In small apartments, it is necessary to correctly place furniture and things for a comfortable arrangement of the room. Multifunctional systems will help you cope with the task, many of which can be assembled at home. For example, an original bed with a lifting mechanism is made with your own hands based on ready-made drawings. By spending a little time and effort assembling a creative piece of furniture, you can save free space without depriving the room of comfort and coziness.

Preparation of the project and drawing

When choosing a ready-made solution or starting production from scratch, start planning:

- They think over the general design concept : how many people the bed will be designed for, whether there are drawers or niches. When choosing a size, take into account the parameters of the room - there should be enough free space around the furniture.

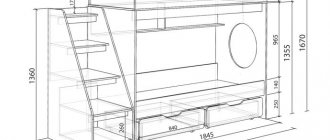

- A preliminary sketch or drawing is made with the main details: the base box and the frame for the mattress.

- Choose a mattress model . Only after the dimensions have been clarified do we begin designing. Otherwise, after making the bed base, you may not find a mattress of the right size.

- A detailed drawing of the base box, load-bearing frame, headboard and backrest is drawn up, indicating the method of fastening the parts together.

A detailed drawing is necessary to purchase materials and fasteners, as well as to prepare the missing tools.

Blueprints

The manufacture of a lifting bed structure begins with a detailed study of drawings and diagrams for fastening elements. The sketches must show the dimensions of the product components, methods of fastening the end and side parts, etc.

The design of the bed is a box, which is created from 4 slabs and 4 transverse elements for the bottom of the frame. When drawing up the drawing, the parameters of the mattress are taken into account; the length can vary from 180 cm, width - from 80 to 180 cm. It is necessary to determine the dimensions and dimensions of the bed, the number of beds.

Planned additional elements (shelves, drawers) are also marked on the diagram. When preparing, it is important to draw up a diagram for fastening elements with a lifting mechanism.

Materials and tools for work

To assemble a bed with a lifting mechanism, you will need the following tools:

- A circular saw if you need to cut parts along the length. It is difficult, sometimes simply impossible, to make an accurate straight cut with a jigsaw or a hand hacksaw.

- Drill or screwdriver with a set of drills and bits.

- Furniture stapler.

- Fasteners and hardware: angles, self-tapping screws, couplers, confirmats and furniture bolts with nuts and washers.

- Screwdrivers, hexagons.

- Tape measure, long ruler, rule or other object for drawing straight lines.

- Pencil or marker.

Depending on the design of the bed, purchase:

- Wooden blocks for the mattress frame.

- Laminated chipboard or planed boards for the base.

- Chipboard or furniture panels for backs.

- Plywood for the bottom.

- Lifting mechanism.

- Thick fabric for upholstery.

- Furniture edge for chipboard ends.

- Legs, if provided by the design.

Other elements provided by the design may also be needed.

Cutting chipboard into pieces of the required size can be ordered at large building materials stores, and the edges are glued there as well. The same services are provided by furniture workshops that exist in every city. Sometimes finished parts of suitable sizes are sold individually.

What are the advantages and disadvantages of handmade furniture?

Buying a new piece of furniture is an expensive option, despite the fact that it is not necessarily of high quality, strong and durable. In this case, many resort to independent production and collection of interior items. Let's consider the advantages and disadvantages of hand-made furniture.

If you don’t have enough money to buy such a ready-made bed, you can try making it yourself. First let's look at the disadvantages:

- Lack of experience can affect the quality of work. If you want to save on your purchase, you can pay twice as much. Lack of experience, inability to work, incorrect calculations can lead to serious mistakes.

- There is some danger in the work. Failure to operate certain tools can cause serious injury.

- You can't always save money. Sometimes it is much cheaper to purchase a ready-made product than to assemble it yourself, since the purchase of some materials can cost an impressive amount.

- Difficulty of the process. Despite the excellent end result, the process itself is quite exhausting. You need to be as focused and attentive as possible.

- You'll have to spend a lot of time. Making parts yourself and assembling them is a long and labor-intensive process.

Making such furniture yourself will require time and certain skills.

It is worth considering that there is a possibility that the final result may not turn out as expected. You need to be prepared for this. Considering all the disadvantages, you need to be sure that this process is necessary. Let's consider the advantages of making furniture with your own hands:

- There is an opportunity to take into account all your wishes. Finished products do not always fully satisfy consumer desires.

- Confidence in quality. When making furniture yourself, you can use the highest quality materials and have full control over the process.

- Pleasure from the final result. This point should not be overlooked, since pride in one’s creation is of great importance.

- Opportunity to save. It is not recommended to make this item a priority, but still the opportunity to reduce costs pleases many.

Making your own will help you make a bed taking into account all your wishes. Knowledge of negative and positive factors will help resolve the issue of making a lifting bed with your own hands.

Only by understanding all the intricacies of the process can you draw a conclusion about whether or not it is worth making such a bed yourself.

Manufacturing stages

Assemble the base frame to which the lifting mechanism, supports for the base of the mattress, headboard and lower back will be attached. Next, a folding base is made and the lifting mechanism is attached. After adjustment, the structural parts are finished.

Andrey Peregubsky

Furniture handyman

Ask a Question

If you have doubts about the correctness of the calculations, then you should start assembling with the lifting base of the mattress and, based on the resulting result, mark and assemble the bed frame.

Frame

The base is made of wood or chipboard. For installation, provide legs or support on side parts.

Manufacturing procedure:

- Prepare the sides of the base, attach legs or gaskets to them.

- On the inside, stops are installed for the movable base of the mattress. The stops are made in the form of jumpers or longitudinal linings on the sidewall.

- The side panels are connected to the headboard and lower backrest. For fastening, furniture corners, self-tapping screws or confirmats (Euroscrews) are used.

- Turn the resulting frame over and screw on the plywood bottom. It is not advisable to use fiberboard; over time, the edges will collapse and the bottom will be squeezed out.

The final finishing of the sidewalls is best done after adjusting the lifting mechanism.

Lifting base

The lifting base can be purchased assembled or made independently from wood; planed timber with a section of 50x50 mm and a board 25x100 mm, plywood are used.

It is important to take into account that the lifting part of the structure must be 1 cm narrower and shorter than the base box, so that it falls into place when lowered without friction on the sidewalls.

Operating procedure:

- The beam is sawed off to the required length: two longitudinal and two transverse.

- The parts are connected into a single structure using furniture corners and self-tapping screws.

- The top is fastened with plywood or cross boards.

Check the correctness of manufacture by attaching the lifting base to the lower frame.

Installation of the mechanism

The lifting mechanism takes on heavy loads when lifting the mattress, so it is important to choose the right installation location and fastening method.

Single and one-and-a-half-size mattresses can be raised to the headboard. Wide, double models are better along the sidewall, this reduces the load.

Due to the heavy load, the mechanism cannot be installed on self-tapping screws. Be sure to drill a through hole in the longitudinal bar and mount the lift with a bolt, washer and nut. The base of the mattress is secured in the same way.

To hide the head of the bolt, you can use an additional strip mounted parallel to the end one.

Another option is to hide the bolt with sheathing so that it does not turn when the nut is unscrewed; they use furniture bolts with a boss on the rod that fits into the through hole.

The installation diagram of the mechanism is necessarily indicated in the instructions, and the dimensions of the indents for drilling holes are also given there.

Before screwing the lifting mechanism, it is advisable to experiment with unfolding the part, making sure that the mattress will be raised to the desired height. At the same time, make sure that there is enough space left for the slight rise of the mattress, which is necessary to unlock the locking mechanism.

Types of beds with a lifting mechanism

Beds with a lifting mechanism are available with different types of opening devices, different sizes, configurations, and transformation methods.

Classification according to the type of lifting device is presented in 3 types: with manual lifting, with spiral springs, with gas shock absorbers.

The fastening with the help of coiled springs is easy to install and reliable in operation. The cost of the fastening system is affordable. However, springs wear out and stretch if the rules of use are violated. If several elements are damaged, the entire system will need to be replaced. The warranty period of the mechanism is no more than 5 years.

The lifting device on gas shock absorbers does not require physical effort during operation, providing easy access to the unit for things and bedding at the bottom of the bed. Gas devices allow you to move the stock to the open position silently and smoothly. When choosing a system, the dimensions and weight of the surface of the sleeping bed are taken into account. The devices are designed to lift bulky mattresses. Manufacturers issue a warranty on the operation of the mechanism for a period of up to 10 years.

Manual lifting of the sleeping bed (on hinges) due to the lack of auxiliary elements requires physical effort when transforming the bed. However, the strength and durability of the device is great. Manual mechanisms are not equipped with systems for smooth lifting and spring devices, and therefore have a low price. To access the bedding unit, you will need to remove the mattress. Mechanisms are not used in furnishing children's rooms.

Depending on the number of beds, there are single and double models.

Single-bed structures are compact, versatile, suitable for small spaces, allowing you to organize an additional place to relax. Models are often made in the form of an ottoman and placed in the corner of the room. Single beds with a lifting device are used in the design of children's and teenagers' rooms. A spring mechanism or gas shock absorbers are used for the configuration. The lifting system in narrow beds is mounted along the short parts.

Double designs are ergonomic, comfortable, suitable for compact spaces and teenagers' rooms. In the unfolded position, the design provides comfortable rest.

The mechanism in double models depends on the weight of the bed and mattress. For massive structures, gas shock absorbers are needed, for light ones - spring blocks.

In accordance with the number of furniture elements to be combined, there are lifting beds with a sofa, an ottoman bed, a resting place that can be transformed into a nightstand, etc. The sleeping bed can be built into a closet. The latest model is the easiest to design and assemble a lift-up bed with your own hands.

Beds also differ in the way they raise the sleeping bed: vertical or horizontal.

Point No. 3: main frame

| Illustrations | Recommendations |

| Array . To create the frame, a board with a thickness of 30–40 mm and a width of 200 mm is used. Only dry planed wood is used. At the final stages of arrangement, light sanding is allowed to correct minor defects. | |

Mounting holes.

| |

| Chamfer . The chamfer is removed from all frame boards and lightly sanded with sandpaper. | |

| Assembly . The ends of the boards are smeared with wood glue, joined and twisted with self-tapping screws. | |

| Stripping . As assembly proceeds, excess glue will protrude; it is advisable to wipe it off immediately. |

Mattress base options

Having decided on the dimensions, you can move on to choosing such an important part of the bed as the base for the mattress. Yes, of course, you can do without a mattress, replacing it with a non-removable filler from the same chair-beds and similar furniture, but at home this is extremely difficult to do, so most often beds are made for a mattress

They are like this:

Today it is already considered a relic of the past, but in some places you can still see a flat base. It consists of boards knocked together to form a wooden shield on which the mattress is placed. There are practically no advantages to this design (compared to more modern options), but there are a lot of disadvantages.

Firstly, the mattress deforms very quickly and loses its useful properties. Secondly, a dream with such a reason is not the most pleasant. Thirdly, the mattress is not ventilated, which is why it can become damp, which will lead to the appearance of various parasites in it or the onset of rotting, which is also not very pleasant.

Decorative elements

We have already talked about soft headboards, but this is far from the only way to decorate a homemade bed. Now on the market you can make to order or buy ready-made decorative elements for covering beds. This can be a small fragment or a whole carved wooden plate.

This decor looks luxurious, the only problem is that handmade work costs serious money. Alternatively, such plates can be ordered from a furniture workshop and made not from natural wood, but from MDF. There are machines that mill patterns in 3D projection.

Carved decor on a homemade bed looks luxurious.

Design

Hanging bed - an unusual design solution in the bedroom interior

Any bed, regardless of shape and configuration, consists of the following components:

- Frame

- Base

- Side and support panels

- Optional design elements (legs, hanging backrests, headboard, storage drawers, lifting mechanism)

A home-made sleeping place usually consists of a frame on which a base is installed - a mattress support. The supporting structure is made from:

- wooden slats (slats)

- metal mesh

- spring mechanism

Furniture for sleeping and relaxation can:

- have legs (most often no more than 20 cm high)

- be floor-standing (the frame is located directly on the floor)

- be suspended (fixed to the ceiling)

Original headboard for bed

The headboard is a decorative element that:

- carved from wood

- sawn from chipboard

- forged from metal

- upholstered with foam rubber and fabric

- can be carved and solid, straight and curved

In addition to the main functionality - a place to rest, the bed also serves as:

- closet

- stand

- sofa

- podium

In these cases, the mattress is hidden in the shell of the body during the day, and at night it is unfolded using a “book” mechanism or a gas lift.

Swimming pool at the dacha: device, step-by-step instructions for arranging it yourself | 65+ Photos & Videos

Legs

The simplest thing is to cut 4 legs from the timber, which will subsequently be located in the corners. Their fastening is carried out first with glue, then it is worth securing the structure with screws and bolts. For reliability, metal corners can also be placed at the fastening points.

The height of the legs is chosen solely for reasons of beauty and comfort. The optimal, most common option is 20-30 cm from the floor. Low beds are very stable, but if you plan to use the under-bed space for storing things or install drawers, you can make it higher.

Headboard

The headboard is installed last. There are a lot of options for its implementation, so there is no universal recipe for attaching it. The standard board version is attached with self-tapping screws to the side where the pillows will lie. Recently, original backrests have become popular, which are not part of the structure and are attached to the wall, and not to the base of the bed. This method of making a beautiful headboard is suitable for most models with the headboard facing the wall.

You can order an unusual backrest or make it yourself by stretching a foam upholstery hidden under textiles or leather onto a cut-out plywood sheet. The sleeping place can be without a backrest, if this is convenient for its owner.