Technology for building houses using 3D panels

3D structural system. Guide to construction, design and calculation. LLC "BUDTEKHINVEST-2007".

Heating a house: consumption 18 W h/m2 at a temperature of -40 oC (for comparison, in typical high-rise buildings, consumption for heating an apartment is 100 W h/m2). The earthquake resistance of our houses is 9 points. The heat transfer resistance coefficient of external walls is 8.17 (m2 °C/W).

The cost of a house made from 3D panels starts from 15,000 rubles. for 1 m2.

The technology of building a house from 3D panels allows you to build a house yourself. A house of 150 m2 can be built by two people in a month.

Before you start building a house, you need to calculate the thickness of the walls of the house under construction. The heat transfer resistance coefficient of the outer wall of a given area (according to SNiP 02/23/2003 for Krasnoyarsk is 3.42 m2 °C/W multiplied by the thermal conductivity of the selected material. The calculation of a detached house and a multi-storey building is calculated differently. In a multi-storey building there is only one apartment the side is outside, and in the house all four sides are outside (cold).

Thermal conductivity of basic building materials

| Material | Thermal conductivity coefficient at operating humidity, W/m°C |

| Ceramic brick | 0,56 |

| Aerated concrete (density 600) | 0,26 |

| Silicate brick | 0,87 |

| Foam concrete | 0,37 |

| Cement-sand block | 0,93 |

| Expanded clay concrete | 0,58 |

| Tree | 0,18 |

| Expanded polystyrene | 0,041 |

| Minplita | 0,09 |

EXAMPLE:

3.42 W/m°C * 0.56 = 1.9 m brick wall thickness 3.42 W/m°C * 0.18 = 0.61 m wood wall thickness 3.42 W/m°C * 0.041 = 0.14 m thickness of polystyrene foam wall (3D panels)

The thicker the wall, the less loss. Over time, energy becomes more expensive and heating costs increase; we installed 100 mm more insulation, which means less heat consumption for heating. The thickness of the wall made from the 3D panel is 0.55 m. Air permeability is one of the main characteristics of the quality of a warm home. Minimum air permeability of the building envelope is a necessary condition for making the house warm. The less air permeability of the house, the better. But ensuring high integrity of structures is not cheap. Remember, small streams of heat through sealing defects easily and imperceptibly turn into rivers of heat loss, which you will have to pay for for many years. How to reduce the air permeability of building envelopes. Structures with high air permeability (mineral wool, expanded polystyrene, aerated concrete, wood, brick) should be covered with a protective layer of materials with high resistance to air permeability. For example, with cement-sand plaster on a metal mesh, the air permeability of this plaster is 386 m2hPa/kg, this is an additional and durable insulation.

3D PANELS

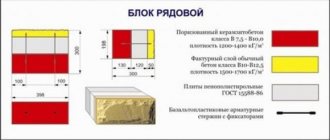

The panels are available in two types: corner (975mm x 975mm x 1200mm) and rectangular (460mm x 1200mm x 3000mm).

The panel consists of two sheets of reinforced foam, the thickness of each sheet is 150 mm, connected by reinforcement with a distance of 150 mm between the sheets. The total thickness of the wall plastered on both sides is 550 mm. Panel size 1250*3000 mm. Double 3D panels are used in construction for exterior walls. For internal walls, panels with a thickness of 250 mm and 200 mm are used.

FOUNDATIONS

Foundations for houses made from 3D panels are used depending on the engineering and geological conditions: bored or strip, which are calculated by the design organization. The design of the foundations is as follows: around the perimeter of the house and under the load-bearing walls inside, a trench is dug with a depth depending on the depth of freezing of the ground and depending on the soil, or wells with a depth of at least 3.3 m are drilled. The distance between the wells is a maximum of 3 m. Reinforcement is placed in the well , concrete is poured under pressure. Such a pile can withstand an average load of 15 tons. Along the perimeter of the house, panels with the height of the plinth are installed on piles, additionally reinforced and filled with concrete. After laying the foundation, gravel is poured onto the ground inside the house, leveled, and polystyrene foam 250-300 mm thick (for Siberia) is laid. With this we protect the house from heat loss, since the temperature of the earth is from +4 to +7 degrees and takes a lot of heat. All communications are carried out along the floor, reinforced and filled with concrete 100 mm thick.

What do we do to make our home as sustainable as possible?

Here are six key design considerations:

Only useful meters.

We are very careful about the size of the building, zoning and shape of the rooms. Everything in the houses is compact, convenient, and there are no unused spaces - long corridors, closets, nooks. We make common rooms spacious and private rooms small without sacrificing comfort.

In the standard design of the RIO-87 house, an area of 87 meters accommodates spectacular day rooms, 3 full-fledged residential isolated rooms, a boiler room and 2 bathrooms.

Attention to the interior

In typical designs of one-story houses, the living and dining rooms are combined into one large room. This combination visually expands the space and makes the interior representative. That is, an interesting planning solution helps to save on design - even in a simple design, the space will turn out to be interesting. But in most cases, rooms can be divided by a partition with beautiful doors.

The illustration shows the interior design of a one-story cottage ADRIATIKA 100 sq m

When planning, we make sure that beautiful views are provided from the entrance to the house and other important vantage points, and that important features (fireplace, sofa, etc.) are placed beautifully.

Ease of redevelopment

Our one-story houses do not have load-bearing walls inside. Therefore, plans can be adapted to suit your needs.

Below is the load-bearing frame of a 1-storey house KRASNODAR 103 sq m, a standard layout and two more possible variations. There may be even more of them.

We carry out minor internal redevelopments that are not related to changes in the structure, facades or communication schemes free of charge .

Laconic appearance.

We try not to use expensive decor, combining the decorative and constructive functions of facade elements. This reduces the cost of construction and almost eliminates the possibility of “damage” to the appearance of the house by builders.

The picture shows a visualization of the appearance of a one-story VILLETTA VILLA of 140 sq m - no frills, but beautiful.

► see architecture ideas for one-story houses

Simple design

A typical project carried out by our architects involves cost-effective, reliable structures, simple technical solutions and generally available building materials. Everything included in the project can be found in any corner of Russia. Most standard projects are developed for the climatic conditions of central Russia (Moscow, St. Petersburg, Kazan, Nizhny Novgorod, etc.), but can easily be adapted for warmer and colder regions.

► Study the principles of design

houses INVAPOLIS

High quality design material

Over the years, we have developed the optimal composition of drawings.

It is slightly different from the usual “passport + AR + KR” - it contains as much information as is needed for construction, and it is presented in the most understandable visual form. Not only the foreman, builders and engineer, but also future residents will understand the drawings. This will help control construction work and expenses. A standard project ensures the successful construction of a cottage exactly as it is shown on the website.

Below is an example of documentation for a small one-story house of 60 sq m, from two albums - AR and SKR

Thanks to their original professional layouts, are spacious, compact and economical.

In terms of construction costs, they can be an alternative to the more common attic houses, and become a “lifesaver” for those for whom the second floor is not suitable, but during construction it is necessary not to go beyond a reasonable budget.

WALLS

After installing the foundation, floors and wiring of communications (water, sewerage, electricity), we begin to install walls from corner panels. We install row panels between the corner panels. Internal walls can be installed from 3D panels with a thickness of 200-250 mm or from any other material. The panels are connected to each other with knitting wire, reinforcing mesh is applied to the seams and knitted. The panels are fitted closely; if gaps form, they are foamed with polyurethane foam.

At the same time, we make openings in the panels for windows. The distance in the opening around the perimeter of the window between the panels is covered with a wooden frame, preparing for pouring concrete mortar into the 3D panel. Sleeves of the required size are placed in walls and ceilings for electricity, ventilation and sewerage to prevent further drilling in concrete walls.

We recommend installing windows with double frames: outer frame

consists of a two-chamber double-glazed window, the inner frame at a distance of 180 mm from the outer one consists of one 4 mm glass. Thus, heat loss through windows is reduced by 5 times.

The mortar for pouring walls is prepared at the construction site in a 1:3 ratio; it is poured using any method; it is recommended to fill it with a gerotor pump. It is poured along the perimeter of the wall to the entire height of the panel up to 3 m.

After installing all the external and internal walls and pouring the mortar, if the ceiling is made with PC reinforced concrete panels, then along the top of the panel the walls in the places where the slabs support are additionally reinforced along the perimeter.

The slabs are laid with a distance of 300 mm from each other. This opening between the slabs is reinforced and filled with concrete. The ceiling can be made entirely monolithic.

Subsequent floors are made in the same way. On average, two installers install from 120 to 150 square meters of walls in one shift. After pouring the walls, we lay all communications (water, sewerage, electricity). Electrical wiring is laid in protective corrugated pipes.

Parameters of an energy efficient home

It is possible to reduce heat loss at home and optimize energy consumption using several techniques.

- Thoughtful orientation and layout. By correctly positioning the house relative to the cardinal directions and the wind rose, you can achieve significant savings. The region of construction is key, but in most areas the west, north and northwest sides of a building are not the best choice for placing large windows. To minimize heat loss, these walls do not have window openings at all or make them small, or rather, sufficient for utility rooms, a garage, etc. On the south, southeast or east side it is better to place a bedroom or living room with large windows, thereby minimizing the need in artificial lighting. The problem of the sun hitting your eyes is easily solved by roller shutters, curtains or blinds, but windows serve as an additional source of thermal energy throughout the day.

- Insulation of enclosing structures . We are talking about the foundation, floors, roof, walls. The thickness of the insulation should be selected based on the thermal resistance standards of enclosing structures for the region of construction.

- Sealing the circuit. It is not enough to have thick or insulated walls and a roof; you also need to get rid of the cracks through which heat escapes from the house.

- Ventilation system with recovery. Natural ventilation is not the most convenient option, and it also leads to high heat loss. To heat cold air masses that replace warm air, additional energy is spent, while the recuperator heats up the “inflow” without consuming energy.

- “Warm” windows and doors. According to statistics, windows account for about 30% of heat loss in a home. To reduce this indicator, window units with increased energy saving parameters are installed (wide multi-chamber profile, several double-glazed windows, low-emissivity glass, argon filling, etc.). To further reduce heat loss, roller shutters are also used.

Stanislav KuzmitskyDeputy Director of Marketing, Alutech Incorporated LLC

When arranging an energy-efficient home, one of the owner’s tasks is to reduce heat exchange between rooms and the street. Significant heat loss in a house occurs through the windows, and installing roller shutters in this case is a very effective solution. When the roller shutters are closed, an air gap is formed between them and the window, which works in a similar way to a thermos.

If planning decisions, the structure of the house and engineering systems are laid down at the design stage, and insulation is carried out mainly during construction, then the tightness of the circuit can be increased and heat loss through windows can be reduced at any time. At the same time, the choice of the optimal design of roller shutters must be approached with all seriousness.

COLORS

The upper floor of a full floor is made as a regular floor, insulated with ordinary sheets of expanded polystyrene with a thickness of at least 300 mm, and a 50 mm thick mortar screed is made over it from a mortar of grade 100. The roof is made of rafters, as usual, and covered with any material.

The upper floor of the attic type is made of 3D panels. When pouring under the metal tiles, embedded elements are placed in the top layer of the panel. An even screed is made under the flexible tiles and the tiles are glued.

PLASTER

After laying all utility networks, plastering work is carried out in two layers with sand-cement mortar, the total thickness of the plaster is up to 50 mm. Plaster can be applied using plastering machines or manually. The productivity of the first layer of plaster is 3 square meters in 6 minutes using 3D panels. Houses built from 3D panels, due to internal plaster 50 mm thick, have an accumulating effect, which serves as a guarantee of comfort in the house.

LADDER

The staircase is also made from 3D panels, the step pitch is 150 mm and 200 mm. The panel is cut at the construction site in 500 mm sections, the steps are tied together with knitting wire and additionally reinforced, then plaster is applied.

VENTILATION

You can install automatic supply and exhaust ventilation with a heated filter in winter, produced by EcoDom Yenisei.

Or you can install an infiltration valve designed to supply outside air into the room. Installed next to the window in every room. Dust does not pass into the room through the filter like through an open window.

ENVIRONMENTAL FRIENDLY

Polystyrene foam does not emit harmful substances and is odorless. In many countries around the world, polystyrene foam is often used not only as a building material, but also for packaging various food products. The high level of environmental friendliness of polystyrene foam is due to its composition; foam granules consist of hydrogen and carbon. This is what makes it possible to produce beehives, fish boxes, and food packaging from polystyrene foam. The level of use of polystyrene foam in everyday life is growing every year.

Nonsense about the dangers of polystyrene foam is spread in society by critics, and with references to each other in a vicious circle. The harmful effects of polystyrene foam on human health have not been confirmed by scientific research!

What qualities are important for a house in the north

Thermal conductivity

The thermal conductivity of the material is, of course, one of the main selection criteria.

The warmest materials for building a house are considered to be brick, ceramic blocks, wood concrete, SIP panels and cellular concrete (aerated concrete, foam block, expanded clay block). Wooden and frame houses in cold climates need insulation.

Frost resistance

Frost resistance of building materials is the ability of a material saturated with water to withstand multiple alternating freezing, which is very important for cold climates. Porous concretes have high frost resistance.

Waterproof

Moisture resistance is the ability of building materials to long-term resist the destructive effects of moisture during periodic wetting and drying of the material. Porous concrete loses here. Brick also has high moisture absorption.

Environmental friendliness

The environmental friendliness of a material and its impact on health is determined by its composition. The most environmentally friendly materials suitable for cold climates are wood and brick. Expanded clay block also boasts environmental friendliness.

Material weight

As mentioned above, the load on the foundation matters. The soil in the north is often weak and swampy. A house that is too heavy may simply sag.

The difference between a house made of 3D panels and other structures

Let's look at what a house made of 3 D panels and its advantages

. The main indicators are thermal conductivity, air permeability and vapor permeability. The wall consists of cement-sand plaster 50 mm, polystyrene foam 150 mm, lightweight concrete specific gravity 1900 kg, then polystyrene foam 150 mm and plaster 50 mm. The heat transfer resistance of such a wall is 8.17 m2.оС/W, air permeability is 376 m2hPa/kg, vapor permeability is 0.3 mg/(m*h*Pa). The wall turns out to be “breathable” - this is the ability of the wall to remove moisture from the dew point to the outside.

When a positive temperature is created in the room, the pressure also increases by 50-150 Pa. And the heat rushes through the wall, ceiling and floor to the outside, thus cooling the room. And that’s why we have 300 mm polystyrene foam insulation inside our walls - the most effective, environmentally friendly and durable. Outside on a reinforced mesh, plastered with cement-sand mortar with low air permeability of 376 m2hPa/kg. Inside the wall, 150 mm lightweight concrete performs the structural part and holds the entire load of the house, on which the floors rest. The interior of the room is plastered with a 50 mm cement-sand layer; it acts as a heat accumulating layer and prevents the room from cooling sharply. The windows consist of two frames with a distance of 180 mm, the outer frame is glazed with double-chamber glass, the inner frame is glazed with 4 mm glass. Heating such a house requires 18 W per 1 m2 (for comparison: in typical houses 100 W h/m2).

Ventilation is the replacement of old air with fresh air from the street. A person emits about a liter of carbon dioxide per day, without forced ventilation the room becomes stuffy and the person is forced to breathe it. Supply ventilation is provided. In each room, an adjustable supply valve with a filter is installed near the window; indoors, a hole is left in the wall between the rooms above and below for air movement, so that the upper holes are at the same level as the exhaust ventilation. You can install automatic supply and exhaust ventilation. By doing this, we have achieved environmental friendliness, comfort and cost-effectiveness in the operation of houses built from 3D panels.

The houses are prefabricated, durable and strong, sismicity 9 points.

Consider a wooden house.

It consists of timber or round wood. To compare with a house made of 3D panels in terms of thermal conductivity, the wall thickness must be 960 mm, the air permeability of wood is 1, heat losses are large, it does not retain heat and when heated under pressure it jumps out, so you cannot build a large house. There is no point in doing supply and exhaust ventilation; heat and air in the ceiling and in the upper crowns goes out, and comes in from the floor and lower crowns. Why are houses like this built in Russia? Because wood is the most affordable building material. At the same time, it is the most environmentally friendly material to use. A wooden wall with high air permeability acts as a filter; over time, it accumulates all the dirt (urea, fat, all bacteria, fungi, the tuberculosis bacillus lives in wood for up to 12 years). Everything that evaporates and is released in the house - everything remains in the walls, mold and mildew spores can never be removed, therefore, several years after use, the house has its own persistent specific smell and a number of other disadvantages: it burns, rots, and changes its properties under the influence of pressure and humidity. sizes. We recommend building summer cottages from wood for living in the summer, and in warm permanent houses using wood for decorative wall cladding.

Consider a frame house .

It consists of USB plates and insulation. Thermal conductivity like that of a house made of 3D panels can be achieved by making walls 300 mm thick. The air permeability of the USB stove is practically zero, and the vapor permeability is also 0.004 mg/m*h*Pa. The walls inside do not have heat accumulating properties. When the ventilation is turned on, the house quickly cools down; when the ventilation is turned off, increased humidity quickly forms as a result of the development of all the negative conditions that form with high humidity. In some countries, such buildings are mainly used as temporary structures and used for rotational work. Low sismicity of the building and fragility.

Is it profitable to install roller shutters?

In fact, roller shutters are a modernized version of the traditional wooden shutters for our country, which used to be on every window in every house. In the summer they helped keep things cool, in the winter they helped keep them warm, and when the residents were away they protected them from dishonest people. In the current, high-tech version, roller shutters come in two types:

Burglar-resistant - made from extruded profiles, which, due to their larger wall thickness and the presence of stiffeners, are characterized by increased resistance to mechanical stress. Such roller shutters are most often installed at public facilities where maximum security is needed.

Energy efficient - made from roller rolled profiles. Thanks to the dense foam inside the profile, excellent heat-saving and sound-proofing properties of the structure are ensured. If the house is located near a noisy road, energy-efficient roller shutters will not only reduce heat loss through the windows, but will also contribute to a comfortable acoustic environment.

However, FORUMHOUSE users have a reasonable question: what actually reduces heat loss - due to the air cushion between the roller shutter and the window or due to the foam inside the profiles?

fgor09FORUMHOUSE Member

I don’t understand, energy efficient roller shutters, not empty inside, but with insulation (foam), profanity? So it's not worth overpaying for them? What kind of roller shutters are needed to insulate windows then?

Stanislav KuzmitskyDeputy Marketing Director

There are several options for covering profiles, including those with foam filling. Heat conservation is ensured by a closed loop and the creation of an additional air gap between the window unit and the roller shutter. But the efficiency of roller shutters made from foam-filled profiles is still higher.

To confirm their thermal efficiency, a set of tests was carried out in one of the most prestigious International research institutes - ift Rosenheim (Germany) according to the methods of the main European standards in this field. The results showed that a window (single-chamber double-glazed window) without roller shutters and without additional insulation has a thermal conductivity coefficient of 1.9. The installed roller shutter allowed us to reduce the coefficient to 1.3. This means that heat loss through windows is reduced by up to 30%! This indicator takes into account the thermal resistance of both the roller shutter itself and the air gap formed between the window and the roller shutter in the closed position.

But given that energy-efficient roller shutters only work when they are closed, private home owners are also concerned whether trying to save money will backfire.

gomis75FORUMHOUSE Member

The more I delve into it, the less I see the obvious advantages of roller shutters.

- When the roller shutters are completely closed, in the absence of the owners, protection is provided against objects thrown through the window or thieves - a definite plus.

- In summer, not fully closed roller shutters protect from direct sunlight - a plus. While completely enclosed structures are a minus, since you need to use artificial lighting, and this is an expense.

- Energy saving with fully closed roller shutters is only at night, otherwise there will be expenses for artificial lighting, and this is a minus.

- There are no security characteristics (GOST - 2 minutes to break into extruded fabric with a hand tool “without noise and dust”). This is a minus.

- A possible reduction in the cost of the insurance policy if there are roller shutters is not an obvious plus.

Stanislav KuzmitskyDeputy Marketing Director

- To protect the room from heating, it is enough to block direct sunlight and it is better to do this outside the room (so that the elements that heat up from the sun are outside and do not begin to heat everything inside themselves - this is a plus of roller shutters, unlike the same curtains). On a weekday in the summer there is usually no one at home, but if there is someone at home, blocking the direct rays is enough.

- In winter, during daylight hours, it is better to open the roller shutters so that the rooms are heated by the sun. And as soon as it goes away and it gets colder, close it. By the way, this is the advantage of roller shutters, in contrast to the same films on windows, which will block sunlight even in winter, preventing the room from warming up.

- Energy-efficient roller shutters are only one element of a home security system, and 2 minutes is almost half of the regulated police arrival time (in case of an alarm, it’s about 5 minutes). In addition, it is worth taking into account the psychological factor: often a thief can refuse to steal where penetration will require additional effort, and without knowing in advance what obstacles there may be behind the canvas.

- Insurance is rather a nice bonus.

To everything else, we can add that in winter it gets dark outside the window already at five o’clock, and in some regions even earlier - you have to turn on the lights. But if there are roller shutters, there will be no heat outflow through the windows for most of the day, and on a sunny day you can also turn down the heating in the rooms.

What do experts say about the economic feasibility of installing roller shutters? How quickly will they pay for themselves?

Stanislav KuzmitskyDeputy Marketing Director

The approximate payback period (according to calculations we carried out about 2-3 years ago) was 5-7 years. But everything very much depends on the region and the cost of energy resources. For example, in the EU this period may be 2-3 years. For convenience, we have made a calculator (with a number of simplifications and assumptions) that will allow you to calculate approximate savings.

Construction of a bathhouse using 3D panels

We are used to building bathhouses from wood, we say that this is a tradition in Rus'. Indeed, they used to build from wood; there was no other available material, but we have forgotten another tradition: in the bathhouse or washing room, as it was previously called, one family washed and the other family was not allowed. This tradition remains only among the Old Believers; they will not allow strangers into the house. This is not faith, this is preserving your life. Wood is an insulation material with a thermal conductivity of 0.18 W/m*K and high air permeability. When the temperature inside the room rises, the pressure also rises to 200 Pa, so the heat from the room goes outside. The tree passes all this through itself and at the same time filters and accumulates it. All the dirt accumulates in the wall of the bathhouse (urea, fat, all bacteria, fungi, tuberculosis bacillus lives in wood for up to 12 years). Over time, wood begins its own life. After a while, when you start heating a wooden sauna, a specific smell begins to be released. It is difficult to heat a wooden bathhouse; you need to make a large stone or brick oven to retain the heat. And if the stove is metal, then you need to constantly heat it.

We offer the construction of baths from 3D panels. External walls are double 550 mm, internal 100 mm. The floor and ceiling are insulated with 300 mm polystyrene foam, a screed and a drain are made. The walls around the stove are lined with bricks. The inside walls are plastered with a cement-sand mortar of at least 50 mm. In the steam room and in the washing room, the walls are tiled, preferably in the color of the wood. In the steam room, decorative aspen gratings are hung on the walls and covered with water-based varnish. In the dressing room, the walls can be lined with wood over plaster. The floor is tiled (a wooden floor can be made in the dressing room). Ventilation is provided in all rooms. The stove is installed small, the bath heats up quickly due to the thick layer of plaster and tiles, heat loss is minimal, and the heat is retained for a long time. Having heated the bathhouse, a stable temperature is maintained and the walls do not accumulate dirt. It is easy to disinfect such a bathhouse once a year by removing the decorative panels and rinsing the tiles well. And your bathhouse will look like it was newly built without any specific bathhouse odors.

Construction stages

The scheme according to which a frame-panel building is erected:

- drawing up a project or agreeing on what is selected in the catalogue;

- bringing necessary materials to the construction site;

- installation of the foundation - for normal conditions it is recommended to choose a strip or pile-screw foundation, as it is reliable and inexpensive;

- installation of the lower ceiling;

- construction of the frame and rafter system;

- roof installation;

- exterior decoration;

- insulation;

- interior decoration;

- installation of windows and doors.

Significant nuances:

- the building needs to be well insulated;

- it is very important to install wind and moisture protection and vapor barrier correctly and hermetically;

- for the front cladding it is advisable to use durable and not blown material;

- the design requires reinforcement with jibs;

- in order for the structure to be fireproof, the wood is treated with an appropriate composition;

- similarly, with rot and mold.