You can even make a welding machine or sawmill yourself, but when you need to make a device with your own hands that will be used in everyday life, then ensuring the safe operation of the product comes to the fore.

Homemade water heater

A homemade water heater will be used by all family members who may have only a vague understanding of electrical resistance, voltage and current. To minimize the likelihood of an accident, you will need to manufacture the device in accordance with all electrical safety rules.

How to choose a heating element for a water heater

Before choosing a heating element for a boiler, it is necessary to take into account the type of flange, power, tubes for temperature control sensors, the presence of fasteners for the anode, as well as the material of the heating element itself. There are cases when it is not possible to select an original heating element. When choosing analogues, pay attention to, which has proven itself to be a reliable supplier of heating elements for boilers produced at the Italian plant of the largest manufacturer.

Flange Types

Pressing stamped flange type RF. One of the most common among flanges. Used in boilers with an internal stainless steel tank from Electrolux, Polaris, ATT, Garanterm, Thermex and others. This type of flange has the following diameters: 64, 72, 82 and 92mm. Pressure cast brass flange. It is manufactured in diameters of 48 and 50 mm and is used in boilers with an enameled internal tank from Thermex, Ariston, and Atlantic companies. This flange has the following subtypes:

- RCA PA – there is an anode holder, characterized by bare elongated contacts and the absence of a plastic dielectric cover;

- RCF – there is an anode holder, the heating element has a bent shape, the contacts are insulated;

- RDF – there is an anode holder, a straight heating element, the contacts are insulated;

- RCF OR – there is an anode holder, the heating element has a bent shape, the contacts are insulated, made for horizontal models;

- RF – no anode holder, contacts are insulated, manufactured for Atlantic boilers.

Pressing flange made of stainless steel type RNSA oval. Manufactured and used in Ariston water heaters. Flange – threaded brass plug. It is used in boilers from almost all manufacturers, as well as in homemade heaters. Has threaded pipe threads of various diameters.

Heating element power

The power is usually output from the tube of the heating element itself. Also, all the necessary information about power can be read in the product passport, as well as on the nameplate. If you cannot find a heating element with the same power as the original, then it is recommended to choose a heater with a lower power.

Heating element material

Heating elements made from various materials differ in quality and durability. Let's look at the three main and most common options:

- Stainless steel is one of the most budget-friendly and short-lived options;

- Copper - more powerful and reliable compared to stainless steel heating elements;

- Silver plated – resistant to scale, disinfects water, and has a long service life.

Thermostat tube

When replacing the original heating element, pay attention to the presence of the thermostat tube. If it is available on the old heating element, it is necessary that the new one also has it. If you find two tubes, then you can purchase a heater with one, because It is usually possible to install two sensors one after the other.

Additional products

When purchasing a heating element for a boiler, do not forget to buy a new gasket for it. If this is a heating element from the MasterProf company, then the gasket will already be included. It is also recommended to replace the anode - this will extend the service life of your boiler. Also, before purchasing, make sure that the thermostat and check valve are working; if they fail, they also need to be replaced.

X

XX

Other methods of making a water heater

You can build a water heater powered by the sun. This is a fairly common design, which is distinguished by its efficiency. The device is often found in country houses. Making the device is not particularly difficult, so many can build it with their own hands.

- large capacity tank (100 l or more);

- PVC pipes for filling the container and supplying water to it;

- steel corners measuring 20 mm or square blocks of wood measuring 50 mm for a frame for a container.

It is more advisable to use polyethylene barrels as containers. They are distinguished by their strength. They should be placed in a sunny place where there is no wind. As a rule, the roof of a summer shower is chosen for installation.

In order for the barrel to heat up better, it needs to be painted black. Screens are installed on the leeward side for protection. They are constructed from boards coated with reflective material similar to foil. In this case, the sun's rays are directed towards the tank and increase the temperature of the water. In hot weather, in a container of 200 liters you can get water whose temperature will be 45 ºС.

Difficult choice

When purchasing a water heater, users naturally face the question of what type of heating element will be best for the boiler. To do this, you must, at a minimum, become familiar with their performance characteristics.

The standard installation of all heaters in products is of the flange type. In this way, full contact with the heated liquid is achieved, but deposits and corrosion products appear on the body during operation. significantly slowing down the heat transfer effect.

The heating process increases over time, which leads to increased energy consumption. Designers from different manufacturers use various modifications that slow down the formation of deposits and scale, but wet heating elements tend to quickly fail, and their maintenance is quite complicated.

Dry heaters have a longer service life due to the fact that their body almost never comes into contact with the heated water. The inside of the tank, as well as the heater mounting flanges, are coated with special enamels based on titanium or glass porcelain - such corrosion protection prevents the occurrence of deposits and scale.

During long-term operation, wet-type thermal heaters become overgrown with scale, which can lead to breakdown and the user will receive an electric shock through the body of the product. In the dry version, this negative possibility is eliminated, because a ceramic bulb, which is a dielectric, is installed between the liquid and the heater body. In addition, this option completely eliminates overheating of the heater housing, service maintenance is reduced to a minimum, but periodic replacement is not excluded, although many times less often.

Many manufacturers have launched the production of large-capacity water heaters using two types of heating elements at once, which contributes to high reliability and increased service life.

Statistics confirm that closed heating elements last three times longer than their open counterparts - wet ones last no more than 5 years, and dry ones no less than 15 years. The cost of open heaters is much lower, they are more practical for repairs, but if you do not plan to maintain your water heater, then it is better to opt for the dry option.

Choosing a tank for the boiler

The volume of the storage tank of the water heater should be calculated based on the daily consumption of hot water in the house. If several people live in an apartment or house, a tank of 100 liters will be sufficient. And for a family of 4-5 people, you should choose a container with a volume of 200-300 liters.

The tank used should be made of an aluminum alloy, stainless steel or other metal that is resistant to corrosion. You can use a large-sized gas cylinder, the walls of which are additionally cleaned and primed. If the walls of the cylinder are not primed, the hot water may have an unpleasant gas smell.

Five holes must be drilled in the selected tank. Two at the bottom for the inlet pipe and emergency drain, two at the side for installing the coil and one hole for water extraction at the top. If you plan to use such a boiler outside the heating season, you must also make holes for installing an electric heating element. For the heating element, one or two holes are drilled from below. Ball valves or shut-off elements are installed in the holes made, after which the tightness of the storage container is checked.

Basic information about the procedure for replacing heating elements

Any manipulations with the water heating device are carried out only when it is completely disconnected from the power source. Before replacing, be sure to drain the water from the tank. The water heater itself is removed from the mounting bracket on the wall and placed on a table or floor to make it convenient to work.

The main lower bar of the boiler is unscrewed to gain access to the heating element. In order not to make a mistake when installing a new part, it is better to take a couple of photographs of how the old one was located.

Afterwards, you need to disconnect the wires going to the heating element and remove it from the tank.

Advice! It is not always necessary to change a part; sometimes to restore its properties it is enough to simply clean off the scale.

The procedure for replacing the heating element in this short video course:

What you need to know about security

Do not forget that we are dealing with a source of increased danger - an electric heating device, therefore, when assembling and using it, you must follow some rules:

Be sure to use a separate electrical line to connect the induction boiler, and also equip it with a safety group.

- If water circulates naturally in the boiler, be sure to equip it with a temperature sensor so that if it overheats, the device turns off automatically.

- Do not connect a homemade water heater to an outlet; it is better to draw a separate line for this with a larger cable cross-section.

- All exposed sections of wires must be insulated to protect people from electric shock or burns.

- Never turn on the inductor if the pipe is not filled with water. Otherwise, the pipe will melt and the device will short out or it may even catch fire.

- The device must be mounted at a height of 80 cm from the floor, but so that about 30 cm remains from the ceiling. Also, you should not install it in a residential area, since the electromagnetic field has a bad effect on people’s health.

- Don't forget to ground the inductor.

- Be sure to connect the device through an automatic circuit breaker so that in the event of an accident, the latter will cut off the power from the water heater.

- A safety valve must be installed in the pipeline system, which will automatically reduce the pressure in the system.

Why is it important to monitor the condition of the heating element?

So, the heating element is something without which your water heater will not be able to do its job. Failure of this part threatens not only with unnecessary expenses for electricity, but also with an immediate danger to life, since the element comes into contact with water. It is necessary to periodically analyze the operation of the device and check the condition of the heating element. The resulting scale is removed, and if it is not present, but the device operates intermittently, then the part should be replaced with one that is suitable for the design.

Which heating elements do you consider the most effective? If you can recommend any specific models, please write about it in the comments!

The law is what the drawbar is, where it is turned there and out

The design on YouTube is not illegal, but it is not very convenient. There is even less chance of setting it up correctly for use. Here are a couple of tips to help you do this somehow:

The radiator in the video resembles something from a car hood. There was no time to figure out what exactly it was, but the point is that you will need not just a coil, but just such a corrugated surface. This will significantly increase the efficiency of the device, on which both efficiency and gas fees (if there is a meter) ultimately depend.

This device is a gas instantaneous water heater, which should produce about 4 liters of warm water per minute. It’s easy to calculate how much power it should have for this:

N = A / t = (4200 x 4 (45 - 8)) / 60 = 10.36 kW, this is the power achievable for a factory gas water heater. You can only find out if you can make an appropriate heat exchanger at home by trying it.

The device itself is a coil, which is connected at one end to a cold riser, and at the other to a shower head or mixer. The flow is regulated by a valve. In this sense, you will have to use an old cast-iron tap at the inlet or a bronze tap at the outlet of the coil. The radiator is placed on the hob grate and heated by one or two burners. It is clear that the hose must be heat-resistant, otherwise various unpleasant consequences are possible.

An adult must supervise the operation of the device and, in case of danger, turn off the supply of blue fuel while someone is washing or doing the dishes. A gas water heater or an electric water heater is much safer from this point of view. I would also like to add that even purchased equipment needs to be configured, which means that the intervention of a qualified technician will be required. Sometimes a set of jets (injectors) needs to be replaced, in other cases a reducer is installed in the gas supply path. In the latter case, the system resembles traditional propane-butane power supply.

Dry ceramic heating element

For boilers and water heaters, you can also use dry ceramic heating elements in a stainless steel flask. Soapstone ceramic heaters are more expensive than metal tube heaters, but they last much longer. The Polimernagrev company produces dry ceramic heating elements with diameters of 42 and 34 mm. The length of the heaters, type of connection, flask and other parameters are made to order with individual requirements. You can order the production of even one heater from us, and when ordering several heating elements, a discount is provided. Please check with our managers by phone or email for the cost and production time.

Indirect heating boiler piping

To connect an indirect type boiler, three working schemes are used:

- Trim with three-way valve.

- Connection to two circulation pumps.

- Tying using a hydraulic arrow.

Trim with three-way valve

The piping scheme using a three-way valve is used most often, especially when consuming a large amount of hot water. To do this, two heating circuits are installed in the system. The first is the main circuit used for heating rooms. The second is intended for heating water in the boiler.

The piping diagram for an indirect heating boiler with a three-way valve is most often used

The principle of operation of the system is quite simple: if the temperature in the storage tank drops below the set value, the valve redirects part of the coolant to heat the water in the boiler. After heating the water, the coolant returns back to the heating circuit.

Piping with two circulation pumps

An indirect type water heater is installed in a system with two circuits: boiler and heating. A recirculation pump is used to regulate each individual circuit. In this case, the pump on the boiler circuit is mounted in front of the heating equipment pump.

In the piping scheme with circulation pumps, the supply of coolant to the boiler is automatically regulated

Both pumps are connected to the boiler thermostat. When the water in the boiler cools, the thermostat turns on the corresponding pump, which redirects part of the flow from the heating and vice versa.

Tying using a hydraulic arrow

Piping using a hydraulic separator is used in central heating systems consisting of two or more circuits. If in a system without a hydraulic switch, the redistribution of flows in the circuits necessarily affects the operation of any equipment, then when it is installed, a smooth redistribution of cold and hot flows occurs.

The boiler piping scheme with the installation of a hydraulic separator ensures the smoothest distribution of cold and hot water flows

For example, a hydraulic separator must be installed in private houses, where a heated floor system is connected to the central heating in addition to an indirect heating boiler. The design of this harness is quite complex to implement, especially with a large amount of equipment. Therefore, it is better to entrust the installation work to specialists.

Coolant recirculation system

This piping scheme is used when it is necessary to minimize the rate of heating of water in the boiler, since with frequent downtime, the water in the tank quickly cools down, and it takes from 30 to 60 minutes to reheat it.

To do this, a “return” to the water heater is installed in the pipeline running from the boiler to the water tap. A circulation pump connected to a thermostat is also installed in this area.

When the water in the pipeline stagnates and cools, the thermostat turns on the pump, which redirects the cooled water back to heating. When the water supply is restored, the user will not have to wait for it to heat up, since it will already be warm.

Heating element device

To understand how a tubular electric heater works, look at the figure below:

Water heater heating element device

- The shell is a metal tube. Copper, steel or aluminum tubes of different diameters are used as shells.

- Contact rod - a metal rod with a thread at the end through which the power supply of the heating element is connected.

- The heating element is a spiral made of an alloy with high resistivity.

- Filler - the dielectric periclase (white magnesium oxide powder) is used as a filler.

- Sealing material - protects the filler from external moisture and thereby preserves its properties.

- Contact washers and nuts are needed to secure the terminals.

- Insulator - separates the contact rod and the shell of the heating element. Needed to protect against current leakage to the housing.

The figure shows the length parameters. Let's decipher their meaning:

- L is the expanded length of the heater. According to GOST, it is equal to the sum of the lengths of straight and curved sections.

- La - active length. Equal to the length of the heating element.

- Lk is the length of the contact rod. The length of the embedment is standardized and indicated in the marking using a letter.

- Ly is the length of the leakage current path. Special standardized value.

- d is the diameter of the heating element.

Required materials and tools

The storage tank of the device is made of heat-resistant plastic, stainless steel, aluminum or ceramic-coated steel.

As blanks for the tank, you can take plastic barrels for food products, aluminum tanks or an unnecessary gas cylinder. As a tool you need to prepare:

- angle grinder;

- electric drill with core drill for metal;

- argon-arc welding machine;

- set of wrenches;

- disc for grinding and polishing metal;

- sandpaper.

Fittings, drain valve and other connecting elements are selected based on the size of the connected pipe. Additionally, FUM tape, a safety valve, a magnesium anode and a nozzle for its installation are purchased.

Types of heating elements, how they differ

Heating elements are different. If the question arises about their planned replacement, it is important to make the right choice.

Heating elements are closed (dry) and open (wet).

Wet heating elements and their features

Wet heaters are in direct contact with the liquid in the tank and are similar in appearance to the spirals that we most often see in electric kettles. If such a spare part malfunctions, it is not difficult to replace it.

For your information! Inside the shell-tube, in addition to the metal spiral, there is sand or magnesium oxide; they perform the task of conducting heat to the shell from the nichrome wire, which is heated by the passage of current.

Wet heating elements have different mounting principles: flange or nut. Flanged ones, in turn, are divided into stamping and casting. Not all parts have an anode socket, please pay attention to this. Most often, parts with a nut fastening do not have it.

Heating elements also differ in their shape. They can have different curves

Open wet elements are good because they heat the water very quickly. The parts themselves are relatively inexpensive, so replacing them will not harm your family budget. To further protect the heating element from corrosion, manufacturers often coat it with glass-based enamel. The same enamel prevents the formation of a layer of scale.

If we talk about the disadvantages of open heating elements, they are considered less safe than dry ones and are more susceptible to scale build-up. A coat of sediment does not allow the water to heat up quickly and, as a result, the device begins to consume excess electricity.

Closed or dry heating elements

This type of heater is located inside a ceramic vessel and eliminates direct contact with water. That is why the heating element is called dry. The vessel itself is made of steatite or magnesium-based silicate.

Such heating elements are considered the safest, as they do not cause short circuits.

They are very easy to replace and work for a long time, consuming energy economically and without forming a coat of scale on the surface. And what is important is that such parts are repairable.

But dry heating elements also have their drawbacks. The main one is that they are not universal. For each specific water heater model, only a branded heating element is suitable.

Thermal insulation

To minimize heat loss, the tank should be wrapped in a layer of thermal insulation.

For this purpose, use:

- construction foam;

- isolon;

- polyurethane foam;

- foam;

- mineral wool.

Some craftsmen use a foil-based backing for the laminate. The water heater is wrapped in this case like a thermos. The insulation is attached using wire, glue or strip ties. We recommend insulating the entire building.

The lining will not only ensure long-term preservation of hot water, but will also shorten the duration of heating of the tank, which will reduce coolant consumption. Without well-equipped thermal insulation, the water in the device will quickly cool down.

Often they resort to the construction of a double tank: a small tank is placed inside a large one. The space created between them also performs a heat-insulating function.

To secure the container, hinges are welded to the top of its body, and a metal corner is installed on the wall to which they are attached.

Heating elements for electric heating boilers

Previously, I wrote a separate article on electric boilers, which I also recommend reading.

Well, okay, let's get down to business. Blocks of heating elements are used as heating elements for electric boilers.

They consist of several heaters, which are combined together with a nut.

To make it clearer, look at the picture below:

Heating element block

The nut is available in the following diameters: 1.25 inches, 2 inches and 2.5 inches.

Such a block is sealed using an annular rubber seal (if it is provided structurally) or by winding with thread or FUM tape.

As for the tubes, they can be made of carbon or stainless steel.

Stainless steel is more expensive, but lasts much longer than black steel.

With powers up to 9 kW, units with a supply voltage of 220 V can be installed inside the boilers.

With higher power, units for a three-phase voltage of 380 V are installed in the boilers.

Preparing the tank for water heater assembly

To make an indirect type boiler, you can use a new or old gas cylinder. This container is made of thick stainless steel 3-4 mm thick and is perfect for working with hot water.

Before assembling the heating structure, you will need to carefully prepare the cylinder. To do this, the product is cut in half using a grinder. The inner surface of the container is cleaned using an angle grinder with an appropriate attachment.

Before assembling the boiler, the cylinder must be opened and the inner surface cleaned

After this, the inside of the cylinder is washed, dried and coated with nitro primer paint. This work must be carried out without fail, otherwise after putting the boiler into operation, the heated water will smell like gas.

When using a tank from other metal containers, preparation is carried out according to a similar scheme.

Purpose and type

For any water heating product, heating elements are the main part. They operate from the electrical network, so designers use them when developing various electric heating devices, from a regular kettle to large-capacity automated boilers.

The heating element for a water heater is structurally a hermetically sealed copper tube with a nichrome spiral inside, which is usually located in the lower part of the product or, in exceptional cases, on the side. The lower location is more acceptable because it ensures uniform heating of the entire volume of water.

Depending on the design, heaters are divided into “dry” and “wet”. The first are so called because they do not have contact with water - their body is hidden by a hermetic flask. Water heaters with dry heating elements are used for modern models. Manufacturers consider this design to be more durable, since the body of the heating element is not constantly exposed to water - the absence of lime deposits and scale significantly extends the life of the heating element. They will not burn out if the user accidentally turns on the boiler without water.

However, the most common model is considered to be wet or submerged heating elements. Some users believe that this is already an outdated model and is completely in vain - they continue to be used everywhere in various water heaters. The main disadvantage of such a heater is considered to be the tendency to frequent breakdowns due to scale and deposits, but compared to their dry counterpart, they are easier to find on sale, easier to replace and, naturally, they are cheaper.

The simplest heat exchanger

A homemade heater looks like this:

A larger diameter shell is welded onto the central heating pipe. The result is a sealed vessel with hot coolant flowing inside it. On opposite sides of the outer pipe (in fact, this is a boiler), flanges are installed for supplying (draining) cold water. When the coolant is hot enough, the water in the boiler heats up quickly. After which the top tap can be opened and the hot water supply can be used until the hot water is replaced by cold.

If we leave aside the legality of re-equipping the collective heating network (there is hardly any serious liability for this), the system works effectively. Hot water is conditionally free, minus one-time investments in materials, and a bottle of strong drink for the welder.

If you install such a instantaneous water heater with your own hands in a private household, there will be no conventional problems.

The only limitation is the volume of the outer container. In real time, the water will not heat up; the reserve of thermal energy in the heating pipe is too small. Therefore, the system works cyclically: heating - use - heating. The higher the diameter ratio (or the longer the pipe), the greater the supply of hot water. Accordingly, the longer it will take to warm up.

Another serious drawback: in the summer (with the heating turned off) such heaters do not work.

Replacement algorithm

Replacing a heating element in a water heater is a very labor-intensive operation and is carried out strictly according to certain regulations:

- disconnect the product from the electrical network;

- drain the water completely;

- remove the water heater from its mounts and turn it over for ease of carrying out all work;

- Unscrew the fastening of the bottom panel, photograph the location and order of wiring;

- disconnect the wires from the heating element and remove it from the tank body;

- clean the plaque and scale; if no damage to the housing is found, then install the heating element in place;

- in case of replacement, install a new heating element and reassemble in the reverse order.

Especially for inexperienced users, to help them carry out this operation correctly, there is a video where an experienced technician replaces the heating element in a boiler:

Stages of work on creating a boiler

The boiler drawing may look like this.

Creating a Heat Exchanger

When choosing the diameter of the future coil, it is important that the water in the tank comes into maximum contact with such a pipe. To do this, leave free space between the turns of the pipe.

To make the work easier, you can use a log or pipe around which the heat exchanger tube will be wrapped. One end of this tube is fixed, and then turns are smoothly created, controlling the density of the resulting spiral.

Preparing the boiler tank.

Having chosen a suitable container, you need to make two holes in it for cold water in and hot water out. Ball valves should be built into each of them for ease of operation. You also need two holes for mounting the heat exchanger. Another hole will be needed for the drain valve, which is located at the bottom of the device.

How to clean the heating element

In many regions, the water is too hard, so scale quickly forms on all heating elements. If you periodically clean this coat, the heating element will last longer. In addition, you will not waste money on unnecessary electricity.

There are two cleaning options: mechanical and chemical. Mechanical is simply scraping off the fur coat with a stiff brush and sandpaper.

The most important thing in this procedure is not to damage the shell of the heating element and its base.

The chemical cleaning option involves the use of special compounds that are sold in household chemical stores. There are special products for water heaters, but you can also use a composition for electric kettles. The principle of its operation is the same. The composition is diluted with water, and the heating element is soaked in it for several hours, after which the scale is easily removed from the surface.

You can also use a handy tool. Scale is afraid of acetic acid. For greater effect, the solution should be heated

Important! Chemicals can damage the rubber seal on the part, so direct contact with acid should be avoided.

Installation methods and shapes of boilers

Boilers come in wall-mounted and floor-mounted versions, horizontal or vertical models. The capacity of the product, which is mounted on the wall, is naturally lower: it does not exceed 200 liters. Floor-standing devices can hold one and a half thousand liters. Boilers are mounted on the wall using standard brackets and suitable dowels. The most common boilers are cylindrical in shape.

Working pipes for connecting the system are located at the rear of the unit for convenience and aesthetic purposes. There is a temperature sensor and a thermostat on the front panel. There are models with the possibility of additional connection of heating elements if the power of the main heat source is not enough.

What kind of heaters are produced?

Different models of water heaters differ in heating devices, so you need to know their features in order to choose an identical heating element for your boiler.

The famous concern from sunny Italy prefers heaters made of stainless steel with a chromium-nickel composition. but with a copper shell. The flange is made of brass - this helps to increase the thermal power of at least 1.5 kW. Heating elements of this design are used in all water heaters, both small-capacity types and volumes designed for hundreds of liters. The cost of a new similar element is in the range of 1.5-2.0 thousand rubles.

Another Italian company supplies its products with two types of heaters at once. which significantly reduces the time for heating water - one with a power of 1 kW, and the other 1.5 kW. They work together or separately, which allows the user to adjust the heating process at their discretion. The body is made of an alloy for which there is a registered patent; the composition is kept secret. A big plus is that instead of them you can install heating elements from other manufacturers, for example, Atlantic or Garanterm.

The Slovenian company uses tubular-type heaters, but covered with protection made of glassy glaze or glass porcelain. similar to the enamel covering the inner surface of the container. In this way, developers successfully combat the appearance of scale and limescale, which leads to frequent breakdowns of this part. The water is heated to an optimal temperature of 90 0 C, so when replacing or installing a heater from another manufacturer, the user must reduce it to 60 degrees so that the heater does not burn out.

What can BKN materials be made from?

- preparation of storage tank;

- heat exchanger production;

- installation of heating elements;

- thermal insulation of the body.

How to make an indirect heating tank

- suitable for food water;

- withstands heating up to 90°.

| Dimensions | Description | 1500 l |

| N | Height | 2285 mm |

| ø ext | External diameter (including insulation) | 1200 mm |

| ø int | Inner diameter | 1000 mm |

| F | Cold water inlet (1″1/4) | 315 - 1″1/4 mm - » inch |

| G | Water outlet from the lower coil (1″1/4) | 470 mm |

| L | Hole for bottom temperature sensor (1/2″) | 582 mm |

| M | Water supply to the lower coil (1″1/4) | 1180 mm |

| N | Water outlet from the upper coil (1″1/4) | 1330 mm |

| P | Hole for top temperature sensor (1/2″) | 1500 mm |

| Q | Recirculation (1″) | 1460 - 1″ mm - » inch |

| R | Water supply to the upper coil (1″1/4) | 1735 mm |

| S | Domestic hot water outlet (1″1/4) | 1935 - 1″1/4 mm - » inch |

| A | Inspection flange (ø internal 114 - ø external 168) | 520 mm |

| B | Additional electrical resistance (1″1/2) | 1255 mm |

| C | Thermometer (1/2″) | 1825 mm |

What material is the heat exchanger made of?

L = Q / D* (Tg – Tx) * 3.14

- coil length - L;

- thermal power - Q;

- heat exchanger diameter - D;

- the expected hot and cold water temperatures are Tr and Tx, respectively.

Heating element for combined BKN

P= 0.0011*m*(tk-tн)/T

- P is the power of the heating element;

- M is the mass of heated water;

- tk is the desired water temperature;

- tн - initial water temperature;

- T is the water heating time.

Indirect heating boiler with electric heating element

How to make thermal insulation BKN

- The body is coated with heat-insulating paint - it contains ceramic components that retain heat. At the same time, the paintwork protects the surface of the tank from corrosion.

- Mineral wool - a thermal insulation layer of about 5 cm. It is optimal to use basalt insulation. The material prevents heat loss, is resistant to moisture and at the same time allows steam to pass through, preventing liquid from accumulating in the layers of the material. The mineral wool is covered on top with any material with a foil base. You can use Penofol and derivatives.

- Instead of three-layer insulation, the use of Polinor is allowed. The insulation is similar to polyurethane foam. Easy to apply and prevents heat loss.

"Wet" heating element

The open type heater has direct contact with water. Thin nichrome wire wound in a spiral type is an excellent conductor for electric current. First of all, it transfers heat to quartz, which fills the voids inside the case, and only then the heat passes to the case and warms up the environment. Such heating elements are classified according to the following technical principles:

- The shape of the heater can be straight or concave. Determined by the type of storage device in the boiler.

- By type of fastenings. There are heaters mounted on a flange or nut. The first ones are produced by casting or stamping.

- The presence of an anode socket or its absence.

In the production of open-type tubular heaters, stainless steel or copper alloys are used. These materials are less susceptible to oxidative processes. The advantages of such a heating element include ease of installation and replacement. And also the market price. Only due to continuous exposure to water, the heater quickly becomes covered with salt deposits and fails. Plus, an open heating element consumes a lot of electricity.

Work principles

To assemble an induction boiler with your own hands, you need to study what it consists of and understand the principles of its operation.

The device heats up due to the energy of the electromagnetic field. The coolant takes it over itself and converts it into heat.

The magnetic field is created in an inductor (this is a cylindrical coil with a large number of turns). As electricity passes through it, it creates a voltage around itself. The magnetic flux moves in a closed circle perpendicular to the electric field. Alternating current creates eddy currents and generates energy into heat. Electricity is transferred to the heater without direct contact.

Induction heat is consumed efficiently and economically, so water with this heating method reaches high temperatures in a short period of time. The coolant receives about 97% of the energy.

Induction water heater components

Organizing a heating system in your own home using an induction boiler will not require major redevelopment. It is based on a transformer consisting of primary and secondary windings.

Vortex flows are formed in the primary winding from electrical energy and create an electromagnetic field. It goes to the secondary, which functions as a heater.

The secondary winding is the boiler body. It includes elements such as:

- external winding;

- core;

- electrical insulation;

- thermal insulation.

To supply cold water to the device and remove warm water to the heating system, two pipes are installed to the water heater. The lower one is mounted on the inlet section, and the upper one on the hot water outlet part.

The heat created by the boiler is transferred to the coolant. Most often it is water, since it can quickly absorb heat. Due to the built-in pump, hot water enters the heating system through the pipe. The liquid constantly circulates, so overheating of the equipment is not possible. Cooled water is supplied and hot water is discharged.

When circulating, the heating fluid vibrates, which prevents scale from depositing inside the pipes. An induction water heater can be installed in any room, since no noise is created during operation.

Design Features

The standard design of a wet heater consists of the following elements:

- hollow copper or stainless steel tubes bent in different ways;

- inside there is a spiral of nichrome thread;

- The insulator is a heat-conducting substance - quartz sand or magnesium oxide.

A dry or closed heating element for a boiler is distinguished by the presence of an insulating flask made of high-strength ceramic. Sometimes its body is made of magnesium silicate or inorganic steatite, but not of metal. Heating occurs through this protective flask, and the tubular element itself does not come into contact with the aqueous environment, and therefore lasts a long time.

If we are discussing which types of heating elements are better, then we should immediately note that there are very significant differences in power and configuration - for wet elements there are differences in the fastening used, bending shapes and materials for making the housing. The type of tank used in the boiler determines the shape of the heater - according to this characteristic, the electric heater can be made straight or bent in different directions. In the main body, wet heating elements are made of copper and stainless steel. A dry heating element for installation in a boiler is made in the form of a straight rod of different lengths and diameters - this depends on the volume of the tank, the body is made of stainless steel, and the soapstone coating is made specifically for each model.

Homemade induction boilers

The simplest circuit of the device, which is assembled, consists of a piece of plastic pipe, into the cavity of which various metal elements are placed in order to create a core. This can be thin stainless wire rolled into balls, wire cut into small pieces - wire rod with a diameter of 6-8 mm, or even a drill with a diameter corresponding to the internal size of the pipe. From the outside, fiberglass sticks are glued to it, and a wire 1.5-1.7 mm thick in glass insulation is wound on them. The length of the wire is about 11 m. The manufacturing technology can be studied by watching the video:

The homemade induction heater was then tested by filling it with water and connecting it to a factory-made ORION 2 kW induction cooktop instead of the stock inductor. The test results are shown in the following video:

Other craftsmen recommend using a low-power welding inverter as a source, connecting the secondary winding terminals to the coil terminals. If you carefully study the work done by the author, the following conclusions arise:

- The author did a good job and his product undoubtedly works.

- No calculations were made on the thickness of the wire, the number and diameter of the coil turns. The winding parameters were adopted by analogy with the hob; accordingly, the induction water heater will have a power of no more than 2 kW.

- In the best case, a homemade unit will be able to heat water for two heating radiators of 1 kW each, which is enough to heat one room. In the worst case, the heating will be weak or disappear altogether, because the tests were carried out without coolant flow.

It is difficult to draw more precise conclusions due to the lack of information on further testing of the device. Another way to independently organize induction heating of water for heating is shown in the following video:

The radiator, welded from several metal pipes, acts as an external core for the eddy currents created by the coil of the same induction hob. The conclusions are as follows:

- The thermal power of the resulting heater does not exceed the electrical power of the panel.

- The number and size of the pipes were chosen randomly but provided sufficient surface area to transfer the heat generated by the eddy currents.

- This induction heater circuit turned out to be successful for a specific case where the apartment is surrounded by the premises of other heated apartments. In addition, the author did not show the operation of the installation in the cold season with recording of the air temperature in the rooms.

To confirm the conclusions drawn, it is proposed to watch a video where the author tried to use a similar heater in a free-standing, insulated building:

Marking of heating elements: decoding

In order to be able to distinguish some heating elements from others, special markings were developed, fixed by the state standard.

It is applied to the surface using a press and should be located close to the insulator.

Consider, for example, the following marking:

100А13/1.6р220 - 2R30

- The number 100 indicates the unfolded length of the heating element in centimeters.

- The letter “A” in the marking encodes the depth of embedding of the contact rod (I will give the decoding below).

- The number 13 indicates the diameter of the tube in millimeters.

- The number 1.6 indicates the heater power in kW.

- The letter “p” encodes the heated medium (in this case, water and weak solutions of alkalis or acids) and the tube material (carbon steel).

- The number 220 indicates the supply voltage is 220 V.

- Number 2 is the number of the heating element shape (in this case it is U-shaped).

- R30 is the bending radius of the heating element in millimeters.

Manufacturing and lining of the firebox

The most difficult task in producing a homemade Titan is rolling the steel sheet into a cylinder. With a significant thickness of the metal, this is not so easy to do; the parts must be welded without stress, because when exposed to high temperatures, the strength characteristics of the weld are greatly reduced.

Initially, you should select the expected internal diameter of the firebox in the range of 50–70 cm and cut two disks to this size. According to the diameter, the circumference is calculated, and a strip is cut out of it from the sheet, from which the walls of the combustion block will be formed. The height of the firebox, as already mentioned, is selected according to the volume of the tank: about 5 kW of heat is consumed to heat every 50 liters of water, which corresponds to approximately 1 kg of dry firewood. Thus, for a 200-liter heater, the firebox should freely accommodate 4 kg of firewood without taking into account the volume of the ash pan. The higher and narrower the heating column, the more efficient the heat transfer occurs, but the stability of the Titan decreases.

The cut steel sheet is laid horizontally, and two disks are installed vertically on its short edge. One is placed parallel to the long edge with a slight indentation - this disk forms the bottom of the combustion block. The second disk is installed parallel to the first with a distance of 20–25 cm from it - this is how a partition is formed between the firebox and the ash pan. You can immediately cut an opening in the partition, the size of which is 40–50 mm smaller than the existing grate.

Two disks act as a rigid mandrel for rolling the cylinder. First, they are welded to the strip on both sides with tacks 10–15 mm long, carefully monitoring the perpendicularity of the installation. Next, the metal is driven over the discs with a sledgehammer; if the metal thickness is more than 5 mm, heating with a propane torch may be required. When the two parts to be welded are pressed tightly, the perpendicularity of the disks is checked, after which the welding seam continues for another 10–15 mm and so on until it goes completely around the circumference. When the seam is completed to its full length, it is covered with another one: the electrode is drawn without separation with heating and surfacing of a wide area, the weld pool is displaced in a zigzag. After welding the discs to the wall, a longitudinal seam is welded on the outside.

When the firebox body is assembled, it is lined from the inside with fireclay bricks without any binder in the seams; the thickness of the lining is about 50–70 mm. To accurately adjust the stones to the size of the firebox, they are first placed vertically on a flat surface in a cylindrical well, the internal diameter of which is approximately equal to the diameter of the firebox. In this case, the bricks are located closely on the inside and with the most uniform indentation from each other on the outside, diverging in rays.

The distance between adjacent stones at the most extreme points must be divided in half and the bevels of the resulting size removed with a diamond wheel, achieving a wedge-shaped shape. After this, the bricks are installed against the walls of the firebox from the inside; if necessary, they are adjusted to each other using an angle grinder. The stability of the lining can be ensured with the help of a steel strip rolled into a ring and installed from the inside. After lining the walls, a grate is placed inside.

Replacing a water heater heating element

Boilers have a fairly simple design and operate on a basic principle. If you don’t want to overpay the craftsmen for the work, then you can handle this task yourself. If your water heater is under warranty, you must contact the service center if all operating rules are followed.

Visual inspection of parts

A visual inspection allows you to objectively assess the condition of the heating element for the water heater. To do this, you will need to disconnect the boiler from the network, drain the water from it and disassemble it, cleaning the heating element from scale.

Inspect the part for cracks, chips, swelling or damage. If you find them, feel free to throw the item in the trash, as it will no longer be possible to repair it. In this case, the only option is to replace the heating element for the water heater with a new one.

This happens due to untimely replacement of the anode. Since after its destruction, the heating element itself and the walls of the boiler begin to corrode. It is extremely important: damage and leakage of the heating element will lead to damage to the thermostat, which will significantly increase the cost of repairs. If the heating element is damaged at the slightest level, it should be replaced immediately!

Tools for replacing heating elements

If a malfunction is detected, you need to prepare for replacement and purchase tools. Most of them are available in almost every home, so there should be no problems with replacement. So, to replace the heating element you will need the following tools:

- Wrench;

- Pliers or pliers;

- Absorbent fabrics (rags or napkins);

- Straight and Phillips screwdriver;

- Phase meter (screwdriver with indicator);

- New heating element.

Replacing the water heating element

Turn off the water supply by turning off the tap near the boiler. If there is no shut-off valve, turn off the water in the entire apartment by shutting off the riser. In addition to shutting off cold water, hot water also needs to be shut off.

The replacement process is quite simple, just do the work in the following order:

1. Draining water 1.1. Turn off the power supply to the device; 1.2. Make sure the water inside the appliance is at a safe temperature; 1.3. Turn off the cold water supply to the water heater; 1.4. Open the hot water tap on the faucet to relieve pressure inside the tank; 1.5. To allow air to enter the tank, open the shut-off valve on the tee installed at the hot water outlet of the water heater. If it is missing, it is necessary to dismantle the connections at the outlet of the water heater; 1.6. Connect the drainage hose directed to the sewer to the shut-off valve on the tee installed at the cold water inlet of the water heater and open it. If not available, a drainage hose must be installed at the inlet of the water heater. Water will flow out from the cold water supply point, and air will flow through the hot water connection point; 1.7. After draining, make sure there is no water inside the water heater. 2. Replacement of internal elements 2.1. Remove the cover of the device; 2.2. To replace the thermostat, slide it out of the socket and disconnect it from the power supply; 2.3. Remove the thermostat; 2.4. Unscrew the heating element or the heating element mounting using an open-end wrench, an adjustable wrench, or a gas wrench; 2.5. Wash the internal tank of the water heater and replace the heating element (anode and thermostat if necessary); 2.6. Assembly is carried out in reverse order. The main thing is to pay attention to the grounding wire.

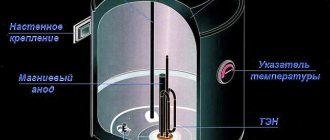

Attention: The magnesium anode is an integral part of the system for protecting the water-containing container and heating element (heating element) from corrosion. It is necessary to check the condition of the magnesium anode annually. If the magnesium anode is severely worn, it must be replaced. It is necessary to replace the magnesium anode at least once every 24 months.

Attention: A tubular electric heater (TEH) is designed to heat water in an internal tank by converting electrical energy into heat. The formation of limescale (or scale) on its surface can lead to poor heat transfer, overheating or failure. Regularly inspect and, if necessary, remove scale from its surface using a descaling agent.

Do-it-yourself water heater: choosing the type of device

Despite the fact that it is much easier to make a storage device at home, you should first of all consider the option of assembling an instantaneous water heater. Such household appliances will allow you to instantly heat water, and electricity will be consumed only when the device is turned on. Unlike boilers, installing a flow-through device does not require much space, and you also do not need to insulate the device.

To heat water, both options use a heating element, but to make a flow-through device you will need to purchase a more powerful element.

Powerful water heating element

Of the additional parts, you cannot do without the use of an RCD. This device will automatically disconnect the contacts if an electrical leak occurs. You should also stock up on large-section copper wires and tools for the job.

Tubular heating elements for boilers

The tubular electric heater - heating element was invented in the middle of the 19th century; over the 158 years of its existence, it has become an indispensable element of many household appliances associated with active heating of water. The heating element for a water heater is the main part - without it, normal operation of washing machines and dishwashers is impossible, not a single electric boiler will be able to heat water in the absence of this component.

Recommendations for use

The operating rules for the water heater suggest turning off the hot water riser, after which you need to open the taps on the water heater and turn on the power supply. Turning off the boiler involves turning off the power, after which you need to turn off the taps on the water heater and open the hot water riser. When bathing, the water should be turned on and off as needed. It is not recommended to let hot water flow continuously.

In case of prolonged non-use, as well as in the process of carrying out repair and any preventive work related to the water supply line, it is necessary to close the individual shut-off valves located on the cold water supply line and on the hot water supply line, and also be sure to turn off the water heating equipment and disconnect it from electrical networks.

Problems that occur

Here is a short list of common malfunctions in the operation of heating elements.

- When cold water runs out of the tap, this is a signal that there has been a violation in the connection between the heating element and the thermostat.

- If the product turns on and then turns off, this is the first signal that a rather thick scale or layer of limescale has formed on the heater.

- When, during self-installation, the user makes various mistakes due to inexperience, a very impressive air cushion can appear in the container. which prevents the heating element from heating the water.

It is much easier to prevent any malfunction than to fix it later, with some effort and financial investment.

What container to make a tank from?

Any corrosion-resistant container is suitable for this.

- The tank can be made of enameled metal, stainless steel, plastic or other containers.

- Containers coated with a layer of glass ceramics and enamel will require replacement within a year after use, since they are not particularly resistant to corrosion.

- If the tank is made from a metal container, then a welding machine will be needed to manufacture the structure.

- Much more durable and reliable than stainless steel containers.

- To make a boiler, you can use a gas cylinder. It is advisable to purchase a new one, but if this is not possible, then you can make a tank from a used cylinder. The cylinder is cut into two parts, thoroughly cleaned and primed. This should be done so that the water entering the container does not smell of propane.

Four holes are made in the selected container:

- one for the tap through which hot water will be poured;

- one for supplying cold water;

- two for mounting a coil with coolant.

How to monitor the condition of the heating element

To promptly monitor the condition of your water heater, you need to follow these recommendations:

- Pay attention to how quickly the water heats up. If the speed has changed, this may be a sign that the heating element will soon fail;

- Monitor the electricity consumption when heating water. If consumption has increased, this is not a good sign.

If you have any suspicions, invite a specialist or try to determine the possible malfunction yourself.

The presence of a coat of scale indicates the need for repairs.

In general, manufacturers advise changing the anode in the heating element every 12 months. If there is no scale, it is quite difficult to visually determine the presence of a malfunction. To do this, you will need a special device - a tester.

Sources

- https://masterprof.net/academy/poleznoe/ten-dlya-vodonagrevatelya-kak-vybrat-zamena-ustroystvo/

- https://teplosten24.ru/trubchatyj-nagrevatelnyj-element-dlya-vodonagrevatelya-chto-eto.html

- https://HouseChief.ru/tehn-dlya-vodonagrevatelya-chto-takoe.html

- https://polymernagrev.ru/nagrev-v-proizvodstve/vidy-elektricheskikh-tenov-dlya-nagrevatelej/

- https://znayteplo.ru/otoplenie/elektricheskie-kotly/teny-dlya-vody-vozduxa-i-drugix-sred/

Main types of breakdowns

Modern manufacturers have learned to create excellent luxury water heating equipment. It uses gas to operate efficiently and rarely fails. However, even the best gas heaters cannot avoid breakdowns. The list of inevitable malfunctions includes:

- water leaks;

- poor heating of the liquid;

- discharge of power elements;

- weak water pressure;

- lack of gas.

Owners of gas boilers can repair some faults themselves. Anyone can change the batteries in the power supply. It is also easy to eliminate weak water pressure - perhaps excess scale has simply formed in the heat exchanger. To remove it, remove the heat exchanger and rinse thoroughly. For these purposes, you can also use special descaling liquids.

It is not difficult to solve the problem of poor water heating on your own. The main reason for such a malfunction is often contamination of the heat exchanger with soot. The solution to this problem is to remove the mentioned element and remove plaque. If more significant problems occur, you should contact a professional.

Those who have seen enough of the video on YouTube about a homemade gas water heater, which consisted of a coil placed directly on the hob in the kitchen, have probably already dreamed of how they can get a lot of boiling water cheaply. Actually this is not true. Today we will talk about why you should not make a gas water heater with your own hands.

Types of solar collectors

The standard device has the form of a metal plate, which is placed in a plastic or glass case. The surface of this plate accumulates solar energy, retains heat and transfers it for various household needs: heating, water heating, etc. Integrated collectors come in several types.

Cumulative

Storage collectors are also called thermosiphon collectors. This DIY solar collector without a pump is the most profitable. Its capabilities allow you not only to heat water, but also to maintain the temperature at the required level for some time.

This solar heating collector consists of several tanks filled with water, which are located in a thermal insulation box. The tanks are covered with a glass lid, through which the sun's rays shine through and heat the water. This option is the most economical, easy to operate and maintain, but its effectiveness in winter is practically zero.

Flat

It is a large metal plate - an absorber, which is located inside an aluminum case with a glass lid. A do-it-yourself flat-plate solar collector will be more efficient if you use a glass cover. Absorbs solar energy through hail-resistant glass, which transmits light well and practically does not reflect it.

There is thermal insulation inside the box, which can significantly reduce heat loss. The wafer itself has low efficiency, so it is coated with an amorphous semiconductor, which significantly increases the thermal energy accumulation rate.

When making a solar collector for a swimming pool with your own hands, preference is often given to a flat integrated device. However, it copes just as well with other tasks, such as heating water for household needs and heating a room. Flat is the most widely used option. It is preferable to make an absorber for a solar collector from copper with your own hands.

Liquid

From the name it is clear that the main coolant in them is liquid. A do-it-yourself water solar collector is made according to the following scheme. Through a metal plate that absorbs solar energy, heat is transferred through pipes attached to it into a tank with water or antifreeze liquid or directly to the consumer.

Two pipes approach the plate. Through one of them, cold water is supplied from the tank, and through the second, already heated liquid enters the tank. Pipes must have inlet and outlet openings. This heating circuit is called closed.

When heated water is directly supplied to meet the needs of the user, such a system is called open-loop.

Non-glazed ones are more often used to heat water in a swimming pool, so assembling such thermal solar collectors with your own hands does not require the purchase of expensive materials - rubber and plastic will do. Glazed ones have higher efficiency, so they are able to heat the house and provide the consumer with hot water.

Air

Air devices are more economical than the above-mentioned analogs that use water as a coolant. The air does not freeze, does not leak, and does not boil like water. If a leak occurs in such a system, it does not cause as many problems, but it is quite difficult to determine where it occurred.

Self-production does not cost the consumer much. The sun receiving panel, which is covered with glass, heats the air that is between it and the heat-insulating plate. Roughly speaking, this is a flat-plate collector with space for air inside. Cold air enters inside and, under the influence of solar energy, warm air is supplied to the consumer.

Such options are durable and reliable and are easier to maintain than devices that use liquid as a coolant. To maintain the desired air temperature in the cellar or to heat a greenhouse with a solar collector, just this option is suitable.

Prices and what do they depend on?

As for specific figures, water heaters produced in Russia will cost approximately 700-800 US dollars. We are talking about a vacuum type model. Approximately the same prices for similar Chinese products. Water heaters from German manufacturers cost approximately 800-900 euros. It is more expensive, but they come with the necessary fasteners, and copper and stainless steel are used to make the collectors. So the money will not be wasted.

Water heater Viessmann Vitosol 200 The price of a solar water heater is influenced by the following factors:

- Brand;

- Housing and heat sink material;

- build quality;

- method of laying insulating material and the cost of the material itself;

- glass thickness.

Naturally, the price reflects the design differences discussed above.

Electric indirect heater

The use of heating elements does not apply to indirect heating methods, since there is direct contact of water with the primary heat source. An exception is the induction water heater. The liquid receives energy virtually, as it were, without touching the internal thermoelement. In fact, it is not in the design at all.

The main advantage of the system is that heating occurs not due to direct thermal contact with a source of electrical energy, but with the help of eddy currents. Losses on the heat transfer coefficient are minimal, efficiency tends to 100%. At the same time, both the metal pipe and the liquid itself are heated (if it is sufficiently thermally conductive). In addition, flow-through induction heaters are significantly safer than boilers with a traditional electric heater: there is no contact of water with an element connected to the electrical network.

The disadvantage is obvious: heating requires an electrical connection. That is, the option of indirect heating using a wood-burning (gas) boiler does not work. The room must be electrified.

Electric water heater market overview

Currently, there are a larger number of manufacturers, both domestic and foreign, on the Russian market of electric water heating equipment. Of course, foreign manufacturers such as MTS and Lorenzi Vasco mainly dominate, but their products cannot be called pure imports. Most companies open their own full-cycle production facilities in Russia, with the production of basic components. This allows us to reduce the cost of production and make it available to a wide range of buyers. One of such companies is the Italian corporation Thermex, whose products have almost become a Russian brand.

It has been successfully operating in Russia for more than twenty years, opening its own factories and providing our market with high-quality electric water heaters. The product range from this manufacturer includes all types of electrical equipment for heating water. The popularity of the Termex water heater among consumers is very high due to the innovative ideas used in its manufacture. The operating principle of the Termex water heater, regardless of the type of device, does not differ from similar products from other manufacturers. But it should be said right away that the company’s products have won the trust of the Russian buyer with their technical characteristics and affordable price.

Why are water heaters from Thermex Corporation so good? Everything is very simple! The product range is very wide and allows almost any consumer to select water heating equipment to suit their needs. Termex electric storage water heaters are available in a wide range of internal volumes from 10 to 300 liters. Flow-through heaters of varying power allow you to almost instantly heat running cold water to the required temperature.

Other advantages of Termex electric water heaters include the following technological and design features:

- the model range of storage water heaters consists of both round and flat models of various volumes with a laconic design;

- high-quality thermal insulation of products and automatic control of operating modes allow significant energy savings;

- various models use both electronic and mechanical control, which allows you to optimize the entire water heating process;

- storage water heater tanks are made of special stainless steel with high corrosion resistance;

- in instantaneous water heaters, the heating module is made entirely of copper, which increases its reliability and durability;

- In some models of storage water heaters, the inner surface of the tanks is covered with bioglass porcelain, which completely eliminates corrosion of the tank.

In addition, the product range includes electric water heaters with a combined water heating system.