Water purification systems for private homes are used primarily to purify water from wells and wells. The water treatment system in a house or cottage processes water in such a way that it can be used as drinking water. Providing your property with drinking water is one of our top priorities.

During the water treatment process, coarse particles, dissolved gases, heavy metals, bacteria, and other elements that can harm the human body are removed from water.

In the article I give an example of a full-fledged (maximum) water purification complex. The private system may differ significantly. After studying this article, you will learn about what elements and filters are used when preparing water in a private home. Such systems are not applicable in apartments due to their large overall dimensions.

Depending on the tasks, budget and availability of free space, as well as the quality of the source water in the house, the water treatment system can be significantly reduced.

This article provides a calculation for a system with a capacity of 2 cubic meters of water per hour (2000 liters).

- Composition and purpose of the water treatment system: Borehole pump

- Coarse water filter - mesh dirt filter

- Storage tank (or hydraulic accumulator)

- Pumping station

- Aerator

- Iron removal filter

- Filter softener

- Rotameter

- Mixing unit

- Fine filter

- Disinfectant (UV lamp)

- Bypass unit

Composition of filtration systems

The water filtration system in an honest home can consist of various elements. In this list, I present the maximum number of elements based on the fact that the water will be as dirty as possible, and the output should be high-quality drinking water.

Water treatment system in the cottage

Main elements of the water treatment system:

- well pump;

- coarse filter - mesh dirt filter;

- storage tank or hydraulic accumulator (membrane tank);

- pumping station;

- aerator;

- iron removal filter

- filter softener;

- mixing unit;

- fine filter;

- disinfectant;

- bypass.

Let's consider what all these elements of the system are intended for. Water passes sequentially from each element to the next.

Purpose

The purpose of the water treatment system is water purification. Purification of water from mechanical particles, dissolved gases and metals, reduction of water hardness to the required value (usually 0.5 - 2 °F) and disinfection.

The degree of water hardness (in the Russian Federation) °Zh is equal to 1 mg-eq/l, which corresponds to the concentration of the alkaline earth element numerically equal to 1/2 of its millimole per liter, which gives 50.05 mg/l CaCO3 or 20.04 mg/l Ca2+.

When thermally treating hard water, metals settle on the heating elements. In fact, this is a deposit on the kettle, on the heating elements and on the drum of the washing machine.

The water passing through the water treatment system becomes clean and suitable for drinking.

Reverse osmosis is not required for such systems. Reverse osmosis systems are primarily used for industrial water purification purposes. Although there are mini reverse osmosis systems under the sink.

Preparatory work

The highest degree of water purification is provided by a reverse osmosis installation.

Before you begin to study the sequence of installing filters, you need to complete all the preparatory measures. They start by assembling some parts of the purification system, which are the plumbing connection. This is a small shut-off valve and tee. This work is carried out in two stages - assembly and installation of the unit on the water supply system.

- Assembling the working unit - inserts.

This stage does not cause difficulties, since it is only necessary to correctly and tightly connect the tee to the tap. One edge of such a tee is equipped with an internal thread of 0.5 inches, the second is external with 0.5 inches, and the third, intended for connection to the shut-off valve, has an internal thread with a smaller diameter. Fum tape or tow is tightly wound around the tap, after which this part is screwed into the tee and fixed well with a wrench. Now is the time to turn off the water supply and begin installing the prepared tap. Insertion of a tee and tap for supplying water to the filter - The next stage is more troublesome, but its implementation does not require special knowledge and skills. First of all, you need to find where the cold water pipe is located. It is equipped with a shut-off valve and needs to be twisted. The prepared working unit is mounted on the cold water pipe. Particular attention is paid to sealing the seams, otherwise the possibility of leaks cannot be ruled out.

After installation, it is recommended to check the functionality of the working node. To do this, place the small filter faucet in the closed position and turn on the water supply. If no leaks appear, you can begin installing the water purification filter.

Well pump

After drilling a well, we think about buying a pump (and generally before). A water purification system for a private home, cottage or summer house begins with a well and a pump. A borehole pump supplies water from a well or well (autonomous water supply) to a water treatment system (storage tank or accumulator) passing through a mesh mud filter.

Well pump from ZDS

The choice of pump depends on:

- from the depth of the well;

- on the required performance;

- from your budget.

Practice shows that the most popular from the middle price segment are such manufacturers as ZDS and Italian pumps Pedrollo and Lowara.

Budget options include Whirlwind, HAMMER, QUATTRO and others. But a well pump is not an element worth saving on. And here is a simple approach - it’s better to spend money once and forget for several (ideally several decades) years.

GRUNDFOS and FORWARD pumps are also popular. The price for GRUNDFOS is usually higher, but I didn’t notice much of a difference (if we take into account pumps that have the same technical characteristics).

We will talk about the general choice of a borehole pump in a separate article.

The average budget for a well pump is 30,000 rubles.

For a system with a capacity of 2 cubic meters per hour, you need to select a pump as follows.

We find an online store for pumping equipment. Let's go to the pumps section - well pumps. We set the minimum productivity in the filter - 2000 liters per hour, maximum - 3000 liters per hour.

Open the card of the pump that you like. Open the documentation (passport, instructions, etc.).

Graph of pressure characteristics of a well pump

We find a graph of pressure characteristics. In the graph, we find the maximum productivity at the pressure height we need (add the depth of the well and the distance the water rises after the well), and look at the productivity indicator.

If, at the required height, the efficiency of the pump is at the point of the required performance, then this model is suitable for us.

Where to buy?

water filters from official online or offline stores from manufacturers.

If there is no representative office in your locality, look at the list of distributors with whom the company cooperates.

By purchasing a water purifier from a trusted place, you will protect yourself from being deceived by scammers who pass off fakes as originals.

Attention! When purchasing, pay attention to the integrity of the box, the packaging (check the presence of each part according to the design), and the absence of mechanical damage to the product. Also make sure that the warranty card is filled out and has the seller’s stamp on it.

Mesh dirt filter

Purification of water from a well begins with a coarse water filter. The water flows to the mud pan, which is designed to purify water from various mechanical objects (particles of heavy metals, dirt and rust). I believe that the best coarse filters are mesh filters, although this is my personal subjective opinion, many believe that cartridge dirt filters are better (there are positive reviews).

If the pump is powerful, then when water is sucked into it at a depth, a “mini vortex” (let’s call it that) is created. As a result, the pump takes in water with particles of sand, clay, silt and other substances at the bottom of the well or well.

A mesh dirt filter is needed to ensure that dirt does not pass further into the water treatment system.

Coarse water filters are:

- mesh;

- cartridge;

- bag

In water purification systems for a country house, mesh dirt filters are used because they are easy to use, have a simple design and can be easily washed yourself. When installing a cartridge or bag filter in a system with a capacity of 2 cubic meters per hour, you will have to change the filter element (cartridge or bag) almost every day.

Mesh dirt filter in a private cold water supply system with a herringbone for the hose

The mesh dirt filter is the cheapest element in the system, the average budget for it is up to 1,000 rubles.

BARRIER EXPERT Hard

The design of the BARRIER EXPERT Hard flow filter involves three stages of cleaning: mechanical, softening and post-carbon. Complete with the filter, the manufacturer supplies all the necessary elements for installing and using the device: a separate faucet for washing, cartridges and connecting parts. You no longer have to worry about leaks, since the Smartlock technology used in the design eliminates the possibility of unscrewing the fasteners.

See also: Rating of construction vacuum cleaners: top 10 best models of 2019–2020

| Performance | 2 l/min. |

| Module resource | 10,000 l |

| Dimensions | 267 x 95 x 368 mm |

| Device weight | 3.5 kg |

| Inlet water temperature | 5-35 °C |

Price: 2,371-3,901 rub.

pros

- easy installation;

- easy replacement of cartridges;

- protection against leaks.

Minuses

- if the water is too hard, the cartridge will have to be changed every 2 months, and this is not cheap.

After installing the filter, the scale disappeared immediately. Finally the kettle is clean! But early I was happy, because two weeks later it appeared again, I had to change the cartridge. Unfortunately, the store didn’t explain to us that the filter is intended mainly for water of medium hardness. We bought it just to cope with this problem. Otherwise, there are no complaints about the system, but we will apparently have to buy a reverse osmosis filter.

Storage capacity

Next, the water enters the storage tank, which is designed to ensure stable operation of the pumping station, as well as to create a water reserve.

Storage container with a volume of 500 liters

Instead of a storage tank, if there is necessary and sufficient water pressure from a well pump, you can use a hydraulic accumulator.

But, the storage tank allows you to create a larger water reserve. This is its main advantage.

Usually they install storage containers that exist (or have been found). Or they buy containers produced by Anion. The capacity is selected taking into account the availability of free space.

The average price for a container with a volume of 500 liters is 10,000 rubles.

If you use a membrane tank (hydraulic accumulator), then the price of this unit will be 5,000 rubles.

The hydraulic accumulator is a small tank in which the membrane is located. Its purpose is to create a small reserve of water, maintain a certain water pressure in the system and protect the pump from idling.

Hydraulic accumulator in a private house

It all happens like this. The tank has a membrane that contains air. The tank is filled with water and the pressure on the membrane increases to a predetermined level. When the water leaves, the pressure in the membrane is applied and at a given lower limit the pressure switch is activated, which starts the well pump.

From the storage tank, water flows to the pumping station.

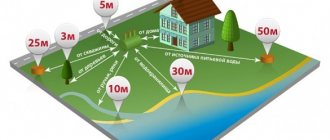

Installation site requirements

A special feature of the operation of such treatment structures is the ability to work with only one point of water consumption. Therefore, the installation of water filters in an apartment, and in some cases in a house, is carried out in the kitchen . The place under the sink is perfect for these purposes - the device is not in sight, but it is accessible for maintenance.

However, it is necessary to measure the dimensions of the free space and ensure that certain conditions are met at the stage of choosing a model:

- The structure should fit freely under the sink without squeezing or squeezing.

- All flasks should be positioned so that it is easy to replace the cartridge.

- Plumbing components (valves, sink drain check valve, etc.) must remain in a freely accessible area for inspection and repair.

Despite the location of the filter under the sink, there is still enough free space under it

Pumping station

The pumping station is designed to maintain constant water pressure in the water supply system. The pumping station usually operates in fully automatic mode. And it only requires initial setup.

DAB pumping station

A middle-class pumping station will cost you 30,000 rubles. But here you can save a lot if you need a low-performance system.

You can select a station according to the required productivity (we have 2 cubic meters per hour).

After the pumping station, the water enters the aeration column.

Aerators: water aeration subsystem

The aeration column is designed to oxidize iron dissolved in water and remove hydrogen sulfide without the use of reagents. Inside the water layer of the aeration column, the water is saturated with air bubbles.

Oxygen entering the water when using an aeration column reacts with iron dissolved in it, the iron is oxidized and changes from a divalent form soluble in water to an insoluble trivalent form, which can be easily removed with a deferrization filter. The aeration column increases the efficiency of these filters and increases the service life of the filter media. Here the pressure aeration system is taken into account. This topic will be discussed further.

Aeration systems (not to be confused with aerator taps) are designed to saturate water with air oxygen. When water is saturated with oxygen, impurities, in particular iron, are oxidized. Iron changes from divalent to trivalent form. Also, when water is aerated, dissolved gases are removed from it.

Water aeration methods

There are three methods of water aeration:

- Pressure aeration.

- Gravity aeration.

- Ejection aeration.

Pressure aeration is performed using a compressor. The compressor supplies air, which through the tube into the cylinder. At the end of the tube, dispersants are located in a cylinder. Thanks to the dispersant, the air flow is divided and the water is saturated.

Compressor for pressurized water aeration

When using pressure aeration, an air separating valve is installed in the head of the aerator, which is designed to remove excess air and gases from the water.

Gravity aeration . Pressure aeration requires maintaining a constant high water pressure in the system. Air is forced into the aeration column using a compressor or ejector.

Gravity aeration allows low pressure in the system. In this case, the water is saturated with air in the tank. Inside the tank, the water is saturated with air, which is supplied by fans.

Ejection aeration occurs using an ejector. Structurally, the ejector consists of a piece of pipe with a conical neck. When water is supplied, a vacuum is created and air is sucked into it. The output is water mixed with air.

Ejector for water aeration

The ejector for the water aeration system works on the principle of the Venturi effect. As a result of the passage of water through the ejector nozzle, it then enters the confuser, in which a vacuum occurs, as a result of which air is sucked in and the water in the aeration column is saturated with it. The ejector is the most compact and economical in the water aeration system.

Ejection aeration is the most common method of water aeration, which does not require expensive and large-sized equipment.

What's better?

It is difficult to say which aeration method is better. It all depends on the specific task and conditions.

The main advantage of gravity aeration is price. Since an aeration column with a compressor and a head is much more expensive than a container and an air supply device.

But the main disadvantage is that free-flow aeration requires longer free space.

With a non-pressure aeration method, a disinfection system will be necessary in any case.

Since bacteria and microorganisms do not survive under pressure. At low pressure in the system, there is a possibility of their presence in the water.

Aeration column assembly in front of iron removal filters.

Composition of the pressure aeration unit

The pressure aeration unit consists of the following parts:

- Filter housing.

- Compressor.

- Air filter.

- Mesh dirt filter

- Header.

- Flow sensor

- Air release valve.

- Dispersant.

The cost of a complete aeration pressure unit (body, head, valve, compressor, etc.) averages 30,000 rubles.

For our system we also select an aeration column based on performance. Next, the water flows to the deferrization filter.

Filters for water purification in a private home

Iron removal filter

Iron is removed from well water using this filter. An iron removal filter with filter material is designed to remove iron, manganese and hydrogen sulfide from water. Iron oxide 3+ remains in the filter media layer and is washed into the drain when the filter is washed.

Loading does not require chemical reagents for recovery; only periodic washing is necessary.

Iron removal filters consist of:

- housings;

- control valve;

- water circulation systems (pipes);

- drainage pipe;

- slot or beam filter.

- supporting layer of gravel;

- layer of filter material;

Composition of the iron removal filter.

Diagram of the deferrization unit

- Drainage beam device.

- Drainage pipe.

- Control valve (flow switch).

- Drainage.

- Entrance.

- Exit.

- Bypass line.

Diagram of the deferrization unit.

The water inlet is always on the right and the outlet on the left.

The cost of an iron removal filter with a loading kit is on average 30,000 rubles.

For this price you can purchase a filter with an automatic control valve. That is, filter regeneration (cleaning of the filter material) will be carried out not manually, but automatically.

The regeneration time can be set manually. Usually this is at night - since during the regeneration process the filter cannot purify the water.

If a continuous supply of water is required, then two filters will need to be installed - one will work when the second goes for regeneration.

Regeneration can be set by time, for example once every two weeks, or by the volume of water consumed. You can also set regeneration depending on which event occurs first.

After iron removal, the water enters the softening subsystem, which is designed to reduce water hardness.

Filter softener

The water softening subsystem in the system is designed to reduce water hardness.

The filter material from aqueous solutions selectively absorbs calcium and magnesium ions and is a cation exchange resin. In return, the same amount of sodium ions is released into the water. Therefore, the salt composition of purified water remains unchanged. The structure of the resin is gel, thanks to which the resin can swell and has a high exchange capacity. Regeneration of the filter material is carried out with tableted salt - sodium chloride.

Water softener for a private home

The softener filter is structurally different from the iron remover in that a salt feeder is connected to the cylinder through a tube.

The filter housing is connected to the feeder using a salt solution extraction hose.

The filter material consists of aqueous solutions, it selectively absorbs calcium and magnesium ions, and is a cation exchange resin. In return, the same amount of sodium ions is released into the water. Therefore, the salt composition of purified water remains unchanged.

The structure of the resin is gel, thanks to which the resin can swell and has a high exchange capacity. Regeneration of the filter material is carried out with tableted salt - sodium chloride.

In fact, the softener filter absorbs everything that forms scale on household appliances.

In this case, the water hardness becomes zero.

Next, the water from the iron remover and softener (with zero hardness) passes through rotameters.

Reverse osmosis

Filters of this kind are successfully used on the ISS, in sea and ocean cruise ships, and in hotels on the sea coast.

Osmosis is a method of separating liquids into molecular components. What is a special membrane used for? Water under a certain pressure passes through such a membrane from a liquid with a high concentration of certain substances into a solution with an almost complete absence of them.

Industrial production of such filters began in the seventies of the last century. At first they were used for narrowly targeted purposes, but gradually began to be used at the household level.

The design consists of filter cartridges, a membrane and a storage tank.

This system works like this:

- Before entering the membrane, water is purified from large, poorly soluble impurities.

- Then it passes through the membrane, while up to 75% of the water with filtered impurities is poured into the sewer system, and the purified water is sent to a special storage tank.

- The water from the tank is further purified and becomes suitable for use.

Filters of this kind have a production resource of 4,000 to 15,000 liters with a productivity of up to 250 liters per day. Approximately once every six months it is necessary to change the input cartridges, once a year – the finishing cartridges. This is easy to do; no special tools are required for this procedure.

Expert opinion

Borodina Galina Valerievna

Such products cost quite a budget, if you keep in mind their benefits for health and purification of drinking water - from 7 to 10 thousand rubles.

Rotameter

A rotameter is a float flow meter that is designed to measure water flow. The ratemeter is installed in front of the softener in order to achieve the required hardness value of the final water using the mixing subsystem. Usually this is 0.5 - 2 degrees of hardness.

Float rotameter

The flow of water passing from bottom to top raises the float by a certain amount. In this case, gravity acts on the float. The float rises to any height. Thanks to the scale on the body, you can determine how much liquid passes through the rotameter per unit time.

Rotameters in a water treatment system in a private house

Knowing how much water passes per unit time from zero hardness and with a certain hardness after the iron remover (a sampler is installed after the iron remover to determine the water hardness), you can use the mixing unit to regulate the final hardness of the water leaving the system.

Aquaphor OSMO 50

The development of a well-known Russian company will significantly improve the lives of those who are forced to use hard water. This reverse osmosis water purifier, in addition to the membrane, has 5 stages of purification, thanks to which it removes dangerous impurities, including bacteria, parasites and viruses, and also completely eliminates water hardness - the cause of scale and breakdown of many household appliances. And everything would be fine, but residents of private houses with their own sewage system are unlikely to be happy that for 1 liter of purified water they will need another 6 liters, which will go into the drainage - this is a lot, and will cost a pretty penny.

| Filtration speed | 0.13 l/min. |

| Water temperature | 5-38°С |

| Line pressure | from 3.5 to 6.5 atm. |

| Storage tank capacity | 10 l |

| Water purifier weight | 10 kg |

Cost: 6,090-11,826 rubles.

pros

- high-quality cleaning;

- large storage tank.

Minuses

- noisy;

- high water consumption.

I have been using a reverse osmosis filter for 3 years. Before this, I tried various water purification systems, ranging from jugs to flow-through filters. To my regret, nothing could save us from the hardness of our water. I lost count of the kettles I had to throw away, and also buried the idea of installing a water heater. And here’s a miracle - Aquaphor OSMO 50 corrected the situation. Now I don’t even think about scale.

Admixture

After processing, the water enters the mixing unit, where the water is mixed after softening and iron removal. By mixing, the original hardness is adjusted to the required value. Usually the hardness is set to 0.5 - 2 °F.

The mixing unit in water purification systems consists of two valves combined into one pipe at the end. At the inlet there are two streams of water passing through the rotameters - from the softener and the deferrizer.

Next, the water flows to a fine filter.

Fine filter

The fine filter is designed to remove fine particles. The filter also traps particles from various filter loads if they somehow get into the water treatment system.

Fine filter in a water treatment system

Composition of the fine filter

Let's look at the composition of the fine cleaning unit using the CF10 series filter as an example. It includes the following elements:

- frame;

- filter element;

- mounting plate;

- pressure gauge;

Fine filter device

Also for installation and dismantling, if necessary, the following set of accessories is used:

- A set of elements for fastening.

- Mounting screws.

- Plastic dowels.

- Brackets.

- "O" - shaped ring.

- Case key.

The operating principle of the fine filter is as follows. Water is supplied to the housing, enters its internal part, between the housing and the outer part of the filter. The water then passes through the filter element and exits the system.

There is a button (usually red) on the housing cover that allows you to remove air from the filter, thereby relieving the pressure.

The filter is selected based on performance. The cost of such a filter starts from 5,000 rubles.

Aquaphor and Geyser filters are popular. For example, the AQUAPHOR Viking A1041 main filter or the Geyser 1P flow filter. For ultra-fine cleaning Fibos-1 FIBOS 131 or Aurus 1.

Lately I’ve been increasingly seeing advertisements for the TITANOF filter, but I consider it an expensive option.

Next, the water goes to a UV disinfection unit.

Ultraviolet lamps for water disinfection

Ultraviolet disinfectant WiseWater

Ultraviolet disinfection units consist of:

- disinfection chambers;

- power supply.

The disinfecting effect is based on the property of UV radiation in the range of 250 – 260 nanometers to actively destroy bacteria, viruses and other microorganisms that may be contained in water.

1 nanometer is equal to one billionth of a meter.

Ultraviolet disinfectant in a water treatment system in a private home

Advantages of this disinfection method:

- water is not exposed to chemical reagents;

- the organoleptic properties of water do not change;

- rapid disinfection within a few seconds;

- there are no negative effects.

This fact ensures optimal operation of the lamp and electrical safety of the system.

This method does not provide disinfection of opaque liquids: juices, milk, beer and others.

Disinfection installation device

The disinfection chamber is the main part of the installation. The water in it flows between the chamber wall and the protective cover, while the water does not interact directly with the lamp.

Components of the disinfection installation:

Ultraviolet disinfection device

- Metal body made of stainless steel.

- Quartz case.

- Ultraviolet lamp.

- Inlet pipe for water supply.

- Outlet pipe for discharging disinfected water.

- Mounting brackets.

- Screw.

- Wire coming from protective cap 9.

- Protective cap.

- Connection device and input inputs.

- Electrical 4-pin connector for power supply.

- Screw.

- Gasket for sealing the quartz case.

The disinfection chamber is mounted in a vertical or horizontal position. If necessary, adapters are used for installation, which are usually included in the delivery package (check when purchasing).

During installation, be sure to provide a free zone of more than 1 meter for free removal of the UV lamp from the quartz case.

The lamp life lasts on average 8000 hours.

For a system with a capacity of 2 cubic meters per hour, the cost of a disinfectant starts from 16,000 rubles. The cost of the lamp is from 2500 rubles.

Next, the water is supplied to the consumer.

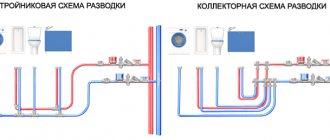

Example of circuit and wiring diagrams

So, you have decided on the equipment. If you decide to install the system yourself, then first you need to create a water treatment system project, which includes at least two schemes:

- Principled.

- Assembly room.

The schematic diagram will reflect the general operating principle of the water treatment system. In general, you can do without it, but it’s better to spend 30 – 50 minutes, think about it and draw a diagram.

Example of a schematic diagram of a water purification system

An installation diagram is a diagram that will allow you not to figure out in your head what will happen and how, but to take and assemble the system in a day or two.

Example of a water purification system installation diagram

Also, thanks to the installation diagram, you can calculate all the fittings that will be required during installation. Figure out where it will be possible to make a connection for the watering hose, how much space the system will take up so that you can freely get to all its elements for maintenance or repair.

Why do I make a wiring diagram after I have decided on the equipment, and not vice versa?

Habit. The fact is that equipment comes in different sizes. The total delta (the final difference in the required space) can sometimes reach tens of square meters. And so when I am sure that I will have 4 cylinders of a certain size, I understand what distance should be between them so that I can freely approach each one, I proceed to drawing the installation diagram.

After the wiring diagram is ready, you need to leave it until the next morning, think and look at it again. Whether I'm such an engineer or something, but usually various improvements come to mind.