Modern apartments have a low level of sound insulation. This is mainly due to the fact that sound insulation is not used during construction, and as a result, while sitting in your apartment, you can hear what your neighbors are talking about. Constant noise can not only ruin your mood, but even cause harm to your health. A nervous breakdown is one of the problems that you may encounter. The problem can be solved if you make high-quality and complete sound insulation of the apartment.

@Sumanet

How you want to come home after a working day and relax. It would seem that it is complicated, but in modern apartment buildings it is very difficult to achieve silence. Despite the abundance of soundproofing building materials, not all developers take soundproofing of apartments seriously, so you have to do everything yourself.

The most effective way of soundproofing is an integrated approach. As a rule, comprehensive sound insulation is done during renovation. Unfortunately, not everyone can drop everything and start repairing, because such activities take a lot of time and effort. There are options that allow you to protect your apartment from extraneous sounds, even without repairs, and this is what will be discussed in the presented material. Sound insulation after repairs has been made is possible, but its effectiveness will differ from that installed initially.

What noise can disturb

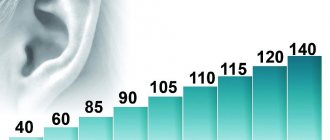

As you know, there are two types of noise: airborne and vibration. As for the first option, judging by the name you can understand that it is transmitted through the air. Such noises include: neighbors talking behind the wall, a working TV, loud music playing, etc. There is also vibration noise that can be transmitted over hard surfaces. Often such vibrations are created by power tools or household appliances. It is possible to protect an apartment from such noise even without renovation. Effective noise protection can be done using:

- rearrangement of furniture;

- use of textiles;

- replacing doors;

- gluing sound-absorbing wallpaper.

By following all the recommendations, you can achieve the expected result, but only in a comprehensive solution. If you protect one wall and everything else remains the same, then such work will not bring results, but with a comprehensive solution to the problem, everything will definitely work out.

Floor insulation

The most common, inexpensive and easy-to-use method is to install a so-called “floating” floor. No, no, you won’t flood your neighbors, and your apartment won’t become the new Venice. The name was formed on the principle of forming a “pie” of the floor - the screed is not laid directly on the floor slab, but through a layer of sound insulation. Stone wool slabs are laid as insulation, covered with film on top and filled with screed. After drying, the finishing floor covering is installed. There are modern roll insulating bases. Their properties as a barrier to sound are slightly worse, but there is a space saving if this is important to you.

There is also a frame method of sound insulation. The floor is mounted on logs, which are attached to the base using anti-vibration pads. The space between the joists is filled with insulating material. The entire structure is covered with chipboard sheets, plywood or floorboards at the request of the apartment owner.

In addition to the above, if ZIPS slabs are for the floor. They are equipped with everything necessary for installation, are easy to install even by inexperienced craftsmen, and the quality of insulation is quite high.

A professionally installed floor allows the owner of the apartment not to hear relatives walking in the rest of the home, and also allows the neighbors below not to disturb you or hear your movements.

Furniture absorbs sound

Coziness and comfort in the house depends primarily on pieces of furniture. If you install a bookcase on the entire wall in a room, the noise level will decrease significantly, since the furniture is able to absorb various sounds. When soundproofing is done in an apartment, the main task of the measure is to increase the thickness of walls and partitions for effective protection.

@Sumanet

Furniture installed along the wall is able to hold sounds without letting them pass further. Of course, in terms of efficiency, this option is less productive than special sound insulation, but, nevertheless, you will not hear so much what the neighbors are doing or who is going up the stairs.

A good option for a room could be a large closet or wardrobe. In most cases, such furniture is intended for clothing, so given the thickness of the furniture walls and hanging items, we can say that the noise level will decrease significantly. Previously, people often installed bookshelves and shelving all over the wall; this option is also effective, since, despite the open type of construction, it accommodates books of varying thicknesses, and this in turn helps absorb noise.

Textiles absorb sounds

As you know, soft surfaces can absorb sounds, and the more textiles there are in the apartment, the more effective the sound insulation without repair. For soundproofing without repairs, you can first lay a carpet or rug on the floor. If we consider coatings in terms of efficiency, carpet will absorb sound much better, but from an aesthetic point of view it is worth giving preference to carpet.

@Sumanet

As an option, you can even hang carpets on the walls as our grandparents did. Soundproofing will be good, but modern decor doesn't have room for a hanging rug. You can hang a carpet on the wall, if it is somehow unique or designer, then you can try to fit it into the interior design. Recently, various tapestries on the walls and blackout curtains are increasingly being used to decorate apartments. Basically, this decor option is suitable for the classic style, and if the existing environment contains some products of this style, then you can try it.

Thick curtains can be hung not only for windows, but also on walls; such an addition will look good. The bedroom and living room will look especially relevant. If we are already talking about the bedroom, then in this room you can improve the soundproofing characteristics by using a soft finishing option. Modern finishing materials allow you to make your home more neat and secure even without renovation. Recently, the use of large beds with huge headboards has been in fashion. In addition to aesthetic beauty, such beds also help reduce noise. It does not matter whether the headboard is made of solid wood or using other materials. This bed will fit perfectly into the bedroom interior and can improve soundproofing qualities.

@Sumanet

Constant development of finishing materials today offers customers a large selection of overlay panels made on a fabric basis. The main advantage of such surfaces is that you do not need to make a full repair to install them. You can do everything yourself using a minimal set of tools. Overlays can use a fabric or paper backing. In the second option, these can be full-length apartments, portraits and landscapes. Often people use all kinds of decorations hanging on the walls to highlight their interior. Of course, from a design point of view, such additions are not always relevant, but in cases of noise insulation, it’s really nothing.

Sound and vibration insulation from internal sources in a residential building

Author: Alexander Boganik

The topic of architectural and construction acoustics is quite extensive; it is no coincidence that in Soviet times, separate scientific institutions dealt with its different areas. Therefore, in order to cover in more or less detail the main issues of acoustic comfort in modern construction, it was decided to create a special “acoustic” series of articles.

Each of them will be devoted to a separate subsection of this specific, but extremely important task for comfortable living - to remove excess noise and vibration where it is not needed, but to provide the required sound parameters where it is necessary.

In the first part of the first article we will talk about the problem of sound insulation from internal sources located in a multi-storey residential building. Existing types of noise in the building will be considered, as well as design options for insulating impact noise. We’ll also talk about structures for insulating airborne noise and the reasons for their lack of effectiveness.

Sound and vibration insulation from internal sources in a residential building

Part I. _ Types of noise, designs for insulating impact and airborne noise

Basic principles of additional insulation

So, the building has already been built. Now you can long criticize the designers who include “cardboard” walls and ceilings between apartments in the project. You can scold the builders (by the way, they are no strangers) who completed the project with deviations and in the direction of reducing the cost. But the fact remains a fact. The walls and ceilings are connected to each other in a box, windows and doors are inserted. Utilities have been supplied, and some are even connected (heating). The house is rented. +++++

With the exception of interior partitions in apartments with an open plan, the question of own sound insulation of enclosing structures is no longer raised. The point concerns their additional sound insulation, if necessary. Unfortunately, for residents and to the delight of sellers of soundproofing materials, in 90% of cases there is a need to increase sound insulation.++++++

According to the inexorable laws of physics, effective additional sound or vibration insulation is possible only if elastic and non-rigid connections are provided between existing load-bearing structures and additional slabs (panels). +++++

The practice of soundproofing work shows that this is one of the basic principles of additional soundproofing , ignoring and disrespect for which leads to a decrease or absence of the effect of the event as a whole. This is equally true for both sound insulation measures and vibration protection tasks. This is where the main difficulty lies in performing effective additional sound insulation, because the requirement for “compliance” of connections between building structures contradicts modern ideas about the quality of finishing work in construction.++++++

To prevent the inner corner of the plasterboard cladding from subsequently causing a hairline crack, it should be reinforced as firmly as possible with a metal corner and sickle. But exactly as firmly as this angle is fixed, the acoustic effect will decrease if the soundproofing cladding structure here is connected to an external street wall, which is an indirect conductor of structural noise.++++++

Or another example. The standard sequence of construction work: “installing a screed - leveling the walls” leads to the fact that the elastic edge gasket along the perimeter of the soundproofing floor, designed to separate the surface of the floor and the wall, is “buried” under centimeter-thick layers of plaster and putty. This also reduces the sound insulation of impact noise by the floor. As a result, everything seems to have been done, the material has been applied, the work has been completed, but the clicking of heels from above interferes with living and relaxing... ++++++

And these are just a few of thousands of examples of conflict between “construction” and “acoustics”. This is precisely what explains why at large (massive) facilities, even where reasonable soundproofing measures were provided, the results are far from design expectations. Practice shows that only conscious compromises on finishing options and total control over construction work make it possible to obtain the expected effectiveness of soundproofing measures. Therefore, other things being equal, the highest results are achieved at facilities where the customer and controller is the apartment owner himself, who is personally interested in the effect. For this reason, despite the “aesthetics of smooth corners,” he will be able to agree with the presence of skirting boards or layouts covering joints with non-rigid connections. +++++

Thus, “quiet” and “beautiful” often become irreconcilable opponents, which only the customer can judge. But the latter, shielded from the problem by an uncompromising architect or interior designer, does not even know about it. Unfortunately. Until you move into your new home... ++++++

Main types of noise in a building

Noises propagating in a building can be divided into three types: impact, airborne and structural (Fig. 1). +++++

Rice. 1 Diagram of noise distribution in a building

At the same time, impact and airborne noise, differing in the method of occurrence, are included in one group that unites them according to the principle of local (point) impact on a specific wall or ceiling. +++++

Airborne noise hits an obstacle after it has been emitted into the air. The source could be a scream, a barking dog, or a running speaker system. In this case, it is important that it simultaneously affects all surfaces in the room.

Impact noise arises directly from the mechanical impact of any object on the ceiling (the knocking of shoes, the movement of furniture, objects falling on the floor). As noted above, this is a local impact. And on the one hand, this makes it cheaper to combat it at the source (elastic padding underfoot), on the other hand, in the absence of proper protection, the level of exposure is higher than that of most sources of airborne noise.

At the same time, the ability to insulate a particular enclosing structure is assessed from its other side - in the premises of the neighboring apartment. For each type of structure (wall, door, window) for various types of premises, the updated SP “Noise Protection” specifies the standard values of the airborne noise insulation index, designated Rw. For interfloor ceilings, additional permissible levels of impact noise under the ceiling are given, Ln,w.++++++

The fact that for floor structures an additional impact noise level indicator has been introduced in the construction regulatory documentation indicates that the problem of ensuring the required sound insulation of floors is at least twice as complicated. This is confirmed by practice - according to statistics, more than half of residents’ complaints about increased noise can be classified specifically in the category “noise from neighbors above.” +++++

It is necessary to say a few words regarding the standard itself and the methodology for assessing the level of impact noise under the ceiling. If an increase in the airborne noise insulation index Rw indicates an improvement in the sound insulation characteristics of the floor, then with regard to the impact noise insulation index the situation is the opposite. The better the ceiling “copes” with the knocking of heels, the lower the noise level in the room below it. When carrying out impact noise tests, a so-called “poplar” machine is installed on top of the floor in a special chamber, which hammers the floor with specially calibrated hammers at a given frequency. The noise level of machine shot measured in the room below, adjusted for standardization of measurements, is called the “reduced impact noise level index”. Thus, the lower the given index Ln,w, the better the floor design from an acoustic point of view.++++++

Structural noise is classified not by the method of excitation, but by the principle of propagation: it is transmitted through the structural elements of the building (through the structure of the building). And its cause may be noise of both impact and air excitation types. But when it spreads through the building envelope, this becomes less important - the noise is heard from all surfaces and only an integrated approach to sound insulation can somehow solve the situation. When someone starts working with a hammer drill across the floor (or maybe two, and even in the next entrance), it is the structural noise that brings you the news that your neighbors in the house have begun a major renovation and, judging by the scope of the work, this will last at least three months . The low-frequency echoes of a home theater coming from a neighbor living two floors below are also his work. The noise that occurs when the elevator operates and spreads throughout all the walls and ceilings of apartments on the top floors also falls into this category.

The most unpleasant thing is that the ability of building structures to insulate structural noise in joint ventures is still not regulated. However, if acoustic comfort is really needed in an apartment in a multi-storey building, it is usually impossible to do without comprehensive measures to isolate structural noise.++++++

Impact noise insulation

In modern house construction, regarding the required sound insulation of enclosing structures, the concept is as follows: the required amount of airborne noise insulation is ensured by the proper massiveness (material density and thickness) of building elements. This issue is mainly resolved at the capital construction stage. For example, the thinnest hollow-core reinforced concrete floor slab with a thickness of 140 mm, used for residential construction, shows an airborne noise insulation index in the region of Rw = 49 - 51 dB. Provided that a leveling screed with a thickness of 40 - 60 mm is applied to it, the total index may well be equal to Rw = 52 dB, which is required, according to the standards of the joint venture “Noise Protection”, for inter-apartment walls and ceilings in residential premises. +++++

At the same time, with regard to impact noise insulation, the required standards are always and everywhere ensured by additional structures of soundproofing floors. This means that if the house is delivered at the “unfinished apartment” stage, when the floor is only a load-bearing floor slab, this structure simply does not exist yet. If you open the design of this building, it is there. On paper. But this in no way guarantees that such a design will appear in your neighbor’s apartment above, will theoretically comply with the standards, and, most importantly, practically after production will effectively perform its acoustic functions.++++++

The situation is such that the peace of the neighbors below is entirely in the hands of the neighbor above. Sometimes these hands do everything wrong, forgetting that the situation is similar on the floor above. And in turn, his own “neighbor from above” may unpleasantly surprise him by “forgetting” to carry out such a necessary construction of a soundproof floor. The previously mentioned “bare” floor slab with a thickness of 140 mm shows an index of the reduced impact noise level in the region of Ln,w = 80 dB. Moreover, according to SP standards, it should be no more than Ln,w = 60 dB! Thus, ∆Ln,w = 20 dB separates such a design from standard indicators, taking into account the fact that the standards themselves do not guarantee complete acoustic comfort and are rather sanitary.

Therefore, if you have purchased a new apartment in a newly built building or the neighbors above have started renovations with a change of flooring, it is extremely important to take the initiative and find out what kind of soundproofing floor design is planned, and whether it is planned at all. Otherwise, the impact noise that hits the ceiling becomes structural and in the apartment below is emitted not only by the ceiling, but also by almost all the walls. And sometimes you can even clearly hear it from the floor. +++++

At the same time, today the most effective structures used on the side of the room below provide a maximum of ∆Rw = 20 dB of additional insulation with a thickness of more than 150 mm. And materials for impact noise insulation used on the floor of the upper room, with a result of ∆Ln,w = 20 dB, are at the very beginning of the list of effective gaskets and at the same time have a thickness of no more than 5 mm!++++++

To ensure impact noise insulation in buildings with reinforced concrete floors, what can be called a “classical” design scheme for a soundproofing floor on an elastic base is used – the so-called “floating” floor. In this design, the leveling screed is laid on the ceiling through a fairly thin elastic gasket (from 3 to 20 mm), which is then “trough” placed on the walls and all other vertical elements (columns), and also “wraps” the utility lines passing through the ceiling ( heating and water supply pipes). This is necessary to exclude indirect routes of noise transmission. And the successful result of the entire event depends on how “clean” and carefully all the edge gaskets are done.++++++

Acoustic efficiency depends on how soft the elastic layer is used in the structure - the dynamic modulus of the effective material should be no more than Ed 0.2 MPa. Impact noise insulation depends on the thickness of the elastic layer, as well as on the mass of the leveling screed laid on top. To ensure the strength of the screed, “floating” floors are recommended to be reinforced with a metal mesh, since otherwise, if cracks form, the broken piece of the soundproofing floor can practically be removed by hand, since it is not connected to the ceiling or the wall. +++++

Interesting observations were made at mass construction sites, where investors decided to install a soundproofing floor on the ceiling when renting out “unfinished” apartments. A good solution was ruined by its implementation. The reinforcing stack was not laid and the screed was cracked. Half of the apartment owners, when carrying out repairs, easily threw cracked pieces of soundproofing floor into the trash. If we also take into account that the floor level dropped by up to 80 mm and, accordingly, the height of the ceilings increased, we can understand the joy of the new owners from the completed operation. It’s just unknown how many residents then restored the soundproofing structure. I believe that there are only a few. +++++

Today there is a huge selection of materials on the market that can be used with greater or lesser success under the screed as an elastic layer. These are all kinds of materials based on polyethylene foam (PPE), polyurethane foam (PPU), polystyrene foam, cork, rubber, synthetic and mineral fibers.++++++

Among this multitude, I would like to highlight several materials that have the highest acoustic properties. First of all, this is a system of soundproofing boards “Shumostop” with a thickness of 20 mm (Fig. 2). The system consists of “Shumostop-S2” fiberglass slabs, which act as the main working layer, as well as “Shmostop-K2” high-density basalt slabs, which act as edge slabs designed to increase the stability of the floor base along the perimeter of the room and around the columns (Fig. 3). This is just a variant of a successful, calculated and proven compromise between “construction” and “acoustics”, when measures to ensure operational stability do not worsen the acoustic properties of the structure. +++++

Fig. 2 Diagram of a “floating” floor for impact noise insulation

Fig.3 Layout of Shumostop-S2 and K2 slabs in front of the floating floor screed

When installing a reinforced leveling screed on top of the “Shumostop” slabs with a surface density of at least 100 kg/sq.m, the impact noise reduction index is ∆Ln,w = 39 dB. This makes it possible to satisfy the most stringent requirements for impact noise insulation with a large margin for any thickness of the load-bearing floor slab. For example, the sound of a glass bottle breaking on the floor in the lower room will be perceived as the fall of a light coin. This is an example of a material whose use provides real acoustic comfort in the room below. +++++

Thin rolled material “Shumanet-100Combi”, only 5 mm thick, laid under a screed with a surface density of at least 100 kg/sq.m, ensures a reduction in the impact noise level by ∆Ln,w= 26 dB, which is a good way to reduce noise from neighbors from above, having agreed with them about laying this material under the screed during the repair. “Shumanet-100Kombi” is also well suited for mass use, since the technology for installing a soundproofing floor on it is the simplest, and the total thickness of the structure is about 60 mm, suitable for use in apartments with low ceilings. At the same time, for floors of any thickness (from 140 mm and above), the use of a soundproofing floor using the Schumanet-100 Combi material will always ensure compliance with the standards of the current joint venture regarding impact noise insulation. Although this has nothing to do with acoustics, one cannot fail to mention another pleasant property of the Schumanet-100Combi. Along with high soundproofing characteristics, it is also a complete waterproofing material. And if during its installation all conditions related to protection from water are met, you can count on it in appropriate force majeure situations. +++++

It should be noted that the materials mentioned above, with a thickness of no more than 20 mm, are, first of all, impact noise insulators. Their ability to reduce noise in the room below is manifested only when used as an elastic gasket in the construction of a “floating” floor in the apartment above . The use of these materials to increase sound insulation by applying them to the ceiling or walls from the side of the lower room is impractical and devoid of any practical meaning.++++++

Airborne noise insulation

As mentioned above, issues of own sound insulation of enclosing structures in the context of a multi-storey residential building relate mainly to interior partitions, and in apartments with an open plan. To this we can add cases when the layout is not free, but the interior partitions are not load-bearing, and they can be dismantled and reassembled. +++++

The question immediately arises: which interior wall is better in terms of sound insulation? There are several options available. These are single-layer structures, which include brick, foam block, plaster walls, as well as light frame partitions with the undisputed leader - plasterboard sheet (GKL) as a facing layer.++++++

In addition to the main task - sound insulation between two adjacent rooms of one apartment, interior partitions participate in the general process of transmission and radiation of structural noise in the building. That is, its own sound insulation may be good, but such a wall will happily “respond” to noise from neighbors coming from different directions, and will do this much louder than load-bearing and external walls. We will try to give each of the above structures a double acoustic characteristic: to evaluate its own insulation of airborne noise, as well as its ability to insulate structural noise. And if the first characteristic can be expressed in the values of the Rw index, then regarding the insulation of structural noise we will use the “school” scale: “excellent”, “good”, “average”, “bad” and “very bad”. +++++

The results are shown in Table 1:

| Name of the interior partition design | Airborne noise insulation index, Rw , dB (own sound insulation, laboratory measurements) | Structure-borne noise insulation |

| I. Single-layer structures | ||

| 1. Brick partition made of red slotted brick 120 mm thick, plastered on both sides | 44 | very bad |

| 2. Brick partition made of red solid brick 120 mm thick, plastered on both sides. | 47 | Badly |

| 3. Brick partition made of red slotted brick, 120 mm thick, plastered on both sides. The internal voids are filled with calcined sand. | 48 | average |

| 4. Brick partition made of red solid brick 120 mm thick, plastered on both sides, installed on elastic “Sylomer” gaskets, followed by hard putty along the vertical joints. | 48 | Fine |

| 5. Brick partition made of red solid brick 120 mm thick, plastered on both sides, installed on elastic “Sylomer” gaskets with non-rigid sealing of seams around the perimeter (Fig. 4a and 4b). | 48 | Great |

| 6. Partition made of foam blocks 150 mm thick, plastered on both sides. | 44 | Badly |

| 7. Partition made of gypsum blocks 80 mm thick. | 40 | very bad |

| II. Light frame-sheathing partitions | ||

| 8. Partition on a single metal frame 100 mm, lined with two sheets of plasterboard on both sides, total thickness 150 mm. The internal filling of the partition is 100 mm mineral slabs. The joints around the perimeter are puttied. | 52 | Badly |

| 9. Partition on a single metal frame 50 mm, lined on both sides with Soundline-dB and Akulain GKLA sheets, total thickness 110 mm. The joints around the perimeter are made through a vibration-isolating gasket "Vibrostek-M". The internal filling of the partition is “Shumanet-ECO” slabs 50 mm. | 56 | Fine |

| 10. Partition on a single metal frame 100 mm, lined on both sides with Soundline-dB and Akulain GKLA sheets, total thickness 160 mm. The joints around the perimeter are made through a vibration-isolating gasket "Vibrostek-M". The internal filling of the partition is “Shumanet-ECO” slabs 100 mm. | 59 | Fine |

| 11. Partition on a single acoustic profile “Vibroflex-WAVE” 100 mm, lined on both sides with sheets “Soundline-dB” and “Akuline GKLA”, total thickness 160 mm. The joints around the perimeter are made through a vibration-isolating gasket "Vibrostek-M". The internal filling of the partition is “Shumanet-ECO” slabs 100 mm. | 62 | Fine |

| 12. Partition on a double metal frame 2x50 mm, lined on both sides with Soundline-dB and Akulain GKLA sheets, total thickness 170 mm. The joints around the perimeter are made through a vibration-isolating gasket "Vibrostek-M". The internal filling of the partition is “Shumanet-ECO” slabs 100 mm. Each frame rests on a soundproofing floor structure and is adjacent to additional soundproofing structures around the perimeter (Fig. 5) . | 65 | Great |

Fig. 4 Structure-borne noise insulation device for a brick partition

4.a – the partition is installed on the elastic gasket “ Sylomer L 25”

4.b – at the joints of the partition with the ceiling and the external wall, the “Vibrostek” gasket was used

Fig.5 Diagram of a frame-sheathing partition on separate frames with structural noise insulation

As can be seen from the table, for practically the same structure it is possible to obtain significantly different values for both airborne noise insulation and structural noise insulation. And between the ratings of “bad” and “good” there are only elastic gaskets made of “Sylomer” or “Vibrostek” materials, placed at the junction of the frame (brick partition) and the adjacent enclosing structures. +++++

Even full compliance with the highest building standards for sound insulation of building envelopes does not guarantee complete silence in the room. The values of required sound insulation established by the joint venture are designed to guarantee compliance with maximum sanitary standards, the violation of which over a certain period of time can irreversibly affect the deterioration of human health. Moreover, all basic calculations on this topic were performed approximately fifty years ago. Over the past decades, the background noise in apartments (even not counting powerful sources, such as home theaters or Hi-End) has increased significantly. Currently, almost every apartment and every room has a TV, telephone, radio or stereo system. The kitchen and bathroom have a washing machine or dishwasher, extractor hoods and air conditioning. The home computer and other gadgets also contribute to the increase in overall background noise.++++++

Practice shows that for modern conditions, the airborne noise insulation index for interfloor ceilings and walls between apartments should be at least Rw = 60 dB (8 dB higher than the current norm). Only with this level of sound insulation can we really talk about acoustic comfort. However, even an overlap with an index of 60 dB will not be able to ensure complete silence in the bedroom if, for example, the neighbor upstairs decided to watch a disaster movie late in the evening with the speaker systems turned on at full power. At the same time, the airborne noise insulation index for interior walls, in our opinion, should be no less than Rw = 50 dB, which is also 7 dB higher than the current SP standards for this case. +++++

Therefore, if the sound insulation of existing enclosing structures is insufficient, it is increased with the help of additional structures . Increasing sound insulation by increasing the mass of the structure is considered an ineffective measure. Indeed, an increase in the thickness of a brick wall (from half a brick to a whole) leads to an increase in the Rw index by no more than 6 dB. At the same time, the load on the base doubles, and the thickness of the additional structure is 120 mm. +++++

The basic principles of effective additional sound insulation have been known for a very long time - lightweight multi-layer cladding should be used with alternating sound-absorbing and sound-reflecting layers. The sound wave, alternately passing through the layers, is absorbed, reflected in the opposite direction, absorbed again and, thereby, attenuates. Thanks to this, the soundproofing ability of this additional insulation design increases significantly. However, the whole difficulty lies precisely in the practical implementation of such structures. +++++

For traditional frame-cladding claddings, the presence of rigid connections (sound bridges) between the wall (ceiling) and the cladding frame significantly limits their soundproofing ability, despite the presence of an effective sound absorber inside, as well as several sheets of cladding. Through sound bridges, vibrations are transmitted practically losslessly to the finishing sheets of cladding and are safely re-radiated by them into the protected room. In this case, out of a potentially possible 10 - 15 dB of additional sound insulation, in fact only 2 to 6 dB remains with a total structure thickness of more than 100 mm. However, there is a powerful force that to this day “lobbies” for the implementation of such ineffective designs. These are builders and finishers who, guided by the desire to make everything as cheap as possible (in cost), stronger and more reliable, exclude even standard elastic gaskets from structures (such as the Dichtungsband tape produced by the Knauf concern), not to mention the more complex ones in installation of elastic elements.++++++

However, over the past 18 years, new types of frame and frameless cladding have been created and successfully implemented for additional sound insulation of walls and ceilings. A little later, in the second part of this article, we will look at the most common soundproofing structures, which are currently successfully used in modern construction to increase the sound insulation of enclosing structures.+++

+++

Doors can reduce noise

Not only walls, but also doors and windows need to be protected from sounds. With the advent of metal-plastic windows, the problem of sound insulation of this element has moved aside, since double-glazed windows effectively and reliably retain noise. The door is another matter. If you need effective sound insulation without repairs, then as an option you need to install heavy doors made of natural solid wood. The cost of such a product is quite high, but the effectiveness is noticeable. You will be able to feel the difference immediately after replacing the door.

If it is not possible to install new wooden doors, then it is worth choosing designs that use sound-absorbing materials. As an addition, entrance doors can be covered with leatherette, which will significantly reduce noise and sound levels.

Strengthening the pipe with a clamp

This measure will reduce resonance when water moves through the pipe. Clamps tightly attach the pipe to the wall and ensure its immobility. They fit very tightly onto the product thanks to the rubber seal.

Using special adapters, you can also soundproof the sewer system passing through the wall. Thus, vibration will not be transmitted to the structure, which will eliminate the appearance of unnecessary sounds.

In addition to soundproofing, experts advise enclosing sewer pipes with a plasterboard box. It will absorb sounds even more. True, this cannot be done everywhere, since such a device requires additional space.

Ceiling soundproofing

For high-quality sound insulation, it is necessary that the entire room is protected, and not just the walls and floor. The ceiling also needs to be soundproofed and this can be done in two ways. The first is to make suspended ceilings on a fabric basis. There are special sound-absorbing materials that absorb sound waves coming from the upper floor. As an option, you can also try to negotiate with your upstairs neighbors to have them soundproof the floors in their apartment. It is unlikely that anyone will agree to such alterations, however, as an alternative solution, you can ask to lay a carpet or paths. By offering to pay for the arrangement, something might come of it at your own expense.

Self-installation rules

Do-it-yourself sound insulation

When installing sound insulation yourself, you should not skimp on high-quality and easy-to-use materials. Experts recommend that beginners use polyurethane foam boards. They are elastic and easy to install on uneven surfaces.

The sound insulator should be secured securely. Wire is suitable for this and can be wrapped on top with plastic film and tape.

Bottlenecks and transitions should be treated with polyurethane foam.

Wallpaper can help

If you need to reduce the noise level in your apartment, but there is no need to completely renovate it, you can use sound-absorbing wallpaper as an alternative. As wallpaper materials, you can use cork, bamboo or wood made from wood chips. Such cosmetic repairs will take a little time and money, but the result will be effective. Acoustic wallpaper can be purchased in various thicknesses. The main distinguishing feature of this material is the porosity of the top layer. Thanks to the porous base, sounds are absorbed and do not penetrate the room.

Soundproofing ventilation with your own hands

Isolation of extraneous ventilation noise in an apartment can be done with your own hands; the work begins with preparatory measures. The sequence of actions is as follows:

- Clean the pipes from accumulated dust and evaluate the quality of the installation. It is necessary to carry out repair work if the passage elbows are not firmly secured, and the pipe sags in some places.

- Check the outlets of the pipe into the general ventilation system of the house, and if necessary, strengthen it.

- Calculate the main parts for installing mufflers.

- Carrying out noise insulation work using fiberglass or mineral wool for these purposes: wrap the ventilation pipe with a layer of heat-insulating material, lay foil insulation on top of it.

- Seal the seams of the heat-insulating material with aluminum tape, strengthen the transition points with a double wrap of adhesive tape.

The easiest way to carry out work to isolate excessive ventilation sounds from neighbors is to cover the pipe with polyethylene foam, preferably in 2 layers, and seal the resulting seams with adhesive tape. Special construction adhesive can also be used. A rubber plate will help get rid of shock and low-frequency sounds. This is a fairly soft material, so it will take the desired shape without much effort. The order of work is as follows:

- Measure out the required amount of material.

- Peel off the adhesive backing and cover the ventilation system.

- Tape the joints.

If there is no sticky backing, then you should use a special construction adhesive designed for metal and rubber products.

Rearrangement of furniture

Sometimes, in order to reduce the noise level in a room, rearranging the furniture is enough. The right combination will help reduce noise levels behind the wall. If you know which wall the sound is coming from, then you can put a TV on it, which during operation can muffle the noise coming from the neighbors. When it comes to the bedroom, it is better to move your bed to the opposite corner or wall of the room. Sometimes completely rearranging the rooms helps. If, for example, there is constant noise in the bedroom, but the office is quiet, then you can redirect the use of the rooms. Make a bedroom where it is quieter, and place the workplace in the remaining room.

@Sumanet

External protection

There is also an option for soundproofing the apartment, but it is designed to protect against noise coming from the street. By covering the walls with special finishing materials, you can protect your apartment from noise and cold in two ways.

Making your home cozy and comfortable is not difficult, especially if you know what to do and what materials to use. The list of modern materials allows you to bring any idea to life, and it will be not only effective, but also beautiful. Using various items you can reduce the noise level, but you should understand that reliable soundproofing of the apartment must be carried out during renovation. The temporary options proposed in the material will help, but you will still have to redo it. There are a lot of soundproofing options for an apartment and everyone can choose exactly what they need, the only thing you shouldn’t forget is that sooner or later you will still have to do repairs and then you need to take care of the soundproofing qualities of the home.

Soundproofing a bathroom: soundproofing methods

Cinemas and multiplexes

Video description

How to soundproof a sewer riser.

Soundproofing of a toilet riser is carried out only after a detailed consideration of the causes of extraneous sounds Source static.tildacdn.com

When soundproofing a bathroom, it is important to install high-quality doors. Even ordinary veneered ones will do if all the cavities inside the structure are filled with construction foam and mineral wool. You can perform this procedure yourself or use the services of specialists. In any case, you will have to disassemble the door.

Externally, soundproofed doors are similar to standard ones, but inside they are layers of soundproofing material Source doors777.ru

The flooring needs sound and waterproofing. To implement the latter, you can use bitumen mastics containing rubber. In order to vibration-proof the floor of the bathroom, it is possible to make a simple screed, then cover it with tiles.