Sooner or later there may be a need to obtain clean water directly on the site.

If you need to do this quickly, cheaply and for a long time, the Abyssinian well will come to the rescue.

Hydro drill drawing

I was guided by the fact that the device should be easily repeatable and could be made by anyone who was interested in this topic.

You will need 2 corners, 75 mm wide on one side, wall thickness 8 mm and 30 cm long. And 2 corners 65 mm long, wall thickness 5 mm. A pipe with a diameter of 32 mm is also required.

The cutting part of the drill will be under a 2 cm cone. We cut it and sharpen it to a cone.

On the cutting edge we make a marking of 17 mm from each edge. It is necessary to cut so that the pipe does not reach the cutting edge by about 10 cm.

To make the holes for the water jet larger, all that remains is to use a grinder to cut out the inside of the corner a little, and at the same time we will make a chamfer on each edge and on the outside of the corner.

To prevent the drill from clinging with sharp edges, when we pull it out, the sharp edges of the corners must be cut off.

Next, we wind a millimeter rope around the pipe to ensure a millimeter gap and intercept it by welding. For more thorough welding, remove the pipe.

Now we need 20 pieces of inch metal pipe, 2 meters each. The ends must be chamfered so that threads can be cut. Except for one, because this one edge will be welded to our drill.

On the one hand, we will cut the threads to half the length of the coupling, immediately screw them on and secure them a little with welding to prevent unwinding during the drilling process.

On the other hand, we will cut the threads a little larger, approximately the entire length of the coupling, and screw on the nuts that protect the pipe from unwinding.

!!! Regarding thread cutting, I recommend going to a turner. since this is a difficult task for such a pipe diameter.

On the pipe that did not have a thread, we put our drill on it, set the same gap everywhere and scald it as shown in the photo.

Let's prepare the ribs for centering the drill. Corner 65 by 65 mm, two pieces of 15 cm. To avoid clinging, cut 3 cm on each side. Now we need to weld it to our drill on different sides, about 30-50 centimeters from the edge.

Drilling tool

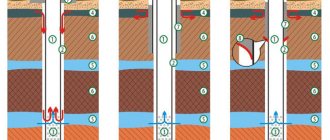

Now let's see which drill to drill into which soil and in what way, see fig. on right:

Hand Drilling Tool

- Auger drill, or simply auger - for rotary drilling of cohesive homogeneous soils of normal density; simply - for soil, loams, slightly damp sandy loams, soft clays. Unlike a garden auger, the auger has a double-thrust design, otherwise the asymmetry of the soil resistance force will lead the auger to the side and it will get stuck;

- Drill-glass, or Sheetz drill bit - for cohesive, but viscous, highly sticky soils in which the auger gets stuck. Drilling - cable-percussion;

- Spoon drill - for loose and loose soils that do not hold in the turns of the auger and in the glass. Drilling – impact-rotary or rotary;

- Bailer - for cleaning the trunk from crumbled soil, silt, etc. very loose or floating soft semi-liquid rock. Drilling - cable-percussion;

Drawings of homemade drills for wellsAs they say, pah-pah-pah over your left shoulder, and God forbid that you don’t need a drill bit to break boulders. The cross section is a plate with rounded edges. Caliber – internal diameter of the casing minus 3-5 mm. Drilling - impact rod.

The cutting edges of all drills are made of hardened steel. Drawings of a homemade drill-glass, an analogue of a spoon drill (the cutting blades are installed by a propeller at an angle of 3-10 degrees) and a diagram of the bailer are shown in the following. rice. on right. The outer diameters of all these drills can be changed depending on the caliber of the well.

Requirements for materials used

Materials used for insulation of water supply pipes must have the following characteristics:

- Low thermal conductivity and the highest possible heat retention capabilities;

- Completely resistant to moisture;

- Good resistance to aggressive external factors;

- Long service life;

- Easy installation;

- Low cost.

Compliance with all the described qualities allows us to say that the selected material is good enough for pipe insulation. However, there are no ideal insulation materials, so you need to choose depending on the specific operating conditions.

Reasons for the disappearance of water in a well

The aquifer can dry out if several wells are connected to it

To make sure that the water level in the well is constantly decreasing, you need to monitor it. Perhaps this is a temporary problem caused by the characteristics of the aquifer or weather conditions in the region. It’s a good idea to talk to your neighbors and find out how things are going with their sources. If the problem arose only with a specific well, then we are talking about resource exhaustion.

The main reasons for the drop in water level in a well:

- clogging of the bottom filter if the source is drilled for a true floater;

- deviation of the mine shaft from the vertical position, subject to technical errors at the time of well construction;

- depressurization of the casing;

- a large number of sources in the village, fed from one aquifer (especially the problem of disappearance of water in a hydraulic structure is noted immediately after drilling a well at a neighbor’s);

- a long period of summer drought (the problem is typical for sand sources);

- construction of a well during periods of high groundwater.

It is advisable to drill a well or deepen it in summer or winter.

It is possible to deepen an existing well if its service life is no more than 5-10 years. At the same time, it is important to weigh all the pros and cons regarding such work. The financial capabilities of the foreman are taken into account (more often than not, deepening a source is more expensive than building a new one), the possibility of extending the casing, and the results of geological surveys. Without them, there is no point in carrying out work, since the next aquifer can be located extremely deep.

Deepening methods

One of the most common methods for restarting a source is the use of a bailer. This is a metal pipe with a valve at the bottom. To ensure that the bailer freely crashes into the ground under its weight during manual drilling, you can sharpen its lower edges or cut teeth. The principle of deepening the well here is as follows:

- The source shaft is completely cleared of liquid residues.

- The casing string is cleared of sludge.

- The bailer is attached to a winch and lowered down into the source.

- From a height of 1-1.5 meters, a metal pipe is thrown so that it crashes into the ground a few centimeters. At the moment of its sharp lowering, the valve opens to take soil from the mine shaft.

- When the bailer is raised, the valve closes, preventing the soil from falling down.

- On the surface, the pipe is freed from sand and the steps are repeated with the recess until the result is obtained.

It is advisable to carry out the work together. As soon as the master reaches the new aquifer, you need to grind the casing from below. To do this, a section of the shaft is assembled on the surface, with a diameter smaller than the existing one, and lowered down. Then two sections of the column are spliced.

The same method is used by specialists with drilling rigs. The difference is that special equipment operates faster and can deepen the well over a larger distance.

Deepening with rings

Bailer with petal valve

An old well can be drilled using rings. They also use a bailer here. To lengthen the casing shaft, sections of rings or pipes similar in diameter to the existing ones are used. The works look like this:

- Using a metal pipe, the source is deepened.

- As the depth of the mine increases, new sections of pipe are installed on top of the casing. Under their weight, they lower the existing trunk down. The main thing is to carefully seal the joints of the elements.

- With each new meter of deepening, the well shaft is sharpened.

After achieving the result, water from the new horizon should be submitted for analysis.

Filter manufacturing and installation

To prevent clogging of the casing pipe with sand, a filter device should be installed in it. You can make it yourself from a pipe of a smaller diameter. We drill or weld holes in it with a diameter of 1.5-2 cm, and install a mesh of stainless wire inside.

The size of the mesh cells should be so small as not to allow sand to pass through. We weld the bottom of the filter with a steel plate. We install a submersible pump or a surface pump hose inside the filter. After this, the new well is ready for production.

Organization of work on site

The artesian well is located on a well-maintained site in a place difficult to reach for heavy equipment. Therefore, we immediately decided to carry out the drilling work for cleaning and deepening with a small-sized installation.

Another difficulty in implementing the plan was that the casing was ø114 mm. significantly limited the choice of necessary uPVC pipes and the available methods for drilling a well.

The first stage, cleaning the open hole, began to be carried out with a drilling cutter with a diameter of ø98 mm. Unexpectedly, at a depth of 82 m, the cutter rested against the bottom of the well.

That is, instead of the depth indicated in the passport of 106 m, the real depth turned out to be 82 m.

The customer was informed about the discrepancy between the passport data specified by the drillers and the actual well design and a new technical specification was agreed upon:

- deepening the well up to 95 meters,

- casing to the entire depth of the trunk with PVC-U pipes ø88 mm. with packer connection and filter perforation in the lower part.

Well design according to technical specifications for repairs.

Filter perforation of PVC-U casing pipe.

Upon completion of the work, the customer was shown the actual drilling depth using a drilling tool. A new passport was issued, reflecting the actual design and parameters of the well.

After pumping to visually clean water, the well was put into operation.

The duration of the contract is 2 days.

The cost of cleaning and deepening the well without the cost of materials is 70,000 ₽.

conclusions

The problems of the artesian source arose due to poorly executed drilling.

Due to dishonestly executed documents and suboptimal design, difficulties arose in repairing the well.

See more

- services of LLC Burgidroproekt for repair of water wells

- Well passport - what is it?

- characteristics and capabilities of a large-sized drilling rig

Deepening method

You can use one of the simplest methods for deepening wells:

- In a metal pipeline with a circumference of 10 cm, 50 gaps of 2 cm each are made.

- A stainless steel grid with an anti-corrosion coating is placed inside. Next, a pump is installed.

- A hole is made at the bottom of the well, where the pipe is installed at an angle so that sediment does not fall into it.

- The result should be filtering equipment for the flow of clean water. Using a gutter on the bottom of the pipe, sand will not fall into the work area, which will help in digging to the required depth.

DIY water well drilling: technology, equipment

An autonomous water supply system quite often acts as the only way to provide water supply for dachas and country houses. A well, which is installed on the site, is selected as a source. Owners, as a rule, show a desire to carry out the improvement process with minimal losses for the territory, this is especially true when the exterior is landscaped. It is also important to save money. Special equipment and additional tools, of course, will be needed, but it is important to decide whether you will manage the work yourself or entrust the job to specialists.

Advantages of hydrodrilling wells

The technology of hydraulic drilling for water has gained popularity among the people relatively recently, and therefore has many misinterpretations. Firstly, it is a misconception that the method is only suitable for small wells. This is wrong.

If desired and with appropriate technical support, hydraulic drilling can be used to drill wells longer than 250 meters. But the most common depth of domestic wells is 15-35 meters.

The opinion about the high cost of the method is also not confirmed by calculations. Good work speed reduces financial costs.

The obvious advantages of the method also include:

- compactness of equipment;

- the possibility of drilling in an extremely limited area;

- minimum technological operations;

- high speed of work, up to 10 m per day;

- safety for the landscape and ecological balance;

- possibility of manual drilling;

- minimum cost.

Perhaps the most significant advantage of hydraulic drilling is the ability to drill in landscaped areas without significant aesthetic troubles.

The technology of hydraulic drilling on an MBU machine makes it possible to carry out a cycle of work on a small site and does not disturb the landscaping of the site

The advantages of hydraulic drilling also become very clear if we compare it with dry drilling technology, where it is necessary to constantly remove the working tool from the shaft for cleaning and load it again.

This technology is best suited for working with fine-clastic sedimentary soils, which are most easily removed from the well using a bailer. And the drilling fluid allows you to do without gelling.

Of course, for a good result of the enterprise, it is necessary to purchase appropriate means of mechanization, because one homemade drill, even at shallow depths, is not enough.

Common mistakes

There are a number of mistakes that inexperienced self-taught drillers make:

- Erroneous identification of the reasons for the disappearance of water, and, consequently, the choice of the wrong method of solving the problem.

- Starting to deepen the well during the rainy season, when the groundwater level is high. This can lead to the fact that during a drought the water in the deep well will disappear again.

- There were technical miscalculations and violations during operation, which caused subsidence of the well rings, or their displacement relative to each other.

In general, work on deepening a well does not represent, from a technical point of view, an insoluble problem. Each owner of a plot of land can do them with his own hands.

Features of manual drilling

The manual drilling method requires a lot of physical strength, but allows you to save on equipment. It is used when installing wells no more than 25 meters deep and is carried out until the drill reaches the waterproof layer.

In the case of manual drilling, use:

- a set of drilling heads (drill bit, drill spoon, coils, bailers);

- rods;

- winch or electric hoist;

- casing;

- for working at great depths - a drilling rig.

The shaft sinking process consists of the following steps:

- A small hole 40-50 cm deep is dug in which the drill will be placed.

- Then one person begins to rotate the drill; when it goes deep enough, you will have to rotate it with two people, then with four people.

- Every 50-70 cm of entry into the ground, the drill must be pulled out and cleaned so that dirt does not cover the entire head.

- If the soil is too hard, the resulting hole must be filled with water.

When the shaft is filled with water from the inside, work stops. Now all that remains is to pump out the dirty water with impurities - approximately 5-7 liters. For this you will need a pump.

Impact method

Using this method, the simplest needle well is installed - the Abyssinian well. This method is actively used by home craftsmen when drilling a well for water in their dacha. The design of the “drilling rig” is a barrel consisting of pipe sections and a tip that cuts the soil layers. The hammer is a weighty woman, which is raised and lowered with the help of ropes: when tensioned, a kind of hammer rises to the top of the structure, and when loosened, it falls onto the headstock - a device of clamps located symmetrically. After the trunk enters the ground, it is extended with a new section, the headstock is attached to the new part, and driving continues until the tip enters 2/3 of the formation into the aquifer.

The trunk-pipe serves as a hole for water to escape to the surface.

The advantage of this well is that it can be drilled in a basement or other suitable room. This creates ease of use. The price is also attractive; drilling a water well in this way is inexpensive.

Impact drilling can be used on any type of soil

Cable-percussion drilling

The most commonly used method. This method involves breaking the soil by lowering a heavy drilling tool from a two-meter height. The design used for this type of drilling consists of the following elements:

- tripod, which is placed above the drilling site;

- block with winch and cable;

- driving glass, rod;

- bailers (for passing through loose layers of soil).

The glass is a piece of steel pipe, beveled inward, with a strong lower cutting edge. There is an anvil on top of the driving glass. It is struck by a barbell. Lowering and raising of the driving glass is carried out using a winch. The rock that falls into the glass is held in it due to friction. In order to penetrate the soil as deeply as possible, a striking rod is used: it is thrown onto an anvil. After filling the glass with soil, it is lifted up and then cleaned.

Drilling a well on loose soils is done using a bailer. The latter is a steel pipe, at the lower end of which a retention drip is installed. After the bailer hits the soil, the valve opens, causing soil to enter the pipe. When the structure is lifted, the valve closes. After being removed to the surface, the bailer is cleaned and the steps are repeated again.

Cable-impact equipment for well drilling

The auger method described above is also effectively used for self-drilling. There is no point in further explaining how to drill a well with your own hands using an auger - the basic principle remains the same.

Advantages of manual drilling:

- financially economical way;

- repair and maintenance of a hand drill is easy;

- the equipment is not bulky, so there is no need to use heavy equipment;

- the method is applicable in hard-to-reach places;

- effective and does not require much time.

The main disadvantages of manual drilling include lowering to a shallow depth (up to 10 m), where layers mainly pass through, the water of which requires purification, and the inability to crush hard rocks.

Shock-rope scheme with a bailer and a punching bit

Where to start the deepening process?

Drilling should begin during the period when the flood level decreases, or when the source is completely drained. If water has a low level of intake, this may be due to the following factors:

- arrangement of multiple artesian springs emanating from one water intake point;

- dry season;

- high level of water source passage.

If you have skills in the construction industry, you can carry out the deepening work yourself. But if you are not sure about the correctness of the event, it is better to use the services of professionals who will accurately create the necessary design.

Removing water

Before deepening a well, you need to pump out all the liquid from it. To do this, it is better to use pumping equipment designed to work with dirty water. This is especially true for sand wells, where there is a high probability of trapping silt near the bottom of the source.

Advice. Drilling work, like conventional drilling, is best done during periods of low groundwater levels. The best time for this is winter or the second half of summer, when aquifers are practically deprived of recharge, which is why they have a minimum volume.

All water is removed from the well, including muddy solution

Removing water

Let's consider how you can deepen a well-type well made of concrete siege rings. First of all, the well should be freed from residual water. This is done using a special motor pump designed to work with sewage.

Conventional water supply pumping equipment is not suitable for such work. As a result of the filter being clogged with silt accumulated at the bottom, the flow of water into the pump will stop, which will lead to its breakdown.

After draining, we inspect the well, finding out whether the rings have become deformed or have shifted relative to each other. If such defects are revealed during the inspection, then the deepening work will be fraught with danger, and it would be better to think about constructing a new well.

When the rings are located exactly above each other, they should be additionally fastened to each other to avoid displacement during operation. For this purpose, steel plates are used, secured to adjacent rings using anchors. If there is a bottom filter at the bottom of the well, pull it out.

Working with a bailer

To deepen a well with your own hands, the easiest way is to use a bailer - a metal pipe with a valve at the end. The diameter of the pipe should be slightly smaller than the casing for free movement inside the well. It is worth noting that the use of a bailer to remove soil is possible only if there are no bends in the column. Even a slight distortion of the structure can lead to a wedge during operation.

The source is deepened as follows:

- The pipe is tied on a cable and lowered down.

- Half a meter before the bottom, the bailer is released and, under its own weight, plunges into the ground, thereby filling the internal cavity.

- During lifting, the valve closes the outlet for the sand mass.

- At the surface, the pipe is cleared of soil, and the process is repeated again until the required water carrier is reached.

Homemade bailer with ball valve

Working with a bailer

Next, we proceed directly to excavation work at the bottom of the well. To do this you will need the following devices:

- A bailer is a percussion instrument that operates on the principle of a chisel.

- Winch and cable for lifting the bailer to the top.

- Casing pipe with filtration holes

Working with a bailer involves constructing another well at the bottom of a drained well, drilled to the next aquifer. A frame in the form of a tripod or cube is installed above the well neck, from which the blocks are suspended.

A cable is thrown over them, one end of which is attached to the bailer, and the other to the swan. To make a bailer you will need a piece of thick-walled steel pipe about a meter long and weighing 50-80 kilograms. Its diameter should be such that it can fit inside the casing pipe.

Next, use a shovel to dig a hole in the center of the well bottom into which we install the pipe. Inside it we place a bailer tied to a winch. By lifting the bailer chisel and dropping it down, we deepen the bottom. After the fall, the bailer is buried in the ground, and when the tool is lifted, it remains inside.

After every 3-4 cycles of rise and fall, the bit should be pulled out and using a sledgehammer, freed from the earth that has accumulated in it. As the well deepens, so does the casing.

Work is carried out until a new aquifer is reached.

Filter manufacturing and installation

After deepening the well, you need to install a filter at the bottom. For its manufacture, a steel or plastic pipe is used, the diameter of which is less than the existing casing. In the lower part of the pipe (about 0.5 m from the edge), many holes are made, placed in a checkerboard pattern with a pitch of 2-4 cm. Next, a stainless steel wire with a diameter of 1.8-2 mm is wound in a spiral, on top of which a metal mesh is mounted.

Advice. To calculate the optimal size of the mesh cells, sand raised from the bottom of the source is dried and poured onto graph paper. Based on the markings, the diameter of the minimum fraction is determined, according to which the mesh for filtration is selected.

On the bottom side, the filter pipe is closed with a wooden plug to protect the trunk from silting. When all the work is completed, the finished filter is carefully lowered into the well.

Sectional view of a filter for a well

What types of water wells are there?

Despite all their diversity, experts distinguish only a few types of water intake wells. The first is the so-called needle well. In this case, the drilling rod, the well casing and the drilling tool constitute a single whole. The drill remains in the ground throughout the drilling process. The process itself is carried out using the shock method. The deepening speed with this method averages about 2 meters per hour. The maximum possible depth is up to 45 meters. A needle well, as a rule, is installed for the so-called Abyssinian wells in the country. They are in demand in the summer, as in winter they can show unstable water intake. A distinctive feature of such a well is that it can last for several decades. However, it cannot be repaired. As soon as the well stops producing water, it is plugged and construction of a new one begins. The diameter of the drill rod is up to 12 cm without the use of a piledriver - this corresponds to an 86 mm submersible pump.

Types of construction of water wells.

The second is an imperfect well. Such a well seemed to hang inside the formation. It is simple to set up and does not require any special skill from the performer. However, the fence made from it is not of very high quality. In order to maximize the quality of water taken from an imperfect well, it is recommended to install a plug at the bottom of the well. In order for an imperfect well to be drilled on your own, you will need to have a fairly powerful aquifer. The third type of well is perfect. In this case, its casing rests on the roof of the waterproof layer. Drilling such a well will require precise knowledge of local geology, as well as the presence of certain skills and abilities of the driller. The quality of water in such a well is the best, and its service life is maximum. The fourth type is the so-called bottomhole well. In turn, it can be either perfect or imperfect. Thanks to the bottom hole, it will be possible to service such a well and, if necessary, repair it. However, only the most experienced craftsmen who are well acquainted with the local geology can drill it.

Where to drill?

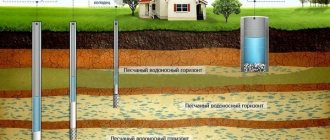

The general scheme of the formation of aquifers in nature is shown in Fig. Verkhovodka feeds mainly on sediments and lies within the range of approximately 0-10 m. High water can be suitable for drinking without deep treatment (boiling, filtration through shungite) only in individual cases and subject to regular testing of samples by sanitary authorities. Then, for technical purposes, the perched water is taken from a well; The well's flow rate in such conditions will be small and very unstable.

Formation and types of aquifers

A water well is drilled independently into interstratal waters; highlighted in red in Fig. It is impossible to drill an artesian well that provides water of the best quality for a very long time, even if you have a detailed geological map of the area: the depth is usually more than 50 m and only in exceptional cases does the formation rise to 30 m. In addition, independent development and the extraction of artesian waters is categorically prohibited, to the point of criminal liability - this is a valuable natural resource.

Most often, it is possible to drill a well on your own into a non-pressure formation - sand soaked in water on a clay bed. Such wells are called sand wells, although the free-flowing aquifer can be gravel, pebble, etc. Free-flowing waters lie approximately 5-20 m from the surface. The water from them is most often drinkable, but only based on the test results and after pumping the well, see below. The debit is small, 2 cubic meters. m/day is considered excellent, and fluctuates somewhat throughout the year. Sand filtering is required, which complicates the design and operation of the well, see below. The lack of pressure increases the requirements for the pump and the entire water supply system.

The pressure strata lie deeper, in the range of about 7-50 m. The aquifer in this case is dense water-resistant fractured rocks - loam, limestone - or loose, gravel-pebble deposits. The best quality water comes from limestone, and such wells last longer. Therefore, water supply wells from pressure layers are called limestone wells. The formation's own pressure can lift water almost to the surface, which greatly simplifies the construction of a well and the entire water supply system. The debit is large, up to 5 cubic meters. m/day, and stable. A sand filter is most often not needed. As a rule, the analysis of the first water sample passes with a bang.

Note: how do you find out which layer is available and accessible in a given place? The methods for finding water for drilling a well are generally the same as for building a well. In the central zone of the Russian Federation, free-flowing water can almost always be found within the first 20 meters of depth.

Types of drill for hydraulic drilling of wells

Drilling rigs may differ based on drilling technique. An impact drill operates through mechanical action using weights. The rotating structure is more complex in structure, but the work is done many times faster.

Types of drilling rigs:

- Shock-rope. The structure of the structure consists of a frame with a pyramidal base and a cable with a projectile.

- Auger. A rotating auger penetrates the ground, drilling a hole. Feature: the well is not flushed.

- Rotors. Hydraulic technology is followed.

- Rotary type manual device. A distinctive feature is the absence of a motor. All work is done by hand, which is a rather labor-intensive process. That is why the popularity of such equipment is quite low.

Screw installations are almost impossible to make yourself. This requires special skills and tools. But creating a DIY setup has many benefits. It is much cheaper, the equipment is compact in size. This can result in a high-quality design that is easy to work with.

Passage of quicksand

In general, the technology of work remains the same as when digging into ordinary soil. However, additional complications arise. In fact, quicksand is a very mobile layer of soil. Therefore, casing speed is important in the work.

If you use conventional methods, there is a high probability that the well will simply be filled with sand. Therefore, it is necessary to use special equipment that can quickly raise the soil to the surface.

In addition, it is necessary to ensure the possibility of quick casing. For this:

- you can use an additional weight that is installed on the repair rings;

- if possible, use an excavator - it will be able to press down the sections with a bucket, and due to this they will quickly go down.

After the sections are installed, they are securely fastened. The final stage is the installation of the bottom filter and plug.

Complete structure

After drilling, it was decided to disassemble the structure and modify it a little. They cut off the cutting part, reduced it by almost half, leaving 3 centimeters from the water outlet holes. This was done due to the fact that the water pressure was simply not enough to penetrate this distance and effectively penetrate the water emulsion.

The operating speed of drilling increased by one and a half times, it became easier to drill and the process went faster

What else can be added to improve the drill. In addition to the fact that we cut off the front part of the drill, we recommend reducing the length of the shank itself by 5 centimeters.

Want to

drill a well

high quality and not expensive, then we recommend professionals.

Author: lomaka

Extending the well pump cable ↑

If it is possible to deepen the well to the required aquifer, a situation may arise when the length of the electric cable of the well pump is not enough for the correct placement of the equipment. In this case, you will have to lengthen it.

For your information. The number of cores in the cable depends on the power supply circuit of the electric motor. Three-phase equipment is connected with a 4-core wire (3 phases and 1 ground). Single-phase pumps are powered using a 3-wire cable (phase, neutral, ground).

Extending an electrical cable involves adding a section of the required length to an existing wire. In this case, the additional segment must be made of the same metal (usually copper) and have a similar cross-section of conductors.

To extend the cable for a well pump, the wires are connected to each other by soldering or crimping, each of which ensures reliable contact. The joint is usually insulated using insulating tape or heat shrink sleeve.

Connection and insulation of electrical wires

Advice from an experienced summer resident

When calculating pump power, two quantities must be taken into account:

- Height of the water column. This is the distance from the water surface to the surface of the earth.

- Horizontal water transmission range. The calculation includes the distance from the well to the distant consumer.

The height of the water column is an indicator that must correspond to the power of the pump. It is generally accepted that every kilowatt allows you to raise water by 10 meters. The power of the pump is designed to create the required pressure in the pipeline so that each consumer can function in normal mode.

When calculating the required amount of water, you need to take into account the consumption rate in the region when it comes to irrigation. But for domestic use, you need to add up the entire flow rate, as if all the points were turned on. In this case, the pump productivity cannot be greater than the well flow rate. Therefore, when the well is ready, they measure how much liquid flows into it in one hour.

Water purification

Upon completion of the main stages, they begin to clean the water source - the well. First, you need to check the suitability of the water by giving it to experts for examination. If it turns out to be dangerous to use, then about half a kilogram of bleach is poured into the well. After an hour, it is recommended to pump the water.

Then go treat the inner walls of the well with antiseptics. For this purpose, a solution of sodium hypochloride may be used, for spraying which a special high-pressure washer is used. Such equipment will not only allow you to apply the compounds, but also clean the surfaces of dirt and organic deposits.

At the next stage, seams and cracks are sealed using liquid glass or cement mortar. A 15 cm layer of soil is placed at the bottom of the well, which will consolidate the soil and reduce contamination.

Features of hydraulic drilling

If you need a water well, then you need to start hydrodrilling in the morning, since the process will take quite a lot of time, sometimes it stretches for several days. The soil is different everywhere, so there may be some nuances in working with it. To drill in sandy soil, it is necessary to prepare a huge amount of water, since sand absorbs a lot of liquid.

Before starting manipulations, you should make sure that you have a clay solution. To do this, clay is loaded into a pit with water and mixed with a mixer. The consistency should ultimately resemble kefir. Such a drilling fluid will flow into the well and will not go into the sand, but will gradually clog the walls, forming a vessel. When drilling a water well, it is necessary to check whether the winches are operational, as well as the pump for pumping out water. During the process of punching soil from sand, stops are not allowed. The casing pipe is lowered immediately, otherwise collapses may occur and the work will have to start again.

Arrangement and automation

Construction of a well with a caisson

To supply water to the house, a well must be equipped and mutually coordinated with the water supply. The arrangement of water supply wells has undergone radical changes in recent years. The traditional scheme (see figure on the right) - a caisson, concrete or steel, or stone pit, which requires a large amount of additional excavation work and usable land area for itself, is becoming a thing of the past. Nowadays, water wells are increasingly equipped with well adapters, see fig. below. Installing the adapter is quite a painstaking task, but it is incomparable with a caisson-pit sweep:

- As soon as the water begins to flow, they judge by the speed of its clearing how much further it is possible to go deeper, and cut the last casing pipe to size from above.

- Before installing it, make a trench to the house to a depth greater than the standard depth of soil freezing.

- A hole for the adapter is drilled in the pipe in advance and installed, plugging the pipes. If you place it directly in a well, it may gurgle there.

- They place the pipe and drill further, orienting the outlet of the adapter into the trench at a depth greater than the freezing depth.

- They rock the well, install the filter, lower the pump, connect the pump supply pipe and the transit pipe to the house to the adapter fittings, and lay the pump cable.

- They put the well cap on, when the water has flowed into the tank, fill up the trench - that’s it.

Construction of a well with a downhole adapter

Water supply to a private house from a well has its own characteristics, but they will not prevent you from later connecting to a collective water supply or drinking water from a well. You won’t have to redo anything, it will only be more reliable.

First, you need a pressure storage tank. The flow rate of a non-artesian well may, for unknown reasons, drop until it stops completely, and then the water flows again as if nothing had happened. Secondly, downstream of the tank along the water flow you need at least a 2-stage membrane filter. In public water supply systems, water quality is continuously monitored, which is not the case at home. What if there is a man-made accident or an unauthorized discharge of pollution somewhere in the reservoir’s recharge zone? Everyone had already forgotten when it was, and the bad water had just reached the well.

Finally, the home water supply must comply with the principle of gradual, uniform water withdrawal, which was discussed at the beginning. Cooperating with neighbors, as when building a common septic tank, is not the best solution in this case. Suddenly there won’t be enough debit for everyone, instead of the community there will be squabbles. Those. we need automation that turns on the booster pump as soon as someone somewhere opens a tap.

There are 2 options here. The first is a pressure tank with a float valve in a warm attic. All automation consists of a rod that passes in a sleeve through the tank cover and rests on the float lever, and a 6-10 A microswitch (micrik) with normally closed contacts in the pump power supply circuit. While the tank is full, the rod presses on the microphone lever, the pump is de-energized. As soon as water began to flow into the house, the rod dropped, the microphone went off, and the pump started pumping.

However, firstly, you need to insulate the attic, which costs a lot of work and money. The second is a pump, it will require an extra 4-5 meters of pressure, and for a 2-story house, all 8-9, so the pump turns out to be expensive. Thirdly, a leak in the tank or a malfunction of the float will at least lead to the ceiling getting wet. Therefore, modern automation for water supply wells, controlled by a microcontroller that monitors flow rate, water pressure and the frequency of turning on the pump, is still cheaper and more reliable. House plumbing is then carried out with a sealed membrane storage tank in the basement.