- March 18, 2019

- Construction

- Marina Lobacheva

A garage is a special structure designed for optimal storage of a personal vehicle. It creates good conditions to keep the machine clean and dry. It can be built on the territory of a private house or in a cooperative. Often the construction process is carried out by the direct owner, so the question arises of how to build a garage. To do this, you can use different materials, and also take into account the requirements and requests of the owner, so the structure can be significant in size and have an inspection hole or cellar.

Where does the process begin?

Before you build a garage, you should decide on some important issues. Here are some of them:

- the type of garage is determined, which can be represented by a separate building or an extension to a private house;

- the purpose of this structure is identified, for which the number of cars in the family and the need to create a living room are taken into account;

- a diagram of the future structure is made, on which you can easily understand what size it will be;

- the area and angle of inclination of the future roof is determined;

- the foundation is calculated, which can be pile, columnar, strip or completely monolithic;

- the optimal facing material is selected, and siding or plastic lining is most often used for the garage.

The most significant issue for every future owner is the search for the optimal material for the planned work. Usually citizens think about how to build a budget garage. In order not to spend too much money on this procedure, it is advisable to choose foam concrete or wood for these purposes; you can create a frame structure. If it is possible to allocate a lot of funds for the process, then it is better to make a brick garage.

We cover the frame with OSB

Now all that remains is to sheathe the finished structure with OSB boards. This is the best option. From the outside they are protected from wind and bad weather by a membrane and finishing material. To make your garage warm, you can use insulation. Then the walls will resemble a sandwich. After covering the perimeter of the garage with OSB boards, foam plastic, mineral wool or other insulation, it is placed in the space between the racks. Everything is sheathed with a vapor barrier film, after which it is sewn up either with the same OSB boards or with other finishing material.

You can see exactly how the process of covering the frame using OSB boards occurs in this video.

However, OSB is not the only cladding option. For this purpose, you can use other materials, such as lining, wooden boards, siding, corrugated sheets, etc. Nobody limits you here, decide for yourself.

Do I need permission?

Even if a citizen plans to build a structure on land that officially belongs to him, he still needs to obtain permission to build a garage. Only in this case can such a structure be officially registered under the owner’s name in Rosreestr. The process of obtaining a permit is divided into the following stages:

- before direct construction work, it is important to send a notification to the regional administration containing information about the planned construction;

- it is permissible not to obtain a permit if the structure does not have a solid foundation and is not used for commercial purposes;

- In addition to the notification, a draft of the future structure must be sent to the administration, on the basis of which a decision is made by government officials;

- If work is performed without prior notification to the administration, the resulting object will be considered an unauthorized construction.

It is possible to start decorating the building after its construction, but if violations of construction or urban planning standards are discovered, the administration may demand the demolition of the object. Therefore, before you make a garage, you should take care of its official design.

Organizational matters

Before starting construction, let us dwell on one important point, namely, whether or not it is necessary to obtain permits for construction.

From the legal point of view, you do not need to prepare any documents in the following cases:

- Construction will be carried out on your own dacha or garden plot and is not commercial;

- The building will be auxiliary;

- The garage will be frame or metal, and not a permanent structure.

This is a complete list; in all other cases, you will need to complete some documents required by law.

We will assume that you have every right to build a garage on your site, then let's get down to business.

Material selection

Initially, the future owner of the building must decide on the optimal material that will be used during construction work. The choice depends on how much money the citizen is willing to spend on the planned structure. The most commonly selected materials are:

- brick;

- foam blocks;

- wooden beam;

- frame structure covered with sandwich panels.

Each option has both pros and cons. Therefore, the parameters of each material should initially be assessed.

Drawing of the frame of the future garage

Without a project, drawing up a detailed diagram indicating the size of the garage, the thickness of the walls, and the depth of the foundation, construction will not begin. The matter should be approached seriously: despite the lightweight design, the garage has a certain weight; you simply cannot place it on the ground. All components, parts of the rack frame, beams are calculated or selected as standard, after the loads have been specified.

For a metal frame, at the design stage you will need to assign an assembly type - welding, bolted or combined. It will determine the complexity and specific configuration of the frame. Wooden parts are traditionally fastened with nails, ties, and staples. If you refuse “deep” design, an assembly diagram, you need to make at least a step-by-step sketch - it will be easier and faster to carry out the assembly.

Some sources belittle the role of drawings and sketches in the construction of a garage. Meanwhile, by transferring your ideas to paper, it is easier to control the process, because you can’t keep everything in your head, and any little thing missed at the initial stage can change the course of work, force you to make unnecessary expenses or replace materials.

In fact, the customer needs to understand what the dimensions of the future garage are, its length/width/height, where the gates are located and their type (sliding, double-leaf swing, with an electric lift, and so on).

Brick building

Brick is chosen for the construction of a garage only by wealthy citizens, since such a structure will have to spend quite a lot of money.

Most often, such material is used by various cooperatives, which make sure that their buildings are not destroyed by intruders. The procedure for erecting a brick building is considered complex, so citizens usually have to resort to the help of professionals, since it is almost impossible to cope with such work on their own.

Roofing device

As for the roof, it can be of two types: gable or single-pitch. Its installation will require a rafter system and cladding material. It all comes down to the fact that the corresponding grooves are made in the frame and on top, to which the rafters will be mounted. Bars with a cross section of 40×100 mm can be used as rafters. In the photo you can see a flat version of the roof.

Next, the sheathing is made and the roofing material is laid. For the garage, bitumen shingles, corrugated sheets, metal tiles, slate or ondulin are most often used. Which material to choose is a purely personal matter.

Use of foam concrete

Often a garage is built from foam blocks with your own hands. The process has many advantages, since you do not have to spend too much money, and you can easily build the desired building yourself. Construction does not require much time, and the result is an insulated structure.

Foam concrete blocks have significant dimensions, and at the same time their weight remains not too large, so citizens themselves, even without work experience, can cope with the task. After the construction of the object, the walls are treated with a special modular or acrylic primer, which protects the material from various negative environmental influences.

A self-made garage made of foam blocks will be durable and warm, but not very attractive. To improve its appearance, it is advisable to use any facing materials.

Summary

As you can see, a cheap building can be erected quite quickly and from materials that are available in almost every area. It is worth remembering that when constructing a garage structure from corrugated sheets, you can use the wall option. It has a lower cost than roofing, but when placed on the wall it is not inferior in strength. A strip foundation can be constructed for a cinder block structure. To do this, you will have to deepen it below the freezing level so that it maintains its integrity. Inside the room, a screed is subsequently poured, the thickness of which must be at least 5 cm in order to withstand the weight of a passenger car.

Recommended Posts

DIY frame sauna

How to choose a stove for a Russian wood-burning sauna

Dimensions of the booth and enclosure for huskies and huskies

How to raise a garage door with your own hands

Frame bathhouse 5x5: projects and drawings

How to make a greenhouse from window frames

Comments

- f

Anonymous09.12.2020 at 18:25

Answer

Wooden garage

Relatively recently, wood was practically not used at all for the construction of a garage, but thanks to the advent of modern impregnations, wood now copes well with various negative influences. Additionally, with the help of fire retardants, wood becomes a material resistant to fire.

This material creates an attractive, inexpensive and warm garage. You don’t have to spend a lot of money on the construction of such a structure. In order to be able to walk in a building without outerwear even in winter, it is advisable to carefully insulate the walls, for which mineral wool is usually used or insulation is sprayed.

Construction of the box - assembling the “skeleton” and sheathing it

Now that the base is ready, you need to make the frame. We begin the work by laying the bottom trim around the perimeter of the foundation. To do this, we use a beam with a cross-section of 100x100 mm and fix it to the concrete using anchors. We connect the beams together in the corners “in half a tree” and fasten them with screws and corners.

Next, we install 100x100 mm racks at the corners of the building and align them vertically. To attach the racks to the bottom frame, we use screws and steel angles. Additionally, we strengthen the racks with struts, which can be made from boards 20-30 mm thick. We immediately tie all the corner posts on top with 100x50 mm timber strapping. After this, we install the racks along the walls in increments of 600 mm. Wall studs can be made from boards at least 30 mm thick and 100 mm wide. We fix and strengthen them in the same way as the corner posts.

Then, on the entrance side, we install 100x100 mm posts to which the gate will be attached, and connect them together with a beam of the same section. As a result, an opening will be formed. To strengthen it, you can install a metal frame made of angle or channel around the perimeter.

Before you begin assembling the frame, treat all boards and beams with fire-bioprotective impregnation, which will increase the durability of the structure.

Next we make the roof frame. To do this, we lay rafters made of 30x100 mm boards on the mauerlat (upper frame frame). Since a pitched roof will be subject to a large snow load, the pitch between the rafters should be no more than 40 mm. To secure the rafters more reliably, we make cuts in the mauerlat along the thickness of the rafters. We nail a board 100 mm wide to the ends of the rafters along the perimeter.

Now that the frame is ready, you can immediately sheathe the walls. To make the building warm, we fill the frame space with mineral wool in slabs. This insulation is cheaper than many other thermal insulation materials, but at the same time it is durable, fireproof and, most importantly, has low thermal conductivity.

On the side of the room we cover the walls with a vapor barrier film. To make the vapor barrier airtight, we overlap the joints of the film sheets and seal them with double-sided adhesive tape. On the outside of the wall, we cover it in the same way with a wind-moisture-proof membrane and properly seal the joints.

To ensure that there is a ventilation gap between the sheathing and the films, we attach a sheathing of wooden slats with a thickness of at least 20 mm to the racks. To fasten the slats we use ordinary screws. To save money, we will not pre-sheath the external walls with OSB boards, but will immediately install siding. The only thing is that it is advisable to use durable metal siding.

To attach the siding along the perimeter of the walls, we attach the starting strip with screws from below, and also install corner profiles at all corners. Then we simply tuck the siding panels into the corner profiles and fasten them to the sheathing with screws. The inside of the garage can be sheathed with any sheet material, such as plywood or OSB. You can secure the sheathing to the sheathing with nails or screws.

When installing OSB boards or plywood, do not forget to provide expansion joints with a thickness of about 5 mm. These seams should be filled with sealant.

Frame structure with sandwich panels

A garage made of sandwich panels is a simple and inexpensive design that can be created on your own. The advantages of such a structure include:

- efficiency of construction of even large-sized objects;

- attractive appearance;

- affordable prices for the elements used;

- A gap is left between the individual panels for laying insulation, which allows you to create a truly warm structure.

Additionally, you can use special OSB sheets equipped with foam plastic. When using them, there is no need to additionally insulate the building. To construct the object, you only need a screwdriver and high-quality fasteners. You can make a garage from sandwich panels yourself or with the help of experienced builders.

Finished projects

The construction of a frame garage is simpler based on its technology, but it cannot be done without drawing up a project. To understand what the future structure should be like, you can borrow ideas from ready-made diagrams. To clarify the task, we will present several projects that are in greatest demand among consumers.

Simple options

There are many options for frame garages designed for one car with a small reserve for storing things and tools. The most convenient projects with different functional contents will be presented for consideration:

You can build a frame garage from boards measuring 6x4 m - the simplest design with a gable roof. The foundation is mounted from concrete slabs. The project provides for a small window to provide daylight. In addition to the garage door, a door is installed to exit to the street.

Wooden garage for 2 carsSource es.decorexpro.com

Garage with additional storage room. The project takes into account space for one car and a utility room equipped as a storage room. A window is planned in one of the side walls and a door through which you can enter the utility room.

Project of a garage with a storage roomSource sk-amigo.ru

Simple garage with a pitched roof Source ro.decorexpro.com

Economy option The building is 6x4 m. It provides space for one car. In such a room you can plan space for shelves for storing tools and placing a workbench. Entrance doors and windows are not provided.

A garage for one car will be inexpensiveSource sk-amigo.ru

The garage is combined with the house, which allows you to save material on the construction of one wall. The advantage is the fact that there is a passage from the house to the garage. There is no additional door to the street or windows. The dimensions allow you to place not only a car, but also a small workshop or utility unit.

Garage adjacent to the houseSource kievnovbud.com.ua

Double garages

Many families, especially those living outside the city, use two cars. In this situation, it is quite logical to build a garage using frame technology for two units of equipment. Below are several options:

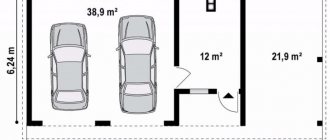

A simple project for a frame garage 6x8 m. Inexpensive in cost, but reliable for the safety of cars. It has a partition to separate places for equipment. There is no door to exit the building, but windows are designed on the side walls. Design designed to store two cars with additional utility room. It can accommodate both a storage room and a workshop. An entrance door through the pantry must be provided. Car spaces are not separated by a partition. The gates are separate.

Garage for 2 cars with double entranceSource lybi.meboganucy.ru.net

Garage for 2 cars with one shared entry Source recreationwishlist.org

The construction of a frame house is clearly shown in the video:

Choosing a foundation

The construction of absolutely any garage begins with the creation of a solid and reliable foundation. For this, different types of foundation can be used, but the most often chosen is columnar or strip.

If there is heaving soil, then a columnar base is ideal. It is optimal for garages that do not have a significant area and weight. Its cost is considered low compared to a strip or monolithic base.

Strip foundations are well suited for heavy construction. It can be built on its own, but for this it is important to understand the rules of the process.

Dimensions of the garage and its design

First of all, you should decide on the purpose of building a garage. If the garage will only serve as a parking place for a car, then it is enough to add one meter on all sides to the size of the car. These sizes are quite enough. If you plan to carry out repair work, then these sizes are clearly not enough, considering that you will need a lift, an inspection hole, and a lot of tools and spare parts. You will have to add another meter to the dimensions in all directions. If you plan to repair not only your own car, then these dimensions will not be enough.

Is a viewing hole necessary?

The presence of a pit makes the project somewhat more expensive. Some owners built a basement under the garage for storing fruits, vegetables, canned food, etc. Naturally, the arrangement of a basement involves large volumes of excavation work.

If you build only a viewing hole in the garage, about 1 meter wide and no more than two meters deep, then it will cost much less. Naturally, the depth of the hole should take into account the height of the car owner, adding about two dozen centimeters to the height. The length of the pit is no more than two meters. As a rule, this is enough to inspect any passenger car.

An example of the construction of an inspection pit

Nowadays, only a few equip their garages with inspection pits, since repairing modern cars is a responsible task that cannot be solved without specialists, so they use the services of a service station. In addition, it is much easier and faster to build a garage without an inspection hole, simply by pouring the floor in the garage with concrete.

Garage foundation options

Considering the fact that a garage for a passenger car is not impressive in size, you can use any type of foundation, as well as their simplified versions, although this approach largely depends on the nature of the soil and weather conditions in the region.

Strip foundation

Strip foundations are considered the most reliable and also the easiest to manufacture. First of all, you should pay attention to the nature of the soil and the level of groundwater, since you will have to lower the foundation below the freezing depth. If we take the middle strip, then this is a level of 1.7-1.9 meters. It is to this depth that a trench should be dug under the foundation, after which the formwork is installed. Then the space is filled with a frame made of reinforcement and poured with concrete. When the concrete has hardened to 50 percent strength, the formwork is removed and the flooring in the garage begins to be poured.

Strip foundation ready for pouring concrete

If groundwater lies at a considerable depth and the soil is not heaving, then a prefabricated strip foundation or a shallowly buried strip foundation, with a strip height of no more than half a meter, is sufficient. A prefabricated strip foundation is formed on the basis of prefabricated blocks, which are connected to each other using cement-sand mortar.

Alternatively, the strip foundation is poured at ground level, and then the foundation is raised by covering it with reinforced concrete slabs.

Pile or pile-grillage type of foundation

It is considered an economical type of foundation, but it is rarely used in the construction of garages. If you make a purely pile foundation for a garage, then it is not very convenient, since the floor of the garage rises to a certain level above the ground. In this regard, it is necessary to think about organizing a check-in. Pile and pile-grillage types of foundations are ideal for construction on heaving soils with a high groundwater level.

The pile is connected to the grillage - this is a pile-grillage foundation

The construction of a pile-grillage foundation is based on digging a pit up to half a meter deep, and then drilling wells in the pit in increments of one and a half to 2 meters. Wells are drilled to the depth of soil freezing. Formwork in the form of pipe sections or rolled roofing felt is inserted into the wells. After this, several bars of reinforcement are inserted inside the formwork so that they protrude from the formwork by 0.7 meters. All this is filled with concrete (wells with formwork). Then they begin to install the formwork on the tape, making a frame from reinforcement so that there is a connection with the reinforcement coming out of the concrete-filled piles. Finally, the entire structure is poured with concrete.

Monolithic reinforced concrete slab

A monolithic reinforced concrete slab is a solution to the problem for any type of soil. Its dimensions are larger than the size of the garage itself by about 0.3 meters in all directions. First of all, the ball of the fertile soil layer is removed, and then a pit is dug at a depth of 0.5 meters. After this, the bottom of the pit is leveled and a layer of gravel about a quarter of a meter thick is poured onto it. The most important thing is that the gravel layer is well compacted, preferably using a vibrating plate.

Formwork is installed along the perimeter of the pit, after which reinforcement is installed in increments of up to 20 cm, both along and across. The result is a grid with cells approximately 20x20 cm. Such a grid should be located in 2 tiers, with a distance of 20 cm. Finally, this structure is filled with concrete.

Both the floor and the foundation

Wall installation

There are many options for making walls, but cheap, non-combustible materials, in the form of foam blocks and gas blocks, are considered the most acceptable, especially since they minimize the load on the foundation, and construction does not take much time. In addition, the walls are warm and heating the garage to a comfortable temperature does not require any special expenses or special heating systems, since it is enough to install a small stove. Naturally, exterior finishing will be required in the style of finishing of other buildings, so as not to disturb the harmony of the overall appearance.

The second option and often used is frame construction, followed by installation of wall material. If the frame is metal, then the walls will be made of metal, and if the frame is made of wood, then the walls can be anything, including metal. In this case, we are talking about a cheap garage that serves as a temporary parking lot for a car.

Frame garage for a country house

Roof arrangement

The simplest option, which is used quite often, is a flat roof with a slope of 8 to 12 degrees. The greater the slope, the less precipitation is retained on the roof. If the garage is located separately, then the roof is raised at the front so that precipitation falls from the rear of the garage. If the garage is attached to one of the outbuildings on the site, then the slope is made in the direction of this building. The disadvantage of a pitched roof is the fact that there is no attic in the form of additional usable space. The advantages are obvious, since the installation of such a roof requires a minimum of resources, and the ease of installation allows anyone to do it.

An example of a gable roof rafter system

The design of a gable roof is somewhat more complicated, and it is also more expensive. In addition, more roofing material is wasted and residues appear. Despite this, this design has a more attractive appearance. The new attic space allows for a more rational distribution of all things, and there can be a lot of them. Some owners build an attic above the garage, which can serve as a room for receiving guests. Naturally, the attic is even more expensive, but it provides a decent amount of additional space.

Gate design

Previously, garages were mainly equipped with swing gates made of metal, but nowadays, many use more modern lifting gates with automatic control. In addition, there are also sliding gates.

Sliding gates are used when the exit from the garage is in the same plane as the fence of the site, although to implement this option it is necessary to have a free section of the wall, the length of which is one and a half meters greater than the width of the gate. This option is good when using a garage in winter, since the gate is easy to dig out if it is covered with snow.

Lifting gates are the most expensive, as they are equipped with a lifting mechanism, but they are the most convenient in any regard. As an option, you can use roller shutters, especially not automated ones, since their cost is not so high. The color can be any, but the roller blinds should be thicker.

Naturally, the automated design is more modern and more convenient. The design of the gate opening must be thought out immediately taking into account the design of the lifting mechanism. Sectional models are more convenient, since when folded they take up little space, but their cost is decent.

Homemade vertical garage doors

-2

Garage interior decoration

Often, car owners do not pay attention to the beauty of the garage walls and leave everything as is after construction. Despite this, some building materials require protection from moisture, otherwise the service life of the walls is reduced significantly. In this case, you can get by with regular plastering of the walls, followed by whitewashing with lime.

Plaster is the best finish

If the garage is frame, then it can be sheathed on the inside with plywood. For a garage that is planned to be heated, any type of plywood is suitable, but for garages that are not heated, it is better to choose moisture-resistant plywood. In any case, any sheet material will do.

Creating a strip base

This type of foundation is most often chosen for large buildings. How to build a garage foundation? To do this, perform the following steps:

- the territory is being prepared, for which green spaces or other elements that may interfere with the planned work are removed from it;

- markings are applied to the ground, on the basis of which the foundation will be created;

- using an excavator or manually, a trench of optimal dimensions is made, with a standard depth of 1 m being selected;

- then a special sand cushion is formed, intended for waterproofing;

- a formwork is created into which the reinforcement is laid;

- a concrete solution is made, which is used to fill the formwork;

- The formwork is removed after about 7 days, after which the resulting base is waterproofed.

Only after this the garage walls are erected. The strip foundation copes well with various negative influences and also has a long service life.

Preparing the base for the garage

When you have in your hands all the necessary drawings, a construction plan and materials for its construction, you can begin preparing for construction. First, you need to know where exactly on the site your garage will be located. Then, it is important to pay special attention to this:

- remove all garbage;

- clear the space of bushes, trees and extraneous buildings;

- remove the fertile soil layer.

After all the steps are done, you can begin to work on the foundation for your wooden garage.

Construction of a garage from sandwich panels

This material has become popular for a long time. If the owner of the land is interested in the question of how to quickly build a garage with his own hands, then it is advisable to choose sandwich panels for these purposes. The construction procedure consists of creating a frame to which the finished panels are then securely attached. It is advisable to choose those that are already equipped with a thermal insulation layer, since in this case the construction process is greatly simplified, since you do not have to insulate the walls.

How to make a garage? To do this, perform the following steps:

- Initially, you need to wait until the foundation is completely dry;

- after this, a metal frame is created, for which you need to follow the diagram;

- metal pipes or profiles are ideal for forming the structure;

- they are connected to each other by welding, so the owner of the building must be well versed in the rules of this process;

- instead of metal, you can use wooden blocks, but they must first be treated with antiseptics and fire retardants;

- fastenings are selected depending on what material is used to form the frame;

- as soon as the latter is ready, the installation of sandwich panels or corrugated sheets begins;

- special sheets already have holes for fastening;

- sheets are installed end-to-end, and corners are also necessarily used;

- a profile is attached to the top and bottom of the walls;

- then the process of creating a roof begins, which can be pitched or completely flat;

- initially a frame is created from metal rods or bars;

- It is optimal to choose corrugated sheeting or even metal lining for covering such a roof.

Even without significant experience in construction, you can get a high-quality and safe garage for use.

How to build a garage with your own hands

To build this structure with your own hands, you don’t have to be a skilled craftsman. It is enough to have basic skills: the ability to work with a hammer, screwdriver, electric saw.

The first and mandatory stage is creating a project. To do this, you also don’t have to resort to the services of a designer. After all, a garage is a simple rectangular box. The optimal option is 4x6 m with a height of 2 m. If you build it for a minibus, you can make the width and length a little larger (although this is not necessary), and the height - 2.5 m.

Construction project

To optimize construction costs, there is nothing left to do but build a frame garage. In accordance with the dimensions, you need to calculate the number of racks. At the same time, do not forget that the spans between them must correspond to the width of the wall panels, taking into account the fact that they are attached end-to-end, and sandwich panels are overlapped (they have special locks for this purpose).

Today it is prestigious to have automatic overhead gates, but they are expensive. Therefore, if you decide to stay within the minimum budget, then choose the cheaper option. You can purchase the same type of gate, but with mechanical (manual) lifting of the door leaf. But still, this element should not be neglected.

Automatic lift gates

There is one more design element that will help optimize the cost of construction. Instead of a gable roof, which requires the construction of a rather complex rafter system, you can make a single-pitch one. The rafter system for it is much simpler. But you should not neglect its strength, since this can affect the strength of the entire structure. The slope of a pitched roof must be at least 25° so that there is no excessive snow load on the structure and it does not collapse.

During construction, you should not forget that the floor must be higher than the ground level so that neither rain nor groundwater gets inside. To do this, it is not necessary to immediately make a concrete screed. You can cover the floor with crushed stone and compact it. Over time, when funds become available, it will be possible to make a screed using this crushed stone base.

Cost of construction

If a person wants to know what is cheaper to build a garage from, then it is advisable to choose a frame structure, which is covered with sandwich panels or corrugated sheets. Additionally, you won’t have to spend a lot of money on building a structure made of foam blocks.

The cost of building a garage can vary significantly, depending on the dimensions chosen, as well as what kind of foundation is used for these purposes. The standard price ranges from 200 to 800 thousand rubles.

Pros and cons of materials

Depending on the choice of material, there will be certain advantages and disadvantages. For example:

- for economic reasons, a tin garage is the cheapest, but a wooden option is the most profitable in terms of quality;

- construction aspect - it is easier to install a wooden garage than a brick one;

- visual considerations - the most attractive from the point of view of decoration are garages made of wood and brick, the least attractive are garages made of tin.

Cheapest options

As already mentioned, the cheapest way to build a detached garage is to choose tin (usually galvanized steel) as the material. There are companies on the market that sell and install such garages. It is also possible to assemble it yourself.

Minuses? Sheet metal garages don't always fit the aesthetics of modern home design. Another drawback is that a detached garage made of this material quickly heats up and quickly loses temperature - this can negatively affect, for example, the condition of a car battery or cleaning products stored in the garage.

The steel frame of a garage is also susceptible to mechanical damage, so tin may not protect the car during some situations.

A more durable solution is a brick garage. It is often built from aerated concrete. However, this option requires plastering and preparation of the metal tiles. The approximate cost of such a project will be higher than in the case of a tin garage.

Wood or reinforced concrete

If you want to combine the aesthetics of a garage with the facade of a traditional house, then you should think about building a wooden garage. In this case, prices increase depending on the materials used.

When choosing a garage of this type, the owner first of all pays for aesthetics, and not for durability.

Don't want to compromise on aesthetics? There are several solutions:

- use materials that look like wood - this will save money and also provide a natural look to the garage;

- use wood in one part of the garage - for example, buy a wooden door and make the rest of the structure from a different material.

A popular material for garage construction is reinforced concrete. The material itself guarantees high resistance of a detached garage to damage and precipitation.

But it is important to understand that a brick garage can look no less attractive than a wooden one. Especially if all the other buildings in the yard are also made of brick. In this case, it is better to use brick.

Selection and installation of gates

A garage is required to have a door. They can be sliding or lifting, automatic or manual. The choice depends on how much money the citizen is willing to spend on this design.

It is recommended to trust the installation of large gates to specialists. Typically, companies that sell gates offer installation at affordable prices. In this case, distortions or other problems can be avoided.

Start of construction

Any construction begins with drawings and a garage project, and the owner must decide:

- How many cars will be parked in the room and what size (OKA or Hummer).

- Do you need additional space for cabinets, equipment, spare parts, and machines?

- Whether or not tools will be stored.

- Whether a pit is provided or not.

Moving from the general to the specific, thinking through specific components and details, you can calculate the size of the required structure.

On a note. A 6*4 garage is enough for a sedan car. For an SUV you need a frame measuring 6*6, and for 2 cars or a minibus you will need a garage measuring 6*8 or more.

Finishing work

Once the main structure of the garage is ready, you can begin finishing work. They are as follows:

- if foam blocks are used to create the structure, they are covered with plaster to give the garage an attractive appearance;

- an additional door is installed, with which you can enter the garage without having to open the gate;

- if necessary, the walls inside are insulated;

- In order for the building to be warm, it is recommended to install high-quality heating in it;

- electricity is supplied to the building.

If you approach the process of creating a structure correctly, you can get a warm, safe and attractive garage. It can be located on a private plot or in a cooperative.

Laying the roof - making the room dry and warm

Now let's start installing the roof. Since the rafters are already there, all that remains is to lay the roofing pie. We begin work by attaching the vapor barrier and sheathing on the inside of the garage. The sheathing slats must be placed across the rafters. We lay insulation on the outside between the rafters.

Then we lay a super-diffuse waterproofing membrane on the rafters. As on the walls, on the roof the membrane is additionally fixed with slats, which serve as a counter-lattice. On top of the counter-lattice we lay boards 25-30 mm thick perpendicular to the rafters in increments of about 30 cm.

Now you need to lay the roofing. An excellent solution for our construction is corrugated sheeting - it is an inexpensive and durable material. We lay the corrugated sheets with longitudinal and transverse overlaps and fasten them to the sheathing with screws. We place the fasteners across the wave in a checkerboard pattern. You can use another roofing option, for example, slate, which is also inexpensive. The principle of its installation is similar to laying corrugated sheets, only we use slate nails instead of screws.

At this point, the garage is almost ready, now all that remains is to install the gate. To save money, you can find suitable used metal gates from an ad. If the garage foundation is not slab, we complete the work by adding a floor. For these purposes, you can lay paving slabs or pour a concrete screed.

This completes the work. If all steps are performed correctly, the resulting garage will not only be strong and durable, but also warm. At the same time, its cost will be several times lower than a traditional brick garage.

Expanded clay blocks

This material is not as popular in the construction of garages as aerated concrete or cinder blocks, but in harsh climates it has no equal in terms of thermal conductivity. Expanded clay (granules 5-40 mm in size) is added to the traditional base of concrete blocks made of cement, sand and water. Expanded clay is a lightweight but quite durable material, and due to its porous structure it retains heat well, because the more expanded clay in the block, the higher the level of thermal insulation you can ultimately obtain.

pros:

- excellent thermal insulation properties, therefore the material is indispensable in northern regions;

- like other concrete blocks, expanded clay blocks are characterized by light weight and large size, due to which construction will progress quickly, while it will be possible to get by with a lightweight foundation;

- strength, durability up to 100 years;

- vapor permeability and environmental friendliness;

- minimum shrinkage rates;

- resistance to frost, temperature changes, high humidity, rodents, mold;

- relatively low price.

It would seem that this is an ideal material, but it also has drawbacks

- difficulties in processing blocks. If cellular concrete can be cut with a hacksaw, then for expanded clay concrete you will have to use a saw with pobedite teeth;

- difficulties during fastening, but you can use anchor bolts and dowels;

- It’s not a very nice surface, so the walls will have to be covered.

Since any car owner wants to equip his car with a warm and dry shelter, the popularity of expanded clay concrete blocks is only increasing.

Other blocks are also used in the construction of garages, but due to their critical shortcomings, we would not recommend them for use. For example, gas silicate blocks are highly hygroscopic, and polystyrene concrete blocks have low strength, so you may encounter difficulties when installing gates. A good option would be wood concrete , which has excellent thermal insulation qualities, but it is afraid of moisture, frost and is more expensive than aerated concrete.

Inspection hole

A comfortable and fairly spacious garage with a pit and a rack is the dream of every car owner who spends a lot of time near vehicles.

The inspection pit is a unique building element of the structure, which is necessary for carrying out repair and maintenance work and is subject to a number of requirements:

- convenience of being inside, the presence of a conveniently designed staircase and sufficient free space;

- small shelves should be installed in the inspection pit to accommodate tools and a lighting ramp;

- It is mandatory for the inspection pit to have a ventilation system, which is necessary according to safety requirements.

To comply with the increased safety requirements for the operation of a garage building, the inspection pit should not always remain open.

When it is not used for its intended purpose, it is covered with special boards or doors that can withstand high weight and prevent accidents.

- Summer shower at a summer cottage: review of designs, materials, and schemes for self-construction

Do-it-yourself tandoor - a traditional oriental stove in a summer cottage, photos of completed projects

A polycarbonate greenhouse is a joy for a gardener, let’s understand the structures step by step (photo + video)

It is not recommended to store harvested vegetables and fruits in an inspection hole; even minor liquid evaporations can cause car damage.

Evaporating moisture is deposited in the form of condensation on the bottom of vehicles, which leads to metal corrosion, even if it has an anti-corrosion coating.

What can you save on?

For greater savings, you can build a lower base and use less expensive roofing materials. Only installing slate battens will make it possible to reduce the cost of constructing a roof as much as possible.

In this case, it is better not to use ondulin, as it can increase the cost of the garage roof by at least 2 times.

The construction of a garage will protect your car from intruders, although its cost may initially frighten you. In any case, the costs after damage or theft of the car will be much higher.