A correctly installed entrance door not only ensures the safety of property, but also reduces heat loss (due to insulation of the frame) and reduces the audibility of what is happening outside the house or apartment. First of all, you should know that installing the front door yourself is possible. Moreover, you can do everything alone, but if the canvas is heavy, it’s easier to work together. There is nothing complicated in the technology itself, but there are several features that you need to know before starting installation yourself.

Selecting the size of entrance doors

The standard dimensions of the entrance group must be known for the correct installation of the door in the opening. Until now, standards have been established, SNiP and GOST, which are observed by manufacturers.

Standard door sizes

The dimensions of doorways are regulated by standards - SNiP and GOST. Currently, even the standard sizes of single-leaf doors in houses vary widely:

- For panel buildings: door width 740-760 mm, height 1950-1980 mm

- For brick buildings: canvas width from 880-930 mm, height from 2050-2100 mm.

Even knowing about the standard opening sizes, going to the store without first measuring it would be too risky.

Experts recommend first measuring the opening, removing the old door from it, and also cleaning the walls from plaster and construction debris. According to GOST 24698-81, the dimensions of metal entrance doors are 2085 mm wide and 2385 mm high. In addition, the principles of proportional increase in the width of the canvas with increasing height apply. According to the standards, it is recommended:

- for single-leaf doors, height 2000mm, width 800-900mm;

- for double doors with a height of 2000 mm, width 1200-1800 mm.

And:

- for single-leaf doors, height 2300 mm, width 900 mm;

- for double doors with a height of 2300 mm, width 1200, 1600, 1800 mm.

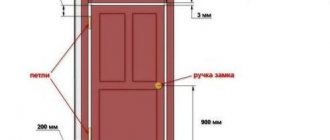

How to choose the right module door

Before placing an order, measure the height, width and thickness of the doorway. To ensure correct measurements, take measurements in several places. During installation, 10-20 mm should remain between the frame and the opening for fastening with mounting foam and wedges. For example, for a doorway of 1000 x 2100 mm, a frame with an external dimension of 988 x 2080 mm is suitable.

Modular sizes of entrance doors

Installation in openings made of gas, foam and expanded clay concrete

Expanded clay block private house or buildings made of gas or foam blocks belong to the category of buildings with fragile load-bearing structures. Therefore, in order to install an entrance door in them, it is necessary to take into account two important requirements specified in SNiP and GOST:

- Increase the number of fasteners on the vertical sides of the box within 4-6 per side. At the same time, their depth should not be less than 20 cm. To fasten metal doors in a foam concrete wall, you cannot use standard metal anchors, which in soft blocks will quickly become loose due to intensive opening and closing of the door. In such houses, according to the standard, it is better to use chemical anchors, for example Hilti.

- Install a crimping structure consisting of two frames made of steel angles with a flange width of 40 or 50 mm. In fact, it’s the same edging, only on both sides of the wall. Both structures are fastened together by crossbars made of metal plates 3-4 mm thick.

Trimming the opening from metal corners

What tools are required to install doors?

It is better to purchase a branded tool for installing an interior door, because the quality of the work performed depends on it.

Before installing the door, select tools and supplies:

- anchor bolts Ø 12 mm * 130 mm for a 15 mm nut;

- drill Ø 2.5 mm;

- socket wrench to fit the size of the anchor bolts;

- hammer drill or drill;

- nail puller;

- screwdriver;

- screwdrivers;

- hammer.

You will also need:

- professional or household polyurethane foam (1-2 cylinders depending on the width of the construction seam);

- mounting pads and spacer wedges;

- bubble building level;

- yardstick;

- household spray bottle;

- segmented construction knife;

- pencil.

With this set you can install entrance doors of any complexity.

Advantages of a homemade door

Making a metal structure with your own hands has a number of advantages over purchasing finished products. At a minimum cost, you can get an entrance door to your apartment without altering the doorways. When making metal doors yourself, you must follow safe work rules and perform all operations carefully and accurately at every stage. Advantages:

- by choosing the material for production yourself, you can be confident in its quality;

- can be made with an individual finishing option;

- You can make an iron door on a budget.

Doing it yourself can save a lot of time.

How to prepare a doorway for installing an entrance door

The quality and installation of doors depends on the correct preparation of the opening.

Stages of preparing a doorway for door installation:

- dismantle the door leaf (remove the door from its hinges);

- remove door frames;

- voids formed by the doorway and door frame, which were filled with insulating material - remove;

- Next, cuts are made on the side parts of the door frame (from top to bottom);

- First, the lower, then the upper elements of the sawn-off box are removed;

- remove the top and bottom bars of the door frame;

- clean the doorway from the remaining insulating material.

How long the door frame will last depends on the quality of plastering of the slopes.

If the doorway was damaged during dismantling, level it and plaster it. When leveling the passage, keep in mind that the upper part should become horizontal and parallel to the floor, the height and width along the entire length should be the same. It is important to carefully check the perimeter of the passage so that there is no narrowing or expansion left, and the walls do not differ in thickness. Preparation also includes adjustment to the dimensions of the door; the smaller the gap between the opening and the door, the more securely the entrance door will be installed. Increasing the doorway does not cause problems; its expansion is carried out using a hammer drill or grinder.

How to reduce the passage: possible options

Narrowing an old doorway during redevelopment involves reducing the size of the door in height or width, as well as in both parameters at the same time.

- If there is a need to reduce it by about 100 mm, the problem is solved with the help of bricks.

Brick is a versatile and durable building material. Brick is recommended for use in cases where it is necessary to narrow the doorway in a load-bearing wall.

- If it is necessary to reduce the opening to 50 mm, insert an additional frame made of a metal profile. A structure is made that covers the wall in the opening on both sides; unnecessary voids formed by the wall and frame are covered with sheets of gypsum board or filled with cement mortar.

Reducing the door opening in width and height has its advantages and disadvantages. Working with drywall is not difficult; it is the ideal material for the job. Drywall is lightweight. To work with it, you do not need any special skills; even a novice master can handle such work.

Soundproofing a metal door

An important property of an entrance door is its ability to contain noise from outside. Metal doesn't help in this regard. On the contrary, it enhances sounds. Therefore, the door is supplemented with special internal and external coatings that reduce the level of penetrating noise.

External covering

This is done using sound-absorbing and vibration-proofing materials. These include:

- polystyrene;

- vibroplast;

- bitoplast;

- bimast.

These are synthetic coatings, they are a canvas that actively dampens any sounds and vibrations.

Sound-absorbing materials consist of several layers of different densities

The work order is as follows:

- The material must be spread over the surface to be insulated and smoothed. Some types are equipped with an adhesive layer; it is enough to remove them from the protective film and press them against the plane of the door.

- For others, you need to first clean and degrease the canvas. Then evenly distribute the waterproof glue, cover the surface with the material and wait until it dries completely. It is advisable to paste both from the outside and from the inside.

Installation of seal

The product is simple but effective. Previously, felt was used as a sealant; today there is a wide range of ready-made rubber and caoutchouc products. There are no installation difficulties, you just need to remove the protective covering and carefully stick the profiled strip along the perimeter of the sash. Its width should not be more than 25% of the size of the door frame support strip. The thickness is chosen so that when compressed (with the doors closed) the seal is reduced by half.

The seal consists of rubber tubes of a special section

Methods for installing entrance doors

Installation of a metal door is possible in the opening of a brick or concrete wall with a thickness of at least 160 mm. These are standard requirements for reliable operation of the door, and if observed, the durability of the structure is guaranteed.

The main criterion for the correct installation of the front door in the house will be maintaining the balance of the door block at any opening angle.

We mount the door frame through the through hole and through the eyes

If the lugs have holes for them, holes are drilled in the wall, a piece of reinforcement is cut off, inserted into the hole and hammered.

First, let's look at the features of fastening the box through the holes. The steel frame in the opening is secured to anchors or parts of steel reinforcement with a diameter of 10-12 mm. The exact diameter of the fastenings is chosen taking into account the size of the purchased door. When using anchors, they must be fastened in such a way that their head goes into the outer hole and does not go into the inner one. The size of the reinforcement must clearly correspond to the diameter of the holes in the box.

Installation on lugs is considered a universal method.

Having purchased the necessary fasteners, make holes. To do this, use anchors, a drill and a hammer drill. Choose a drill of the same diameter as the selected anchor, with a length of at least 300 mm. To determine the depth to which the drill bit will go into the wall, apply masking tape to the drill bit. With its help, you will mark the depth to which the drill entered the base.

If there are no holes in the eyes. Such eyes are made of thick metal. To attach such a frame, drill two holes near the attachment point, drive two pieces of reinforcement near the plate and weld an eyelet to them.

It is better to start installing fasteners from the hinge side. Carry out the work carefully so as not to accidentally move the leveled box. First, make a hole at the top, install the anchor and hammer it with a hammer so that the anchor goes into the wall to the edge of the box, now insert a screwdriver into the slot and hit it with a hammer. When the anchor is driven in, it needs to be tightened with a screwdriver, making two or three turns. Now check the evenness of the frame with a level to make sure it has not moved.

Installing a lugged frame requires even more care on your part. When carrying out work, it is easy to move the frame from the selected location, but to adjust its position you will have to put in a lot of effort.

Install the fastening at the bottom, and then check the evenness of the box vertically and horizontally. If you are installing lightweight doors, check how they fit into the frame. Hang the doors on their hinges and check how smoothly the door sits and whether there are any cracks, distortions or other problems. Check the functionality of the locks.

Installing a door on an anchor fastening

An example of a step-by-step installation of an entrance door.

Do not experiment with heavy door panels. When the door weighs 100 kg, install all fasteners on the hinge side and at least one fastener on the lock side to check. After this, check the evenness of the installation of the frame vertically and horizontally, and then hang the door and check the quality of opening and the functionality of the locks.

Anchors for installing metal doors are the most optimal fastening option.

If the check does not reveal any problems, you can continue installing the door; if any problems are identified, you will have to remove the frame and reinstall it. The checked canvas is removed from the frame, the anchors are finally tightened, and then all other fasteners are installed, for which there are holes in the frame. After installing the fasteners, the door is hung back in its place.

It is extremely important to choose the right anchor for installing the front door, since the strength of the connection of the product with the enclosing structure and the overall reliability of its location in the wall opening depend on the parameters and characteristics of these fasteners.

Now you need to fill the mounting gaps with foam. It is best to use foam with a low expansion coefficient - this will make your work easier. To improve the polymerization of the foam, pre-moisten the cavities to be filled with water using a household spray bottle. You need to foam the cavities across the entire width of the door frame, this will improve sound insulation and reduce the likelihood of drafts.

After we foam and the foam dries, the box will remain in this position.

If foam gets on the canvas, it must be quickly removed with a damp sponge or cloth. After a few minutes, it will be much more difficult to remove the polymer without harming the painted canvas. And if the foam has not yet had time to harden, then it is very easy to remove. The final polymerization will be completed in about a day, after which you can consider that the installation of the door is completed and all you have to do is hang the slopes.

Grip fastening

Grip fastening.

This method is used in apartments and houses with monolithic walls, without drilling or drilling holes. Also well suited for mounting a metal door. The box is attached with the outer edge to the opening, and a hook is welded on the inside for fastening to the wall. This method is optimal for buildings with monolithic walls and eliminates the need to drill holes.

Preparatory activities

Preparation before installing metal entrance doors involves the following work:

- the plaster must be cleaned down to the brick or artificial stone. This must be done in such a way that there is a gap of 2-2.5 cm between the wall and the door block;

- a door frame should be built if the installation of a metal door is carried out in a house made of timber or a log building. Only then it is necessary to fasten the door frame maintaining a gap of 10 cm.

If there is a need to install an entrance door with your own hands in a structure made of stone, concrete or brick, then in this case during installation work you cannot do without using a hammer drill. It can be replaced with an electric drill. You will also need a chisel and hammer. The owner of a wooden house can do without them. However, a chainsaw and a hacksaw must be present. You don't need to use a chisel, but you should have a chisel at hand.

When installing a steel door with your own hands, it is undesirable to remove the packaging from the door leaf during work. It should remain on the canvas until the very end of the work. However, preserving the packaging layer does not allow checking the quality of the product. You should know that if you decide to save money and install a metal door yourself, then in this case you will lose the manufacturer’s warranty.

If during installation work a dent or scratch appears on the surface of the metal door, the selling company will not consider the claim. To ensure the quality of the product, even before starting work, it is necessary to remove a layer of packaging material and inspect the purchased product , and then, having attached the packaging in place using mounting tape, begin work. In this case, damage to the decor of the door structure with tools or polyurethane foam will be excluded.

Installation of doors in aerated concrete and in a wooden house

Stages of installing doors in aerated concrete

To carry out such work, it is necessary to prepare welding and buy a metal corner with a shelf width of 3.5 to 5 centimeters (the choice depends on the weight of the door and the expected loads).

Next, it is necessary to trim the metal corner so that when welding the joints of individual parts, it can cover the doorway along the entire perimeter on both sides. To strengthen the two frames together, it is necessary to weld the embedded parts, and the shank must have a thickness of at least 3 millimeters and a width of 5 centimeters. These elements are placed at the places where the door frame is attached. The door frame is fixed using screws on previously installed lintels.

For reliable fastening, you should use 12-centimeter self-tapping screws, which are screwed into each of the tires. It should be noted that the door will also be attached in these places, so the screws should under no circumstances overlap each other. At the next stage of installing doors in aerated concrete, use a building level to align the door frame, and then fix its position using wooden wedges.

The final fixation of the door leaf is carried out using screws up to 15 centimeters long or dowels.

After this, it is necessary to coat all the cracks with sealant or blow out with foam.

Installation of an iron door in a wooden house

You can install a new front door with your own hands in just three steps:

- dismantling the old structure;

- doorway preparation;

- installation of an iron door.

The old entrance doors to the apartment are dismantled like this (mostly wooden):

- Provided that the door leaf worked on collapsible hinges, we pry it open with a crowbar or other lever. This way the panel will rise and jump off the loop. Provided that the hinges are not dismountable: you need to unscrew the screws that hold the door in the frame using a screwdriver or screwdriver.

- It is not difficult to dismantle an empty box with your own hands if it is made of wood. To do this, fasteners (visible) are unscrewed: screws, anchors, nails are pulled out. If the box is firmly held in the opening and cannot be removed, its side posts are sawed off and torn off with a crowbar. After which the lower and upper parts can be removed without any problems.

- If a metal box is being dismantled or a wooden box is attached to the opening with anchors, then it is easier to saw them off with a grinder, just like metal posts.

- Next, the opening is cleaned of old insulation, remnants of plaster, protruding fasteners and other things. Provided that the doorway for the new door has been previously correctly measured, its size should exceed the perimeter of the frame by a couple of centimeters. This is necessary so that there is enough space to align it in the opening. If you made a mistake in measurements earlier, you will have to work hard to widen the passage with a grinder with a circle on the stone. If the opening is too wide, it can be narrowed by additionally applying cement mortar.

A metal frame can be attached to a doorway in two ways:

- through technological holes in the box profile;

- using special mounting plates.

It is permissible to install the box through the holes in the profile provided that the wall thickness exceeds 150 mm, otherwise the box can easily be torn out from the wall along with the canvas.

We put the input structure:

A door frame without a leaf is installed in the opening. Wood wedges are placed under it, which are necessary for fixing, adjusting its position and to ensure technological clearances.

- Having adjusted the position of the box, they begin to drill holes in the wall through the previously made holes in the profile: 15-20 cm deep. Anchors are inserted into the drilled sockets, and the position of the racks is checked again. When positioned correctly, the anchors are twisted and covered with decorative elements matching the color of the box.

- Next, the door leaf is hung on pre-lubricated hinges and all the fittings are attached. The canvas is covered, and the gaps around the perimeter of the rack are checked, which should not exceed 4 mm.

- The functioning of all latches and locks is checked. Inaccuracies are eliminated with wedges. Holes are drilled for the second pillar, which we also secure and check for smooth movement of the door leaf and locks.

- The technological gaps between the box and the wall opening are filled with foam, which must dry for at least 24 hours. After which the remaining foam is cut off, and the surface of the wall is puttied. Installation completed.

Mounting the door block on plates is one of the most common methods and is somewhat simplified for doing the work yourself. Often, metal structures are equipped with mounting plates with prepared holes for fasteners, which are welded directly to the frame.

Stage 2 - installation work

Step 1. Installation of the box.

1. Together with an assistant, insert a new metal frame (without the door leaf) into the prepared opening. To prevent the block from falling out of the hole in the wall, first secure it with wooden wedges. Cut the wedges in advance and insert them with little force at 20-centimeter intervals along the entire perimeter of the box.

2. Using a level and plumb line, in all accessible planes, as carefully as possible, check the vertical installation of the tray. If a discrepancy is detected, loosen or drive the wedges deeper, thereby moving the box in the desired direction.

The installed box must be secured with wedges

3. When the desired result is achieved, fix all the wedges as firmly as possible so that the tray does not move during the process of drilling mounting holes in the walls, and once again make sure that it is vertical.

Important! If, in order to save money, the manufacturer did not make holes for bolts in the frame of your new door, drill them yourself before installing the frame. The standard number of holes is 3 pcs. on vertical posts and 2 on horizontal posts.

4. Drill holes in the walls for anchor bolts through the mounting holes in the hinge jamb. Start drilling from the top point of the jamb; for drilling, use a Pobedit drill bit of suitable length and diameter.

If your inexpensive door does not include fastening hardware, purchase 150 mm anchor bolts with a diameter of 12-15 mm yourself. Insert anchors into the finished sockets and tighten them.

Step 2. Hanging the door.

5. After lubricating the hinges, temporarily hang the door on the jamb. Check the movement of the door - it should not squint or close spontaneously. If the door moves smoothly and turns in its hinges without applying significant force, it means that the frame is positioned correctly and can be further secured.

All voids are covered with polyurethane foam

6. To do this, remove the door from the awnings, drill holes in the opposite wall in the same way and secure a stand with a locking strip in it, then secure the threshold and, at the end, the lintel.

7. Close the anchor heads with decorative caps and finally hang the door leaf.

Completing the installation

When the door frame is secured, the door leaf is hung and its operation is finally checked. To do this, the door opens first 45 degrees, and then 90. In these positions, it should not move spontaneously. There should be no play when closed. If everything is fine, then it’s time to start sealing the gap between the door frame and the wall. Filling with foam will speed up and facilitate this process. The strength of the polyurethane foam may not be enough, and this will affect the burglary resistance of the structure. It is best to use cement mortar with the addition of alabaster. The entire gap is tightly filled with the solution. This will be much more effective with your hands than with a trowel or spatula. The solution for filling the space is prepared so that it does not float. It is advisable to bring it to the state of a loose solution, similar to a curd mass.

The operation of the locks must be checked and, if necessary, the mating parts located on the door frame are adjusted. A rubber sealing tape is carefully glued around the perimeter of the door. Every other day, you can remove the protective film and previously applied masking tape. All that remains is to hang the platbands on the outside of the doorway if necessary. They are screwed onto a wooden door using self-tapping screws with a countersunk head. For reliability and safety, it is better to recess the heads of the screws into the wood of the trim and cover them with wood putty.

In the case of a metal door, the platbands are reinforced with rivets or bolts. In fact, this is where the process of installing the front door ends. After this, it is necessary to build slopes with the help of which to hide the door fastening points and give a normal aesthetic appearance to the inside of the doorway.

Measurements and preparation of the opening

So, the old front door no longer fits its purpose both in functionality and reliability. It is necessary to purchase and bring to your house (apartment) a new model, which is selected based on appearance, functionality, and size.

But before you go to the store, you need to take the dimensions of the doorway. You need to get to its ends, which are hidden under the platbands with a layer of leveling mortar and polyurethane foam:

- The platbands are dismantled, there is no need to stand on ceremony with them, they will no longer be useful in the future.

- The plaster layer is removed.

- If foam was used during installation, it will also have to be removed.

- The threshold is dismantled.

The front door stands in front of you, and the edges of the door frame (that’s what a door frame is called in professional language) and the ends of the opening are clearly visible. There is always a gap between them. Now you need to measure the distances between the opposite ends of the opening. This must be done in at least three places with an equal distance between measurements. The same is true with the horizontal direction. From these, the smallest values are selected, which are taken as the basis for the dimensions of the door frame with a deviation of 1-2 cm in the smaller direction.

For example, if the height of the opening turns out to be 2.12 m, then to select the height of the hole, the size of 2.1 m is taken.

The principle of correctly taking dimensions from a doorway

It should be noted that different manufacturers have their own model line, in which each door has its own dimensional parameters. Therefore, the actual dimensions of the opening will have to be adjusted to fit standard door designs from a specific model range.

Dismantling the loot

The difficulty of dismantling the door hatch will depend on what material the walls of the house are built from. If it is gas, foam or expanded clay concrete, then all dismantling work must be carried out with great care - it is important not to spoil the fragile masonry, which is prone to chipping.

Removing the old box from the opening

In general, the procedure is as follows:

- the door leaf is removed from the hinges;

- the box is cut with a grinder or hacksaw into several parts.

- The cut pieces are dismantled using a crowbar or crowbar.

Cleaning the doorway

Cleaning consists of removing old fasteners, flimsy plaster mixture and, if any, polyurethane foam from the ends and adjacent areas.

Old metal fasteners are removed with a grinder

But if the house is old and the front door has been in use for decades, then it is necessary to check the floor beam that is installed above the doorway. If its quality leaves much to be desired, then you should think about how to replace it. It is better not to carry out this repair operation with your own hands.

Pay attention to the area below the threshold. Typically, in brick houses that have been in use for a long time, wide openings are formed filled with loose brick material, so this debris must be gotten rid of.

Sealing cracks and voids

When all defects in the doorway are discovered, they must be repaired with ordinary cement-sand mortar, which is diluted in a ratio of 1:3 (1 part cement to 3 parts sand). Large voids are filled with broken or solid bricks and mortar. Small ones - only with a cement mixture, the same applies to cracks. Before sealing the latter, it is recommended to use a deep penetration primer. It will not only hold together the grains of wall material, but will also go deeper into the thickness of the concrete, making it more durable.

If you need to level a large area, you can install guides from boards, securing them with a clamp

There is no need to level the surfaces of the ends of the doorway. You can raise the floor by pouring screed, or level the area under the threshold.

Where can I buy entrance doors to my apartment?

Entrance doors are bought in a construction hypermarket, at the market, and in a specialized salon. Convenient to buy through the online store. The online store presents the entire assortment and sorts it according to the desired parameters. The optimal solution would be the official online store of the manufacturer, where they offer competitive prices and quality products. All you have to do is choose a manufacturer who makes door blocks conscientiously. Select a factory for the production of steel entrance doors, study the prices and products presented. The quality must comply with GOST standards. The company provides a guarantee, exchanges and returns are made in accordance with the law. When placing an order in the official factory store, use the services of professional door installation.

Is it possible to make metal doors with your own hands?

Reliable metal doors have long won the sympathy of consumers. They are used wherever additional protection is needed: in houses, garages, apartments, warehouses. According to the demand, the supply market has also grown; a great variety of ready-made steel doors can be found on the pages of newspapers and Internet resources.

There are various types of metal doors on the market.

However, many craftsmen prefer home-made doors to purchased products. Their advantages include lower financial costs and independent choice of design and materials. These factors allow you to assemble a door of any shape, including non-standard options, and also give confidence in the quality of the finished product.

Thin steel on the front surface of finished metal doors is cut without much effort

Self-assembly of a metal door requires not only special equipment, but also certain skills. This is especially true for welding joints. To apply a seam of the required quality, you need skill and a certain dexterity. The cost compared to a factory door will be 30–35% lower, but the quality may be higher.