The ceilings serve as a diaphragm of rigidity in the horizontal section of the house. They ensure the stability of the structure and serve as the ceiling for the lower floors and the floor for the upper floors.

To learn more about floors in the house, it is recommended to familiarize yourself with their features, types, purposes and requirements.

What does the concept mean?

The term “beam floor” refers to an element of a beam system, which is often used in a multi-story building. It is a horizontal supporting structure that serves as a height separator for the building. Floors are made of different materials, depending on the design features of the building.

The main differences between beam floors and others:

- the load-bearing element is the beams;

- they are mounted into walls at a certain distance;

- to obtain a complete horizontal structure, filler is placed in them;

- to arrange the floors, use wooden, reinforced concrete or metal products.

Unlike beamless floors, which are constructed from homogeneous elements, here the beams themselves act as the load-bearing part. If we compare these two types of floors, the significant difference is that in beamless structures the base is poured with concrete using reinforcement or can be prefabricated.

There are no solid elements in beam floors: the planks are laid from wall to wall and, after assembly, they are filled with flooring.

Lining the rough ceiling with plywood

Here the work will be carried out according to a slightly different principle. In particular, plywood has low load resistance. If the sheets are simply fastened between the beams, they are guaranteed to burst, damaging the finish coating.

Therefore, plywood hemming is carried out according to the following scheme:

- a waterproofing membrane is attached to the beams or joists;

- a frame is made from a wooden block of small cross-section on top;

- then the plywood is installed.

Considering that the installation is supposed to be on a frame base, it will not be possible to glue the sheets; they are screwed on with self-tapping screws or nailed with thin nails. After this, the structure is insulated and finished.

Types of floors

Beam floors can be divided into several types. They are divided by design, by the type of beams themselves .

By design

To begin with, it’s worth considering what kind of ceilings there are in design.

Monolithic reinforced concrete

The essence of such an overlap is not to make the slab too thick, but to concentrate the material in certain places, thereby reducing the weight of the overlap.

Such structures are very simple in calculations: the slab works only in one direction, a section is cut out of it and calculated like a beam. The same is done with the main beam. The monolithic slab rests on beams, which in turn rest on columns. Beams can be located both along and across the building.

Prefabricated monolithic

This solution is one of the most modern and is a lightweight but reliable design. It consists of :

- special beams;

- liner blocks;

- reinforcing frame and concrete.

This design makes it possible to carry out work in places with limited access to equipment. In this case, the slab turns out to be more even than a factory-made reinforced concrete product.

Prefabricated

This structure consists of panels or slabs, as well as beams that support them. Such planks are called crossbars; they rest on columns. The filler is often gypsum concrete or lightweight concrete slabs.

By beam type

Based on the type of floor beams, they can be divided into:

- wooden;

- metal;

- reinforced concrete.

In private housing construction, wood is often chosen.

They have minimal cost, light weight and easy installation. But such planks are prone to rotting and damage by bark beetles. Metal crossbars are more reliable and durable, but this option is not in demand among developers. They have good fire resistance and high load-bearing capacity. Such beams are prone to corrosion in places of high humidity and have a high cost.

Reinforced concrete planks can span large spans up to 7 meters long. They are reliable and durable

More information about the types of floor beams here.

Typical buildings of the USSR

Typical panel and brick 5-story houses began to be actively built during the times of Khrushchev, starting in 1957. The country needed cheap housing and as quickly as possible. That is why such projects were developed, some intended for the southern regions, others for the northern. The brick ones had a slightly better layout and room sizes.

The same serial project, built in different regions, could be slightly different. Different climatic conditions and the soils on which the construction was carried out made their own adjustments to the size of the five-story buildings. It is clear that each project differed in the height of the building.

Type series K7

Type series II-14

Type series II-05

Type Series 1605-AM-5

Type series 1-335

The length of a 5-story building with 4 entrances for a typical 5-story building of project 1-528-3k is 72.4 meters. It depended on the layout of the apartments and slightly on the thickness of the panels. The wall thickness of the panels ranges from 300 mm to 400 mm.

The length of the five-story building with 4 entrances is 72.4 meters

“Brezhnevki” were built until the end of 1980, and successful projects are being taken as a basis even now. They were not particularly different from the “Khrushchev” apartments, but the entrance area was larger, the flights of stairs were wider and a garbage chute was installed.

Requirements

The requirements are partially determined by SNiP 2.01.07-85 “Impact loads”, which states that floors must have the necessary strength to withstand their own weight, as well as the loads that act on them.

Structures in residential buildings must evenly withstand a load of at least 200 kg per 1 square meter . In private construction this figure increases, but for attics, on the contrary, it decreases.

The ceiling must also be rigid and not bend under loads. It should not be unsteady and not wobble when moving furniture on the floor or when people move. The ceilings must protect the room from the penetration of airborne and impact noise. According to SNiP, they should not be expensive to produce.

As a result, we can emphasize the main design requirements :

- rigidity;

- strength;

- availability;

- efficiency.

The beam covering material is selected based on where the structure will be used. Wooden ones are used in private construction, and reinforced concrete ones are used in the construction of multi-storey apartment buildings.

Permissible building density in the city

For cities, the population density of territories is no less important. The accepted standards are given above:

| Territory zone | Coefficient value - density |

|

|

|

|

|

|

Experimental fields and testing grounds, reserve territories and sanitary protection zones are not taken into account. However, only specialists can help calculate the density in a particular case.

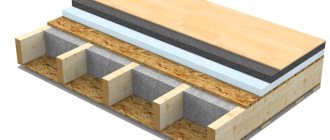

Pie layer diagram

The design of the ceiling pie has a certain scheme. It is better to adhere to it in order to achieve strength and rigidity of the structure.

can be given based on wooden floor beams:

- Wooden blocks that are laid with the ribbed side or in a straight position.

- Boards that serve as rough finishing for the ceiling.

- Thermal or sound insulation. It can be mineral wool, slag, sand, polystyrene foam or expanded clay.

- Waterproofing material made of dense polyethylene or rolled rubber.

- Rolling of rough or finished floor.

- A layer of vapor barrier on the ceiling side.

After laying all the layers of the cake, you can finish the surface. If the beam ceiling serves as the floor for the 2nd floor, then it makes sense to perform insulation.

This will help prevent excessive dampness in the room, increase the temperature in the building, and prevent the appearance of fungus and condensation. In addition, such a step will reduce heating costs. The same applies to the attic, which without floor insulation can turn out to be a cold room.

Materials for filing a rough ceiling

You can hem the rough ceiling with various building materials, but here you need to take into account the specific use of the room.

Drywall. This is one of the most popular and sought-after materials on the construction market. GLA attracts attention with its practicality and affordable price, however, the sheets are very sensitive to a humid environment, therefore, if we are talking about damp and unheated rooms, you need to choose a material with a moisture-resistant coating. Drywall is installed on a metal profile frame or glued directly to the base.

PVC panels. A universal material that fits organically into any interior. The advantage of plastic is its neutrality to any external environment; in addition, due to its light weight, it does not create additional load on the supporting structures and foundation. The only drawback: low resistance to mechanical damage, but given the fact that we are talking about ceiling finishing, this nuance can not be emphasized. The panels are mounted with a stapler on a prepared frame or glued with liquid nails. The second option is used in cases where the base forms a perfectly flat surface.

Lining. A beautiful, but relatively expensive way to cover a rough ceiling. The slats can be installed on a base or a pre-prepared frame. For fastening, self-tapping screws or thin nails without heads are used.

MDF. Plastic panels that subtly imitate natural coating: stone, plaster, wood. Considering that the material is of artificial origin, it can be used even in rooms with high levels of humidity, such as kitchens or baths. MDF panels are attached to the frame using clamps (special fixing brackets), which reliably press the edge of the panel to the base.

Plywood. An inexpensive and practical finishing material, which after installation forms an almost perfectly flat surface, which significantly simplifies the finishing process. To ensure that plywood lasts a long time, it is pre-treated with antiseptic compounds.

Board. A fairly common option for filing a rough ceiling. As in the previous case, the building material is treated with an antiseptic; the evenness of the sides does not play a special role here: the surface will be covered with a finishing coating.

When choosing a material, you need to be guided not only by cost, but also by technical characteristics. For example, any products made of plastic, PVC and MDF, have low thermal insulation properties, so installation will require laying a thick layer of insulation. Drywall gets wet when exposed to moisture for a long time, and even a water-repellent coating cannot solve this problem. Boards made of coniferous wood are not suitable for lining a sub-ceiling in bathhouses: when heated, the lumber will release resin, which is not very good in terms of fire safety.

Calculation

To calculate beams for the construction of floors, you need to know the size of the span, the size of the beams themselves and the step with which they are attached. This information will help calculate how much load the beam can withstand.

For example , the span is 5000 mm, while the width and height of the cross section of the beam is 100x200 mm. In addition, the pitch of the beams with which they are fixed is 70 cm. It follows from this that the maximum load on one beam will be 215 kg/m2. In this case, it is better to consider the recommended maximum load on a beam for an interfloor floor to be at least 400 kg/m2.

Read more about the principles of calculation in the article at the link.

The process of installation and fastening of beams

Before installing beams. It is necessary to arrange them. To ensure that the floor has one level, auxiliary beams are laid in the load-bearing walls lower than the others at the height of their section. The beams themselves are placed in specially prepared niches in the wall.

For durable and reliable support, the embedment depth of the beam must be at least 150 mm . In this case, an air gap of 20-30 mm should remain in such a niche. It will prevent the beam from contacting the wall, which may be cold.

If the walls have insulation on the outside, then the niche should not be filled with anything. If there is no insulation, then the niche can become a conductor of cold. The ends of wooden beams are sawn off at an angle of 60-70 degrees before laying them in the wall.

Full information about installation is in this article, and about mounting here.

How to lengthen and splice?

Sometimes it happens that it is necessary to fill spans with beams that are larger than the wood material itself. This often happens when using timber, which is available in lengths of up to 6 meters. In this case, the technology of extending the beam along its length is used.

Several methods are used for this :

- butt connection;

- oblique cut;

- overlap

When joining end-to-end, the ends of the beam are sawed off at an angle of 90 degrees, wooden pads are used for splicing, securing the screws in a checkerboard pattern.

When building up with an “oblique cut,” the ends of the elements are cut at an oblique angle, connecting through a through hole with a pin. This option is relevant for square beams. When connecting with an overlap, the joint itself must be at least 1 meter.

Read more about splicing beams here.

Reinforcement

Reinforcement of floor crossbars occurs when wooden beams are used . This allows you to extend the service life of the structure. Wooden beams become partially unusable over time, which can threaten the integrity of the building.

The reasons for this are rodents, dampness, sudden temperature changes or natural wear and tear. Beams can be reinforced using special overlays, metal prostheses, as well as by increasing the cross-sectional area or carbon fiber.

Description of technologies:

- Overlays are needed when there is damage in a certain area. Reinforcement consists of installing wooden plates on both sides, securing them with bolts, nuts and washers.

- Steel prosthesis is used as a replacement for wooden overlays or at the junction of the beam and the wall. For this purpose, round profiles are used. Channels, angles or sheet metal. Fastening occurs with bolts, washers and washers.

- Increasing the cross-sectional area is suitable when the calculation was initially made incorrectly. Waterproofing must be laid between the beam and the material to increase the cross-section.

Carbon fiber is laid in layers in the desired location and secured with glue. This method is suitable when the above methods are not relevant.

Defects, causes and their elimination

Defects in beam floors include :

knots on wooden crossbars;- cracks in reinforced concrete beams;

- rotten areas;

- areas with mold formation;

- beam deformations;

- corrosion of steel structure;

- impacts and dents on reinforced concrete or metal products.

The causes of such defects are not only improper installation of the device, but also their location in places that were not prepared for this . Wooden products rot due to lack of ventilation in the niche where they are placed. This is where condensation settles and fungus forms. Deformation of metal products occurs during improper transportation.

To straighten sagging beams, they need to be raised and their load-bearing capacity strengthened. The crossbar is lifted using screw steel jacks, sometimes with the help of vertical beams that are longer than the distance from the floor to the ceiling. This can also be done with metal strips equal in width to the height of the beam.

Distribution of territorial zones

Each standard used to determine the distance directly between high-rise and other buildings necessarily takes into account the distribution of territories in the city. The peculiarities of operation, intended purpose, in accordance with urban planning regulations, and the presence of environmental and sanitary zones are taken into account. Separately, territories are allocated for general use, which can be occupied by streets, driveways, squares, embankments, roads, parks, reservoirs and other objects aimed at meeting the public needs of the population. You can learn about the procedure for exploiting public land from local authorities, since they are the ones who develop regional legislative acts.

Dear readers!

Our articles talk about typical ways to resolve legal issues, but each case is unique. If you want to find out how to solve your specific problem, please contact the online consultant form on the right →

It's fast and free!

Or call us by phone (24/7):

If you want to find out how to solve your particular problem, call us by phone. It's fast and free!

+7 Moscow,

Moscow region

+7 Saint Petersburg,

Leningrad region

+7 Regions

(toll-free call for all regions of Russia)

Urban planning activities may also be limited if there is a historical building nearby, a cultural reserve, an area where cultural and historical monuments are protected, a specially protected natural area, a coastal protective strip, an area with minerals, territory , where development is prohibited due to the possible occurrence of natural and man-made emergencies.

Pros and cons of the design type

The main advantages of the beam structure:

- ensuring the overlap of spans with increased dimensions;

- large margin of safety, which allows you to distribute high loads;

- good sound insulation and noise protection characteristics.

The disadvantages include the need to use lifting equipment for installation, as well as additional costs associated with delivering crossbars to the site.