The story you will read is based on real events. Two brothers decided to build two identical houses, but did not know what would be the best material to make the roof from. What will come out cheaper, and is it just about money? They checked all the suitable options and tabulated the final price, as well as all the pros and cons.

Here you will not read about “how to choose a roof in three steps.” The decision will not be simple, but it will be - and each reader will decide for himself. We will only tell you how it happens for ordinary people. People we know.

All prices and figures are current as of July 2021. Names have been changed.

Chapter 1: "The Beginning"

In one city, located within a radius of 500 km from Moscow, lived two brothers - Sasha and Yura. Sasha worked as a lawyer, and Yura worked as a mechanic.

Everyone had a dream - to build their own house, so that there would be plenty of space for a large family, for gatherings with friends and so that they could have picnics in the summer: barbecues, a small garden, perhaps a bathhouse in the future.

The brothers saved up money and, as they say, started over: they bought two neighboring plots outside the city - each 10 acres - and decided to build houses.

- Listen, why build two different houses? Let's hire a designer who will make us one project - we will build two houses based on it. Our land is the same - why overpay? - said Sasha.

- Great idea! At the same time, we can give each other advice if we encounter difficulties,” Yura agreed.

That's what they decided on. A week later they found a designer, and two weeks later they approved the design of a two-story house with a residential attic, a half-hipped roof and a small canopy at the entrance.

But at the law firm Sasha was overwhelmed with work, and he had no free time left. And he doubted his own construction skills. Therefore, Sasha decided to hire a smart team to do everything for him from start to finish. But Yura was used to working with his hands and decided to do everything himself - of course, with a little help from his friends from the car service center.

- Sanya, let me watch your builders while you are at work. And maybe I’ll spy on something useful from them,” Yura suggested, grinning.

- Phew, a stone off my shoulders, thank you, Yurok! “I’m really tired,” Sasha thanked.

Construction began in the spring. As time went. The builders Sasha and Yura moved at approximately the same pace. By the end of April, the site was prepared, the foundation was poured, and communications were installed. By the beginning of July, walls, ceilings and rafters had already been erected. And once the facade was dealt with, it was the turn of the roof.

Types of metal tiles

Metal tiles can have different profile shapes, which largely determines its technical characteristics and appearance.

The following main varieties are distinguished:

- Square shape. It is a low profile with clearly defined edges. The bends are made at right angles.

- Rectangular profile. Unlike the previous type, the upper platform is more elongated. The leaf may have a low or, conversely, large, clearly defined profile.

- Round form. Waves can be convex (rounded crest) or concave (pointed crest).

The wide range of metal tiles is complemented by special types of profiles. The most popular types are:

- Monterrey. This option is closest in shape to classic ceramic tiles. The standard sheet width is 119 cm, wave pitch is 35 cm, profile height is 14 mm. There is also a Supermonterrey variety with an increased profile height of 21 mm.

- Dune. It has a hidden fastening. The length of the sheets is from 38 cm to 6 m. Models are produced on a copper base with a polymer coating.

- Adamant. This Finnish profile is made in the Romanesque style. Wavelength – from 85 to 820 cm.

- Valencia. This species has high aesthetic qualities. Metal tiles have a large, pronounced wave, with clear lines.

- Finner. This Finnish development has folds on the leading edge of the sheet. Sheet width - 119 cm.

- Cascade. The profile is close to rectangular and has a clear pattern. The profiling step is 35 cm. Another variety is MaxiCascade with a step of 40 cm.

- Andalusia. Has a Z-lock and hidden fastening. Sheet sizes range from 45 to 715 cm.

- Country. It is close in shape to Adamante, but has a different polymer coating.

- Banga. Has an original wave shape.

- Quint. Low profile with a distinctive groove on the wave. Sheet width - 121 cm.

- Decorray. This is one of the lowest profiles. It features an original shape. Sheet width - 118 cm.

- Maxi. Similar in many ways to Supermonterrey, but with a wave pitch of 40 cm.

There are other types of metal tiles. The shape of the profile largely determines the appearance of the roof.

Chapter 2: “What to take?”

This is where the problems started. The brothers have already bought thermal insulation for the roof and all the necessary films and membranes: vapor barrier and hydro-wind protection. But there was a problem with the roofing material.

The fact is that in 2021, prices for almost all roofing materials have skyrocketed. The neighbors vying with each other shouted to Sasha and Yura that they needed to buy one thing or another. Which completely confused them.

- Sanya, I don’t know what to do with this roof anymore. Everything is getting so expensive that mom don’t worry! Yesterday, Kolyan came to me from the house opposite to the construction site and spent the whole evening talking about the need to take cellulose-bitumen - this, they say, is the only thing that remains relatively cheap,” Yura said one evening to his brother.

“Yeah, but my comrades from work have eaten up my baldness with stories about metal tiles and flexible tiles,” answered Sasha.

“We need to decide something, otherwise we’ll be left croaking without a roof in the winter - it’s July, and we only have rafters,” Yura remarked reasonably.

“Then let’s check these three options: flexible tiles, metal tiles and this bitumen tile with cellulose.” First, let’s look at what kind of materials they are—after all, we had only lived in apartments before. Let’s look on the Internet, ask experienced people,” Alexander reasoned.

- Let's. We’ll just have to see how it all looks right on the roof. “To read it is one thing, but to see it for yourself is completely different,” Yura answered.

Tiled roof installation

Tile behaves best on fairly steep slopes. The optimal slope is from 22° to 50°. If the slope is less steep, additional waterproofing is required; for larger slopes, additional fasteners are required. Then each tile is “set” on a self-tapping screw, roofing nail or clamp.

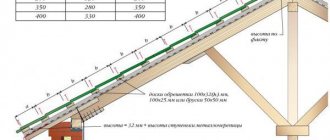

Selection of bars and installation pitch for the rafter system

The bars will require a large cross-section: one tile weighs from 2 kg.

The basis of the structure is the rafter system. This roofing material is heavy - the average weight of one square meter of clay tiles is 40-60 kg. Considerable mass. To this it is necessary to add the thickness of the snow cover that falls in the region. So the rafter system needs a powerful one.

But when constructing a rafter system, it is unprofitable to use very thick bars. It will be much cheaper if you install medium-sized rafters more often. The load-bearing capacity will not be affected, and you will pay less for building materials. So in central Russia, a beam of 75*150 mm is considered an acceptable option (maybe more or less depending on the amount of snow and slope). Installation step 60-90 cm.

Having finished installing the rafters, they are treated with antiseptic and fire-retardant impregnations. A wind barrier film is secured to the rafter system, and then installation of the sheathing begins.

Sheathing device

The distance between the horizontal slats is determined by the size of the selected tile and the angle of the roof. Most often, the installation step is specified by the manufacturer (found in the installation instructions). But you can decide for yourself.

The rafter system and lathing are two key points when laying a ceramic roof with your own hands

The length of the tiles varies, but the most common are 40-42 cm. When calculating the pitch of the sheathing, you need to take into account the useful or effective length. After all, the rows overlap each other. The more one tile overlaps another, the shorter the useful length. And the amount of overlap depends on the angle of inclination of the roof: the smaller it is, the more the rows overlap (so that water does not flow in):

- slope angle 11-25° - overlap 100 mm;

- slope 25-35° - approach 75 mm;

- steeper than 35° - approach 45 mm.

When calculating the pitch, take into account that it is possible to make a larger approach, but less - only to the detriment of the quality of the roof, since water can flow in. Excessively increasing the overlap of one row with another is unprofitable for material reasons (more tiles are required), so you shouldn’t get carried away with this either.

For the sheathing, timber 50*50 mm or 60*40 mm is used. It also needs to be treated with impregnations before installation. The number of crossbars is one less than the number of rows that will be laid on the roof (one is added running along the overhang).

Heat and vapor barrier

The heat insulator is installed from the side of the under-roof space. These are usually mineral wool mats and are rigid enough to fit between joists.

One of the roofing pie options for a tile roof

The heat insulator should fit very tightly and without gaps: the slightest gap is a bridge through which heat will escape. This is an unacceptable luxury for baths. That’s why we insulate it especially carefully. Then a sheathing is laid on top of the insulation, which will hold the insulation, and a vapor barrier membrane is fixed on top. It is secured with a counter-lattice, to which the interior decoration can be attached if the room is inhabited.

Read more about insulating a bath in the article “Vapor barrier for a bath.”

Chapter 3: "Material Wanted"

The brothers began to study articles on the Internet and ask every friend, neighbor and acquaintance (who had their own home) about roofing. It turned out that the majority had metal tiles, but there were also many who covered the roof with flexible tiles. And a couple of neighbors had “Euro-slate” - a bitumen-cellulose roofing.

Sasha and Yura watched a bunch of videos, listened to dozens of reviews, and even climbed on the roofs themselves to see what everything looked like in real life. The brothers “filtered” all the opinions on the Internet through the personal experiences of those who actually had that material. As a result, they ended up with a table with opinions about the pros and cons of different materials that are important to them.

| Material | pros | Minuses |

| Metal tiles |

|

|

| Flexible tiles |

|

|

| Cellulose with bitumen |

|

|

After sifting through a bunch of information, Yura and Sasha decided to discuss what they had found.

- Well, what do you think? I like metal tiles, but flexible ones are okay too. True, there are more problems with the flexible one, but it seems to last longer,” said Sasha.

- Yes? Don’t look at the bare numbers: we won’t order “super-duper-extra-class” in any case, otherwise we’ll be left without pants. I’m telling you from the experience of spare parts: everywhere there are groups such as “economy”, “standard”, “premium”. And the maximum numbers are for top products. We need something from the standard, perhaps at the upper limit - and according to the guarantees it is approximately the same. By the way, why didn't we consider slate? It seems cheap,” Yura remembered.

- Do you remember when we were kids throwing slate into the fire? He shot provocatively, right? - answered the brother.

- Yeah, it was cool! If only now... - here Yura stopped mid-sentence, apparently understanding where Sasha was going, - No, yes, indeed. But we don’t refuse bitumen! I want to understand what we can get for the money.

- Then let’s do this: it turns out that we need three sets of different materials for the roof, the price and quality are average. Let's ask my foreman to write down the positions for us - for metal tiles, flexible tiles and bitumen-cellulose tiles. After all, each one needs its own strips, screws, linings, and much more. As soon as it’s ready, we go shopping and ask how much,” Sasha summed up.

- Come on. But I’ll do everything myself, and you also need to take into account the cost of installation,” Yura summed up.

Choosing tiles based on characteristics

Today there are several classic types of tiles:

- Natural;

- Flexible (soft);

- Metal;

- Composite.

Natural tiles include two types: cement-sand and ceramic. The main components of cement-sand tiles are cement and quartz sand. The material perfectly absorbs noise, has very high frost resistance, retains heat for a long time, and can withstand heavy loads.

The minimum roof slope is 16°. Disadvantages: small selection of colors and high cost.

Clay is used to make ceramic tiles. The material is environmentally friendly, fire-resistant, very durable - service life is at least 50 years, and has a high level of sound insulation.

Disadvantages - heavy weight, requiring the construction of additional support, and price. This roofing covering is practically not produced in our country.

Chapter 4: "Wandering around the shops"

Foreman Sashi (his name was Anatoly) was surprised that he was asked to count materials for three types of roofs at once. He probably thought that the brothers had gone completely crazy. He grumbled that they needed to do the layout for all three at once, and that it would take a long time, but still, after a couple of days, he gave them a list by position.

“I described each roof for you, but I didn’t count the wood.” Because the counter-batten and step batten are needed the same for all three options. But for flexible tiles you will need OSB and a lining - I took this into account and included it in the list, don’t worry,” said Anatoly.

- Thank you, Tol. Then we’ll go shopping for a couple of days and see who will offer us what. Maybe we can get a discount based on your name,” the brothers smiled.

“Yeah, but for now I’ll wait until you choose metal tiles,” joked the experienced foreman.

With the printed papers, Yura and Sasha went to hardware stores in their city. They even had one “field” where there were such offices like mushrooms after rain. This is what they did.

- Metal tiles. The brothers chose the average price category of metal tiles with a thickness of 0.5 mm. The first company gave a 10% discount for private owners, the second - 18%, the third did not give any discounts. Everything was calculated with a margin, taking into account the cutting of the material.

Qty Company 1 Company 2 Company 3 Price Sum Price Sum Price Sum Metal tiles of the middle segment m2 186 805 149 730 956 177 816 945 158 193 Flat ridge strip 145x145 0.5 PC. 28 650 18 200 1420 39 760 798 20 110 Cornice strip 100x65x2m PC. 34 300 10 200 845 28 730 912 27 907 End strip 80x100x2m PC. 28 1414 39 592 990 27 720 1259 31 727 Junction strip 90x140x2m PC. 6 1414 8 484 790 4 740 1259 6 799 Self-tapping screws 4.8x29/35 PC. 1500 3 4 500 5 7 500 5 6 750 Packaging of metal tiles PC. 1 1 2 000 1800 1 800 0 — Price without discount 232 706 288 066 251 485 Discount price 209 435 236 214 251 485 - Flexible tiles. Sasha and Yura found out that it can be single-layer, two-layer and three-layer. But the price, starting from two layers, was so “biting” that we decided to settle on the simplest: single-layer. Not a single company gave a discount.

Qty Company 1 Company 2 Price Sum Price Sum Single-layer flexible tiles m2 174 565 98 310 350 60 900 Ridge/cornice pack 4 2386 9 544 2386 9 544 Valley carpet rul. 1 4922 4 922 4922 4 922 Underlay carpet type 1 rul. 3 2971 8 913 2971 8 913 Underlay carpet type 2 rul. 4 5158 20 632 5158 20 632 Mastic kg. 3,6 244 878 244 878 Rough nails kg. 5 880 4 400 880 4 400 Cornice strip 2 m PC. 34 328 11 152 328 11 152 End strip 2 m PC. 28 328 9 184 328 9 184 Junction strip 2 m PC. 6 248 1 488 248 1 488 OSB-3 2440x1220x9 PC. 54 1503 81 162 1503 81 162 Total 250 585 213 175 - Bitumen-cellulose. It turned out that this material was not so easy to find, even in a place where there were a bunch of construction companies. Only one company was involved in it, which made the calculations very reluctantly. Sasha and Yura jokingly thought that they were rich and did not need money.

Qty Price Sum Sheet 1950*950 PC. 101 667 67 367 Skate 1000x360x360 PC. 56 384 21 504 Cornice strip 100x65x2m (0.45 mm) PC. 34 300 10 200 Tong 1000x200x200 PC. 56 384 21 504 Junction - Endova 1000x150x150 PC. 12 384 4 608 Nail 70×3 mm 100 pcs. pack 20 240 4 800 Total 129 983 - Cost of work. While the brothers were shopping, Sasha saw that the offices were full of builders with whom they were collaborating. Therefore, he found out the price for installation directly from them. Even Yura became interested, because there was a lot of work to be done.

sq. m Cost per 1 sq. m. (from the rafters) Installation time the total cost Metal tiles, bitumen-cellulose roofing 167 800 7 days 133 600 Flexible tiles 167 1 100 14 days 183 700

Advantages and disadvantages

Advantages and disadvantages

Metal tiles have the following advantages:

- Easy to install. It is simplified due to the convenient dimensions of the sheet - on the one hand, the increased dimensions allow you to cover a significant area of the roof at once, and on the other hand, the dimensions allow you to easily transport the sheet upstairs (without lifting mechanisms). Metal tiles are easily attached using standard fasteners.

- Increased durability. In reality, it reaches 30–50 years.

- Relatively small specific gravity. Typically, sheets weighing up to 5 kg per 1 m2 are used.

- High mechanical strength. It is provided with a steel base and a profile that forms stiffeners.

- High degree of protection from atmospheric influences. Can be used in almost any climate zone. It is achieved by triple protection - galvanizing, passivation and polymer coating.

- Good sealing (waterproof). This is achieved due to the small number of joints. The sheets fit tightly at the joints, and the overlap prevents water from penetrating under the roof.

- Attractive appearance. There is a choice of different colors and profile shapes.

- Possibility of laying over old soft roofing. Metal tiles can be mounted directly on roofing felt or roofing felt.

- A wide range to satisfy every taste. The Russian market offers numerous models from the best domestic and foreign manufacturers.

It should be noted that there are some disadvantages of this roof:

- Noisy during precipitation and wind. It cannot be completely eliminated even with good sound insulation.

- High thermal conductivity. In summer, a metal roof gets very hot under the influence of sunlight, and in winter it cools quickly. This drawback increases the requirements for additional insulation.

- Electrostaticity. Metal is highly electrified, and therefore requires the installation of a grounding system (lightning rod).

- Restrictions on the slope of the slopes, the angle of which cannot exceed 14 degrees. Metal tiles cannot be installed on steep roofs.

- Significant waste when covering roofs of complex shapes. The sheets have to be cut, which increases the amount of waste.

- Accelerated corrosion of the base in places where the integrity of the coatings is damaged. Such rusty spots lead to depressurization of the roof and dramatically worsen the appearance.

In general, metal tiles enjoy well-deserved popularity, because reliability, durability and solid appearance cover all the shortcomings.

Life time

Most manufacturers set fairly long service life for their products - 25, 30 or even 50 years . No one can confirm the long deadlines yet, but practice shows a noticeable discrepancy with the declared and real indicators. The reasons for this are considered to be difficult climatic conditions, installation or operation errors, and the purchase of counterfeit material.

To increase the service life of the material, you must initially purchase a high-quality coating and follow all manufacturer recommendations regarding installation technology. This will help maximize the service life of metal tiles.

Manufacturers in the Moscow region

The Moscow region has quite a few production organizations engaged in the production of metal tiles. In this matter, the regional affiliation of the material is not very important; the technology and materials used in manufacturing are much more important. Modern equipment allows you to obtain a high-quality product regardless of where it is installed.

The products of craftsmen from the Moscow region have stable parameters and are widely in demand on the market due to their balanced cost and quality. We work with M28 UNIKMA metal tiles and are certified specialists and winners of the UNIKMA 2018 roofers tournament.