As energy prices rise, more and more attention is paid to the thermal insulation of homes. A significant part of the heat loss occurs through the cracks in the entrance doors: this means the gaps between the leaf and the floor or frame. As for interior doors, such defects noticeably worsen the aesthetic perception of the interior of the premises and the level of sound insulation between individual rooms.

- Self-adhesive tapes

- Eliminating side gaps

Without cracks - no way

There must be a certain gap between the door along the entire perimeter of the frame, otherwise it simply will not be able to open and close. The dimensions of the gaps are strictly regulated by the relevant GOST. The material used to make the canvas and the box is of great importance. For example, wooden products tend to change their size to a certain extent, depending on the level of humidity (the so-called “drying out” and “swelling”).

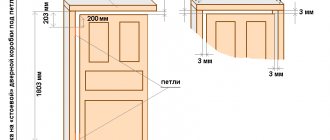

Recommended clearances in the doorway

Proper formation of gaps at the installation stage directly affects how convenient the door structure will be to use. In addition to the material of manufacture, the parameters of the gaps depend on the height, width and weight of the canvas. Certain errors are acceptable, usually within 1 mm of deviation in one direction or another.

A slight increase in the distance between the frame and the door is allowed in the following cases:

- The indoor microclimate is too humid and there is no ventilation.

- The material used to make the door block is natural wood or lumber, which is prone to absorbing moisture.

As for the clearance between the canvas and the floor (threshold), it is recommended within 20–25 mm.

To increase ventilation efficiency and ease of opening, this parameter can be increased to 40 mm.

Dismantling - features

Many home craftsmen do not attach importance to the door structure, believing that it is enough to take a nail puller and dismantling will be successful. In reality, everything is not so simple. Often, especially in apartments of old construction, part of the wall collapses along with the door frame being aggressively broken out.

To prevent this from happening, you need to approach the process with an understanding of the matter. First of all, you need to decide whether you will use the old door structure later, for example, in the country, or whether it will go to waste.

There are two types of dismantling:

- gentle - with preservation of the structure;

- fast - after it all elements are sent to a landfill.

In both cases, accuracy will not hurt - you need to dismantle the door with minimal damage to the opening.

How is the door structure constructed?

First of all, you need to know that any door consists of:

- door frame - 2 vertical posts, crossbar, threshold;

- door leaf.

In addition, the old doors were painted dozens of times, which made the doors heavier, and the locations of the nails were hidden under the layer of paint. Previously, a wooden block was necessarily installed between the frame and the doorway, the thickness of which was difficult to predict. It is on this block that the box is nailed with nails that have rusted during use - there is no hope for simple dismantling.

Recommendations for arranging the correct gaps

The most effective way to eliminate too large gaps around the perimeter of the door leaf is to correctly form the gaps at the installation stage.

To do this, you need to follow a few simple recommendations:

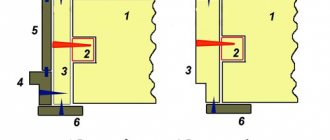

- When exposing the canvas and the box, you need to focus on the primary gaps within 10-20 mm. Take into account the fact that under the influence of hardening polyurethane foam, compression forces will be exerted on the box.

- Precise formation of the gaps begins after the foam has hardened. During this process, the sides and top of the block are lined with inserts of the required thickness. For a standard box this is 3-4 mm.

Gaps when installing the door (top view) - To prevent the box from moving out of the opening, it is securely wedged.

- Next, door balancing is tested. A building level is used as a measuring device. The wedges used must be strong enough to hold the blade firmly in both the closed and open positions.

Correct adherence to these recommendations will ensure that the removal of wedges and pads will not in any way affect the correct placement of the canvas inside the box.

A few tips for novice carpenters

People say that “the first pancake is lumpy.” Therefore, those who have done the work of installing the box themselves for the first time should not be upset by the mistakes made, which in most cases can be easily corrected.

- An unsightly joint between the laminate and the door threshold can be hidden with a plinth or metal trim.

- If the doorway turns out to be smaller, it is easier to trim the posts and crossbars of the frame, but on the condition that you can adjust the size of the door leaf. Otherwise, you will have to widen the doorway.

- If the width of the casing is not enough for the gap between the frame and the wall, the latter is plastered and then finished with the same material that was used before the door was installed. Therefore, in new buildings, doors are installed first, and then the walls are finished.

- When installing a box made of wood or MDF into walls made of concrete or brick, first drill a hole in the rack with a drill or screwdriver, and then drill the wall with a hammer drill.

- Special mounting systems simplify the process of installing the box - there is no need to use wedges. Detailed instructions for their use are included in the packaging.

- In new houses, the door cannot be attached directly to the wall due to possible shrinkage. Here, first a wooden block is attached to the opening, and a door block is attached to it.

In conclusion, installing a door frame in an opening is not such a difficult job that can be done by yourself in just a few hours. But the effect of this is significant - the family budget will save approximately 3,000 rubles on each door (the average price for installing a door frame by professional builders is indicated).

Gaps in entrance doors

In practice, it is not always possible to initially install entrance doors correctly. As a result, cold air and dirt from the street begin to penetrate into the room. The reasons for this phenomenon may also be subsidence of the structure during operation and insufficient insulation of the canvas itself. How to fix the problem directly depends on where exactly the door is located.

Installation of the second door

This is the most optimal option for increasing the protection of the door block from blowing from the street. After installing the second door, an intermediate vestibule appears: the resulting internal air cushion reduces heat loss by an order of magnitude. If the home is located on the first floor of a multi-storey building, it is necessary to achieve automatic operation of the door to the entrance. Installing a door closer also brings good results.

Installation of a second entrance door

Insulating the front door

The material used for making entrance doors in most cases is steel sheets, which tend to create the so-called. cold bridges. The situation is aggravated by the presence of microscopic gaps in welds and in places where fittings are installed. Due to the fact that almost all metal doors have a void inside, good opportunities for additional insulation open up. As a rule, mineral wool or slab foam is used for this.

Operating procedure:

- Dismantling protruding fittings (lock, handles, peephole).

- Disassembling the door leaf. If individual sheets were fixed by welding, they are cut off with a grinder.

- Laying insulation cut to size for internal cavities. When using polystyrene foam, the joint areas between the individual slabs and the metal frame must be filled with polyurethane foam.

- Reassembling the structure.

To insulate non-removable panels, internal heat-insulating linings (standard size 1x1 cm) are usually used. They are screwed onto screws around the entire perimeter of the removed door. After tensioning the upholstery, it is additionally fixed in the area of the linings with special nails.

Dismantling with preservation

Now let's look at the possibility of dismantling the structure while maintaining its performance qualities.

- Place a nail puller or crowbar between the door leaf and the floor, and slightly lift the leaf; the hinges should begin to separate. If this does not happen, no matter how hard you try, then the elements will have to be lubricated with anti-corrosion spray and return to work after a while;

- The next stage is the dismantling of the platbands. Often these items are in very poor condition, so they are not preserved. Drive the ax between the box and the trim and press firmly on the handle. In the gap that appears, you can see the location of the nails. Now insert the pry bar into the slot and disconnect the element;

- After removing the trim, you can start working on the box. It may be difficult to pull out thick, rusty nails, but this can be done. Carefully inspect the rack; fastening points should be visible on the lower and upper parts. Step back 20 cm from the bottom and push the ax into the gap as deep as possible. Carefully move the element away from the wall - difficulties are likely to arise. As soon as the gap increases to a size that a nail puller can be inserted into it, dismantling will proceed very quickly. Both nails are pulled out at once, alternately. Once one rack is removed, all other elements can be removed without difficulty.

At the moment, there is no need to save the door frame, since similar structures are on sale in almost all hardware stores. But if it is important to you, and you are afraid to take on the dismantling yourself, then if you wish, you can always order the dismantling of the doors https://pro-expresspereezd.ru/, and experienced craftsmen will disassemble the structure while preserving it completely.

Advice! If the pillars are in good condition, there are no chips, cracks or rot, you can learn how to update the door frame with your own hands without disassembling the structure, and install a new door pillar in place of the old door leaf.

If the door was installed not so long ago and the fasteners are screws, then just pick up a screwdriver and unscrew all the fasteners. This design can be disassembled independently in less than an hour.

Eliminating cracks around the door perimeter

Even after high-quality insulation of the door leaf, cold air will continue to enter the home through large gaps between the door and the frame. The easiest way to solve this problem is to use a special seal: thanks to it, you can achieve complete tightness of the door block and significantly reduce the level of heat loss. This material is presented on the building materials market in several varieties, the installation of which is slightly different from each other.

Insulating the door around the perimeter

Self-adhesive tapes

The simplest and most inexpensive option for sealing the door leaf around the perimeter. To make such tapes, rubber or plastic can be used. To simplify its installation, an adhesive layer is applied to one side of the tape. The width and thickness of the tape may vary, which allows you to choose the most optimal option for a particular case. It should be taken into account that this seal has to be replaced periodically (this is especially true for frequently closed entrance doors, which causes compression of the gasket material).

The procedure for installing self-adhesive tape is as follows:

- Preparation of the area to be finished (end of the door leaf). It is cleaned of dirt and degreased.

- Taking dimensions and cutting off the seal. It is recommended to cut the strips with some margin (5-10 mm).

- Gluing strips. It is more convenient to start work from the upper corner of the canvas. The protective film is not removed from the entire segment: 5–10 cm is enough. After this, the tape is applied to the doors and carefully glued, gradually removing the protective paper. During the gluing process, the strip must be pressed tightly.

- The areas where the loops are located are glued along the outer plane of the stopper. Corners must be trimmed carefully.

A cheaper option for insulating tape are products without a self-adhesive base. They are mounted in a similar way; nails or special glue are used for fixation.

other methods

A more reliable option for eliminating cracks around the perimeter of entrance doors is the so-called. "floor planks". According to the type of construction, they are wedge-shaped and external; according to the material used for manufacturing - plastic, metal or foam. They can be replaced with strips of felt, wooden glazing beads, etc. The main thing is to use screws or nails rather than glue as fastening.

Installation of floor strips

How to trim trim

Sometimes it becomes necessary to trim the platbands. Most often this is necessary in old wooden houses that have suffered severe shrinkage, Khrushchev-era buildings with uneven walls. To trim trims made of different materials, it is recommended to use the following tools:

wood or foam can be planed with a plane or knife;

MDF trims are covered with decorative lamination on the front and side surfaces. The structure of MDF itself, as a pressed board made of sawdust and an adhesive base, is fragile and cannot be processed with a plane. Its thickness can only be adjusted with a sharply sharpened knife, removing chips no more than 25% of the original thickness of the plank. When the thickness of the platband is trimmed, it will lose its decorative effect and it is the sidewalls that will suffer, since the PVC coating is brittle and breaks unevenly when trimmed, with chips.

Seal the gap at the bottom of the door

As a rule, all entrance doors are equipped with a threshold. Blowing from the bottom is eliminated by increasing its height or decorating the area of contact with the canvas with a special seal. Given the constant contact with water and cold air, it is recommended to use reliable rubber as a seal. An excellent option are special threshold slats of a combined type, equipped with nylon brushes. The presence of a special groove protects the home from the penetration of external moisture.

Installation procedure for the combined threshold strip:

- Cutting the strip and brush to the size of the threshold. It is important to ensure that the overhanging edge penetrates into the opening. You can use a hacksaw as a tool.

- Brush installation. In the correct position, it should exert some pressure on the bar.

- Screwing the brush onto the lower edge of the canvas (away from the home). For this, a screwdriver and self-tapping screws are used.

Gaps in interior doors

Unlike entrance doors, these structures generally do not require outstanding thermal insulation qualities. However, it is advisable to eliminate large gaps around the perimeter of the canvas, because this spoils the overall impression of the interior of the room and complicates the use of doors (they do not close tightly, they slam in drafts).

Eliminating side gaps

In addition to the above-mentioned self-adhesive tapes, silicone paste, which is sold in special tubes, is often used to seal interior doors. To apply it you will need a special gun.

Operating procedure:

- Tape the application areas on both sides with masking tape or Vaseline. This will eliminate the possibility of contamination of adjacent surfaces of the canvas.

- Charge the gun with a package of silicone. The thickness of the extruded seal is adjusted by cutting the edge of the tube. This parameter should slightly exceed the dimensions of the gap seal.

- The optimal angle for holding the gun relative to the surface during application is 45 degrees. You must press the lever smoothly and move the gun evenly and slowly.

- The treated door is closed until the silicone dries completely (the time is indicated in the instructions).

- After drying, the door is opened to remove excess sealant.

Applying silicone paste into the crack of a doorway

The convenience of this method lies in the speed of application and good sealing of joints (the property of silicone is to completely repeat the configuration of the gap). Most often, doors to the bathroom, toilet or kitchen are designed in this way, which allows you to create a reliable barrier to moisture and odors.

You can watch the video for more information about applying silicone using this method:

Gap between floor and door

The appearance of excessive clearance in this area does not always indicate an error in installing the interior door. Such a defect is often discovered after replacing the floor covering, when the new material is inferior in thickness to the previous one.

There are several ways to fix the problem:

- Lower the hinges to the desired height. If the owner of the house has at least a little experience in carpentry, it is better to use this method. To do this, you need to remove the door and move the hinges on the frame lower. This does not require additional seals or linings.

- Install sealing brushes or pads. Specialized departments offer a choice of rubber pads of different thicknesses. It is necessary to select a product so that it closes the gap without creating additional interference when opening and closing. The seal is cut to the width of the canvas and screwed to the bottom end.

- Use a decorative threshold or flat threshold strip. As a rule, such products are equipped with special holes for self-tapping screws. The cut-to-size strip is fastened to the floor using dowels or screws.

- Installation of a lowering tire seal. We are talking about automatic sealing devices of the “Dichtomat” type. Before installing the system, the door must be closed, using pads to achieve strict horizontal fastening. The size of the mechanism, strap and rubber insert is adjusted using a hacksaw. The support mechanism is fixed to the bottom of the box using screws. The metal plate must be placed strictly at the border between two rooms, under the door.

Door frame trims

if the platbands are worn out, have acquired an unpresentable appearance, or are moving away from the jamb in some places, this indicates the need to replace them.

New trims are purchased taking into account the immediate dimensions and type of connection.

The platbands are removed and the surface of the frame is sanded. When removing the platband, a gap may form between the wall and the frame. During repairs, this gap is foamed.

Algorithm for replacing the platband:

- Perform markings. The part is applied horizontally so that the upper edge deviates from the outer border of the vertical casing by approximately 5 mm, and the edge on the inside from the edge of the frame by 5 mm. If necessary, the structure is leveled;

- Holding the part, place a mark 5 mm horizontally from the inner edge of the frame. Similar manipulations are carried out with the other casing;

- The workpieces are cut at an angle of 45 degrees relative to the applied markings. After which they are fixed on the box;

- The vertical casing is also made and attached;

Important! The corners of the new design are also fixed with self-tapping screws.

Installation of the door and its adjustment should be carried out as accurately as possible so as not to deform the panel or frame.

Experts recommend that if you have wooden interior doors, you should do preventive maintenance, at least once a year, and then the door product will last a long time. If there are doubts about your own adjustment and repair, then it is better to entrust all manipulations to specialists.

Voted over 268 times, average rating 4.6

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Miscellaneous Options for insulating a wooden entrance door with your own hands Owners of private houses are concerned with the question of how to insulate the entrance ...

Miscellaneous Types of sound alarms on the front door and additional features An audible alarm installed on the door becomes ...

Platbands, Miscellaneous The correct choice of platbands for installation on interior doors Refining defects or hiding them becomes the final...

Hinges, Miscellaneous Detailed algorithm for installing butterfly hinges on an interior door Hinges for interior doors are a mandatory element, without ...

Bottom line

The best way to avoid the appearance of gaps in the doors is to carry out proper installation of the frame and door leaf. But it happens that during use the product shrinks or warps. There are several ways to eliminate the gaps that appear in this case. The choice of a specific option is influenced by the function of the door (entrance or interior), the material used to make the door, and the skill of the performer.

How and how to seal a gap in a door: entrance, interior

door repair