Living in many sparsely populated areas and country houses is complicated by the lack of running water. Where water supply is limited to a well or water intake from a well, you can organize a full-fledged water supply for your home. A compact domestic pumping station connected to the pipelines will continuously supply drinking water.

Criterias of choice

When a person is faced with choosing a product, he will learn about many characteristics that affect the cost. Manufacturers work according to an individual strategy, but basic indicators are taken into account:

- Tank size.

- Water pressure.

- Operating power.

- Mains voltage.

- Water intake depth.

Types of pumping stations for a private home

Pumping stations have several bases for classification.

Based on water intake parameters, systems are distinguished:

- with built-in ejector;

- with a separate ejector.

The former are suitable if the water is at a depth of up to 10 meters, and the latter can also cope with liquid that is at a depth of up to 100 meters.

According to the design of the tank there are:

- models with aperture;

- storage systems.

In the first case, water is taken in under pressure, and storage systems are suitable only for those areas where it is possible to place a water tank at the same height as the points of water consumption.

Depending on the nature of the source, pumping stations are:

- superficial;

- submersible

In surface-type systems, the ejector is placed on the tank, which increases its maintainability. Submersible systems are located at depth, and their main advantage is the absence of noise during operation.

According to the control method, stations are divided into:

- manual;

- automatic;

- remote.

The first ones are suitable if water is needed extremely rarely, for example, only in the summer on weekends at the dacha for watering plants. Automatic ones work with virtually no human intervention, but have a high cost. Remote ones occupy an intermediate position between these two types.

Calculation of pump performance

Before purchasing products, a performance calculation is made. For this purpose, the chemical composition of wastewater and the amount of precipitation are taken into account. An on-site specialist determines the height of the liquid rise. The pump must cope with the increased pressure. In populated areas, this parameter is unstable, so there is a large load on the electric motor. The average model with a power of 1200 watts provides a throughput of 4 cubic meters per hour. If the diving depth is less than 10 meters, 1000 watt equipment is enough. Compact models are produced with an average power of 800 watts.

Maximum water intake depth

Pumping stations are capable of operating in wells of different depths. The standard model is sold with a pumping capacity of up to 10 meters. Sometimes the groundwater level exceeds this mark and more powerful pumps are used. If we consider 800-watt models, they have a throughput of 3.7 cubic meters per hour and draw water from a depth of 9 meters. There are universal models with a pressure of more than 30 meters, their power is 4000 watts, and a productivity of 40 liters per minute is provided.

Hydraulic accumulator tank volume

A hydraulic accumulator tank is otherwise called an expansion tank or a membrane tank. The main task is to maintain stable pressure that is created in the water supply. Automatic stations are produced with various protections; the pressure is shown through a pressure gauge. Problems with pressure surges are often associated with the electric motor. There are devices on the market with hydraulic accumulators with a capacity of 10 liters or more. If we consider an 800 W model, it can use a 20-25 liter tank. More powerful products are equipped with 30 liter expanders. The choice of hydraulic accumulator depends on various factors:

- Relay operation frequency.

- Electric motor reliability.

- Pump activation system.

- Average pressure in the system.

- Water compressibility coefficient.

- Fluid flow rate.

Water pressure in the system

One of the most important characteristics of the product is water pressure. Not everyone is familiar with setting up equipment. Before purchasing, it is important to determine the flange adjustment and learn the principles for eliminating malfunctions. The pressure in the pipeline changes, so the main task is to ensure stable pressure. Mid-price devices provide a pressure of 40 meters. Units with a 20-liter hydraulic accumulator are more productive, much depends on the engine. Considering small wells, a pressure of 25 meters is enough. If we are talking about deep wells (more than 5 m), the figure should be more than 40 meters. When calculating pressure, the following characteristics are taken into account:

- Hydraulic accumulator volume.

- Maximum suction depth of the pump.

- Motor power.

- Equipment set.

Power and voltage

Manufacturers provide a wide range and there is plenty to choose from. Stations differ in power and voltage, much depends on the area of use. Not only synchronous, but also asynchronous AC motors with voltages of 220, 380 volts and more are presented. Power starts from 500 watts. Various protections are offered, the buyer pays attention to the following features:

- Rotor winding.

- Number of phases.

- Availability of starting devices. If there are problems with the network at the dacha, it is better to use protected stations that are not afraid of short circuits. The most common are pumps with asynchronous motors, with a rated power of 800 W or more. Such models operate at a voltage of 220 volts, they are suitable for pumping clean. You can hope for a capacity of 60 liters per minute and provide a pressure of more than 30 liters.

Unit type and functionality

Stations are classified according to different features. First of all, the type of water is taken into account - it can be clean, slightly polluted, or dirty. Universal models are sold, and consumers evaluate the type of case. Various materials are offered in this regard:

- Alloy of aluminum and steel.

- Brass.

- Stainless steel.

- Aluminium alloy.

- Plastic. Models are supplied with a 5 and 25 liter hydraulic accumulator. The pressure parameter depends on the relay. In 2021, users often prefer devices with remote control. There are interesting products from European manufacturers with high-quality centrifugal pumps. Self-priming models are used with or without a filter. Additionally, the devices differ in the size of the connected pipe. The pump is provided with 1, 1.2, 1.5 inch connectors. The hydraulic accumulator is also made of different materials; interesting models with an aluminum or brass tank are offered.

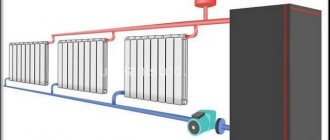

Equipment connection features

The diagram we are considering and the details of connecting a home pumping station will subsequently eliminate the occurrence of technical inconsistencies in the work.

At the first stage of installation, it is necessary to prepare a supporting base for the pumping unit. It can be made of wood, brick or concrete.

We must cover the surface with a rubber mat in order to reduce the level of vibration of operating equipment.

Using anchor bolts, we fix the legs of the equipment to the base, which will ensure its stability.

The connection process will require the use of an American tap, a one-inch coupling, appropriate diameters of a steel angle with external threads and a check valve. The presence of a check valve will protect the pump from “dry running”.

The valve device includes a spring element and a locking element. Typically, the installation of a check valve is done in front of the station or at the inlet of the suction pipe.

You can also purchase a pipe already equipped with a check valve.

We secure the pipe with a coupling, and fasten the tap using threads.

For the other output of the pumping station, which will communicate with the water supply system, parts are assembled in the following sequence: the tap is connected to the outlet, a propylene combined coupling is mounted into it, and a water pipe is fixed to it by soldering.

Ensure sealing of assembled parts using linen sealing windings and special sealing paste.

After connecting the pumping equipment to the water intake and water supply system, it is recommended to check its correct functioning.

Then you need to open the tap and connect the power supply. The motor will start and water will begin to flow into the pressure pipe, squeezing out all the air.

The pressure will rise to the specified level - 1.5-3 atm, after which the automation will work and the station will turn off.

We recommend watching a video that will clearly demonstrate how to connect a pumping station to the water supply system with your own hands.

Video:

Also, in most private houses (for example, in a country house), a sewage pumping station is installed. It is necessary for pumping out sewer and household waste.

Installing a sewerage station will allow you to equip a kitchen area and a bathroom on the ground floor.

The design of a sewerage station includes the following elements: a tank, a pump, a fill level sensor for a storage tank. Basically, these elements are made of polymer materials, which eliminates the effects of corrosion.

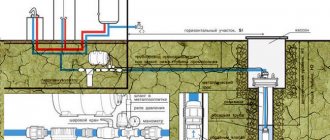

Installation of a sewage pumping station begins with the creation of a project in which it is necessary to carry out all the necessary calculations.

For an internal sewer system, it is necessary to calculate and outline the location of plumbing fixtures and pipes.

For the design of an external sewer system, it is imperative to take into account the condition of the soil and ground. Next, calculate the depth for the pit taking into account the dimensions of the sewage pumping station.

The video below shows the design and operation of a sewage pumping station.

Video:

Which company should you choose?

Various companies are engaged in the production of pumping stations. Each of them is ready to offer systems that differ in various parameters, including price.

Consumers give preference to companies that have been on the market for a long time and have proven the reliability of their products for many years.

These include:

- Italian brands Marina, Pedrollo,

- German companies Karcher, Wilo,

- domestic companies Gilex, Whirlwind and Autorobot.

Stage 1. Source equipment

Digging a well

In order for water to appear in your dacha, you will first have to arrange its source with your own hands. And in the absence of running water, we have two options: a well or a borehole.

An autonomous water supply system is the only way out in the absence of a centralized water supply

If the aquifer lies relatively shallow (up to 6–10 m), then it will be easier to dig a well. In terms of reliability and performance, it will most likely be inferior to a well, but we will spend several times less money on the device.

The easiest way to determine the water level is by looking at wells in neighboring areas. If this is not possible, then exploratory drilling will be required to search for the aquifer.

We equip the water source as follows:

In the selected location of the summer cottage, we dig a hole about 1.5–2 m deep.

The diameter of the pit must be greater than the diameter of the concrete well rings - this way we will gain access to their outer surface.

We lower the concrete rings for the well into the hole and level it. This must be done either with the help of a crane or along strong wooden guides, with several strong assistants.

We seal the joints of the concrete rings with cement mortar to protect against leaks. We carry out sealing both inside and outside.

Additionally, you can strengthen the rings with metal inserts in the shape of the letters “H”.

We gradually deepen the well, digging up the rings from below and settling them.

Upon reaching the aquifer, we select approximately 0.7–1 m of wet soil so that we have a water supply.

We add a layer of gravel to the bottom, which will act as a coarse filter, trapping silt and clay particles.

Using a cheap submersible pump, we flush the water supply. To do this, we pump out water and sand in forced mode until we achieve its maximum purification.

The sand pumped out from the bottom of the well is mixed with clay and used to fill the gap between the edge of the pit and the concrete rings.

We make a clay or concrete blind area around the perimeter.

Cover the top ring with a lid. Over time, in its place we will make a caisson or a house for pumping equipment.

Well drilling

A more efficient water supply system in a dacha can be built using a well. Usually, the work of drilling a water well is entrusted to professionals, but in this case the price of the system will be very high. So if the water carrier lies at 15-20 m, then you can try to cope with it yourself.

Photo of a pit with optimal dimensions

The work algorithm is quite simple:

Digging a pit

It doesn’t matter whether our plans are a well or a borehole, we need to start by digging a shallow (up to 1.5 m) hole by hand. In the case of drilling, this will make it easier for us to position the tool.

Drilling

Using an auger or impact drill, we deepen our pit, gradually plunging deeper and deeper. We remove the excavated soil from the work site.

The most convenient tool for drilling is an auger drill

- Casing. We insert metal or plastic pipes into the drilled hole. We connect the pipe joints by welding, ensuring maximum tightness.

We make the casing for the source from steel pipes

- Filter equipment. After passing through the aquifer, we install a mesh filter into the lower part of the casing. It will be used for water purification.

Stainless steel mesh filter

- Well pumping. As in the case of a well, we lower a submersible pump into the casing to supply water and pump out the water until the sand stops flowing.

Water supply systems based on wells require the mandatory installation of a cap - a special sealed nozzle that covers the casing pipe. But the head is usually installed after installing the pump.

When pumping, you need to remove all contaminated water and as much sand as possible.

The best pumping stations for a premium private home

Grundfos CMBE 3-62

For water supply and irrigation, this station with a pressure of more than 9 bar is considered.

A self-priming motor is used and the frequency needs to be adjusted. It is made of stainless steel, so the body is durable. A 2-liter tank is used; in addition, the system has a significant head of 39 m. Technical characteristics:

Power: 1100 W

Capacity: 4500 l/hour

Head: 40 m

Hydraulic accumulator volume: 2 l

Advantages

- Suitable for watering

- Long cable with plug

- Easy installation

- Station performance

Flaws

- Noisy during operation

- High electricity consumption

DAB E.Sybox

The device cannot be called compact, but a huge pump with high power is used.

It is suitable for pumping various types of water (even with abrasive impurities) and is unpretentious in terms of temperature. Withstands a maximum pressure of 7 bar and takes into account the protection of the engine. All wiring is hidden, according to user reviews there is a very low noise level. Specifications:

Power: 800W

Capacity: 600 l/hour

Head: 35 m

Hydraulic accumulator volume: 20 l

Advantages

- High pressure

- Pump power

- Built-in frequency converter

- Availability of LCD display

Flaws

- Installation problems

- Pressure adjustment

Marina APM 200/25

The maximum suction depth is 25 meters (although it is frankly difficult for the ejector on it, but this is still a working value). per hour, pressure - up to 45 meters. We didn’t find a working curve in the instructions – but that’s a minus for that. The instructions themselves in Russian look, to put it mildly, strange. The capacity of the hydraulic accumulator is 25 liters. Despite the decent price, the materials here are no frills: the pump housing is cast iron, as is the external ejector housing. The shaft and flange are stainless, the diffuser and impeller are made of noril. This pumping station is assembled quite conscientiously - minor defects do not annoy, although the warranty of only one year is not enough.

Advantages

- Good characteristics

- Decent level of quality and reliability

Flaws

- Traditionally for this brand, installation is inconvenient

- Poor (and this is putting it mildly) instructions, but ejector “depths” have their own specifics of launch and maintenance

Stage 2. Installation of pumping equipment

For a well

The water supply system for a summer residence usually operates either on the basis of a submersible pump or on the basis of a surface pumping station. The option with submersible equipment is easier to implement, so we will focus on it.

Submersible pump for well

The well pump is installed quite simply:

- Assembling the device. We attach a water supply hose, cable and power cable to the unit. We carefully insulate the cable connection point with heat-shrinkable tubes.

- Immersion of the pump. We lower the pump on a cable into the well so that the water intake holes are approximately in the middle of the aquifer.

- Cable fastening. To compensate for vibration, we attach the cable in the upper part using an elastic suspension (harnesses or cords with a rubber core).

Schemes for installing a submersible pump in a well

For well

A submersible pump for a well is mounted somewhat differently:

- Pump assembly. As in the previous case, we attach the hose, cable and cable to the pump. For maximum reliability, we connect all three elements with clamps with a pitch of no more than 2.5 m.

The fastening of the torso, hose and cable to the pump is carried out with mandatory fixation with clamps

- Immersion of the device. We lower the pump on a cable into the casing pipe so that water is drawn to 2/3 of the depth of the aquifer.

We use elastic suspension only for shallow - up to 20 m - wells.

We lower the pump into the casing on a cable along with a hose to lift water

- Installation of the head. We install the head on top, through the holes in which we pass the hose and power cable. We attach the cable to the eye bolt in the head cover. We tighten the fixing screws, which press the gasket and ensure the tightness of the well.

The lower part of the head with the cable fastening to the eye bolt and a cable with a hose passed through the holes

You can also install a surface pumping station to lift water, which is more convenient to use. Alas, such systems are more expensive, and their installation requires the equipment of an insulated pit - a caisson.

How to use

Before choosing a particular pumping station, you need to find the place where it will be located. To do this you need to know the following points:

- The device should be located close to the source of the liquid.

- Installation is carried out on a level, dry, warm, well-ventilated place.

- It should not be placed next to walls or any other objects.

- The equipment must be freely accessible at all times.

After the location and pump have been selected, it is necessary to connect it to the pipeline system and other elements. Before starting, the pressure in the hydraulic tank must be checked and adjusted. When everything is ready, the station can be launched.

Procedure for the first start:

- Unscrew the valve/unscrew the plug that closes the water hole.

- Fill the pump and pipe (suction) with liquid.

- Screw the valve/screw the plug into place.

- Connect the device to the network and start it.

- Remove air from the system by opening the tap slightly.

- Let it run for a few minutes until the water comes out.

If everything went well, then you should set up all the automation according to the instructions that come with each device. Do not forget that if you follow all the rules established by the manufacturer for each unit, then it will serve its owner for a long time without any breakdowns.

Useful tips before purchasing

- Decide for what purpose the pumping station is being purchased. The required power, performance, and cost will depend on this.

- Perform approximate calculations necessary for comparison with the technical characteristics of the equipment.

- Choose a manufacturer based on recommendations from experts and consumer reviews.

- It should be taken into account that the higher cost of installation in a metal case compared to plastic will be paid off by a long service life and savings on maintenance.

The pumping station will provide water supply to a private home for a long time if it is correctly installed and operated according to the instructions.

Basic operating rules

After putting the station into operation, it is necessary to carry out regular preventive inspections. If necessary, wash the filters and tighten the threaded joints. If the filters become clogged, water begins to flow into the network in pulsating jerks, and sometimes stops flowing altogether. The frequency of filter washing depends on the quality of the water in the well.

The hydraulic accumulator should also be inspected approximately once a month. If the pressure reading in its air chamber is below the required level, then it should be raised using a car pump through the nipple. For proper operation and maintenance of the device, you need to carefully read the diagram of the pumping station and the manufacturer’s recommendations, usually indicated in the technical instructions.

Circulation pump

In this case, the pump installed for the hot water supply of the house ensures continuous circulation of water in the circuit. Why is this necessary?

The DHW circulation system has two advantages over a dead-end system:

- It is capable of providing instantaneous supply of heated water to any water supply point. In a dead-end system, water has to be drained for a long time before it is heated;

- It ensures round-the-clock operation of water heated towel rails. In a dead-end system, they heat up only when hot water is consumed.

The operation of the heated towel rail is ensured by continuous circulation of water

However: if the first problem is not relevant for you due to the short length of the water supply system, it is easier to replace the water heated towel rail with an electric one. It consumes only 40-100 watts - about the same as a circulation pump.

The photo shows an electric heated towel rail in the author’s house. Power consumption - 40 W

Device and characteristics

In this case, the Grundfos circulation pump for home water supply - model UPS25-60 180 - will serve as a model for our study.

Our hero

| Parameter | Meaning |

| Type | Centrifugal, wet rotor |

| Power | 50-60 W |

| Performance adjustment | Stepped, 3 speeds |

| Allowable pressure | 10 kgf/cm2 |

| Maximum head | 6 meters |

| Housing material | Cast iron |

| Case length | 180 mm |

| Thread diameter | DN15 (1/2 inch) |

Connection diagram

The pump is installed in a gap in a closed DHW circuit. And in this case, it is advisable to provide a couple of taps to turn it off without draining the water supply.

In a circuit with an autonomous water heater, water supply can be organized according to one of two schemes:

- With connection to two water heater pipes (if operation in a circulating water supply system is provided by its manufacturer);

Scheme with an indirect heating boiler equipped with an additional pipe for recirculation

- Using a thermo-mixing unit that stabilizes the water temperature in a closed circuit. In this case, any water heater with two pipes can be used.

Most boilers have only two connection pipes

DHW circuit with a boiler without outlet for recirculation and a thermal mixer

Design and principle of operation of the hydraulic accumulator

Hydraulic accumulators are metal tanks, usually with a volume of 20 to 100 liters. They have an inlet and an outlet. These devices are designed to maintain operating pressure in the water supply network when the pump is turned off.

To do this, there is a rubber membrane inside the metal tank, which stretches when the container is filled with water. When the pump turns off, the membrane, due to the compression force, pushes the water contained in the tank into the network. Thus, the pressure necessary for the operation of plumbing fixtures is maintained in the plumbing system.