What it is?

Recirculation is a heating circuit piping system , as well as a hot water supply line, designed for constant movement of coolant or hot water.

It is designed to increase the efficiency of boilers, as well as to increase the comfort of residents when using hot water.

For example, if the hot water supply tap is located remotely from the boiler, the water in the pipes quickly cools down.

You have to let it pass for a long time until the temperature rises to the desired value. If recirculation is used, water constantly moves from the boiler to the water collection point and back. It does not cool down, which makes it possible to use hot water immediately, without waiting.

In heating systems, circulation ensures optimal thermal conditions. A hot coolant enters the heating circuit, which passes through a cascade of radiators and releases its thermal energy.

Returning to the boiler, the cooled coolant heats up again and enters the heating circuit for a new cycle. The efficiency of heating and uniform heat transfer at the beginning and end points of the circuit depend on the speed of water movement.

In a private house

Recirculation of hot water in a private home is carried out by piping a boiler or, less commonly, a heating boiler.

There are single- and double-circuit models that can only prepare coolant for heating, or simultaneously supply coolant and hot water for domestic needs. In addition, there are volatile and non-volatile boiler models.

The former are capable of operating without being connected to a power supply and only require a fuel supply. The latter need to be connected to the power supply network. They are equipped with their own circulation pumps that ensure the movement of coolant through the heating circuit.

As a rule, the boiler itself provides coolant circulation. To recirculate hot water, use an additional piping equipped with a circulation pump.

It is connected to the boiler, carried to the most distant consumption device, and returned back to the boiler. There is additional energy consumption to power the pump, but there is a noticeable saving of water, and the convenience of using hot water increases.

In a multi-storey building

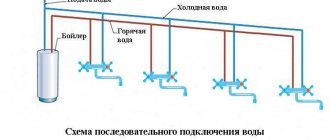

Modern hot water supply schemes use a boiler system , in which network hot water is not supplied to apartments. Water is heated indirectly in a boiler, from which hot water is supplied to the heated towel rail and hot water system.

Each apartment in a multi-storey building is one of the sections of the general recycling scheme. Its peculiarity is the vertical movement of water - from the bottom point to the top floor, and back. As a rule, circulation is organized along the line of heated towel rails.

It is powered from the DHW pipeline, so the water in the boiler never cools down and maintains its operating temperature.

Hot water rises up the riser, connects to the heated towel rail pipeline and goes back to the boiler.

However, it is impossible to organize its own circulation for each water supply point (kitchen sink, washbasin or bathtub) , so the water in the outlets from the riser often cools down.

The solution to this problem can be installing your own boiler and installing a recirculation loop. This is an effective measure if the apartment is large and the appliances are located far from the storage tank.

Private sector

What hot water supply schemes with circulation are used in cottages?

Actually, there are only two basic diagrams: with circulation through the water heater (for this it must be equipped with an additional pipe for connecting the DHW return) and with a thermal mixer. The water is driven by a small-sized pump with a wet rotor.

Closed circuit with circulation pump and boiler with three outlets

Pump for heating and hot water needs with a wet rotor

A three-way thermostatic valve allows you to implement recirculation even if in your home an electric boiler or an indirect boiler with two pipes (DHW and make-up) is responsible for heating the water.

Scheme with a conventional boiler and a three-way thermal mixer

How to do it yourself?

The piping of the boiler of a private house is done in each case according to its own scheme. The reason for this is the large number of projects, different configurations and layouts of houses. In addition, the choice depends on the design of the boiler, its features and volume.

Before starting work, you should draw up a wiring diagram and mark on it the installation points of all consumer devices, pumping equipment and other elements.

Typically two options are used:

- through an indirect heating boiler;

- through a storage boiler.

Let's consider both options in detail.

Through an indirect heating boiler

An indirect heating boiler is a container with a coil installed inside it. It is connected to the heating boiler, and the coolant circulates in a closed loop without mixing with hot domestic water.

This boiler is equipped with five pipes:

- a straight pipe running from the boiler to the coil;

- return pipe through which the return from the coil enters the boiler;

- cold water make-up pipeline;

- straight pipe (supply) of hot water to water collection points;

- return pipe leading to the boiler.

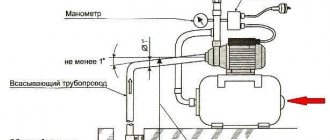

The circulation pump is installed in the return pipeline . This is done to create normal operation of the device and prevent overheating of parts.

The diagram shows a heated towel rail that always remains hot thanks to recirculation. This allows you to ensure a dry and warm microclimate in the bath, eliminating the appearance of dampness or mold.

Through a storage boiler

A storage boiler is a regular container with thermally insulated walls into which hot water flows from the boiler.

The reservoir contains a working volume of hot water sufficient for the household needs of the family. Typically its capacity ranges from 100 to 1000 liters , depending on the number of residents of the house and their needs.

The recirculation connection diagram to the storage boiler is a loop, where T3 is the supply, T4 is the return line.

It enters the make-up pipeline B1, and the entry point is located after the shut-off valve assembly with a check valve. A circular pump is also installed on the return line, along with shut-off and control elements.

The peculiarity of this scheme is that the temperature of H2O in the boiler and the make-up line are different. This is achieved by setting up a mixing unit that connects hot water from the make-up pipe to the cooled return pipe.

In this case, it is necessary to take into account the possibility of mixing layers of water in the container. If the water is made up with water that is not too hot, the temperature in the boiler will be noticeably lower than the standard value.

The specificity of the operation of storage boilers is such that water is heated only by replenishing it during disassembly.

Over a long period of time, a simple drop in temperature is inevitable, and recirculation becomes useless. Therefore, the use of storage tanks is recommended for houses with high and constant consumption of hot water.

When is it necessary?

The need for circulation arises in long lines with a large number of subscribers, for example, in apartment buildings or public buildings. In a dead-end pipeline, the water will quickly cool down.

This phenomenon is pronounced at night, when water intake practically stops and the water loses thermal energy.

Starting circulation allows you to:

- constantly update the flow in the pipes,

- heat cooled water to ensure standard values.

In small water supply systems of one-story private houses, circulation is rarely used. The distance from the water heater to the water collection points is relatively small, so it is not advisable to spend money on purchasing or installing a pump, assembling a loop, and starting the process.

It’s easier to let a little water through, which has had time to cool down, to get a normal hot stream.

In two-story houses or cottages, a circulation system becomes a necessity.

Installation process

Installation of a recirculation piping is one of the stages of assembling a hot water supply and heating line. Usually, it is carried out simultaneously with the installation of the boiler, assembly of the heating circuit and other work.

It is recommended that assembly be entrusted to experienced personnel who have the necessary skills and training. However, sometimes home owners assemble the system themselves.

Tools and materials

To assemble the recirculation loop you will need:

- a welding machine of one design or another (depending on the type of water pipes);

- device for cutting pipes (grinder, electric saw, jigsaw);

- a set of plumbing windings, Unipack type thread paste;

- set of fittings, adapters, fasteners.

In addition, you will need tools to install load-bearing elements:

- hammer drill with drills;

- impact electric drill, etc.

Necessary equipment

To install the line you will need the following devices:

- pipes and fittings (different types are used, from copper to metal-plastic);

- circulation pump;

- shut-off valves (valves or ball valves, three-way valves, check valves, etc.).

The circulation pump should be low-power. It is only needed to create a slight pressure to move the flow. Models that are installed in a heating system cannot be used.

The choice of pipelines is dictated by operating conditions and personal preferences of the owner. For example, to install copper (brass) pipes you will need to solder connections, which requires a torch, solder and an experienced craftsman.

You can use compression fittings in combination with polyethylene or metal-plastic pipes. This does not require the use of complex equipment, but is only suitable for DHW systems with low operating pressure.

Algorithm of installation actions

The circulation loop is assembled in stages:

marking walls or other load-bearing surfaces in accordance with the developed scheme;- installation of load-bearing elements (brackets, clips, clamps);

- cutting pipes along the length of routing sections;

- serial line connection, connection of fittings and adapters;

- connection of mixing units, circulation pump, shut-off valves;

- connecting the return line to the boiler.

When assembling complex lines, some deviations from the given scheme of work are possible. As a rule, additional elements are added or control devices are connected.

Advantages of a hot water supply system with circulation and its scope

The practical advantages are obvious:

- the stream is at least well warm immediately after opening the tap;

- It’s easy to adjust the temperature by turning the valve and adding a little cold water;

- there is no overspending - precious liters of liquid do not pour into the drain, because you do not wait for it to heat up;

- with constant use there are no traffic jams or clogging of pipes, and if they appear, they are immediately noticeable;

- a large number of end consumers are seamlessly integrated within one solution;

- it can be implemented on the basis of any heater - storage, indirect heating boiler or double-circuit boiler.

Hence the scope of application is clear. Such systems are relevant for one- and multi-story buildings, in which water treatment equipment is installed in a technical room, away from the inhabited rooms, and/or there are several bathrooms and many intake points. They are in demand at facilities with long communication lines and help reduce fluid losses and increase the efficiency of its heating and use.

Attention, this is a global solution, and therefore its implementation (regardless of the topology) is possible at the construction stage or at least a major renovation. It is futile to modernize an existing and standard plumbing complex - too much money will be required, it is cheaper and easier to implement everything from scratch.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

Operation and mode of operation

After assembly and performance testing, the recirculation system is put into operation. It works continuously.

Some users, trying to save energy and equipment life, turn off the system at night or during a long absence.

This is a completely effective solution, but you will have to get up early in the morning to start the movement of water and raise its temperature. However, you can spend a little money and install a control unit. It will automatically stop the circulation and restart it according to the set program.

In private

For a private home, continuous circulation operation is recommended. This is especially important if the house uses an independent sewer system.

Discharging excess water will require frequent pumping of the receiving tank, which will require extra costs and add to your worries.

In a multi-story

DHW recirculation in multi-storey buildings works automatically, without the participation of residents. The system is configured in such a way that all controls are located in the basement (in the boiler room) and do not require outside intervention.

All maintenance, repairs and other work are carried out by employees of the management company. This is convenient for apartment residents, as it relieves them of worrying about the condition of the equipment.

Useful information from professionals

In conclusion, useful tips from professionals are provided. They will be useful when installing water heating systems for domestic use and will allow you to avoid troubles during operation:

Kotov Vladimir Viktorovich, site foreman: At the initial stage of construction of a country house, you can install a boiler for heating water with a volume of 100 liters. This will provide comfort to those living on site. When using the house seasonally, for example, as a summer house, it is advisable to install an instantaneous water heater. It is compact and easy to use.

Dmitry Yuryevich Litvinov, water supply systems designer: For a small family size, you can install a boiler with a capacity of 50 - 100 liters. It will compensate for heat loss and water consumption. When purchasing a gas boiler, it is better to give preference to a ready-made kit with a boiler and boiler. Their parameters are correctly selected by the manufacturer.

Kudryashov Valery Leonidovich, plumber: If there is a high content of impurities in running water in amounts over 140 milligrams per liter, it is recommended not to use instantaneous water heaters. Impurities will fall out on the heating element and pipes. The flow heater will fail soon. If there is a boiler in the house using alternative fuel sources, be it wood or coal, the use of a storage tank will allow organizing a secondary water supply circuit. This will avoid additional energy costs for heating water.

Controlling water recirculation in a hot water supply system

You can organize the control process in one of three ways:

- by carrier temperature;

- by time;

- on both these parameters at once.

Any modern and high-quality pump has all the automation necessary to implement each of these methods. Often, it even boasts a “learning” function: based on statistics, it is determined when and how much liquid people consume and, in accordance with the data obtained, the time of downtime and active use is adjusted. Inexpensive models require additional attachments, such as a timer.

Gas boiler with built-in boiler

Compared to the option described earlier, this type of hot water supply makes it possible to obtain better heating stability and is an order of magnitude more convenient for obtaining hot water.

This option makes it possible to constantly have from forty to sixty liters of hot water in reserve. But this system, in addition to its advantages, also has its disadvantages:

- Large dimensions and weight.

- Large expenditures of fuel resources in order to maintain a stable water temperature in the boiler.

- High price.

Such systems are used quite rarely.