, which invariably leads to heat loss. Of course, mineral wool is still considered one of the popular thermal insulation materials today.

However, this is not due to high efficiency, but to an affordable price. If there is a need for really high-quality thermal insulation of premises, penoizol is used during construction. This is a liquid insulation material that is rapidly gaining popularity in our country.

Penoizol

Penoizol is a heat and sound insulator based on hardened carbamide resin. In working circles you can hear the following names for the material: foamed or liquid foam plastic, poured plastic. Other name options: eco-insol or teploizol (due to its properties). Used in solid and foam states.

Insulation of internal walls with foam insulation

In solid form, it resembles foam plastic, only without large air bubbles. A white foam-like form is obtained by mixing urea resin, foaming agent and phosphoric acid and then pouring water. This mixture is actively used when filling cavities in building structures.

This material differs from others in its special insulation characteristics:

- Compression of a substance at low density is applicable when insulating walls. To do this, the substance is brought to a liquid state and tightly poured into construction voids, cracks and gaps. Even hard to reach ones. Hardens only on contact with air after 15 minutes;

- Low thermal conductivity;

- In a solid state at high density, eco-isol can withstand the weight of a person;

- Due to its chemical composition, it is not attractive to rodents and microorganisms;

- In case of minor deformations, we will restore the material to its previous condition;

- Service life (more than 50 years) depends on compliance with recommendations;

- Doesn't rot. Therefore, it is beneficial for insulation on the outside of the building;

- Resistance to fire and temperatures (+120 - -50°) is in demand in many areas. Especially when using flammable items. Penoizol does not melt, does not burn or smoke;

- Absorbs sounds and noise from the streets or neighbors;

- It is a breathable thermal insulator;

- Harmless water absorption is up to 20%. Moisture does not remain for a long time due to the porous surface of the material;

- Chemical resistance to various active substances.

Roof insulation

Such properties make it possible to efficiently and quickly insulate a private house with foam insulation. But, like everything, it has its drawbacks. These include :

- Due to the relationship between density and volume, severe shrinkage is detected during hardening. Even with well-carried out installation work, voids may form when penoizol hardens;

- Installation work becomes more complicated due to shrinkage of the insulation. Knowledge and practice, strict adherence to the technology of applying penoizol are important;

- Ecoizol is protected by another substance on the outside to avoid chipping in the solid state;

- Special equipment is required for installation;

- It is advisable to carry out work outdoors at temperatures from +15 to 20. The street temperature does not affect interior work;

- Possible long-term accumulation of rain moisture and reduced thermal insulation;

- The use of poor quality material leads to an unpleasant odor.

Independent reviews from construction forums

To understand the real effectiveness of insulation, you should not unconditionally trust the words of sellers and manufacturers. It will be much more effective to turn to the reviews of real people who have already used the subject of our conversation for insulation. Let us immediately note that opinions on the properties of liquid thermal insulation are divided.

Not bad, but there was a small nuance. Alexander (www.forumhouse.ru)

Penoizol is an excellent alternative to any type of modern insulation. The price is quite reasonable, the mice will not be stolen, the declared characteristics are at a high level. However, during practical use, a small drawback emerged: when insulating wooden walls, unfilled areas remained.

Recommended by friends. The house has a comfortable microclimate. Ildar (mastergrad.com)

We decided to insulate the walls with foam insulation about 5 years ago: the outer wall is made of block and brick. 6-7 centimeters left between the masonry . Glass wool and mineral wool did not give the expected result: the wall began to mold, the rooms were quite cool.

Friends recommended penoizol. As the crew worked, one could hear and see the insulation filling the space between the walls, emerging from the cracks. Now the house maintains a comfortable microclimate at any time of the year.

No complaints, but problems arose during the filling process. Mikhail (forumnov.com)

It is clear that seamless insulation has undeniable advantages. There are no complaints about the quality of insulation, however, for the operation of the equipment, a connection to a 380 V . I did not have such an opportunity, which caused some difficulties during the pouring process.

I really don't like the toxic smell. Konstantin (forum.vashdom.ru)

After pouring, penoizol noticeably decreased in volume, which already reduces the quality of thermal insulation. In addition, the material has an unpleasant and clearly toxic odor. They said that the composition includes formaldehyde, the use of which has long been abandoned in European countries. I recently insulated the house, so I can’t say anything about the properties of the material, however, doubts about the correctness of the choice are already tormenting me.

The price of the work is steep. Eduard (www.forumhouse.ru)

Personally, I am satisfied that penoizol will not be chewed by mice, the insulation accurately fills any gaps, and provides reliable heat and sound insulation. I didn't like the fragility of the material and its susceptibility to deformation. And the overall price of the work is a bit steep.

Is penoizol harmful to health?

*

After testing, Russian manufacturers were convinced of the safety of using penoizol. There are certificates confirming this. But polystyrene foam is prohibited in Canada and is not used in the USA as insulation. In the UK, safety guidelines are followed regarding the use of urea foam as a toxic substance. The problem lies in the concentration of formaldehyde, which is released during polymerization. At high concentrations in the air it causes allergies and tumors in the future. Therefore, it is very important to use high-quality materials and adherence to pouring technology. In high-quality products and in the hands of craftsmen, the minimum content of formaldehyde is safe.

Manufacturers of urea foam plastic in the Russian Federation

Many companies in Russia and Europe are engaged in the production of penoizol. However, to purchase quality material, you need to take a responsible approach to choosing a manufacturer. Therefore, we advise you to pay attention to the products of such companies:

- "New construction technologies" . The company was founded in 1990 and specializes in the production of thermal and waterproofing, fiberglass, fiber-reinforced concrete. Today, this is one of the main suppliers of penoizol on the Russian market. By the way, the rights to use this trademark belong to this company.

- "Varmal LTD". This is a British company engaged in the production of liquid insulation flotofaum - the name of penoizol.

- LLC "Uveis" Russian company located in the city of Orenburg. The manufacturer has been working on the market for a long time, so it carefully monitors the quality of its products.

In addition, buyers speak positively about the products of ProTeplo LLC, Penoizol-Omsk LLC, and Murmansk Universal Plant CJSC .

Insulating a house with foam insulation

Judging by reviews from professionals, urea-formaldehyde foam is best suited for insulating frame houses, rooms with three-layer brick walls, roofs, attics, and spaces between floors (floors). Work can be carried out from inside and outside. The external method is preferred when the apartment area is small, when the walls are frozen, for public buildings or apartments with radiators located inside the walls. With it, slabs are attached to the front side of the house. With internal insulation, the space between the wall and the sheathing is filled with foam insulation. In this case, it is used to insulate a private house. Carrying out the work yourself is quite problematic, as it requires special skills and equipment.

If you decide to do it yourself, the work should be carried out in several stages:

- The method of insulation is selected;

- Everything is being prepared for the process. The equipment necessary for independent insulation is assembled;

- Then the composition is mixed. Stirs;

- In a liquid foam state, it is poured into prepared recesses. The air pressure from the foam jet affects the success of sealing the room. This is the most crucial moment;

- Polymerization is the evaporation of liquid and hardening of foam. Passes in a few days;

- After 2-3 days, the excess is cut off.

Injecting penoizol into wall partitions

This method will allow you to carry out all the insulation work within one day.

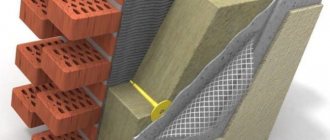

The process of insulating a house from the outside using lathing

This method is suitable for external insulation of wooden, brick and panel houses. Only houses should be low.

The lathing will ensure reliable fastening of the insulation to the wall. When choosing a wooden sheathing, the frame is treated with antiseptics. This is necessary to avoid rotting. With metal, this is not required.

Stages of work:

- On the front side of the building there are small areas for attaching the sheathing;

- For fasteners, holes are drilled in the marked places;

- These holes are filled with a solution of cement or gypsum. After hardening, plugs are driven into them;

- The vertical parts (1m) of the sheathing are attached to the outside with self-tapping screws, which are screwed into the installed plugs;

- Vertical elements (0.5 m) are attached;

- Modified foam takes longer to apply;

- A restrictive mesh is attached to the frame to secure the eco-insulation from leaking and drying out;

- Everything is covered in a pre-selected finish.

Installation of lathing for penoizol

*

This method is labor-intensive, but more convenient.

Rules for pouring liquid foam

In order for penoizol to fully live up to the hopes placed on it, it is necessary to strictly adhere to the pouring technology. If this is your first time dealing with liquid thermal insulation, it is better to immediately contact specialists who can do the job efficiently.

Wall insulation is carried out according to the following scheme:

- Holes are drilled in the wall structures, into which penoizol is pumped through filling hoses.

- Install a protective facade made of metal profiles, leaving a gap of 5-10 cm between the wall and the metal.

- Fill the free space with insulation.

- Wait 4 hours for the material to set, cut off excess insulation, and begin finishing.

Roof insulation:

- The surface intended for insulation is covered with a film, which should extend 10-15 cm .

- Fix the membrane with staples.

- The slats are stuffed on top of the film.

- The space between the slats is filled with insulation.

- Wait 15-20 minutes for the insulation to become viscous and level the surface.

- After 4 hours, you can begin further work.

Floor insulation:

- Wooden sheathing is being installed.

- All sections are filled with insulation.

- When the material hardens, a plastic film is placed on top.

- Finishing is carried out: boards are laid or concrete is poured.

In principle, working with penoizol is practically no different from installing other types of insulation.

What to consider when starting work

Before starting work, you will need to prepare the walls, as well as equipment and tools. Some points to consider:

- Forms of using penoizol in installation. In liquid form, sheet or granular. Some are used for facade insulation, others for interior insulation, and others for attic insulation. As a result, equipment is selected.

- Features of manufacturing penoizol. Liquid is prepared just before use. Otherwise it will be unusable.

- Low density of the substance with large volume and shrinkage.

Price

One of the advantages of this material is not only that it is considered environmentally friendly, but also the low price of penoizol . Moreover, if you compare its main advantages over other types of thermal insulation (resistance to mechanical damage, protection from rodents and insects, moisture resistance), then the prices will seem more than profitable.

In this case, pouring occurs immediately at the construction site. This allows you to reduce most of the costs of storing material. If we talk about average prices, then 1 cubic meter of solution costs about 1,900 rubles.

If a solution of higher density is used, the price will be from 2200 rubles. In some cases, the calculation is carried out depending on the area. In this case, the price is about 200 rubles per 1 sq. m. meter.

Floor insulation with foam insulation

Necessary equipment

When working with liquid insulation, you will need the foam insulation itself, an apparatus, a metal profile with a drill and dowels. The special machine consists of 3 containers for water, hardener, and resin. When you turn on the device, the elements are mixed in a separate chamber. There the mixture foams from strong air pressure. Then it goes into the sleeve and fills the insulated openings.

There are several types of equipment for insulation procedures. This is a GZhU installation, Potok-2000DMU or Potok 3000/10UM from Logrus, Turbojet-6.

The GZHU is a cheap and easy machine to use.

The Potok series from Lorgus has a selection of simple machines, more complex and productive ones. The devices allow you to dose substances and regulate the flow rate. Which is very important during installation.

Compressor for the production of penoizol

Turbojet-6 (turbomechanical mixing) - there is a high-pressure mixture supply and a start-stop function (for better control of the supply of the substance).

Sometimes a lathing with a restrictive mesh is used.

Consumption rates for insulating material per 1m2

When planning a construction budget, you need to accurately determine the amount of material. To determine the amount of liquid insulation that will be required to insulate the entire building, you need to know the consumption rates of penoizol per square meter.

According to manufacturers, the consumption of liquid foam per 1 m2 varies between 1-1.3 liters.

To calculate the required amount of material, you need to multiply the length and width of the wall by the consumption rates stated by the manufacturer. For example: 7*3.2*1.3=29.12 l. In this case, the final amount of thermal insulation must be taken with a small margin, taking into account unforeseen situations.

Interwall thermal insulation with foam insulation

This technology for home insulation is applicable in panel, frame and brick buildings. The work can be done in several ways.

Method 1 – for a building under construction:

- The product tightly fills the cavity in the wall. This method is of the highest quality, as it fills the open space from one side to the other;

- In brick buildings, pressure is supplied from above as the floor is built.

Method 2 – with a building in use:

Holes are drilled at the joints (according to the diameter of the pumping equipment hose) in a checkerboard pattern. The sleeve is first mounted in the lower holes. Through them, the mixture is supplied under pressure into the interwall cavities. When a substance appears in the holes an order of magnitude higher, the supply stops. The sleeves are moved a row higher. And so on up to the ceiling. Filled holes are closed with plugs.

Insulation injection at the construction stage

Method 3 – in a brick building:

A gap is formed between the layers of bricks and through it the empty cavity is filled with a sealant.

Specifications

To obtain a qualitative assessment of the properties of this material, it is necessary to evaluate its technical indicators. These include:

- Operating temperature range – from -50 to +120 degrees;

- Material density – 5-75 kg/m3;

- Daily water absorption by mass – 10.5-20%;

- Thermal conductivity – 0.028 –0.047 (W/m) *°C;

- Humidity (mass fraction) – 5-20%;

- The standard service life is 50 years. According to recent studies, it is not limited.

Tensile strength:

- For bending deformations – 0.1-0.25 kg/cm. sq.;

- For compression (at 10% linear deformation) – 0.07-0.5 kg/cm. sq.;

- Tensile – 0.05-0.08 kg/sq.cm;

Slab penoizol

Thermal insulation of the façade with foam insulation and cladding with cladding slabs

This method of insulation is used only for exterior decoration of the house. The scheme of work is as follows:

- The number of slabs, galvanized steel profiles or other elements for the entire facade is calculated. A galvanized steel frame is attached to the facade of the building with dowels and screws. That is, it is a metal cladding attached vertically;

- Plates (metal or plastic facing panels) are installed and secured to the frame;

- Holes of 35-40 mm are made in the casing at a distance of about 2 m from each other. Penoizol is poured into them using a pump;

- The holes are filled in a checkerboard pattern from bottom to top.

- After completion of the work, the drilled holes are sealed;

- The façade is being decorated.

Using slabs for facade insulation

Each of the above methods of insulating a house with foam insulation has its own advantages, but they are all united by an unusual insulation with excellent thermal insulation characteristics.

Kinds

There are several types of penoizol for various types of work. The most popular of them are the following:

- Liquid penoizol - this type is most often used in the construction industry, since among specialists it is considered the most convenient. It is manufactured immediately at the construction site using special equipment. It can also be purchased in special cylinders if there is no need for extensive work. This type is suitable for filling gaps when renovation work is being carried out in buildings.

- Leaf variety. To obtain such material, liquid foam is poured into special molds. Then the mass hardens and is cut into layers of a certain length. After this, the material must be dried and cleaned. Some companies also offer customers special foil foam insulation. It will not be possible to use glue, since such sheets must be installed using dowels. A cladding must be installed on the surface.

- Chit. This type of penoizol is obtained by crushing a finished solid sheet of material. Its size should not exceed 15 mm.

Recommendations, installation

In order to reduce the costs associated with the thermal insulation of a structure, you can not purchase ready-made equipment, but install it yourself at home.

Such a device must have:

- gas-liquid unit;

- hoses for supplying reagents and foam;

- plastic containers;

- compressor;

- taps.

Installers advise working with penoizol according to this scheme:

- assembling the installation in accordance with the instructions;

- mixing all the necessary components in a barrel;

- preparing the surface to be treated by dismantling old facing materials (the base does not need leveling: a layer of liquid foam can hide all bumps, protrusions and other flaws);

- installation of metal or wooden sheathing (wooden structures must be treated with antiseptic compounds);

- installation of logs from wooden beams;

- applying a uniform layer of penoizol or foaming voids;

- cutting off excess material with a construction knife after it has hardened;

- installation of reinforcing mesh after polymerization of insulation;

- facing works.

In order to install a heat insulator efficiently, it is best to contact certified installation organizations.

Craftsmen are able to quickly insulate any structure and provide a guarantee for the work done.

Resistance to various influences

Liquid foam plastic, which forms an insulating layer on various surfaces indoors and outdoors, is highly resistant to various biological and chemical influences. The material is not subject to the destructive influence of various solvents and active substances.

The presented insulation does not harbor various insects and mice do not gnaw through it. The fungus is also unable to reproduce on its surface. These qualities allow you to create a healthy microclimate indoors.

One of the advantages of the material is its ability to pass air. This allows you to regulate the humidity level in the room. The owners of such a house note that the indoor microclimate is healthy and there is no dampness. The inside of the building is dry and warm. Various pathogens practically do not reproduce in such an environment.

How to choose?

When selecting equipment, consider a number of nuances:

- To install liquid foam, two types of installations can be used: gas-liquid and pneumohydraulic technology. The first, budgetary one, is advisable to use for insulating small objects, for example, a private house. Pneumohydraulic equipment is characterized by large dimensions, productivity and cost. It should be chosen if large-scale work is necessary.

- It is recommended to give preference to installations with a built-in compressor and receiver.

- Pay attention to what the plunger pump is made of and its options. Choose a pump made of stainless steel or plastic. It must have a speed control function.

- You should not buy a unit with a foam generator attached to the pump part.

It is strongly not recommended to purchase penoizol “blindly”. Be sure to ask the seller to prepare the material and demonstrate its qualities.

The sample should:

- have a white color;

- do not decrease in volume immediately after leaving the installation sleeve;

- withstand hand pressure after 15 minutes of hardening;

- do not have large and heterogeneous pores;

- recover quickly after pressing.

If the prepared mass meets these requirements, you can safely purchase it.

The difference between polyurethane and polystyrene

The closest analogue of polyurethane foam is polystyrene foam, which has similar characteristics and is also used for insulating various surfaces.

Expanded polystyrene belongs to the group of slab insulation materials that are made by foaming. Expanded polystyrene also has many advantages compared to many other slab insulating elements. But at the same time, the functionality of this material is slightly limited when compared with polyurethane foam.

Expanded polystyrene cannot be used for spraying pipes, ventilation ducts and, in general, any elements that have complex geometry. But at the same time, you can apply this material yourself, whereas this cannot be done with polystyrene foam.

To apply PPU foam, it is necessary to use special equipment, which, as a rule, is only available to construction teams of workers. Of course, there is an option to apply polyurethane foam using small cylinders, but it will not be effective if it is necessary to apply insulation over a large area.

Areas of application

Thermal insulation is used by both private owners and professionals. It has proven itself not only as a heat retainer, but also as a sound insulating element.

They are equipped with:

- Exterior walls.

- Facades.

- Roofs.

- Pipelines.

- Vegetable storage facilities.

Sandwich panels are also created using foam. Horizontal structures are insulated with granulated mettemplast: floors, attics, between floor spans.

Liquid polystyrene foam should not be laid out on moist areas due to the loss of thermal insulation abilities after repeated freezing and thawing. This refers to the base, foundation, basement. Roofing cake is also included in this number; quality is lost from the negative influence of the sun.

Classification according to acceptable use

Taking into account the recommended purpose, the slabs are divided into several categories:

- general use in rooms with humidity not more than 65%, air temperature not less than +20°C;

- for use only indoors without direct contact with water;

- for humid conditions (relative humidity exceeds 85% for several weeks of the year);

- withstands static and dynamic forces;

- fire-resistant and bioresistant.

It must be borne in mind that additional finishing coatings significantly change the factory properties of MDF boards.

Varnish for MDF

Flaws

The main disadvantages are different: penoizol is not suitable for all structures; it should act only as a middle layer and be reliably protected from external factors.

Penoizol gives significant shrinkage (1-3% of volume). Since penoizol can only be installed at a certain temperature, this may cause a delay in construction work, which is also a disadvantage.

Please note: penoizol can only be installed at an air temperature of 6 degrees or more.

Despite the fact that pouring insulation does not take much time, this work must only be performed by a specialist, otherwise the material may lose its properties.

Penoizol must be insulated. In addition, it is often necessary to additionally insulate the material in the structure, which leads to unnecessary costs.

If this has not been done, the insulation may release formaldehyde gas, which causes an allergic reaction in people.

It is the poor quality of work and material that causes negative reviews.

Be careful: before purchasing, you should make sure that the manufacturer is reliable and has quality certificates; beware of counterfeits.

This article is about the features of equipment for the production of penoizol.

Read the article about making penoizol with your own hands here.

DIY production technology

When ready, the consistency of the mixture is similar to a soufflé. The substance hardens when it comes into contact with air. When applied, this mixture fills all voids. Therefore, the noise and thermal insulation characteristics of the room are improved after foaming the roof and other surfaces.

Types of equipment for do-it-yourself penoizol

Any premises can be used to set up production. But significant savings can be achieved if the process is organized in the same place where construction work is taking place.

The following types of devices are expected to be used:

- compressor;

- Electric Energy;

- pumps for solutions;

- foam generators. Their material matters;

- foam supply pumps;

- steam generator.

All equipment can be easily purchased on the construction market or in specialized stores. Including those working remotely via the Internet.

Russian and Ukrainian installations in this area give the best results. They are aimed at high-quality insulation of walls with foam insulation.