A well is the main source of water for supplying private country cottages, cottage-type houses, and other facilities in the absence of a centralized water supply main. In most well sources, during long-term operation, the flow rate decreases due to clogging of the casing filters, while the only low-cost way out is to clean the well yourself.

Sometimes situations arise when the water in a well source is contaminated by surface sewage or other wastewater, rust from pipes, and usually no chemical reagent for cleaning wells (citric acid, vinegar, bleach) is used, limiting oneself to pumping out unsuitable water.

To carry out cleaning work, mechanical and electromechanical devices are used; devices of simple design are made independently, choosing the appropriate method from several options. In order not to waste extra time and money when carrying out work, it is useful to study various cleaning methods and the devices used, the choice of which depends on the parameters of the well and the type of blockage.

Well types

Different types of wells and reasons for their clogging

It should be noted that all types of wells, depending on the drilling depth, are divided into three classes: Abyssinian, sandy and artesian.

Modern Abyssinian shallow wells up to 30 m below ground level are constructed from a lightweight casing in the form of plastic pipes of various diameters; due to its low weight, if installed correctly, it is not lowered to the bottom of the underground water layer. Therefore, water from a properly installed Abyssinian well has a small amount of sand and dissolved clay impurities and, accordingly, rarely needs to be cleaned.

Another nuance of Abyssinian wells is the frequent use of a pipeline made of low-pressure polyethylene pipe (LDPE) of various lengths as casing. This allows you to clean the filters and the area below by simply removing the pipe section from the borehole channel.

In deep artesian wells, the bottom of which (bottom area) is located at a distance of 100 m and below from the surface of the earth, a column of casing pipes is installed on a dense limestone bottom - thanks to this, the well practically does not become clogged, and its service life without cleaning works reaches 50 years .

The most problematic from the point of view of operation are wells in sand, the optimal depth of which varies in the range of 30 - 70 m. When installing them, a massive column of casing pipes rests on a sandy-clay bottom, while sand and clay not only enter the water, but and during operation they gradually clog the filter holes, settling in the bottom in a layer that is constantly increasing in height.

Well pumping

In addition to natural inevitable processes, other reasons for the rapid clogging of sand wells are:

- Technical errors during well construction, for example, an incorrectly selected filter at the end of the casing pipes. The fact is that any well in sand has a certain size of sand particles at the bottom - this is taken into account when installing the terminal filter. If its cells are too large, sand will accumulate in the face, the height of the sand layer will increase and it will block all channels of water flow - the flow rate will decrease and the well will have to be cleaned.

- Also, unscrupulous drillers can hand over to the user a well source with fine dispersed sand - such a well will silt up in 1 - 2 years and no amount of cleaning will help.

- Interruptions in operation often cause the well to silt up due to lack of flow as a result of sedimentation and compaction of sand and clay particles suspended in the water. A similar situation occurs in a high-productivity well with a low volume of water taken.

- The use of vibrating electric pumps leads to the fact that, as a result of constant vibrations, bottom sediments of clay and sand are compacted and prevent the flow of water into the borehole channel.

- Incorrect placement of the electric pump also leads to silting; if it is suspended at too great a distance from the bottom, stagnation occurs in the bottom - as a result, sand and clay particles calmly settle to the bottom and gradually clog the filter holes.

Bailer and cleaning scheme

How to choose the right cleaning option?

It can be difficult even for a specialist to determine exactly why a well’s production rate has dropped. As a rule, pollution is complex. If the pump “drives” sand with water, this does not mean that the soil is not silted.

When cleaning a well with your own hands, you should be patient. You may have to apply several methods in succession and try hard before obtaining a satisfactory result.

We recommend starting with the simplest: pumping with a vibration pump. If pumping does not help, move on to flushing. We start with washing if the source has almost dried up. If there is a lot of sand at the bottom, a bailer will help to scoop out sand.

But it cannot be used for plastic casings, only for steel ones. For polymer barrels we use only bubbling. If there is neither sand nor water in the steel casing, we move on to water hammer technology.

This is, of course, if the aquifer itself has not dried up. Renting a washing machine, of course, costs a pretty penny, but the cleaning efficiency is noticeably higher than when using homemade methods.

Well cleaning methods

All well cleaning technologies are conventionally divided into two large categories: electromechanical using submersible electric pumps and manual mechanical using, in most cases, self-made devices.

Since the essence of cleaning is to extract the layer of clay and sand that clogs the filters onto the surface, it is rational to use electric pumps for these purposes, adapted to work in an environment with large solid particles. Among the types produced by industry, the following classes have such qualities: drainage, screw, vibration pumps.

Drainage types are designed for operation in shallow immersion (usually no more than 20 m); due to their overall dimensions, they simply will not fit into a borehole channel with a standard diameter of about 100 mm, so there is no talk about their use. Screw-type ones can work with dirty water and are suitable for immersion in wells, but their working mechanism in the form of a spiral nozzle and a sealed rubber bushing wears out quite quickly from exposure to solid sand particles, and replacing parts will cost a pretty penny.

The last type, a vibration pump, is a budget-friendly and easy-to-use unit, the rubber piston and check valve of which will also be subject to accelerated wear due to the negative impact of solid sand particles. But replacing these parts, unlike vibration models, will be cheaper, and a worn-out set can be used repeatedly to clean a well source.

To clean wells using mechanical methods, a special device is most often used - a bailer, which is lowered to the bottom and then raised up with a captured layer of silty-sandy deposits.

Vibration pumps

Clogging of sources with sand

This problem usually manifests itself in shallow wells in which the aquifer lies in a sand and gravel layer. If the source is properly equipped, if sand gets inside the casing, it will be in small quantities.

When the productivity of a well decreases and grains of sand can be seen in the water, there are the following reasons for their appearance:

- Sand enters from the surface as a result of a leak in the caisson or cap.

- The filter is incorrectly selected because its cells are too large.

- The integrity of the filter is compromised.

- The tightness between the sections of the casing structure is not maintained, because the thread was not tightened completely, or the welding was performed poorly, or mechanical damage to the plastic pipe occurred, or a hole appeared in the steel casing pipe as a result of corrosion.

If leaks occur inside the wells, they cannot be eliminated. If fine sand constantly penetrates through the filter, it is partially washed out as the water rises. But when large grains of sand get into the well, the source often becomes unusable.

So that the owner does not have to deal with the problem of how to clean the well on his own, you need to pay increased attention to the correct installation of casing parts and know how to choose a high-quality filter.

Well cleaning with a vibration pump

Industrially produced electric vibration pumps (Malysh, Rucheek, Rodnichok, Whirlwind) have a standard maximum pressure of 40 m, another modification is capable of lifting water from depths of up to 80 m - these characteristics allow the use of units of this type for cleaning any wells in sand.

Advice: Since during cleaning procedures the electric pump draws water into the bottom area of the well, it is rational to use modifications of vibratory pumps with lower water intake.

Do-it-yourself well cleaning using a pump is carried out in the following way:

- Connect the electric pump to the pressure hose, tie a holding cable to it, tie together the electric power cable, supply hose and cable with ties.

- The vibration pump is lowered to the bottom of the well, after contact with sand, the pump is raised by 100 - 200 mm, fixed to the surface and turned on.

Note: To maintain a constant distance to the bottom, sometimes a large-diameter rigid hose made of rubber or elastic plastic about 200 mm long is inserted into the lower part of the pump housing, securing it to the shell with an external clamp.

- The water raised to the surface is poured into a large-volume container for settling and further use for irrigation and other household needs, or it is redirected to a ditch outside the site.

- As the sand-clay mixture is pumped out, the vibration pump is lowered lower, the cleaning is repeated until clean water appears at the outlet at a pump lowering depth that corresponds to the immersion distance of the main centrifugal electric pump.

When cleaning a well with one vibrating electric pump, it is useful to loosen the bottom layer of silt deposits; for this you can use a massive mechanical pin with teeth or a piece of pipe with sharpened edges and a tied cable. Before pumping, pointed metal objects are thrown into the well several times and then retrieved to the surface using a cable.

Cleaning a well with a pump - diagram of immersion and arrangement of the unit

Flushing with a gas-air mixture

The cleaning method using a gas-air mixture is called bubbling. In this case, the well is purged with a compressor. In this case, a sprayer is lowered to the bottom of the well so that it is located in the thickness of silt or sand. Then a powerful compressor supplies compressed air.

The resulting bubbles rise to the surface, carrying the contaminants with them. To ensure the removal of dirty water, flushing liquid is constantly added to the source manually or using a hose. You can use closed circulation of water between it and a previously prepared container.

Experts do not consider the combined method of flushing with simultaneous blowing of the well with compressed air effective and efficient. The fact is that this process moves slowly and may take several days or weeks to complete if the contamination is severe.

Bubbling has advantages over alternative methods:

- Sometimes it is the only option for cleaning the source and filter if pumping with water is unsuccessful.

- The implementation of effective methods for removing sand using a bailer or silt deposits by water hammer is accompanied by the creation of serious vibrations that can damage a filter made of a fine mesh. The likelihood of fragile, worn-out steel or plastic casing breaking or collapsing is even greater. As a result, the source may be completely disabled.

- Knowing how to blow out a well with a compressor using a gas-air mixture, you should not be afraid of troubles. This method is the most gentle technology that will not cause any damage.

Using two electric pumps

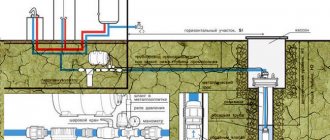

The use of a second electric pump for pumping the well increases the efficiency of the work due to the following factors:

- the layer of sludge stagnant at the bottom is agitated and pumped out more efficiently;

- the water raised up is immediately sent back to the well and does not need to be disposed of.

To carry out cleaning procedures, one electric pump for pumping out muddy water is prepared in the above way, and the second is lowered into a container with drained water and a pressure hose is connected to its output, work is continued in the following way:

- In order to avoid repeated operations of lowering and repairing the hose supplying water to the well and the suction pump, they are connected together by screwing the sleeve at a distance of about 200 mm below the electric pump housing.

- The pump is lowered into the well together with the pressure hose of the second electric pump until it touches the bottom and is turned on to pump out water, while the outer container is filled.

- After the barrel with a volume of about 200 liters is filled, the pump sucking water from the well is turned off and the second pump, located in the middle water layers of the catchment tank, is turned on.

- The settled water is sent back to the well and stirs up the silt deposits in the bottom area. After draining a sufficient amount of water to half the tank, the external pump is turned off, the deep pump is turned on and the source continues to be pumped.

- As the height of the silt layer decreases, the immersion depth of the water-suction pump changes.

- After repeating this procedure, check the quality of the lifted water several times, focusing on the initial immersion depth of the main electric pump.

Types of bailers

Precautionary measures

In order to avoid the slightest damage to the system during the cleaning process, you need to follow the simplest and most banal rules for flushing a well, namely:

- Under no circumstances should you use equipment for cleaning that is not designed for this purpose.

- The entire cleaning process must be carefully controlled. Remember that leaving the well itself and, of course, the pumps unattended is strictly prohibited.

- If you notice that very massive particles of plastic or metal begin to appear, then you must immediately stop the pumping process.

There are still many ways by which you can completely clean the well. The more often the cleaning process occurs, the better this will affect its overall condition. The fact is that periodic cleaning can not only increase the service life of all existing pumping equipment, but will also allow you to keep the entire system in order and clean.

And, most importantly, the service life of the pump will increase significantly if you carefully monitor the cleanliness and general condition of the well. Remember that before you start cleaning the well on your own, you must carefully study all the available information about it.

Source of the article: https://kanalizaciyalite.ru/vodoprovod/chistka-skvazhiny-vibracionnym-nasosom

Cleaning with a bailer

The bailer is the only device for cleaning deep wells from bottom silt using manual technology; these devices are used not only in households, but are also manufactured in a factory for use in industrial well sources.

The typical design of a bailer is a piece of pipe, often with jagged edges, at the bottom of which a valve made of rotating plates or a ball is installed that operates in one direction.

The principle of operation of the bailer is to sharply lower it to the bottom of the well, while bottom mud enters the cylindrical body through a check valve. When the bailer is raised, the valve closes the pipe channel, preventing silt deposits from escaping back into the well source. After healing to the outside, the body is emptied of the collected mud mixture and the procedure of lowering the bailer into the borehole is repeated.

To lower and raise the bailer, a manual winch is usually used; if the depth of the well is quite high, an electric motor (homemade electric winch) is used to rotate it.

Design and main components of homemade bailers

Making a bailer

In households, when making their own, two main designs of bailers are used: with a ball or flaps as a shut-off valve. The ball version, although it looks quite simple, is actually more difficult to manufacture both technically and mathematically to determine the optimal weight of the ball check valve.

With its high mass, it will rise a small distance when immersed - this will lead to the fact that the amount of silt deposits entering will be small. If the mass of the ball is too small, when the internal cavity of the pipe is filled with dirt, it will not be able to sink to its bottom and the lifted rock will go back into the well.

Therefore, in the household, a bailer is mainly made from one or two rotary valves; the main stages of installation of a popular design are as follows:

- Take a piece of pipe about 800 mm long, which is the body, and weld a handle to its end to lift the device; if you don’t have a welding machine, you can tie a wire to two through holes made in the walls.

- A check valve system is assembled; for this purpose, a piece of a pipe similar to the body is cut off, about 50 mm long, teeth are cut on its edge with a grinder, and a steel ring is welded from the inside.

- They make a check valve by cutting out a circle along the inner diameter of the pipe section, welding one wide or two narrow loops of wire to its plane, and threading a piece of smooth-walled reinforcement through them.

- A piece of fittings together with a lid placed on it is welded over the inner ring of the pipe section in such a way that it can easily open inward.

- After assembling the check valve system, its 50 mm body is welded to the main pipe of the bailer.

Read more: How to make a bailer with your own hands.

Homemade bailer. An effective method!

The main rod of the bailer will also be a metal pipe with an internal diameter of 70 mm and a length of 600 mm. It is important to take into account the weight of the pipe, which will directly depend on the thickness of its walls. The weight should be sufficient so that you can manually lift a bailer filled with silt and sand.

Sludge extraction

So, on top of the pipe you need to tie or weld a handle made of thick wire. Drill two holes at the bottom of the pipe for the bolt. Their diameter should be 8 mm. You should retreat 1 cm from the edge of the pipe. The presence of this bolt will allow you to assemble the bailer as such.

In the construction of such a bailer, the key role will be played by the valve, which can also be made by hand. To do this, you will need a regular plastic bottle with a capacity of two liters. The valve should be elliptical in shape. The smaller diameter will be equal to the diameter of the pipe inside. In our case it is 70 millimeters. The larger part of the valve should have a diameter 20 mm larger.

Note!

The effectiveness of a homemade bailer will be high only if the valve element is made correctly!

Using soft wire, screw this valve to the bolts. Four holes are pre-made in the valve. If these fasteners are made free, then the bolt can be pulled out of the wire fastening, and when reassembling the bailer, they can be inserted back.

During installation, the valve must be bent moderately to push it into the middle of the pipe. The bolts are then inserted through pre-made wire rings. At the very end, they must be secured and tightened with a nut.

On what principle will it work? At the moment of its immersion, the side valves are compressed under water pressure. During the removal process, due to the elasticity of the material used, the valve will restore its shape and close the pipe. The result will be the extraction of water and silt to the surface.

Sludge from a well

As mentioned above, this design is much more efficient. This is mainly due to the fact that up to three liters of liquid can be removed in one go. However, this directly depends on the diameter and length of the pipe.

Other methods of cleaning wells

In addition to the above cleaning methods, which are most often used in everyday life, you can also use less common alternative methods using special equipment and various equipment that are auxiliary to the main pumping of water with electric pumps.

Plunger mini-wash

Using a fire truck

Unless you are a fire chief or have the right connections, using a special machine to clean out an individual well will cost a considerable amount of money, if it is even possible.

The principle of cleaning with a fire engine is to supply water to the well bottom with high pressure, while silt deposits instantly rise up and mix with water. All that remains is to pump out the agitated water as quickly as possible and the cleaning process is completed.

Important: When using a fire engine, an additional amount of water is supplied to the well, which can rise through the channel and, along with dirt, spread over the surface of the area - if measures are not taken to protect it, this will lead to irreversible pollution.

Siltsucker

An easier way to clean a well from sand and silt using special equipment is to use a vacuum cleaning machine (sludge sucker), used to empty septic tanks, cesspools, gray water sumps, and clean wells from silt deposits. The machine is equipped with a storage tank, a vacuum pump, and is often equipped with a high-pressure plunger electric pump with a nozzle for washing away sludge.

Sludge pump at work

To clean a well, a suction hose from a sludge sucker with a load is immersed in it and the tank is filled with dirty water; if necessary, solid sludge is washed away with a high-pressure jet of water from a plunger pump.

Siltation of unused wells

During operation, small particles of calcium deposits, sedimentary rocks, clay, and rust begin to accumulate in the soil in the area where the filter is located. When a lot of them collect, the pores of the aquifer and the filter cells become clogged, and it becomes increasingly difficult for liquid to get through its openings into the mine shaft.

As a result of this, the flow rate of the source drops and you have to think about the problem, if the well is silted, how to clean it. Otherwise, the negative process continues until the water disappears. If the source is used regularly, siltation occurs slowly - over several decades.

If you do not constantly pump, you will soon need to think about how to clean the well of silt, since it becomes unusable after one to two years. Provided that cleanup is done in a timely manner before the spring completely dries up, there is a good chance that it will continue to supply people with water. Then water will begin to flow in the volume required for water supply to housing.

How to clean a well with your own hands: video

When cleaning wells yourself, more often than other methods, vibration pumps or homemade hand-held devices - bailers - are used. Cleaning a well using these methods is the most effective in terms of price and quality: vibration pumps are considered budget products (a new unit for pumping and use in the household can be purchased for 1,300 rubles), and making a bailer yourself if you have a welding machine will only require a piece of steel pipe and several pieces of metal.

Types of well construction

Before you start cleaning the well, it is important to know exactly everything about the device. Then the entire cleaning process will become much easier, and also much more reliable.

There are two types of wells:

- having a straight trunk of a certain constant diameter;

- with a filter.

A recess with a straight barrel is considered simpler and often in demand. In it, the submersible pump can be lowered to the very bottom, and this, in turn, completely eliminates silting. This type is presented in the form of a fairly long barrel, which consists of pipes having the same diameter; they are connected by welding or a threaded connection.

Method #3 – mechanized cleaning

The most effective method for deep wells is mechanized cleaning. The best option is to use two pumps operating in pairs.

A deep pump equipped with a lower hydraulic intake is located at the bottom of the well. It raises water with mud and silt. The pump, working in pairs with it, supplies water to agitate the deposits under pressure from the reservoir. For cleaning to be truly effective, the water drainage hose should be shaken and ensure that the amount of contaminants is not too large; if their concentration in the water is very high, overheating and even equipment breakdown may occur.

The equipment must also be selected correctly; the selection depends on the depth at which the water is located. Vibrating pumps are used if the water depth is more than 10 meters.

Mechanized well cleaning using a deep-well pump and a pump, which we work with it in pairs, is recognized as the most effective method. Much depends on the correct selection of pumps, so before cleaning it is better to consult with specialists

Cleaning a well from silt and sand - proven methods with instructions

If one day you discover that the well can no longer function as before, then do not panic. After all, there are no “eternal” sources of water supply and it is possible that the well has become mechanically clogged. In this article we will tell you how to deal with this problem yourself, without the involvement of specialists. Cleaning a well from silt and sand is not as complicated a procedure as it might seem at first glance. And if you arm yourself with our instructions, then no problems will arise at all!

Cleaning a well from silt and sand

Water well diagnostics

To identify blockages and siltation, geophysical and television diagnostic methods are used.

In order to understand how correctly the drilling was carried out and the casing columns were installed, as well as to check the water level, a geophysical method is used.

To carry out repair work, a television diagnostic method is used. Using a small video camera with LED light, you can view the seams on the pipes and the degree of siltation.

If a submersible pump fails, you can recognize the cause on video.

It is necessary to clean the water well at the initial stage of siltation. Otherwise, you may completely lose your source of water, since if the blockage is severe, cleaning measures may not help. In this case, you will have to drill again.